Tolerances Design - Gateway Engineering Education Coalition

advertisement

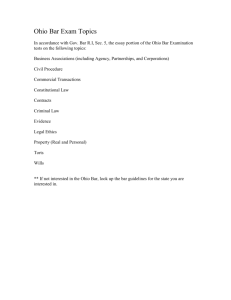

GATEWAY Tolerance Design Department of Mechanical Engineering, The Ohio State University Sl. #1 GATEWAY Design Specifications and Tolerance Develop from quest for production quality and efficiency Early tolerances support design’s basic function Mass production brought interchangeability Integrate design and mfg tolerances Department of Mechanical Engineering, The Ohio State University Sl. #2 GATEWAY Definition “The total amount by which a given dimension may vary, or the difference between the limits” - ANSI Y14.5M-1982(R1988) Standard [R1.4] Department of Mechanical Engineering, The Ohio State University Sl. #3 Source: Tolerance Design, p 10 GATEWAY Affected Areas Engineering Tolerance Product Design Quality Control Manufacturing Department of Mechanical Engineering, The Ohio State University Sl. #4 GATEWAY Questions “Can customer tolerances be accommodated by product?” “Can product tolerances be accommodated by the process?” Department of Mechanical Engineering, The Ohio State University Sl. #5 GATEWAY Tolerance vs. Manufacturing Process Nominal tolerances for steel Tighter tolerances => increase cost $ Department of Mechanical Engineering, The Ohio State University Sl. #6 GATEWAY Geometric Dimensions Accurately communicates the function of part Provides uniform clarity in drawing delineation and interpretation Provides maximum production tolerance Department of Mechanical Engineering, The Ohio State University Sl. #7 GATEWAY Tolerance Types Size Form Location Orientation Department of Mechanical Engineering, The Ohio State University Sl. #8 GATEWAY Size Tolerances Department of Mechanical Engineering, The Ohio State University Sl. #9 GATEWAY Form Tolerances Department of Mechanical Engineering, The Ohio State University Sl. #10 GATEWAY Location Tolerances Department of Mechanical Engineering, The Ohio State University Sl. #11 GATEWAY Orientation Tolerances Department of Mechanical Engineering, The Ohio State University Sl. #12 GATEWAY Tolerance Buildup Department of Mechanical Engineering, The Ohio State University Sl. #13 GATEWAY Statistical Principles Measurement of central tendency Mean Median mode Measurement of variations Range Variance Standard deviation LSL USL X 3s tolerance Department of Mechanical Engineering, The Ohio State University Sl. #14 GATEWAY Probability Probability Likelihood of occurrence Capability Relate the mean and variability of the process or machine to the permissible range of dimensions allowed by the specification or tolerance. Department of Mechanical Engineering, The Ohio State University Sl. #15 GATEWAY Tolerance SPC Charting Department of Mechanical Engineering, The Ohio State University Sl. #16 Figure Source: Tolerance Design, p 125 GATEWAY Tolerance Analysis Methods Worst-Case analysis Root Sum of Squares Taguchi tolerance design Department of Mechanical Engineering, The Ohio State University Sl. #17 GATEWAY Initial Tolerance Design Initial Tolerance Design Department of Mechanical Engineering, The Ohio State University Sl. #18 Figure Source: Tolerance Design, p 93 GATEWAY References Handbook of Product Design for Manufacturing: A Practical Guide to Low-Cost Production, James C. Bralla, Ed. in Chief; McGraw-Hill, 1986 Manufacturing Processes Reference Guide, R.H. Todd, D.K. Allen & L. Alting; Industrial Press Inc., 1994 Standard tolerances for mfg processes Machinery’s Handbook; Industrial Press Standard Handbook of Machine Design; McGraw-Hill Standard Handbook of Mechanical Engineers; McGraw-Hill Design of Machine Elements; Spotts, Prentic Hall Department of Mechanical Engineering, The Ohio State University Sl. #19 Figure Source: Tolerance Design, p 92-93 GATEWAY Worst-Case Methodology Extreme or most liberal condition of tolerance buildup “…tolerances must be assigned to the component parts of the mechanism in such a manner that the probability that a mechanism will not function is zero…” - Evans (1974) Department of Mechanical Engineering, The Ohio State University Sl. #20 GATEWAY Worst-Case Analysis m WC max N p i Tp i i1 m WCmin N p i Tp i i1 Ne + Te => Maximum assembly envelope Ne - Te => Minimum assembly envelope Department of Mechanical Engineering, The Ohio State University Sl. #21 Source: “Six sigma mechanical design tolerancing”, p 13-14. GATEWAY Assembly gaps m Gmax N e Te N p i Tp i i1 m Gmin N e Te N p i Tp i i1 m Gnom N e N p i i1 Department of Mechanical Engineering, The Ohio State University Sl. #22 GATEWAY Worst Case Scenario Example Department of Mechanical Engineering, The Ohio State University Sl. #23 Source: Tolerance Design, pp 109-111 GATEWAY Worst Case Scenario Example Department of Mechanical Engineering, The Ohio State University Sl. #24 Source: Tolerance Design, pp 109-111 GATEWAY Worst Case Scenario Example • Largest => 0.05 + 0.093 = 0.143 • Smallest => 0.05 - 0.093 = -0.043 Department of Mechanical Engineering, The Ohio State University Sl. #25 Source: Tolerance Design, pp 109-111 GATEWAY Non-Linear Tolerances y f (x1, x2, x3,...xn ) f f f f Toly tol1 tol2 tol3 ... toln x1 x2 x3 xn f f f f Nomy x1 x2 x 3 ... xn x1 x 2 x 3 x n Department of Mechanical Engineering, The Ohio State University Sl. #26 Wource: “Six sigma mechanical design tolerancing”, p 104 GATEWAY Root Sum-of-Square RSS Assumes normal distribution behavior 1 (1/ 2)[x )/s ]2 f (x) e s 2 Department of Mechanical Engineering, The Ohio State University Sl. #27 Wource: “Six sigma mechanical design tolerancing”, p 16 GATEWAY RSS method Assembly tolerance stack equation f (x) T T T ...T 2 1 2 2 2 3 2 n Department of Mechanical Engineering, The Ohio State University Sl. #28 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Pool Variance in RSS Tol s adjusted 3Cp 2 Tpi Te s gap 3Cp i1 3Cpi 2 m Department of Mechanical Engineering, The Ohio State University Sl. #29 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Probability ZQ ZQ Q Gnom s gap m Q N e N pi i1 2 Te Tpi 3Cp i1 3Cpi 2 m Department of Mechanical Engineering, The Ohio State University Sl. #30 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Probability for Limits ZG min ZG max Gmin Gnom 2 Te 2 m Tpi 3Cp i1 3Cpi Gmax Gnom 2 Te 2 m Tpi 3Cp i1 3Cpi Department of Mechanical Engineering, The Ohio State University Sl. #31 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Dynamic RSS ZG min ZG max Gmin Gnom 2 Te 2 m Tpi 3Cpk i1 3Cpki Gmax Gnom 2 Te 2 m Tpi 3Cpk i1 3Cpki Department of Mechanical Engineering, The Ohio State University Sl. #32 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Nonlinear RSS f 2 2 f 2 2 f 2 2 f 2 Toly tol1 tol 2 tol3 ... toln x1 x 2 x 3 x n Toli s adjusted 3Cpki Department of Mechanical Engineering, The Ohio State University Sl. #33 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY RSS Example • Largest => 0.05 + 0.051 = 0.101 • Smallest => 0.05 - 0.051 = -0.001 Department of Mechanical Engineering, The Ohio State University Sl. #34 Wource: “Six sigma mechanical design tolerancing”, p 128 GATEWAY Taguchi Method Input from the voice of the customer and QFD processes Select proper quality-loss function for the design Determine customer tolerance values for terms in Quality Loss Function Determine cost to business to adjust Calculate Manufacturing Tolerance Proceed to tolerance design Department of Mechanical Engineering, The Ohio State University Sl. #35 Wource: “Six sigma mechanical design tolerancing”, p 21 GATEWAY Taguchi Voice of customer Quality function deployment Inputs from parameter design Optimum control-factor set points Tolerance estimates Initial material grades Department of Mechanical Engineering, The Ohio State University Sl. #36 Wource: “Six sigma mechanical design tolerancing”, p 22 GATEWAY Quality Loss Function Identify customer costs for intolerable performance Quadratic quality loss function Ao L(y) k(y m) (y m) 2 o 2 Department of Mechanical Engineering, The Ohio State University Sl. #37 Wource: “Six sigma mechanical design tolerancing”, p 208 GATEWAY Cost of Off Target and Sensitivity Cost to business to adjust off target performance Sensitivity, b Ao A Ao 2 A [b (x m)] Department of Mechanical Engineering, The Ohio State University Sl. #38 Wource: “Six sigma mechanical design tolerancing”, p 226-227 GATEWAY Manufacturing Tolerance Sl. #39 Ao o A b Department of Mechanical Engineering, The Ohio State University GATEWAY Summary Importance of effective tolerances Tolerance Design Approaches Worst-Case analysis Root Sum of Squares Taguchi tolerance method Continual process Involvement of multi-disciplines Department of Mechanical Engineering, The Ohio State University Sl. #40 GATEWAY Credits This module is intended as a supplement to design classes in mechanical engineering. It was developed at The Ohio State University under the NSF sponsored Gateway Coalition (grant EEC-9109794). Contributing members include: Gary Kinzel…………………………………. Project supervisor Phuong Pham.……………. ………………... Primary author Reference: “Six Sigma Mechanical Design Tolerancing”, Harry, Mikel J. and Reigle Stewart, Motorola Inc. , 1988. Creveling, C.M., Tolerance Design, Addison-Wesley, Reading, 1997. Wade, Oliver R., Tolerance Control in Design and Manufacturing, Industrial Press Inc., New York, 1967. Department of Mechanical Engineering, The Ohio State University Sl. #41 GATEWAY Disclaimer This information is provided “as is” for general educational purposes; it can change over time and should be interpreted with regards to this particular circumstance. While much effort is made to provide complete information, Ohio State University and Gateway do not guarantee the accuracy and reliability of any information contained or displayed in the presentation. We disclaim any warranty, expressed or implied, including the warranties of fitness for a particular purpose. We do not assume any legal liability or responsibility for the accuracy, completeness, reliability, timeliness or usefulness of any information, or processes disclosed. Nor will Ohio State University or Gateway be held liable for any improper or incorrect use of the information described and/or contain herein and assumes no responsibility for anyone’s use of the information. Reference to any specific commercial product, process, or service by trade name, trademark, manufacture, or otherwise does not necessarily constitute or imply its endorsement. Department of Mechanical Engineering, The Ohio State University Sl. #42