EDA\01_intro_CAD-

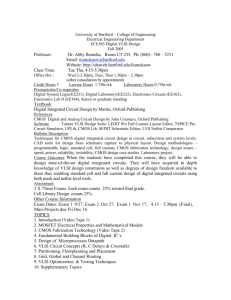

advertisement

الگوريتمهاي طراحي فيزيكي VLSI 1 مراجع • • • • • 1. 2. Andrew B. Kahng, Jens Lienig, Igor L. Markov and Jin Hu, VLSI Physical Design: From Graph Partitioning to Timing Closure, Springer, 2011. N. Sherwani, “Algorithms for VLSI Physical Design Automation”, 3rd edition, Kluwer Academic Publishers, Boston, MA, 1999. T.H. Cormen, C.E. Leiserson and R.L. Rivest, “Introduction to Algorithms”, McGraw-Hill, New York, NY, 1990. Practical Problems in VLSI Physical Design Automation, Sung Kyu Lim, Springer, 2008. P. Lee, “Introduction to Place and Route Design in VLSI,” Lulu, 2007. Charles J. Alpert, Dinesh P. Mehta, Sachin S. Sapatnekar, Handbook of Algorithms for Physical Design Automation, ed., Taylor & Francis Group, 2009. L. Scheffer, L. Lavagno, G. Martin, “EDA Handbook (EDA for IC Implementation, Circuit Design, and Process Technology),”, Ed., CRC Press, 2006. 2 VLSI CAD Conferences • DAC Design Automation Conference • ICCAD Int’l Conference on Computer-Aided Design • ISPD Int’l Symposium of Physical Design • ASP-DAC Asia and South Pacific DAC 3 VLSI CAD Conferences • DATE (EDAC) Design Automation and Test in Europe • ISCAS Int’l Symposium on Circuits and Systems • ICCD Int’l Conference on Computer Design • APC-CAS Asia-Pacific Conference on Circuits and Systems 4 VLSI CAD Journals • IEEE TCAD IEEE Transactions on CAD • ACM TODAES ACM Transactions on Design Automation of Electronic Systems • Integration, the VLSI Journal • IEEE Transactions on Circuits and Systems • IEEE Transactions on VLSI Systems • IEEE Transactions on Computers 5 Web Sites •Papers: http://scholar.google.com/ •Benchmarks: http://vlsicad.eecs.umich.edu/BK/Slots/slots/Circ uitandMicroprocessorDesignExamples.html http://vlsicad.eecs.umich.edu/BK/Slots/slots/Wir elengthdrivenStandardCellPlacement.html http://www.cbl.ncsu.edu/benchmarks/ 6 Web Sites • VLSI CAD Bookshelf: http://vlsicad.eecs.umich.edu/BK/ • VLSI Design Automation Café: http://www.edacafe.com 7 8 9 10 Integrated Circuits (ICs) • What are they? Electrical components built by layering different materials on a silicon base (wafer) • IC Designer Transforms a circuit description into a geometric description - Layout process 11 Integrated Circuits B 12 Size Issue 50-70 microns 0.020 microns 0.025 microns Tens of 13 Moore’s Law In 1965, Gordon Moore: • Number of transistors on an IC doubles every year. • 10 years later, he revised it: doubles every 18 months 14 VLSI Physical Design Automation • Modern chip design: very complex • Largely performed by specialized software Tools are frequently updated to reflect − improvements in semiconductor technologies − increasing design complexities 15 VLSI Physical Design Automation • User of this software needs: a high-level understanding of the implemented algorithms. • Developer of this software needs an understanding of : how various algorithms operate and interact what their performance bottlenecks are 16 Questions How is functionally correct layout produced from a netlist? (Analysis) netlist physical design layout How do we develop and improve software for VLSI physical design? (Algorithm design) 17 System Specification ENTITY test is port a: in bit; end ENTITY test; Architectural Design Functional Design and Logic Design Circuit Design Physical Design DRC LVS Physical Verification and Signoff ERC Fabrication Packaging and Testing Chip 19 System Specification • Specify overall goals and high-level requirements: Functionality Performance Physical dimensions Production technology Overall power constraints • Trade-offs: Market requirements, costs, economical viability 20 Architectural Design • Define basic architecture to meet the system specifications: Integration of analog and mixed-signal blocks Memory management (serial/parallel?) + addressing scheme Number and types of computational cores − E.g., processors and DSP algorithms/units Internal and external communication − support for standard protocols, … 21 Architectural Design (cont’d) • Define basic architecture to meet the system specifications: Hard/soft IP blocks Pinout, packaging and die-package interface Power requirements Choice of process technology and layer stacks 22 Functional and Logic Design • Functional design: Main functional units and their interconnections Behavioral specification of each module (not implementation) −input-output mapping −timing behavior 23 Functional and Logic Design • Logic design: RTL spec. in VHDL/Verilog + target library Logic synthesis and simulation Result: Netlist i.t.o. library elements 24 Netlist (a: N ) 1 (b: N ) 2 Pin-Oriented Netlist (c: N ) 5 (x: IN1 N , IN2 N , OUT N ) 1 2 3 (y: IN1 N , IN2 N , OUT N ) 1 2 4 (z: IN1 N , IN2 N , OUT N ) 3 4 5 (N : a, x.IN1, y.IN1) 1 (N : b, x.IN2, y.IN2) 2 (N : x.OUT, z.IN1) 3 (N : y.OUT, z.IN2) 4 (N : z.OUT, c) 5 Net-Oriented Netlist 25 RTL Specification • RTL: Control flow Register allocation Data path: −Arithmetic operations −Logic operations −Buses and interconnections 26 Circuit Design • Some critical modules must be designed at the transistor level: SRAM blocks I/O Analog circuits High-speed functions Electro-static discharge (ESD) protection circuits • Verification by SPICE simulation 27 Physical Design Circuit Description Geometrical Description Manufacturing 28 System Specification ENTITY test is port a: in bit; end ENTITY test; Architectural Design Functional Design and Logic Design Circuit Design Physical Design DRC LVS Physical Verification and Signoff Partitioning Chip Planning Placement Clock Tree Synthesis Signal Routing ERC Fabrication Timing Closure Packaging and Testing Chip 29 • DRC: Physical Verification Checks technology-imposed constraints • Circuit extraction and LVS: Layout netlist Compare with original netlist • Parasitic extraction: Layout RC(L) circuit Check for electrical characteristics • Antenna rule checking: Antenna effects damage transistors • ERC: power and ground connections signal transition time (slew) fan-out constraints 30 Fabrication • Tapeout (Stream out): Generation of layout data in GDSII format Delivering the design to manufacturing process • Wafer size: 200-300 mm • Die size: 25 mm2 − Layout is converted to several dozens of photolithographic masks 31 Testing and Packaging 32 Physical Design • Arrange devices on a plane • Determine interconnection paths so that Constraints: − Functionality is preserved − Performance constraints are met − Manufacturing design rules are met Metrics for optimization: − …. 33 Physical Design • Metrics: Performance: − Gate delays and interconnect delays Area: − larger chips higher costs + slower chips + higher power Reliability: − E.g. vias Power consumption Yield • Efficiency of algorithms 34 Physical Design Cycle Break the circuit up into Partitioning Placement/ Floorplanning Routing smaller segments Place the segments on the chip Lay out the wire paths 35 System Specification ENTITY test is port a: in bit; end ENTITY test; Architectural Design Functional Design and Logic Design Circuit Design Physical Design DRC LVS Physical Verification and Signoff Partitioning Chip Planning Placement Clock Tree Synthesis Signal Routing ERC Fabrication Timing Closure Packaging and Testing Chip 36 )Partitioning( افراز • Reasons: • Highly complex circuits • Memory limitation of computers • Speed limitation of computers Sets of partitions Netlist Number of partitions Partitioner Partitions netlist Block sizes 37 )Partitioning( افراز 38 Chip Planning • Floorplanning: Determines shapes and arrangements of modules Frequently done manually • Power & ground routing: Distributes VDD and GND nets throughout the chip • Pin assignment: Determines the locations of ports 39 )Floorplanning( جاسازي Recently, SoCs with many cores: Manual floorplanning not possible Deadspace 40 )Placement( جايابي 41 Clock Network Synthesis • Determines: routing of the clock signal buffering clock gating (e.g., for power management) • Constraints to meet prescribed skew delay requirements (power requirement) 42 Clock Network Synthesis 43 )Signal Routing( مسيريابي • Complete interconnections between blocks acc. to netlist • Routing area: Channels Switchboxes • Global routing: Specifies which channels/switchboxes are to be used for each net • Detailed routing: Specifies exact interconnections within various ch/sb 44 Global Routing Cell 1 Cell 2 1 Cell 1 Cell 2 45 Detailed Routing The actual wires are routed in the channel The goal of the entire process: − To produce the shortest wires and consume the least amount of space Cell 1 Cell 2 1 Cell 1 Cell 2 46 Timing Closure • Optimizes circuit performance by specialized placement and routing techniques RC(L) Extraction: − Layout circuit Timing Analysis: − Calculate delays and determine critical path(s) Timing Optimization 47 History Time Period Circuit and Physical Design Process Advancements 1950 -1965 Manual design only. 1965 -1975 Layout editors, e.g., place and route tools, first developed for printed circuit boards. 1975 -1985 More advanced tools for ICs and PCBs, with more sophisticated algorithms. 1985 -1990 First performance-driven tools and parallel optimization algorithms for layout; better understanding of underlying theory (graph theory, solution complexity, etc.). 1990 -2000 First over-the-cell routing, first 3D and multilayer placement and routing techniques developed. Automated circuit synthesis and routability-oriented design become dominant. Start of parallelizing workloads. Emergence of physical synthesis. Design for Manufacturability (DFM), optical proximity correction (OPC), and other techniques emerge at the designmanufacturing interface. Increased reusability of blocks, including intellectual property (IP) blocks. 2000 - now Deeper level of integration (instead of indep’t point tools) 48