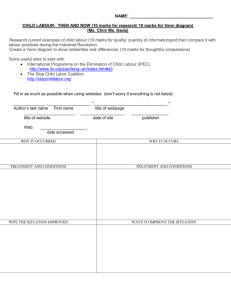

question 1 - Varsityfield

advertisement

Copyright reserved

Faculty of Economic and Management Sciences

Department of Financial Management

Financial Management 200 (FBS 200)

Date:

18 November 2011

Total marks: 120 Marks

Duration:

180 Minutes

Date of perusal:

Monday 29 November 2011 [09h00 – 11h00]

HSB 3 - 23

Internal examiners:

Mr F Blom

Mr FJ de Hart

Ms L Erasmus

External examiner:

Ms Y Erasmus

Instructions:

Answer all the questions.

The question paper consists of 11 pages (excluding the cover page).

You are not allowed to bring any teaching materials or notes into the examination venue.

You are allowed to do your rough work on the examination paper and may take the paper with

you when you leave the venue at the end of the examination session.

SUGGESTED SOLUTION

Important information

1. The results of examinations and supplementary examinations for first year students only will be

displayed on the notice-boards next to the Human Sciences Building.

The results for first, second and third year, as well as postgraduate students will be available on the

MTN line and Students Online (SOS). Results will be mailed as soon as possible to candidates

after the examination period. Results will be available at telephone nr. 083 123 1111, as well as on

the Intranet address: http://www.up.ac.za, students online.

LECTURERS AND ADMINISTRATIVE STAFF WILL NOT GIVE CANDIDATES THEIR RESULTS

PERSONALLY OR PER TELEPHONE.

2.

Supplementary examinations are not granted automatically, but are subjected to current

Departmental policy.

3.

The FBS200 supplementary examination will take place on 1 December 2011 from 15:30 – 18:30 in

HSB 4-2. Timetables to determine the date, time and place of supplementary examinations are

available on:

3.1 Notice boards at the main entrance to the Merensky Library;

3.2 Students Online (SOS);

3.3 MTN telephone nr. 083 123 1111.

4. The regulations concerning multiple choice examination papers are brought to your attention.

SUGGESTED SOLUTION 1

29 MARKS

a) i) Raw materials may be valued at actual cost or at standard cost

ii)

Closing inventory Raw Materials valued at .......

Profit before raw materials

Purchases

(450-440)kg = 10kg x (R1440/.450) ; (1 000g x R3)

Closing inventory

Actual loss

Actual

R1 362 642 R1 362 642

(1 440 000) (1 440 000)

32 000

30 000

(45 358)

(47 358)

80 000 u – 78 000 u

(R542 400 + 520 000)/ 80 000

2 000 u x R13.28 =

b) i) Variance in volumes (units)

Standard contribution per unit

Volume variance - Adverse

Standard

2 000 u

R13.28

R26 560

ii) The volume variance represents the difference between planned sales volumes (units)

and actual sales volumes (in units). For each of these units (in this instance 2 000

units) a contribution of R13.28 will not have been realised (hence adverse variance).

The actual profits therefore cannot be compared to the planned profits (cannot

compare apples with pears), but rather against the standard profit i.e. the profit that

would have been planned for if the plan at the start of the year was for the actual units.

The planned profit (R542 400) should therefore be adjusted downwards (in this case)

with the variance of R26 560, before a meaningful reconciliation of profits can be done.

R3 000 000 x 78/80 – R2 730 000 =

(440kg x R3 000) - 78/80 x R1 200 000 =

R224 016 – (78 000x R12.50 x 0.2ure) =

78/80 x R180 000 – R195 000 =

R60 528 – (12 000u x R4.80) =

78/80 x R57 600 – R57 600 =

R552 414 – R520 000 =

c) i)

ii)

iii)

iv)

v)

vi)

vii)

Sales price variance

Raw material usage variance

Direct labour rate variance

Direct labour efficiency variance

Variable overhead expenditure

Variable overhead efficiency

Fixed overhead expenditure

d) i)

Any valid reason explaining a lower than planned selling price eg. discount sales,

drop in demand leading to reduction of selling prices or special orders placed at

reduced prices etc,

ii)

Suppliers that granted discounts, errors on invoices in favour of Take It To Task, bulk

purchases at reduced/discounted prices etc

iii)

Unforeseen increases, inflation, incorrect suppliers etc that may have lead to higher

costs.

iv)

Packaging was damaged, errors made in packing etc which led to more packaging

required for the dummies produced.

1

R195 000

R150 000

R29 016

R19 500

R2 928

R1 440

R32 414

(A)

(A)

(A)

(A)

(A)

(A)

(A)

SUGGESTED SOLUTION 2:

22 MARKS

1. C

Cost driver

14,000.00

6,000.00

20,000.00

Product B

Product J

2 C

Cumulative average for first 4 units

Cumulative average for first 2 units

Cumulative average for first unit (and time)

3 D

Cumulative average for first 8 units

Cumulative average for first 16 units

Total time for first 16 units

Time for first 4 units

Time for order of 12 units

4 D

All the statements are correct

5 D

NPV of project 2 is R49 947

Joint cost

28,000.00

12,000.00

40,000.00

3 240 / 4 =

810 / 0.9 =

900 / 0.9 =

810 minutes

900 minutes

1 000 minutes

810 x 0.9 =

729 minutes

729 x 0.9 =

656.1 minutes

656.1 x 16 = 10 497.6 minutes

= (3 240) minutes

= 7 257.6 minutes

Annual equivalent is R22 972 (PV (NPV) = R49 947, i = 18%, n = 3, FV = 0)

6. A

Clock hours

40

:

:

Productive hours

35

0.5

:

:

:

Units

350

5

Rate per productive hour:

Clock hours : Productive hours

1 : 0.875

R 34.30 per clock hour = R 34.30 per 0.875 productive hours = R 39.20 per productive

hour

Rate per unit

R 39.20 per productive hour x 35 productive hours

350 units

= R 3.92 per unit

7 A

Sales

Variable costs

Fixed costs

Profit

=

75 000 x 8 =

R185 000 + R75 000 =

2

R1 080 000

(600 000)

(260 000)

R220 000

8 D

Profit per variable

Add: Fixed costs in inventory

Profit per absorption basis

(80 000–75 000) x R2.40 =

R220 000

12 000

R232 000

Sales

Production costs

80 000 x (2.4 + 8) =

Closing stock

5 000 x R10.40 =

Over-recovery–fixed overheadsR185 000–(80 000 x R2.40) =

Less non-production fixed costs

Profit for the year

R1 080 000

(832 000)

52 000

7 000

(75 000)

R232 000

OR

9. A

10 D

INCREASE

4 ℓ : 5ℓ

LOSS

5%

50%

100%

0%

Before loss:

5 700 ℓ ÷ (1 – 0.05) = 6 000 ℓ

Before increase:

4ℓ

:

5ℓ

4 800 ℓ

:

6 000 ℓ

11 C

Total

Maintenance

Stores

Maintenance:

Stores:

Production

Department 1

262 500

0.6M

0.75S

Production

Department 2

491 250

0.3M

0.2S

94 500 – 1M + 0.05S = 0

126 750 + 0.1M – 1S = 0

94 500 – 1M + 0.05 (126 750 + 0.1M) = 0

94 500 – 1M + 6337.5 + 0.005M = 0

88 162.5 = 0.995M

3

Maintenance

Stores

94 500

(1M)

0.05S

0

126 750

0.1M

(1S)

0

M = 101 344.22

S = 136 884.42211055276381909547738694

Total

Maintenance

Stores

Production

Department 1

262 500.00

60 806.53

102 663.32

425 969.85

Production

Department 2

491 250.00

30 403.27

27 376.88

549 030.15

Maintenance

Stores

94 500

(101 344.22)

6 844.22

0

126 750

10 134.42

(136 884.42)

0

A mere observation of the options would also have made it CLEAR that option C is

correct! Department 2 before any allocations already has total costs of R491 250,

leaving only B and C as potential options! Then 30% of Maintenance (R94 500) and 20%

of Stores (R126 750) must be assigned to Department 2. Clearly the answer is C.

4

5

SUGGESTED SOLUTION 3:

34 MARKS

A suggestion is to determine the period for the last six months as follows:

Sales

Raw materials

Labour

Overheads

Administration

Selling expenses

Net profit

Taxation (28%)

Net profit after tax

First six

months

For the first

year

Rands

2 250 000

720 000

525 000

348 000

96 000

67 500

493 500

(138 180)

355 320

Rands

4 950 000

1 692 000

1 155 000

744 000

192 000

172 500

994 500

(278 460)

716 040

a)

Calculation (‘000)

Total costs

Cost per unit

Budget volumes (to nearest 1 000)

Units in 1st six months

Total units per six month period

2250-493.5; 4950 – 994.5

Sales units per month (÷ 6) =

iii)

b)

Increase in sales volume

(2 700/2 250 – 1) or (6 000/5 000 -1)

(R1 692 – 720)’000 =

=

Data for last

6 months

Rands

2 700 000

972 000

630 000

396 000

96 000

105 000

501 000

(140 280)

360 720

(i)

First six

months

(ii)

Last six

months

R1 756 500

R58.55

30 000

30 000

R3 955 500

R59.93

66 000

(30 000)

36 000

5 000

6 000

20%

i)

Total raw material cost

Number of units

Cost per unit

R972 000

36 000

R27.00

ii)

Total labour cost for

30 000 units =

Total labour cost for

36 000 units =

i.e. cost in total changed

R525 000

R630 000

Labour cost per unit

30 000 units =

Total labour cost for

36 000 units =

i.e. cost in per unit remained fixed

R17.50

R17.50

Labour cost meets the definition of a variable cost as it remains fixed per unit

but changes in total.

6

iii)

Total costs for

Total costs for

36 000 units =

30 000 units =

6 000 units =

R396 000

R348 000

R48 000

Variable portion per unit R48 000 / 6 000 units =

Total fixed

R396 000 – (36 000 x R8) =

Fixed per month

÷6=

c)

Selling price

Raw materials

Labour

Overheads

Administration

Selling expenses

R8.00

R108 000

R18 000

Calculation

Contribution per unit

Fixed

R2 250 000 / 30 000 =

R720 000 / 30 000 =

R75.00

(24.00)*

(17.50)

(8.00)

(1.25)

24.25

R216 000

192 000

90 000

R498 000

12 x R18 000 =

See note 1

See calc 1

Break-even

(R498 000 ÷ R24.25) =

@ 5 000 per month

Will break-even in month 5

20 536 units

*The raw material cost is R27 from month 7 onwards and contribution per unit will be

R21.25.

Note 1: The administration costs remain fixed in total (R96 000 per period of six

months) and therefore would have reduced per unit (36 000 u vs 30 000 u).

Administration costs are fixed

Calc 1:

Total costs for

Total costs for

36 000 units =

30 000 units =

6 000 units =

Variable portion per unit

Total fixed (stepped)

d)

R105 000 – (2 x 5 000)6 =

R67 500 – (1 x 5 000)6 =

R45 000

R37 500

R7 500

R7 500 / 6 000 units =

R5 000 x 6 + R10 000 x 6 =

R1.25

R90 000

Monthly sales volumes if accept

6 000u x 1.3333 =

First six months, extra

8 000 – 5 000 =

Last six months and thereafter, extra

8 000 – 6 000 =

8 000 units

3 000 units

2 000 units

Incremental cash-flows:

Year 1

First six months:

3 000 x 6 x R24.25 =

Last six months

2 000 x 6 x R21.25 =

Total for year 1

Additional selling costs (2nd person – for 1st six months) 6 x R5 000 =

7

R436 500

R255 000

R691 500

(30 000)

R661 500

Years 2 and 3

Incremental revenue cash-flow per annum

Cash-flows after tax:

Year 1

Years 2 and 3

e)

2 000 x 12 x 21.25 =

R510 000

R661 500 x 0.72 =

R510 000 x 0.72 =

R476 280

R367 200

Cf0 =

Cf1 =

Cf2 =

Cf3 =

Rnil

R476 280

R367 200

R367 200

i=

18%

NPV =

R890 833.70

The maximum fee that Relkap should consider is R890 834.

8

9

SUGGESTED SOLUTION 4:

35 MARKS

PART A (19 marks)

1. (i) Traditional (blanket-wide) approach

Cost driver

Total LH

18 000.00

42 000.00

60 000.00

Frying pans

Casserole pots

Budgeted FOH

1 077 000.00

2 513 000.00

3 590 000.00

Units

produced

12 000.00

20 000.00

Budgeted recovery rate per unit

89.75

125.65

Units

produced

12 000.00

20 000.00

Budgeted recovery rate per unit

40.00

62.50

Units

produced

12 000.00

20 000.00

Budgeted recovery rate per unit

20.00

50.00

Units

produced

12 000.00

20 000.00

Budgeted recovery rate per unit

5.00

4.00

1. (ii) Activity based costing approach

Purchases

Cost driver

Orders

Budgeted FOH

48.00

480 000.00

125.00

1 250 000.00

173.00

1 730 000.00

Frying pans

Casserole pots

Melting

Cost driver

Batches

Budgeted FOH

24.00

240 000.00

100.00

1 000 000.00

124.00

1 240 000.00

Frying pans

Casserole pots

Moulding

Cost driver

Frying pans

Casserole pots

Moulds

Budgeted FOH

600.00

60 000.00

800.00

80 000.00

1 400.00

140 000.00

Quality control and packaging

Total cost

Frying pan

Allocated to casserole pots

Per casserole pot

ABC cost per unit

R10 x 12 000 =

R480 000

(120 000)

R360 000

R360 000 / 20 000 =

R18.00

Frying pan

Casserole pot

10

R40 + 20 + 5 + 10 =

R62.50+ 50 + 4 + 18=

R75.00

R134.50

2. Explanation

Traditional:

ABC:

Budgeted fixed production overhead recovery rate per unit:

Frying pans

Casserole pots

Recovery rate

89.75

125.65

89.75

125.65

Budgeted fixed production overhead recovery rate per unit:

Frying pans

Casserole pots

Purchases

40.00

62.50

Melting

20.00

50.00

Moulding

5.00

4.00

Inspection & packaging

10.00

18.00

Recovery rate

75.00

134.50

Explanation:

Frying pans

Under the traditional approach, some of the production cost incurred in

respect of casserole pots are allocated to frying pans; causing the frying

pans to bear (carry) production costs not incurred by it ('cross

subsidisation').

The ABC approach corrects this problem by only including in the frying

pan's recovery rate, only production costs incurred in respect of frying

pans (not that of the casserole pots as well).

Casserole pots

Under the traditional approach, some of the production cost incurred in

respect of casserole pots are allocated to frying pans; causing less

production cost to be borne (carried) by the casserole pots.

The ABC approach corrects this problem by including all production

costs incurred in respect of the casserole pots into the casserole pot's

recovery rate.

11

PART B (16 marks)

2000

6000

-100

1900

6000

12000

-600

11400

5% normal loss

0%

RM:

Nuts

a)

10%

40%

RM: Salt water

OH: Spraying

Outputs

Closing inventory

Completed production

Normal loss (5%) at 80% stage

TOTAL OUTPUTS

Inputs

Introduced

Hence, opening inventory

50%

70%

OH: Roasting

=(13 300/0.95) – 13 300

80%

100%

OH: Quality inspection

RM: Packets

OH: Packaging

6 000 kg

13 300 kg

700 kg

20 000 kg

20 000 Kg

18 000 Kg

2 000 kg

1

c)

Equivalent units table

Normal loss (S&C)

Started & Completed

WIP (closing)

Normal loss (WIP B)

WIP (Opening)

Outputs

600

11 400

6 000

100

1 900

20 000

Proceeds - n/loss

Cost per equivalent kg =

Macadamia nuts

600

11 400

6 000

Water solution

600

11 400

4 000

18 000

2 880 000

-2 100

2 877 900

16 000

140 000

R159.8833

2

Packages

11 400

Spraying

600

11 400

4 000

1 900

13 300

16 000

26 600

70 000

Roasting Inspection

Packaging

600

600

11 400

11 400

11 400

100

1 900

14 000

325 000

100

1 900

14 000

56 000

1 900

13 300

53 200