Improving CHEP Inventory Management

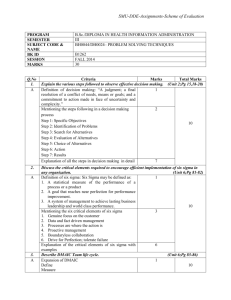

advertisement

at Bolthouse Farms Amanda Cebell Ruby Juarez Will Altmiller Asif Sohail Bolthouse Farms (History) 1915 Michigan 1972 Bakersfield 1990 Baby Carrots 2003 2007 Premium Beverages Salad Dressing Source: www.bolthousefarms.com 2 Bolthouse Farms Mission: We are a market driven, fully integrated farming company. We are innovative in agricultural and packaging technology. Within the parameters of our Corporate Philosophy, our focus is to offer quality products at the lowest possible cost through a “state of the art” plant, quality raw material and the maintenance of trust and credibility with our customers, growers and employees. Products: Premium Beverages Yogurt and Vinegar Based Dressings Fresh Carrots 3 Pallets Commonwealth Handling Equipment Pooling • consumer goods, produce, meat, home improvement, beverage, raw materials, petro-chemical and automotive industries. • Containers and pallets are not for sale. •Rental price for pallets varies depending on contract agreement. 4 Step 1 of DMAIC - Define Pallet Tracking Issue: Over or Under-stated Inventory Levels No inventory maintained in the System Vendor (CHEP) Complaints Continuous Manual Adjustment Potential loss of pallets not reported 5 CHEPs Flow at Bolthouse 6 Step 2 of DMAIC - Measure Measurements and Goals for Improvement The variance b/w In and Out Currently 2000 (approx) pallets per week 500 pallets + or – per week is the goal Audit of Transfer/Customer Orders Less than 1% discrepancy b/w physically on rail car and what the transfer order shows Physical count Less than 0.5% variance b/w physical count and inventory level in the system. 7 Step 3 of DMAIC - Analyze 8 Step 3 of DMAIC – Analyze (cont….) Check Sheet Week # Inbound Pallets Outbound Pallets Variance Percentage 1 26,865 29,079 -2,214 -8.24% 2 60,267 56,160 4,107 6.81% 3 50,880 45,576 5,304 10.42% 4 54,141 45,354 8,787 16.23% 5 52,239 49,575 2,664 5.10% 6 107,451 99,717 7,734 7.20% 7 63,501 40,956 22,545 35.50% 8 66,420 59,886 6,534 9.84% 9 111,660 119,418 -7,758 -6.95% 10 44,754 42,642 2,112 4.72% 11 46,383 39,132 7,251 15.63% 12 43,212 42,675 537 1.24% 13 41,454 40,959 495 1.19% 14 45,099 42,303 2,796 6.20% 15 47,100 37,389 9,711 20.62% 16 38,694 43,347 -4,653 -12.03% 17 56,757 44,469 12,288 21.65% 18 60,729 46,815 13,914 22.91% 19 51,258 42,696 8,562 16.70% 20 52,098 45,963 6,135 11.78% 21 53,856 43,062 10,794 20.04% 22 49,032 47,925 1,107 2.26% 23 66,960 48,639 18,321 27.36% 24 159,819 153,546 6,273 3.93% 9 Step 3 of DMAIC – Analyze (cont….) Weekly Percentage Variance 10 Step 4 of DMAIC – Improve I. Goals for Improvement 1. Reduce Current Average Variance from 10% to 3% 2. Minimize the Financial Impact . II. Alternatives: 1. New Software system implemented Con: too costly current system is already implemented. 2. RFID tag all pallets– too costly 3. Efficient Accountability (See Following Fish Bone Diagram) 1. Process Auditing 2. Using the Existing ERP System 3. Physicality Measures 4. Regular Reconciliation 11 Step 4 of DMAIC – Improve (cont….) 12 Step 5 of DMAIC – Control Continued Process Improvement: Monthly Reconciliation with CHEP Develop and Implement SOP: Staff Training Timeliness/ Inventorying Accountability Practices Annual SOP review and updating Control Charting 13 Conclusion Define: The tracking of CHEP Pallets at Bolthouse Farms Measure: The Variance between in/out Audit of Transfers/Customer Orders Physical Count Analyze: Data & Process Flow of Inventory Management Improve: Reduce Variance Minimize Financial Impact-Utilize Technology Control: Monthly reconciliation of CHEP Staff Training Accountability 14 15