LCA Abstract2 - EGR260

advertisement

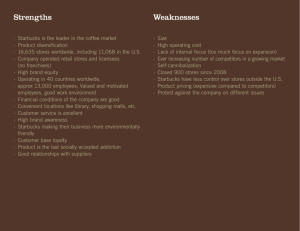

Abstract 1. Introduction and Objective Melissa, the owner of Elbow Room Café, a small coffee shop near Smith College, has inspired us for this project. She is currently working towards making her café environmental friendly by reducing her emissions. An LCA is a powerful tool in evaluating the present status and the repercussions of any product or process. Hence, we believe that this analysis will help in the improvement of Elbow Room Café. This project is geared towards providing a rough idea about where the performance of Elbow Room Café stands in comparison to coffee giants like Starbuck at downtown Northampton who promote various environment friendly campaigns. In tracking the production of coffee will focus on the overall energy usage of the two cafés. We will look into environmental impacts as far as possible. 2. Methodology 2.1 Goal and Scope We compare the life cycle of a cup of coffee in Starbucks to the coffee in Elbow Room. In doing so we will evaluate the energy used in each process of the life cycle and seek possible options for increasing the efficiency of Elbow Room. Our main focus will be on air emissions followed by other environmental impacts. The functional unit for our comparison is a cup of 16oz of drip coffee made using single origin Arabica coffee beans ground with a universal grind. We will assume that the beans for both the Cafés come from farms in Columbia. Our criteria are listed as follows: Parameter Weight Assesment Environmental Impacts: A. Resource 50 Consumption: i. Electricity (incl. building use) ii. Fuel iii. Natural Gas iv. Water [N] v. Land [N] B. Air pollution 50 i. CO2 emission ii. NO iii. SO iv. Particle emission C. Water pollution [N] *[N]=things we are not worried about right now but might consider in the future if we have time Our searches were based on the primary data we collected from Starbucks and Elbow Room. Assumptions and generalizations were made wherever specific data was hard to find. For Starbucks at Northampton the assumptions have been based on primary data and claims in Starbucks’ website. 2.2 Life Cycle inventory 2.2.1 Green Coffee Production This process is assumed to be the same for both cafes considering that they obtain green beans from similar farms in Columbia. We consider that Starbuck gets green coffee beans from Narino, Columbia and Elbow Room obtains green beans from Cacua, Columbia via Dean’s Beans a coffee supplier in Massachusettes. 2.2.6.1 Cultivation The cultivation of coffee occurs at most 8 weeks after time of harvest in order to germinate. The seeds are sown in the soil 2 cm deep, and grow to reach the surface in 5-8 weeks. Once the seeds reach the surface, they are transported into special foil planting bags called polycovers. The seeds are then set in shaded beds for 6 months. During these 6 months, the plants will grow 30-50 cm tall. The plants are transported again to be planted again, where shading trees called Guames are placed around the coffee plants. In 3-4 years, the coffee tree will begin to bear fruit. 2.2.6.2 Harvest The harvest of coffee occurs in a 8-9 month period from the time a blossom appears on the coffee tree. A single tree yields around 2,000 beans per year, which is equivalent to 1 kg of coffee per year. The seed of a berry from the coffee plant is called the cherry, and it appears as two flat sided seeds. About 9 months later, flowers begin to blossom on the tree, and harvesting begins. Harvesting will last for approximately 4 months depending on the weather and location. Assuming that berries are picked by hand, workers selectively pick cherries that are at their peak ripeness. 2.2.6.3 Milling The milling process starts with the cherry which have a red skin wrapping two coffee grains. The skin is removed in a machine called a huller. The skins are called pulpa and are used later as fertilizer once they are taken off the bean by the huller. The beans are then kept in fermentation tanks for a period of around two days. The mucilage, which covers the cherry, becomes water soluble in the fermentation tank. After the two days, the beans are washed and the mucilage is dissolved. Once the beans are washed, they are still covered with an outer hust covering called Parchment, and are spread out on drying patios for several days under the sun. The beans are then put into a grooved cast iron cylinder which holds the beans and the beans rub against each other to remove its outer husk. The beans are then sieved to remove damaged beans and other foreign objects, and pass through a conveyer belt to sort into different grading standards. After they are sorted, we assume the beans are packed in burlap bags which hold 150 lb of beans, and are exported to the roasting plants. 2.2.2 Coffee Bean Manufacturing 2.2.6.1 Sorting A classifier separates the beans from heavier material such as stone, metal and other stuff. 2.2.6.2 Roasting After screening to remove dirt and other debris, the first stage is endothermic. Then the next step is the first crack, the temperature will be 205 °C, and the weight lose will be 5%. As the temperature rises, the coffee beans continuous to lose weight, until the temperature rise to 220°C. In this process, it will also release carbon dioxide. Followed by a short endothermic period and exothermic step which is called second crack, the roaster color will change to medium-dark brown. After beans reach the desired color, they will be immediately quenched with water, this process is called quenching. Then is the cooling process, the beans will transferred to an enclosed cooler, and a rotating stirring arm and blower will be used in the process. It will also have some solid waste left such as chaff. On average, roasting reduces the coffee beans 18% by weight. For our considerations, we will account for medium roasting as it is a preferred choice in Starbucks. 2.2.6.3 Control Equipment Usually a high-efficiency cyclone will be used in order to manage the particulate matter emissions from the roaster and cooler. The efficiency of the machine ranges from 70% to 90% by weight. Catalytic or thermal oxidizers typically control gaseous emissions. By recycling process, 70-90% emissions will be reduced or recycled by oxidation of some of the pollutants. [Cyclones are usually installed in large roasting plants as they are expensive. Hence we assume that Melissa does not have one installed.] [Up to 10 ml of carbon dioxide (at STP) can be produced per gram of roasted coffee ( Barbera, 1967), although values of 2–5 ml per gram are often reported ( Clarke & Macrae, 1985). The amount of carbon dioxide produced during roasting depends upon the type of coffee and the roast conditions.] 2.2.3 Packaging Assume that the packaging material is same initially. The coffee beans are imported in 150-pound Burlap bags and brought to the roasting plant. After roasting, coffee from Starbucks is sealed in vacuum-channeled Flavor Lock bags and transported to retail stores. Similar Flavor Lock bags are used to store the spent coffee grounds. [Packaging used by Melissa still to be figured out.] 2.2.4 Transport Assuming coffee bean are shipped from Columbia to United States in 20-40ft cargo containers for both parties, the following distances are calculated there after as the beans are processed and transported to retail stores: Distribution Starbucksa Elbow Roomb Export Harbor -Import Ship: n/a Ship: n/a Harbor Import Harbor - Roasting Trucks: 192 mi Trucks: 36.3 mi Plant Vans: 29.4 mi Roasting Plant - Retail Trucks: 372 mi Vans: 29.4 mi Stores *All distances have been calculated with the Google maps considering the closest ports and shortest route between the two locations. a. Transport route for Starbucks: Narino > Buenaventura, Columbia > Port Authority of New Jersey, NJ > Roasting Plant, York, Pennsylvania >Starbucks Northampton b. Transport route for Elbow Room: Cauca > Buenaventura, Columbia > Conley Ocean Cargo Terminal, Boston > Dean’s Beans > Roasting Plant > Elbow Room, Northampton 2.2.5 Consumption 2.2.6.4 Grinding Roasted coffee beans are ground to different sizes in a grinder to suit the coffee brewing process. Starbucks uses universal grind size for all its coffee brews. We will assume the same grind size for Elbow Room as it is the grind size that suits all types of coffee maker and all the beans are grinded completely. 2.2.6.5 Brewing Water is boiled at 180F -210F inside the brewing machine. Hot water is brought in contact with ground coffee using various ways. The results of brewing depend on the amount of water, coffee, grind size, brewing temperature and brewing time. The particle emissions in this phase are very small hence will be unaccounted in this LCA. We will assume medium brew coffee here. Starbucks uses []. Melissa uses an automatic drip brewer which [we will assume equivalent to average household drip machine]. We will also assume that all amount of coffee beans used will be disposed off as used coffee grounds after brewing. 2.2.6.6 Service By service we refer to the sales of coffee to the customers in the respective café. We will estimate the energy used for producing cups used as well as for running the cafes. We considered accounting for energy used in running cafes because Starbucks and Elbow Room Café vary a lot in size and operating hours that will lead to a lot of difference in energy used. Specific details and assumptions for coffee consumption are listed in table Table 1 Inputs per 16 oz cup of coffee Parameter Amount of green coffee beans (in oz)c Amount of Roasted Coffee Beans = Amount of Ground Coffee(in oz) Amount of Water (in oz) Amount of Used Coffee Grounds(in oz) Electricity i. Coffee Brewing ii. Running Store Value Per 16oz cup Starbucks at Northamptona 1.04oz Elbow Room Cafeb 4.35oz 0.85oz (16 oz beans/ 300oz Coffee)*(16 oz Coffee/cup)=0.85oz beans/cup 17.07 0.85 3.57oz (10 oz beans/ 48oz coffee)*(14 oz Coffee/cup)=2.91 oz beans/cup 16.67 3.57 [N] 6.78 KWh/ ft 2 space/mnth ~1.5 KWh [N] Natural gas 0.058 therms of Natural [N] 2 gas/ft / mnth a. Assumption based on website estimations (1 lb of coffee per 320 oz water to yield 300 oz brewed coffee) b. Based on primary data c. Assuming coffee beans are reduced 18% by weight after roasting. 2.2.6.7 Disposal Because the solid waste produced green bean processing and roasting processes were hard to quantify and also because we expect them to be similar, we will account only for wastes produced during the service phase. This includes used coffee grounds from brewing and cups used. Paper towels, straws and other supplements used will be neglected. We will account for wastes from packaging if we can find concrete data. [According to Report on Management of MSW in 2008, 54.2 % wastes were discarded in landfills, 33.2 % wastes were recycled and 12.6% were incinerated. This will be our basis for further calculations] Figure 1 Left: Enery consumption for cups according to LCA by Starbucks; Right: Emissions from all Starbucks café according to Starbuck’s corporate responsibility report. 3. Mass Balance 4. Energy Balance 5. Life Cycle Impact Analysis