Heat Islands - Loyola University Chicago

advertisement

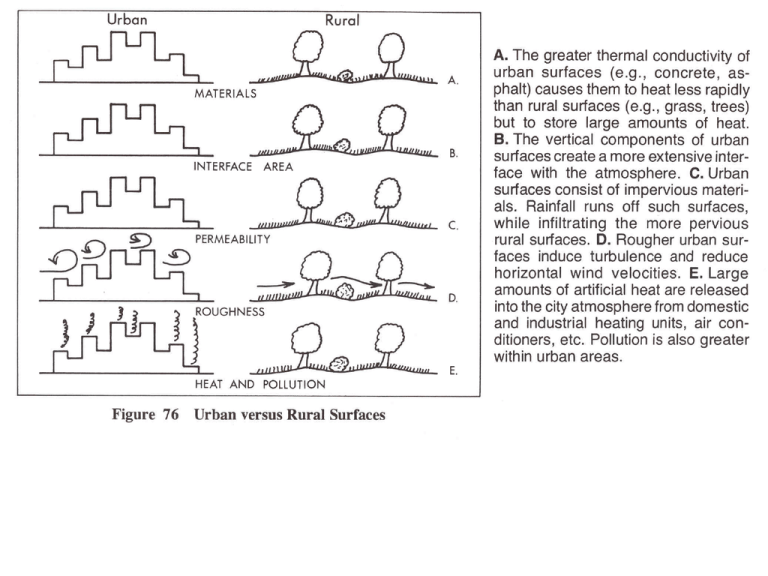

Albedo = Fractional reflectance Surface Perfect Fresh snow Old snow Clouds 300-600 m thick Clouds 150-300 m thick Clouds < 150 m thick Clouds (average) Sea ice Desert Grassland Green leaves Green forest Water Concrete bare ground Average road Bitumen road Freshly paved road Charcoal no reflection Albedo % 100 80-90 45-70 59-84 45-75 25-63 50-55 30-40 25-30 16-20 5-25 5-10 5-10 17-27 15 12 5-10 ~4 4 0 Material Albedo Emissivity Concrete 0.3 0.94 Red Brick 0.3 0.90 Tar Paper 0.05 0.93 White Plaster 0.93 0.91 Bright Galvanized Iron 0.35 0.13 Bright Aluminum Foil 0.85 0.04 White Pigment 0.85 0.96 White Single-Ply Roofing* 0.78 0.90 Black EPDM Roofing* 0.04 0.88 Gray Pigment 0.03 0.87 Green Pigment 0.73 0.95 White Paint on Aluminum 0.80 0.91 Black Paint on Aluminum 0.04 0.88 Aluminum Paint 0.80 0.27 – 0.67 Gravel 0.72 0.28 Sacramento Night-time temperatures June 29, 1998. White is hottest, followed by red. Blue is coolest Heat Wave of July 1995 – 526 dead in Chicago average max 4 days 101F Heat Wave of July 1999 – 232 dead in 9 State Area 127 in Illinois, predominately Chicago average max 4 days 97 F, shorter duration, better Public health The heat wave in July 1995 in Chicago was one of the worst weather-related disasters in Illinois history with approximately 525 deaths over a 5-day period. As noted by Changnon et al. (1996), "The loss of human life in hot spells in summer exceeds that caused by all other weather events in the United States combined, including lightning, rainstorms/floods, hurricanes, and tornadoes." Weather hazards such as tornadoes, floods, lightning, and winter storms each result in about 100 deaths per year on average, while heat waves result in about 1000 deaths per year on average. A Social Autopsy of Disaster inChicago Heat Wave Eric Klinenberg Climatology of Midwest Heat Wave of 1999 (Plaecki and Changnon, UIUC) 80% Deaths Night time cooling minimal Planting and higher density ballast are estimated to decrease the amount of direct sun on the total roof by 25%. The design of the rooftop garden is intended to retain and utilize the maximum amount of water needed for the plants. In order to ensure plant viability throughout the summer, the green roof's semi-intensive and intensive zones will be irrigated as necessary to ensure that the vegetation receives enough water. The projected avoided energy cost is $3,600 per year. The total direct savings are estimated to be 9,272 kWhr per year and the corresponding savings in natural gas for heating are 7,372 therms per year. Light-colored roofing is a time-honored method of lowering the temperature of a building. Since the advent of air conditioning this strategy has been largely ignored. On average, 17% of our urban landscape is covered with dark asphalt shingled roofs. This means that more than 60% of the rooftops are dark colored. Dark rooftops absorb and radiate heat causing outdoor air temperatures to rise, thus adding to the Urban Heat Island effect. Using light colored roofing materials or reflective coatings lower indoor and surrounding temperatures, which reduces smog. It will not make your home colder in the winter. The winter time sun is too low in the sky and too weak to provide much heating benefit to your home. One way to measure the amount of heat reflected is by calculating the albedo or solar reflectance of a roof material. Tree Facts: A single mature, properly watered tree with a crown of 30 feet can "evapotranspire" up to 40 gallons of water in a day, which is like removing all the heat produced in four hours by a small electric space heater. One large, mature sugar maple can sequester 450 pounds of carbon from the atmosphere. Twenty-nine such trees remove the CO2 generated by a car; one tree absorbs the CO2 produced by a car over 26,000 miles Good High albedo High emissivity Paving Materials for Heat Island Mitigation M. Pomerantz, H. Taha, A. Chen,* A. RosenfeldÝ *Center for Building Science, Energy & Environment Division, LBNL. ÝSenior Advisor for Energy Efficiency, Office of Energy Efficiency & Renewable Energy, U.S. DOE. One of the causes of higher temperatures in cities (compared to their environs) is the absorption of sunlight by dark pavements. In warm climates, this absorption can contribute damage to the environment by adding to air-conditioning electrical demand and smog. In this work, the dollar value of potential savings from lighter pavements is estimated. We examined the effect of paving urban roads, driveways, and walkways with materials that are lighter colored than black asphalt. The lighter color means that the sunlight is reflected rather than absorbed, and so the pavement is cooler. If a pavement is cooler, its lifetime is longer and the environmental damage of disposing of it is lessened. Reflectivity is also a safety factor in visibility at night, and this factor reduces the demand for electric lighting for streets. The drawback of high reflectivity is glare, which may be a limiting consideration. We considered new pavements, which are made of cement concrete; more flexible surfaces, like asphalt concrete; and porous pavements, such as grass pavers. We also reviewed materials for resurfacing existing pavements. We assembled information on the compositions of the materials, their suitabilities for particular applications, and their approximate costs. We have shown by computer simulation that, if all possible pavements were whitened to an albedo of 0.35, the cooling of the city would save electricity and reduce smog damage. The present dollar value of these savings in Los Angeles is estimated to be $1.80/m2 ($0.17/ft2) of pavement. The cost of pavement depends on the amount of material used. If the surface layer is thin enough, its cost may be sufficiently low that the savings from a lighter color would pay for any extra cost. Thus, it may happen that a lighter pavement is overall less costly than a dark one. We illustrate this in the Figure. If the savings is $1.80/m2, for a 6-mm (1/4-in.) thick resurfacing, money would be saved, as long as the extra costs of the aggregate and binder are within the triangle to the left of the filled squares. For example, an increase of binder price by $1.64 per liter ($6.25 per gallon) and no increase in aggregate price will not increase the pavement cost more than $1.80/m2. Or, aggregate priced at $138 per Mg ($126 per ton) more than present cost, and no increase in binder price, could be used without exceeding the benefits of the cooler surface. Such aggregate can be quite white and yield a more reflective surface, with no overall extra cost to society. If the pavement is 25 mm (1 in.) thick, the range of affordable price increases is confined to the area below the line defined by the open squares. The four times thicker surface implies a four times smaller range of affordable price increases. City of Chicago Web Site, DOE Fall 2001, Alderman Mary Ann Smith 48th. Gravelpave2, porous structure In 40x40 inche square 144 rings 2 in diameter 1 inhigh, held together by Geofabric layer. Handles up to 3”/hour rainfall without connecting to sewers Loyola’s New Life Science Building Roof 3= Green Env. Seminar Series Fall 2000 Injected Idea of Green roof Into the design