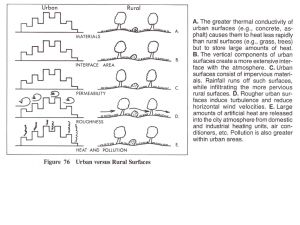

Using Computer Modeling to Improve the Design of Unbonded Concrete Overlays

advertisement

2012-02TS Published May 2012 RESEARCH SERVICES O F F I C E O F P O L I C Y A N A LY S I S , R E SE A R C H & I N N OVAT I O N TECHNICAL SUMMARY Technical Liaison: Shongtao Dai, MnDOT Shongtao.Dai@state.mn.us Project Coordinator: Dan Warzala, MnDOT Dan.Warzala@state.mn.us Principal Investigator: Roberto Ballarini, University of Minnesota PROJECT COST: $110,000 Using Computer Modeling to Improve the Design of Unbonded Concrete Overlays What Was the Need? As pavements age, they are subject to cracking, rutting and other deterioration that decreases their ride quality and ability to sustain traffic loads. Since completely reconstructing pavements is costly, transportation agencies sometimes extend their lives and restore their ride quality using rehabilitation techniques that involve overlaying an existing road with new pavement layers. One such method, called unbonded concrete overlays, or UBCOs, involves applying a layer of asphalt to an existing surface followed by a layer of portland cement concrete, or PCC. The asphalt interlayer of UBCOs helps prevent reflective cracking in which the deterioration of the original pavement surface transfers stress and damage to the new concrete layer. UBCOs can also be placed quickly and efficiently, making them an increasingly popular method of pavement rehabilitation. By using advanced computer modeling that employs fracture mechanics to better predict cracking in pavements, it may be possible to design thinner, more cost-effective unbonded concrete overlays that achieve the same performance as more conservative designs. However, current UBCO design procedures for determining layer dimensions and materials use models that do not account for the effect of the asphalt interlayer on limiting the propagation of cracks between layers. Researchers are interested in refining these models to design pavements that are no thicker than necessary for their intended performance lives since thinner pavements are less costly and also more environmentally friendly because they reduce the carbon footprint of construction. What Was Our Goal? The objective of this project was to develop a method for designing UBCOs using fracture mechanics to model crack propagation through pavement layers. What Did We Do? Researchers began by reviewing Minnesota procedures for UBCO design. Then they analyzed crack propagation using finite element computer modeling and the cohesive zone model, or CZM, which uses nonlinear fracture mechanics to predict how existing cracks will spread into cohesive zones or uncracked areas. Linear fracture mechanics account for only the strength, stiffness and dimensions of materials, while nonlinear fracture mechanics also account for fracture energy, which is the energy required to crack a given surface area and is a measure of resistance to crack propagation. UBCOs can be placed quickly and efficiently to restore the ride quality and structural capacity of aging pavements. Researchers used CZM to relate the ultimate load capacity of a pavement—or the load at which it will fail—to its dimensions and material properties. Then they verified the accuracy of CZM by using ABAQUS software to model two sample structures and compare the results to available theoretical and experimental data. Researchers used CZM to conduct failure simulations for various single-layer PCC pavement designs to derive equations relating pavement load-carrying capacity to material properties and structural dimensions. They established design recommendations for UBCOs, including layer thicknesses and material properties, that would yield the same load capacity using the same equations. Then they compared the expected performance of these designs to observations of four thin-layer UBCO test sections at the MnROAD pavement research testing facility. continued “As MnDOT districts make increasing use of UBCOs, this study is a step toward optimizing their design.” —Shongtao Dai, MnROAD Research Operations Engineer “We developed a model that more accurately simulates the propagation of cracks in pavements than existing methods. This is critical to developing thinner overlays.” —Roberto Ballarini, James L. Record Professor and Head, University of Minnesota Department of Civil Engineering The model developed in this study allows engineers to design a UBCO (right) with the same load capacity as a single-layer pavement designed to current specifications (left). What Did We Learn? Results suggest that the fracture mechanics-based design procedure for UBCOs shows promise. The model developed in this project can be used as an additional tool to assist in the design of UBCOs by determining the load capacity of a new single-layer PCC pavement designed using current procedures, and then determining thickness and material properties for a UBCO that will yield the same load capacity. The CZM model used in this study improves on traditional stress-based failure criteria used by other models, which are not capable of quantifying the loads required to initiate and propagate reflection cracks in PCC pavements. Use of this model suggests that increasing the strength of the interlayer or overlay and decreasing the stiffness of the interlayer are effective ways of improving the load-carrying capacity of the UBCO pavement in terms of crack propagation. However, this method does not consider the effects of temperature, moisture and traffic loads. The UBCO test sections observed at MnROAD only cracked near poorly designed joints separating the sections. This suggests that thus far the design of these sections is sufficient to resist reflective cracking. What’s Next? Further research is needed to assess the model developed in this study by comparing its predictions to field observations of UBCO test cells. Research is also needed to evaluate the effects of climate conditions and traffic loading. With further investigation, three-dimensional fracture mechanics simulations could provide additional insights into whether UBCOs can be made thinner and more cost-effective. Produced by CTC & Associates for: Minnesota Department of Transportation Research Services MS 330, First Floor 395 John Ireland Blvd. St. Paul, MN 55155-1899 (651) 366-3780 www.research.dot.state.mn.us This Technical Summary pertains to Report 2012-02, “Mechanistic Modeling of Unbonded Concrete Overlay Pavements,” published January 2012. The full report can be accessed at http://www.lrrb.org/PDF/201202.pdf.