Chapter 17

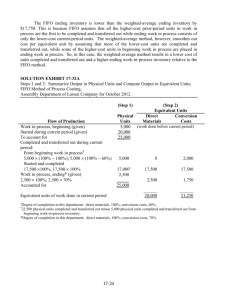

advertisement

Chapter 17 Sequential Processing Departments T-Account Model of Process Costing Flows Process Costing and Direct Labor Dollar Amount Direct Materials Direct Labor Direct labor costs may be small Mfg. Ovhd. in comparison to other product costs in process cost systems. Type of Product Cost Process Costing and Direct Labor Dollar Amount Direct Materials Direct labor costs Conversion may be small in comparison to other product costs in process cost systems. Type of Product Cost Direct labor and manufacturing overhead is combined into one product cost called conversion. Production Report Example Global Defense uses process costing to determine unit costs in its Assembly Department. Upon completion, units are transferred to the Testing Department. Direct materials are added at the beginning of the assembly process. Conversion costs are added evenly during assembly. Process Diagram - Assembly Conversion costs added evenly during process Transfer Assembly Department Direct materials added at beginning of process Testing Department January 2009 Assembly Department - No Beginning/No Ending Inventory Work in process, January 1: Materials: Conversion: 0 units $ 0 0 Production started during January: Production completed during January: 400 units 400 units Costs added to production in January Materials cost Conversion cost $ 32,000 24,000 Work in process, January 31 0 units Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in January: ? February 2009 Assembly Department - No Beginning/Some Ending Inventory Work in process, February 1: Materials: Conversion: 0 units $ 0 0 Production started during February: Production completed during February: 400 units 175 units Costs added to production in February Materials cost Conversion cost $ 32,000 18,600 Work in process, February 29 Materials Conversion 225 units 100% complete 60% complete Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in February: ? Equivalent Units of Production Equivalent units are partially complete and are part of work in process inventory. Partially completed products are expressed in terms of a smaller number of fully completed units. Equivalent Units of Production Two half completed products are equivalent to one completed product. + = 1 So, 10,000 units 70 percent complete are equivalent to 7,000 complete units. Quick Check For the current period, Jones started 15,000 units and completed 10,000 units, leaving 5,000 units in process that were 30 percent complete for conversion costs. How many equivalent units of production did Jones have for the period? a. 10,000 b. 11,500 c. 13,500 d. 15,000 Calculating and Using Equivalent Units of Production To calculate the cost per equivalent unit for the period: Cost per equivalent unit = Costs for the period Equivalent units of production for the period Quick Check Now assume that Jones incurred $27,600 in conversion costs for the 11,500 equivalent units of production. What was Jones’ conversion cost per equivalent unit for the period? a. $1.84 b. $2.40 c. $2.76 d. $2.90 Quick Check Now assume that Jones incurred $27,600 in production costs for the 11,500 equivalent units of production. What was Jones’ cost per equivalent unit for the period? a. $1.84 $27,600 ÷ 11,500 equivalent units b. $2.40 = $2.40 per equivalent unit c. $2.76 d. $2.90 March 2009 Assembly Department - Some Beginning/Some Ending Inventory Work in process, March 1: Materials: Conversion: 100% complete 60% complete 225 units $ 18,000 8,100 Production started during March: Production completed during March: 275 units 400 units Costs added to production in March: Materials cost Conversion cost $ 19,800 16,380 Work in process, March 31: Materials Conversion 100 units 100% complete 50% complete Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in March: ? Process Diagram - Testing Conversion costs added evenly during process Assembly Department Transfer Testing Department Direct materials added at the end of the process Finished Goods March 2009 Testing Department with Transferred-in Costs – W.A.Method Work in process, March 1: Transferred-in Materials: Conversion: 100% complete 0% complete 62.5% complete 240 units $ 33,600 0 18,000 Transferred-in during March: Production completed during March: 400 units 440 units Costs added to production in March: Transferred-in cost Materials cost Conversion cost $ 52,000 13,200 48,600 Work in process, March 31: Transferred-in Materials Conversion 200 units 100% complete 0% complete 80% complete Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in March: ? March 2009 Testing Department with Transferred-in Costs – FIFO Method Work in process, March 1: Transferred-in Materials: Conversion: 100% complete 0% complete 62.5% complete 240 units $ 33,600 0 18,000 Transferred-in during March: Production completed during March: 400 units 440 units Costs added to production in March: Transferred-in cost Materials cost Conversion cost $ 52,480 13,200 48,600 Work in process, March 31: Transferred-in Materials Conversion 200 units 100% complete 0% complete 80% complete Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in March: ?