Production of Titania Nanocomposites for Photovoltaic Applications

advertisement

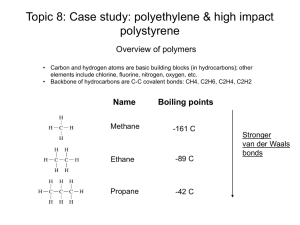

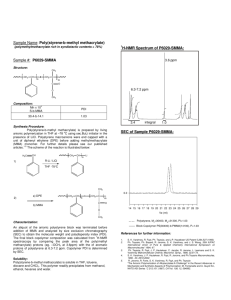

Synthesis of Block Copolymers for the Production of Titania Nanocomposites for Photovoltaic Applications Dustin Phillips and Dr. Devon Shipp Department of Chemistry and Biomolecular Science, Clarkson University Introduction Photovoltaic devices or solar devices are used to covert sunlight energy into electrical energy. The most common type of photovoltaic devices currently in use are based on the semi-conducting material silicon. However, dye-sensitized solar cells that instead utilize a ruthenium dye attached to TiO2 have the potential to allow for the production of inexpensive solar cells which can be applied to a variety of flexible substrates, including clothing. Current fabrication of dye-sensitized solar cells results in unstructured TiO2 which achieve an efficiency that is less than 10%. Structuring the solar cell on a nanometer scale will allow for maximized surface area for the ruthenium dye and less opportunity for electrons to recombine with positively charged molecules, thus allowing for greater efficiency in energy production. Therefore, one of the ultimate goals of PV device production is to create a simple, easy method of making nanostructured titania materials in order to improve photo-generated current efficiency. Project Research Goals The primary goal of this research is to synthesize and then use a block copolymer to create nanometer sized titania nanorods that can be used to structure the dye-sensitized solar cell on a nanometer scale. The use of a self assembling block copolymer composed of polystyrene PS block PVP block and poly(4-vinylpyridine) [PS-b-P4VP] (see Scheme 1)can be used in structuring n m the dye-sensitized solar cell. Therefore, we describe here our efforts to make the N PS-b-P4VP block copolymer and characterize its molecular weight and composition. Dustin Phillips Scheme 1 2008 REU Chemistry Dr. Devon Shipp Results and Discussion We anticipate that a thin film of the block copolymer will align to form upright rods approximately 10 nanometers in diameter (see Fig. 1), where poly(4-vinylpyridine) forms the cylinder surrounded by polystyrene. TiO2 nanorods can be created from PS-b-P4VP using similar methods outlined in the literature by Russell et al. Briefly, this involves the use of selective solvents to create nanopores that can be backfilled with TiO2 to form the TiO2 nanorods. We expect that the dye-sensitized solar cell can be created by attaching the ruthenium dye to the structured titania nanorods. Fig. 1 The appropriate block copolymer for self assembly of nanorods is composed of a 45,000 molecular weight polystyrene block with a 20,000 molecular weight poly(4-vinylpyridine) block attached. The use of reversible addition-fragmentation chain transfer (RAFT) polymerization allows for the production of polymer chains with these well defined molecular weights and with low polydispersity. In RAFT polymerization the RAFT agent, typically a thiocarbonylthio compound, undergoes reversible attachment/reattachment to the polymer chain as it polymerizes, thus slowing and controlling the process of polymerization. Altering the mole ratio of monomer to RAFT agent alters the resulting molecular weight of the polymer, therefore allowing for the creation of polymers with specified molecular weights. In creating the block copolymer, RAFT polymerization is first used to create polystyrene with the desired molecular weight of approximately 45,000 g/mol. The polystyrene sample is then collected and used in the creation of the block copolymer. This polystyrene, along with 4-vinylpyridine monomer and the initiator AIBN, are combined and the RAFT agent that is attached to the polystyrene works in the same way as the poly(4-vinylpyridine) polymerizes onto the polystyrene. Multiple reactions were done to find the appropriate mole ratios to yield block copolymer with a poly(4-vinylpyridine) block of molecular weight 20,000 g/mol. Gel permeation chromatography (GPC) testing of multiple trials showed that a mole ratio of 800:1 styrene monomer to RAFT agent yields the desired polystyrene molecular weight of 45,000 g/mol. (see Fig. 2). Nuclear magnetic resonance (NMR) spectroscopy data showed that the 4-vinylpyridine was successfully Dustin Phillips 2008 REU Chemistry Dr. Devon Shipp polymerized onto the polystyrene/RAFT (see Fig. 3). Using mole ratio of 250:1 4-vinlypyridine monomer to polystyrene/RAFT the poly-4-vinylpyrine added a molecular weight of 63,000 g/mol to the polymer. Further trials will attempt to decrease the poly-4-vinylpyrine weight to achieve the desired additional molecular weight of 20,000 g/mol. 600 M = 45,000 550 n M /M = 1.2 RI Signal (mV) w n 500 450 400 350 300 10 12 14 16 Retention Volume (mL) 18 20 Figure 2. GPC data of polystyrene. PS block PVP block n m N 5 2 2 6.5 6.0 5.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 ppm 8.83 7.0 2.73 7.5 2.54 8.0 1.00 8.5 Figure 3. NMR spectrum of PS-b-PVP block copolymer. Works Cited Shipp, D. A. “Living Radical Polymerization: Controlling Molecular Size and Chemical Functionality in Vinyl Polymers” J. Macromol. Sci. C: Polym. Rev. 2005, 45, 171-194. Park, S.; Wang, J.-Y.; Kim, B.; Xu, J.; Russell, T. P. “A Simple Route to Highly Orientated and Ordered Nanoporous Block Copolymer Templates” ACSNano 2008, 2, 766-772. Dustin Phillips 2008 REU Chemistry Dr. Devon Shipp