3110-Formulas-e2

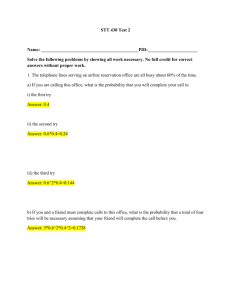

advertisement

MGT 3110: Exam 2 Formulas Chapter 6 and 6S Pareto diagram: Relative frequency=frequency/sum of frequencies -Chart if is known: X z X , LCL = X z X and UCL = X z X where, X mean of the sample means, or target value set for the process = Standard deviation of sample means = / n = population (process) standard deviation n = sample size z = 2 for 95.45% confidence and 3 for 99.73% confidence -Chart if is unknown: X A2 R , LCL = X A2 R and UCL = X A2 R where, X mean of the sample means, or target value set for the process R Average range of samples A2 = Value found in Table S6.1 R-Chart LCLR = D3 R , UCLR = D4 R ; Where, D3 and D4 are values from Table S6.1 p-Chart: 𝑝̅ ± 𝑍𝑝̅ LCLp = 𝑝̅ − 𝑍𝑝̅ , and UCLp = 𝑝̅ + 𝑍𝑝̅ ∑ 𝐷𝑒𝑓𝑒𝑐𝑡𝑠 where, p mean fraction of defective = (𝑁𝑜.𝑜𝑓 𝑠𝑎𝑚𝑝𝑙𝑒𝑠)(𝑛) , p (1 p ) n Z = 2 for 95.45% confidence and 3 for 99.73% confidence p = defectives/n p standard deviation of sampling distribution = c-Chart: 𝑐̅ ± 𝑍√𝑐̅, LCLc = 𝑐̅ − 𝑍√𝑐̅ and UCLc = 𝑐̅ + 𝑍√𝑐̅ where, c = number of defectives per unit output Z = 2 for 95.45% confidence and 3 for 99.73% confidence USL X X LSL Process Capability Index Cpk = Minimum of , 3 3 USL LSL 6 Where LSL = Lower specification limit, USL = Upper specification limit = Process average, and = process standard deviation >= 1⅓ for 4-Sigma capability and >= 2 for 6-Sigma capability Process Capability Ratio Cp = Acceptance Sampling Pa = P(X<= c) = From Poisson table using nPd, where, Pa = Probability of accepting the sample Pd = Probability of defectives in the lot n = sample size c = Critical number of defectives in the sample X = number of defectives in the sample Producer’s risk = 1 – Pa with Pd = AQL where, AQL = Acceptable Quality Limit Consumer’s risk = Pa with Pd = LTPD, where, LTPD = Limit Tolerance Percent Defective Average Outgoing Quality AOQ = where, ( Pd )( Pa )( N n) N AOQ = Average Outgoing Quality Pa = Probability of accepting the sample Pd = Probability of defectives in the lot n = sample size N =Lot size Chapter 12 Inventory Management ABC Classification rule: Class A: ~15% of items, 70-80% annual $ usage Class B: ~30% of items, 15-25% annual $ usage Class C: ~55% of items, 5% annual $ usage Item $ Usage % of $ usage Basic EOQ Model Q* Cumulative % of $ Cumulative % of no. of items where, D = Demand per year S = Ordering cost for each order H = Holding (carrying) cost per unit per year 2 DS H Expected number of orders (N) = D/Q Expected time between orders (T) = (Q/D) No. of days per year = Q/d Class Annual ordering cost = NS = (D/Q)S Annual carrying cost = (Q/2)H Total annual cost (TC) = (D/Q)S + (Q/2)H POQ Model Q *p 2 DS H (1 d / p ) where, D = Demand per year S = Ordering cost for each order H = Holding (carrying) cost per unit per year p = Daily production rate d = Daily demand rate = D/No. of working days Length of production run (t) = Q/p Rate of increase of inventory during production = (p - d) Maximum inventory = Imax = (Q/p)(p-d) Average inventory = Imax/2 Expected number of batches (N) = D/Q Expected time between orders (T) = (Q/D) or No. of days per year = Q/d Annual setup cost = NS = (D/ Q)S Annual carrying cost = (Imax/2)H Total annual cost (TC) = (D/Q)S + (Imax /2)H Quantity discount model Q 2 DS IP where, D = Demand per year S = Ordering cost for each order IP = H = Holding (carrying) cost per unit per year I = Holding cost as a % of item cost P = Item cost per unit Step 1: Determine Candidate Q a. Compute Formula-Q for each price break price. b. If Formula Q < Lower limit for price, then Candidate Q = Lower limit If Formula Q is within the limits for the price, then Candidate Q = Formula Q If Formula Q > Upper limit for price, then no candidate Q, ignore the Formula Q Q-Range Price Holding cost/unit = % x P Formula Q Adjusted Q Step 2: Compute total annual cost (TC) for each valid candidate Q and select the candidate Q with least cost as EOQ. Total annual cost (TC) = (D/Q)S + (Q/2)H + PD Total annual cost = Annual holding cost + Annual ordering cost + Annual item cost i.e. = (Q/2)H + (D/Q)S + PD, where P = cost of the item per unit Q-Range Price Adjusted Q Annual total cost = PD + (D/Q)S + (Q/2)H