NC Fire Code - Wake County Government

advertisement

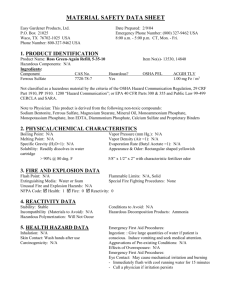

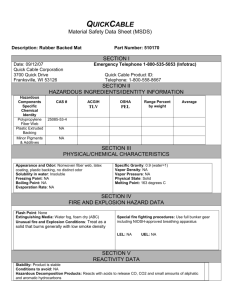

Hazardous Materials – North Carolina Fire Code BEST Conference - 2005 Presenter Charlie Johnson Wake County Public Safety Fire/Rescue Division (919) 856-5519 cejohnson@co.wake.nc.us Objectives Describe how hazardous materials are regulated by building and fire codes. List the permit requirements for hazardous materials. Describe the control area concept of hazardous materials management. Describe the general code requirements for storage, dispensing and use of hazardous materials North Carolina Fire Code Development process began in 1997 by three model code groups – SBCCI – ICBO – BOCA Model codes updated to more consistently regulate hazardous materials Hazardous Materials - Defined Those chemicals or substances which are physical hazards or health hazards as defined and classified in Chapter 27, whether the materials are in usable or waste condition Physical Hazards 1. Explosives and blasting agents. 2. Flammable and combustible liquids. 3. Flammable solids and gases. 4. Organic peroxide materials. 5. Oxidizer materials. 6. Pyrophoric materials. 7. Unstable (reactive) materials. 8. Water-reactive solids and liquids. 9. Cryogenic fluids. Health Hazards 1. Highly toxic and toxic materials. 2. Corrosive materials. Resources to help classify? North Carolina Fire Code - Appendix E Hazardous Materials Classification Guide HMEx Assistant MSDS Manufacturer Permits 105.7.6 Mandatory permit. A construction permit is required to install, repair damage to, abandon, remove, place temporarily out of service, or close or substantially modify a storage facility or other area regulated by Chapter 27 when the hazardous materials in use or storage exceed the amounts listed in Table 105.6.21. Permits EXCEPTIONS: – 1. Routine maintenance – 2. For emergency repair work performed on an emergency basis, application for permit shall be made within two working days of commencement of work. Permits 105.6.21 Optional Permit. An operational permit may be required to store, transport on site, dispense, use or handle hazardous materials in excess of the amounts listed in Table 105.6.21. – May be required in some jurisdictions by local ordinance HMMP Where required by the code official, each application for a permit shall include a Hazardous Materials Management Plan (HMMP). The HMMP shall include a facility site plan designating the following: – 1. Storage and use areas. – 2. Maximum amount of each material stored or used in each area. – 3. Range of container sizes. – 4. Locations of emergency isolation and mitigation valves and devices. HMMP cont. – 5. Product conveying piping containing liquids or gases, other than utility-owned fuel gas lines and low-pressure fuel gas lines. – 6. On and off positions of valves for valves that are of the self-indicating type. – 7. Storage plan showing the intended storage arrangement, including the location and dimensions of aisles. – 8. The location and type of emergency equipment. • The plans shall be legible and drawn approximately to scale. Separate distribution systems are allowed to be shown on separate pages. HMIS Where required by the code official, an application for a permit shall include a HMIS, such as SARA Title III, Tier II Report, or other approved statement. The HMIS shall include the following information: – 1. Manufacturer's name. – 2. Chemical name, trade names, hazardous ingredients. – 3. Hazard classification. HMIS cont. – 4. MSDS or equivalent. – 5. United Nations (UN), North America (NA) or the Chemical Abstract Service (CAS) identification number. – 6. Maximum quantity stored or used on-site at one time. – 7. Storage conditions related to the storage type, temperature and pressure. Hazardous Occupancies Hazardous Group H occupancy includes, among others, the use of a building or structure, or a portion thereof, that involves the manufacturing, processing, generation or storage of materials that constitute a physical or health hazard…………… in quantities in excess of those found in Tables 307.7(1) and 307.7(2) of the North Carolina Building Code. Hazardous Occupancies Physical hazards – Table 307.7(1) Health hazards – Table 307.7(2) Hazardous Occupancies Stricter code requirements for Group H occupancies – Building height and area restrictions – Separation requirements – Increased fire protection – Ventilation – Other special features Hazardous Occupancies H-1 H-2 H-3 H-4 H-5 Detonation hazard Deflagration hazard Physical hazard Health hazard HPM facility (semiconductor fabrication) Refer to table 307.7(1) to determine group Hazardous Occupancies Maximum allowable quantities per control area (MAQPCA) – “exempt amount” – storage or use? Same tables are listed in Chapter 27 of the North Carolina Fire Code Control Area? Spaces within a building which are enclosed and bounded by exterior walls, fire walls, fire barriers and roofs, or a combination thereof, where quantities of hazardous materials not exceeding the maximum allowable quantities per control area are stored, dispensed, used or handled. Control area concept Chapter 27 – Hazardous Materials 2701/2703 – general requirements for all hazardous materials regardless of amount 2704 – special requirements for storage if above MAQPCA 2705 – special requirements for use if above MAQPCA Quantities < MAQPCA 2703.1.3 The storage, use and handling of hazardous materials in amounts not exceeding the maximum allowable quantity per control area shall be in accordance with Sections 2701 and 2703. – General requirements General Requirements Systems, equipment, and processes – Approved containers – Piping, valves, fittings – Listed equipment – Installation of tanks • Liquid-level limit control for tanks > 500 gallons – Maintenance – Seismic bracing for equipment General Requirements Release of hazardous materials – Unauthorized discharge must be reported MSDS readily available NFPA 704 placards – If quantity requires a permit NFPA 704 General Requirements Control of ignition sources – Smoking, open flames, industrial trucks Construction requirements – Buildings – Control areas – Gas rooms – Exhausted enclosures – Gas cabinets – Haz-mat storage cabinets General Requirements General safety precautions – – – – – – – – – Personnel training/procedures Fire department liaison Security Vehicle impact protection Electrical wiring approved Static accumulation (flammable mixture) Light/shock sensitive materials Separation of incompatible materials Shelf storage General Requirements Handling & transportation – Valve protection for gas cylinders – Toxic/highly toxic compressed gas - must have outlets capped or plugged – Approved carts/trucks required to transport • > 5 gallons in corridor or exit enclosure • Material with NFPA 704 rating of 3 or 4 Quantities > MAQPCA 2703.1.4 The storage and use of hazardous materials exceeding the maximum allowable quantity per control area shall be in accordance with this chapter. – 2701/2703 – general requirements – 2704 - storage – 2705 - use Storage Spill control – Individual vessels > 55 gallons – Aggregate of multiple vessels > 1000 gallons Secondary containment – Same as above for liquids – 550/10,000 lbs.for solids Storage Ventilation – 1 cfm per square foot of floor area Separation of incompatible materials – 3 options • 20 ft distance • Noncombustible partition • Cabinet or exhausted enclosure Storage Fire protection – Minimum sprinkler design – Ordinary Hazard Group 2, design area 3,000 square feet Explosion control – As required by Table 911.1 (Fire Code) Storage Standby/emergency power – Ventilation systems – Treatment systems – Temperature control – Alarm/detection equipment Limit controls – Temperature/pressure Storage Manual fire alarm system Electrical supervision for all fire protection systems Noncombustible floors Outdoor control areas – Weather protection – Clearance from vegetation Dispensing & Use Separation of incompatible materials – 3 options • 20 ft distance • Noncombustible partition • Cabinet or exhausted enclosure Noncombustible floors – Also must be liquid-tight for dispensing/use in open systems Dispensing & Use Spill control – Dispensed into vessels > 1.3 gallons – Open system use > 5.3 gallons – Closed system use > 55 gallons Dispensing & Use Secondary containment – Open systems • Individual vessel > 1.3 gallons • Multiple vessels > 5.3 gallons – Closed systems • Individual vessel > 55 gallons • Multiple vessels > 1,000 gallons Dispensing & Use Limit controls – High-liquid-level for open containers – Low-liquid-level – Temperature – Pressure Dispensing & Use Standby/emergency power – Ventilation systems – Treatment systems – Temperature control – Alarm/detection equipment Electrical supervision for all fire protection systems Adequate lighting must be provided Dispensing & Use Fire protection – Minimum sprinkler design – Ordinary Hazard Group 2, design area 3,000 square feet Ventilation – 1 cfm per square foot of floor area Explosion control – As required by Table 911.1 (Fire Code) Dispensing & Use Liquid transfer of material with NFPA 704 rating of 3 or 4 – Safety cans – Closed piping system – Suction pump on top of container – Gravity through automatic-closing or selfclosing valve w/ spill control and secondary containment provided – Approved engineered systems Hazardous Materials Chapters 28-44 contain additional materialspecific requirements for all physical and health hazard materials – – – – – – Flammable/combustible liquids Cryogenic fluids Corrosive materials Compressed gases Toxic materials Oxidizers Flammable Liquid Cabinets 120 gallons maximum per cabinet – Not more than 60 gallons being Class I or II Maximum 3 cabinets in single fire area – Factory/Industrial can exceed this limit with 100 ft. separation between groups of 3 Questions Need to purchase code? NC Department of Insurance 322 Chapanoke Road Suite 200 Raleigh, NC 27603 (919) 661-5880 www.ncdoi.com