Improved groundnut varieties

advertisement

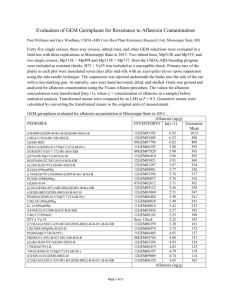

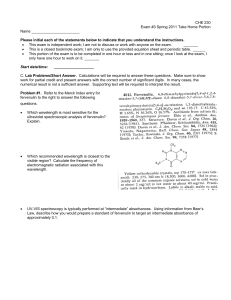

Groundnut Varieties Improvement for Yield and Adaptation, Human Health, and Nutrition Pre- and post-harvest aflatoxin mitigation in groundnuts 3-4 December 2012 McKnight CCRP Groundnut Breeding and Afaltoxin Project DRD-Naliendele Agricultural Research Institute P.O. Box 509 Mtwara, Tanzania. E-Mail mpondaomari@hotmail.com Project Team members and locations ICRISAT NASFAM-Malawi KCH Malawi E S Monyo – Breeder/Principal Investigator B Chinyamunyamu – Principal Collaborator Economics F Madinda – Now O Mponda – Lutheran Hosp. Principal Arusha Collaborator Breeding M Siambi – Collaborator Agronomy C Nakhumwa – Collaborator Economics I Mwakasungula E Kafiriti – Collaborator Agronomy S.Anitha Aflatoxin Diagnostics S Phiri Project Technician T Chilunjika M Sijaona – Collaborator Pathology Wills Munthali Project Officer Breeding DRD-Tanzania DANISH MANAGEMEN T Nick Nathaniels – Communication specialist Project Locations: Tanzania & Malawi Crop Systems Challenges/Opportunities being Addressed Low agricultural productivity and food insecurity. Poor soil fertility, unreliable rainfall and diseases are major factors limiting crop productivity. Malnutrition particularly in Children: lack of protein, oil and vitamins in a largely cereal-based diet Poverty >half of the population Challenges in the Project Area • Small farm holdings 0.5 – 1.0ha • Lack of farm machinery (only hand tools) • Fungal foliar and Plant viral Diseases • Aflatoxin contamination Research Hypothesis • Improved groundnut varieties (for yield, disease and aflatoxin resistance) will stimulate farmer adoption and increase production enabling smallholder farmers to overcome – Malnutrition – Health related ailments – Increased rural poverty – Loss of soil fertility Major Achievements: 9 Varieties released to date IN 2012 NEW GROUNDNUT VARIETIES IDENTIFIED FOR RELEASE IN TANZANIA Participatory variety selection Rural seed fairs Afaltoxin contamination – trade and health effects • Aflatoxins (B1, B2, G1, G2), the poisonous secondary metabolites produced by Aspergillus flavus and A. parasiticus, are one of the most frequent contaminants in several crops produced under rainfed conditions such as groundnut, maize, millets, chillies, various nuts, etc. Aflatoxins Toxic metabolites produced by Aspergillus flavus and related species in several crop species Aflatoxin B1 is a potent toxin It is considered as carcinogen Aspergillus flavus: Aflatoxin producing mold Aflatoxin B1 Economic Impact • FAO estimates 25% of world food crops affected by mycotoxins – aflatoxin being the most notorious • Aflatoxin causes losses to livestock and poultry producers due to reduced growth rates, low yields, feed efficiency losses • Aflatoxin is a Barrier to trade • Regulatory programs are costly Countries with Permissible Limits for Total Aflatoxins in Food & Feed Top 20 Groundnut Exporters, 2008 Rank Country 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 India China USA Argentina Netherlands Nicaragua Brazil UAE South Africa Vietnam Paraguay Belgium Gambia Singapore Australia Bolivia UR of Tanzania Egypt Spain Uzbekistan Quantity Value (1,000 Unit value (tonnes) US$) (US$/tonne) 293,128 274,154 935 167,054 232,183 1,390 216,936 198,593 915 148,962 180,890 1,214 80,287 137,390 1,711 77,973 90,058 1,155 44,361 50,586 1,140 15,938 15,799 991 10,202 15,027 1,473 14,300 13,700 958 9,230 9,778 1,059 6,282 9,395 1,496 18,000 8,200 456 6,093 7,336 1,204 3,984 7,254 1,821 4,056 6,658 1,642 14,817 6,280 424 5,684 6,138 1,047 3,275 5,874 1,794 6,461 5,545 858 Source: FAOSTAT Groundnuts Production-Tanzania Cropped Production Av. Area (2008- (2008-10 Yield (2008- Potential 10 avg) avg) 10 avg) (A) yield (B) million million ha tonnes Kg/Ha Kg/Ha 0.54 0.39 721.38 3,000 Realizable Yield (C) Yield Gap (C-A) Kg/Ha Kg/Ha 1500 778.62 Major Groundnuts production and exporting countries 20012007 (000’ MT ) Rank Country Production Country Export 1 China 13,936 China 700 2 India 6,870 Argentina 273 3 Nigeria 3,281 USA 192 4 USA 1,822 India 188 5 Indonesia 1,382 Netherlands 117 6 Myanmar 891 Viet Nam 63 7 Sudan 782 Nicaragua 55 8 Senegal 527 Brazil 31 9 Viet Nam 443 South Africa 26 10 Ghana 427 The Gambia 19 World Total 35,828 World total 1,894 Groundnut Aflatoxin component Specific Objectives – ensure that the general public is knowledgeable about aflatoxin and its effects on health • Disseminate available aflatoxin reducing technologies • Building capacity of front line staff and farmers through farmer friendly integrated aflatoxin management packages Factors Favorizing Aflatoxin Production • • Interactions among fungus, the host & the environment – Pre-harvest • Presence of A. Flavus in the soil • insect damage • Water stress, high temp, prolonged drought, • Specific crop growth stages, soil fertility, high crop densities, weed competition Post-harvest. Warm Temperature High humidityrewetting Poor storage conditions Harvesting overly mature crop Mechanical damage Relationships between Grain contamination and Soil fungus Fitted probabilities of contamination >4ppb as influenced by soil fungi (log (cfu)) reveal Clear relationship between grain contamination and A.flavus in the soil. (as cfu increase beyond 3000 (log(cfu)>8). Relationships between Farmer exposure to groundnut production and grain aflatoxin contamination Fitted probabilities of contamination >4ppb as influenced by exposure to groundnut farming (years) Reveal that both less experienced and older farmers are more likely to produce groundnuts contaminated with aflatoxin. Relationship between district mean growing temp and Aflatoxin contamination Plotting the values of proportion of samples >20ppb for each district against district mean temperature revealed that groundnut contamination is to a greater extent more likely in warmer locations Groundnut Aflatoxin workshop with traders in Mtwara WABISOCO, MTWARA 17 June 2011 Moulds in groundnuts Microscope view of fungi aspergillus flavus- Aflatoxin contamination levels in groundnuts in Tanzania (ppb) Samples Mean AfB1 93 85 93 121 68 115 Lifecycle- 1.Aflatoxin contamination starts in the field 2.How to reduce contamination in the field – Timely harvesting is important 3. Delayed harvesting may lead to aflatoxin Contamination 4. Browning of the inner side of the podmaturity 5.How to reduce contamination during harvest – 10% moisture level (pod ratling) 6.How to reduce contamination during dryingDry on raised platform 7. Jute bags good for groundnut storage 8.Sorting broken kernels and mould nuts may reduce aflatoxin contamination in groundnuts Sorting and Grading – reduced aflatoxin contamination Joint action needed – by value chain actors Policy makers (Ministries of Agriculture, Health, Industry, Finance, Trade, PMO, Loc GOvt),TFDA, Input & service suppliers (incl extension, SIDO, AMCOS; Farmer groups, PvT TOSCI,ASA, NGOs) Farmers Research community NARS, ICRISAT,IITA, TFNC,TBS Traders Exporters Processors Supermarkets Consumers Adapted from Homann-Kee Tui (2010) Training/Planning Workshop Report on Establishing Small Stock Innovation Platforms, Gaborone Field Technology Demonstrations Aflatoxin Susceptible Early Late Water Management Resistant Time of Planting Variety GRD, Aflatoxin Box Ridges Open Ridges Affordable Tools for Monitoring Aflatoxin Contamination For successful mycotoxin management in food and feed, simple low-cost monitoring tools are required ICRISAT has developed ELISA based technologies for the detection of AFB, AFM1, FMB, OT etc. in food and feeds. And detection of AFB1-Albumin biomarker from blood Summary of researcher/communicator engagement with groundnut stakeholders 2011-12 and recent results highlights Market traders Small scale processors Agric Coops District Council Chairmen District Agric Extension Face-to-face information meeting, 2011, brings a new understanding of mould and aflatoxin 2011 Are encouraging better practices at the market through internal meetings on aflatoxin, and encouraging their suppliers to do the same. Will teach others in their networks Want to ensure all crops in go-down are mould free: have requested training Have raised aflatoxin issue in Nanyumbu. and Ward Development Committee Meeting Has sensitised AEOs and will contintue training of farmers and Agric Cooperatives Stakeholder meetings 2011/12 for information sharing, debate, consolidating an appreciation that pre-and postharvest actions all contribute together to addressing aflatoxin. Time-line of NARI/Danish Management’s continuing/proposed sub-projects to support these stakeholder’s own learning/training activities, Tanzania 2012-13 planting Weeding/earthing up Harvesting/grading/drying shelling Identify test groups SRM New radio series Radio series cont’d Radio series cont’d Shooting of groundnut GAP for aflatoxin control video Swahili aflatoxin leaflet + pretest ongoing Nov Dec 2012 Jan Edit and pretest leaflet use in training, + feedback for improvement Feb Mar Apr 2013 Evaluation and planning for radio + interactive voice messages with TFNC Radio series cont’d May Dissemination, use in training, feedback & evaluation Improved leaflets, wider dissemination, feedback & evaluation Jun Jul Aug Sep Oct Key points of our ICMM work 1) Researchers are engaging constructively with communication media specialists and with a range of stakeholders in the groundnut sector on pre- and post-harvest control/mitigation. 2) Diverse stakeholders included in decision making of training/communication productions via feedback loops. 3) Our methodology – the informal Learning Alliance – is systematically building relationships, sharing information, encouraging joint analysis of problems and solutions that for collaboration across stakeholder groups. 4) The approach can be extended to inform higher level policy Gender consideration in aflatoxin mitigation measures • Groundnut is considered a women crop • Women do the planting, weeding, harvesting, plucking, shelling ,grading for the market • There is fresh and dry groundnut value chains • Women make decision in consumption/preparation of food (need for focused training targeting women) Groundnut/Aflatoxin Research challenges • Farmers have no incentive to clean grain as there is no incentive by way of price differentials. – no grades and standards (Policy) • Capacity in aflatoxin detection at NARI and rapid testing in major groundnut producing zones at buying centres • Mass use of polypropylene sacks by farmers and traders (policy) • Lack of specialisation in agriculture among media personnel (low understanding/reporting in aflatoxin– degree training in communication (policy) • Inadequate funding for groundnut /aflatoxin research • Inadequate availability and supply of improved groundnut seeds • Competition from edible oil imports – Cheap oils imports (policy) • Importation of aflatoxin free groundnuts for plumpynut processing – Power foods AREAS OF INTEREST TO LINKING WITH PACA Key Proposed actions 1. Capacity building for management of aflatoxin in groundnuts variety development and enabling policy environment enhanced. 2. Nutritional status, dietary diversity, human health and mycotoxin contamination problem spatially characterized 3. Bio-control options – pre-harvest contamination :atoxigenic strains of A.flavus, post harvest contamination in stores– plant extracts, essential oils, ammonia vapour 4. Innovative Communication aflatoxin mitigation strategies - Timeline 2013-2015 2013- 2015 2013-1015 2013-2015 Thank you