CNC Turning - Rahma Najjar

advertisement

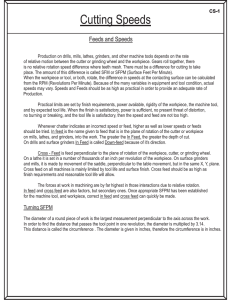

ANSWER KEY Academic Year: 2012-2013 Teacher: Eng. Rahma Najjar Section: 12.52-12.55 AEE Applied Engineering (Mechanical) Subject : Module : Name: CNC Turning Content organization Language Knowledge End date for submission Date of submission Total mark Question 1: Fill in the table with the coordinates of the points shown on the 2-D Cartesian coordinate system shown below. a b c d X 80 -60 -40 20 Y 60 40 -50 -20 Question 2: Use the coordinates table below, to locate the points "a" through "d" on the 2-D Cartesian coordinate system shown in the figure. a b c d X 10 -80 40 -30 Y 20 -30 -70 50 Question 3: Enter the Cartesian coordinates of the points "a" to "g" in the table. Determine the corresponding diameter values of the X-coordinates. a b c d X 0 40 40 80 Z 140 140 100 100 e f g 80 110 110 50 50 0 Question 4: Write (T) for true and (F) for false following statements: a) ( F )Moving on a turning machine on the X-axis from the center of the workpiece to the end is a positive direction. b) (F)Workpiece zero point is defined by the manufacturer and cannot be changed. c) (F) In incremental dimensioning all measurements are taken from workpiece zero point. d) (F) Moving on a turning machine towards the chuck on the Z-axis is positive direction. Question 5: Enter the Cartesian coordinates of the points "a" to "d" in the table. Determine the corresponding diameter values of the X-coordinates. a b c d X 40 40 70 70 Z 0 -60 -60 -85 Question 6: Calculate the rotational speed, if a 15mm diameter workpiece made of Bronze is to be machined (rough cut). the cutting tool is HSS. 𝑛= 𝐶𝑠 𝜋. 𝑑 Cs = 27 m/min (for Bronze rough cut, from the table) d = 15mm n= 15 1000 27 3.14 x 0.015 = 0.015 m = 573.24 RPM Question 7: Calculate the rotational speed, if a 1.6 cm diameter workpiece made of cast iron is to be machined (finish cut). The cutting tool is made of HSS 𝑛= 𝐶𝑠 𝜋. 𝑑 Cs = 24 m/min (for cast iron finish cut, from the table) 1.6 d = 1.6 cm n= 100 = 0.016 m 24 3.14 x 0.016 = 477.71 RPM Question 8: Calculate the rotational speed required to rough turn a 40 mm diameter piece of machine steel, the cutting tool is made of HSS. 𝑛= 𝐶𝑠 𝜋. 𝑑 Cs = 27 m/min (for Machine steel rough cut, from the table) d = 40mm n= 40 1000 27 3.14 x 0.04 = 0.04 m = 214.97 RPM Question 9: If a work piece with the radius of 7mm is to be machined (rough cut) using a HSS cutting tool, the workpiece has a rotational speed of 477.71 RPM. 1. Calculate the cutting speed. 2. What is the material of the workpiece? 𝑛= 𝐶𝑠 𝜋. 𝑑 Cs = unknown r = 7mm 7 1000 = 0.007 m diameter = 2 x r = 2 x 0.007 = 0.014 m 477.71 = Cs 3.14 x 0.014 Cs = 477.71 x 3.14 x 0.014 Cs = 21 m/min 2. From the table for the rough cut, and the cutting speed is 21 m/min The material of the work piece is tool steel