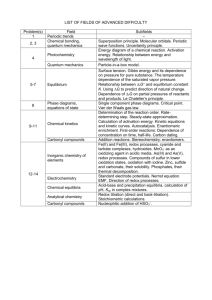

presentation - Summer School on Organic Aerosols

advertisement

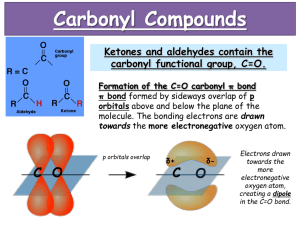

Determination of carbonyl compounds from monoterpene oxidation using the IfT chamber Ariane Kahnt 23.06.2008 Leibniz-Institut für Troposphärenforschung Permoserstr. 15 04318 Leipzig, Germany Content 1. Introduction 2. Experimental 3. Method development for carbonyl compound analysis 4. In-situ derivatisation of carbonyl compounds on DNPH- coated denuders 5. First results from gas- and particle-phase analysis 6. Further improvement 7. Summary 2/38 Introduction - Monoterpenes are biogenic volatile organic compounds (BVOC) - Emission from various plants and coniferyl trees 3/38 Introduction - - - Estimated global emission of volatile organic compounds (VOC): 1150 Tg C/year (Guenther et al. 1995): comprised of - 44 % isoprene - 11 % monoterpenes BVOC emission exceed those of anthropogenic compounds by a factor of ~10. Most BVOCs are more reactive than many anthropogenic non-methane volatile organic compounds (NMVOC) 4/38 Introduction Monoterpenes - C10H16-skeleton -pinene - - b-pinene limonene 3-carene camphene sabinene Act as repellent, Pheromone for insects Most abundant monoterpenes emitted are -pinene, b-pinene and limonene 5/38 Introduction - - - - Atmospheric degradation of monoterpenes includes reactions with NO3, OH radicals and O3 Oxidation leads to multifunctional oxidation products with low vapour pressure Their condensation and coagulation-processes lead to particle formation / growth (formation of secondary organic aerosol = SOA) SOA scatters solar radiation and can act as cloud condensation nuclei 6/38 Introduction Challenge: - SOA formation is complex and not well known - Composition of SOA is largely unknown Motivation: - Emission of BVOC is driven by climate (temperature, light) - Atmospheric oxidation leads to products that effect climate - Get more information about the oxidative decomposition of monoterpenes 7/38 Introduction - Monoterpene oxidation produces semivolatiles and (or) multifunctional compounds such as carbonyl compounds and caboxylic acids - Carbonyls play an important role in photochemical reactions - Carbonyl compounds undergo photolysis and react with OH and NO3 radicals - Some of them partition between the gas- and particle-phases 8/38 Introduction Mainly first oxidation products from monoterpenes are oxo-compounds (aldheydes and ketones) Their reactions are not well characterised - What are the next oxidation products? - What are their yields? - What are the mechanisms? The challenge is: - Carbonyl compounds are hard to sample and analyse - Not all reaction products are available for positive identification and quantification 9/38 Introduction Examples of aldehydes originating from monoterpenes Campholenic aldehyde Endolim (from limonene) Nopinon (from β-pinene) Pinonaldehyde (from -pinene) 10/38 Experimental 11/38 Experimental Aerosol chamber at the IfT (LEAK – „Leipziger Aerosol Kammer“) - Overall chemistry in the atmosphere is far complex - Chamber studies provide a better understanding of atmospheric reactions - Controlled parameters LEAK („Leipziger Aerosol Kammer“ at the IfT) 12/38 Experimental Characteristics of the IfT chamber - Made of Teflon® foil - Cylindrical geometry - Volume: 19 m3 - Surface/volume ratio: 2.1 m-1 - 60 UV-lamps - Thermostat 13/38 Experimental Analysis of carbonyl compounds - Polar carbonyl group - Some carbonyls can partially or completely pass the sampling or analytical technique - Derivatisation is necessary: e.g. with 2,4-Dinitrophenylhydrazine (DNPH) 14/38 Experimental - DNPH is a derivatisation reagent for aldehyde- and keto-groups - Precipitation reagent - Well known method for the identification of aldehydes and ketons by the melting points of the formed hydrazones (Brady 1931; Allen 1937) - The formed hydrazones are: - Coloured. This makes them detectable with UV-spectroscopy - Easily ionisable using electrospray ionisation (ESI). This makes them detectable with HPLC/ESI-MS. solution of DNPH addition of a carbonyl compound 15/38 Experimental Analysis of the hydrazones: HPLC-UV coupled with ESI-TOFMS HPLC (high performance liquid chromatography): - Separation of compounds based on their distribution between a stationary phase (column) and a mobile phase (eluent) - Depending on their affinity to the phases. The compounds are eluted at certain time ESI-TOFMS (Electrospray Ionisation Time-Of-Flight Mass Spectrometry) - Ionisation of the compounds by electrospray - Formed ions are accelerated in an electric field - The velocity of ions depends on mass to charge ratios (m/z); hence the mass to charge ratios of the analyte ions can be calculated from the time required for the ions to reach a detector - TOF-MS is a high resolution mass spectrometer 16/38 Experimental First Step Method development for standard compounds - Available or synthesised monoterpene oxidation products were derivatised: - Campholenic aldehyde Endolim Nopinone Pinonaldehyde to form the respective hydrazone - Analysis and characterisation with HPLC/ESI-TOFMS 17/38 Results from the method development of carbonyl compound analysis 18/38 Method development for carbonyl analysis Hydrazone standard Benzaldehyde-DNPH Structure M [g/mol] 286 C13H10N4O4 Campholenic aldehydeDNPH 332 C16H20N4O4 Endolim-di-DNPH 528 C22H24N8O8 19/38 Method development for carbonyl analysis Hydrazone standard Nopinon-DNPH Structure M [g/mol] 318 C15H18N4O4 Pinonaldehyde-diDNPH 528 C22H24N8O8 20/38 Method development for carbonyl analysis Standard-Hydrazone-Mix Benzaldehyde (m/z 285), Pinonaldehyde (m/z 527) Nopinon (m/z 317), Campholenic aldehyde (m/z 331), Endolim (m/z 527) 21/38 Method development for carbonyl analysis Characterisation of the analytical method Hydrazone standard RT R2 [min] LOD RSD [mg/ml] [%] Benzaldehyde 11.4 0.9979 0.012 2.49 Campholenic aldehyde 14.2 0.9970 0.024 3.56 Endolim 15.1 0.9956 0.097 9.53 Nopinon 13.5 0.9993 0.072 2.87 Pinonaldehyde 15.1 0.9943 0.005 8.71 22/38 Method development for carbonyl analysis Suitable method regarding: - chromatographic separation (except the isobaric hydrazones of endolim and pinonaldehyde) - sensitivity - stability TOFMS allows the determination of exact chemical formula also for unknown compounds due to its high sensitivity 23/38 Method development for carbonyl analysis - To collect also small carbonyl compounds which can not be collected with resin based denuder-sampling, on-tube derivatisation is performed Use of annular denuders: Advantages: - - Larger sampling capacity Operate at higher sample flow rates Disadvantage: - Diffusion equation not characterised 24/38 Method development for carbonyl analysis Coated Denuders - With the adsorbent XAD-4 as a collection surface - Additional with DNPH + H3PO4 for the on-tube conversion of carbonyl compounds 25/38 In-situ derivatisation of carbonyl compounds on DNPH-coated denuders 26/38 In-situ derivatisation of carbonyl compounds on DNPH-coated denuders - - First compound: campholenic aldehyde Chamber experiments with different concentration of campholenic aldehyde injected concentration [ppb] 10 40 80 160 - Sampling with the DNPH-coated denuder - Denuder extraction - Analysis with the developed HPLC/ESI-TOFMS method 27/38 In-situ derivatisation of carbonyl compounds on DNPH-coated denuders Gas-phase calibration of campholenic aldehyde on DNPH-coated denuders 70000 60000 area 50000 40000 2 y = -2.3119x + 790.87x - 5040.1 30000 R2 = 0.9971 20000 10000 0 0 50 100 150 200 injected amount [ppb] 28/38 - Cleaning procedure is necessary to remove the acid - Should be done directly after the experiment SPE (solid phase extraction) Oasis® HLB cartridges with a Hydrophilic-Lipophilic-Balanced sorbent - Reversed phase polymer sorbent 29/38 First results from gas- and particlephase analysis 30/38 Results from gas- and particle-phase analysis Chamber experiment -pinene Initial HC concentration [ppb] O3 100 RH [%] ~ 50 T [°C] 21±1 Reaction time [h] 2.5 Sampling time [h] 1 Seed particle NH4HSO4 60 31/38 Results from gas- and particle-phase analysis Filter Extract: particle-phase products - Identification of the hydrazones from formaldehyde (m/z 209) and pinonaldehyde (m/z 527) 32/38 Results from gas- and particle-phase analysis Denuder Extract: gas-phase products - Identification of the hydrazones from formaldehyde (m/z 209), acetone (m/z 237) and pinonaldehyd (m/z 527) 33/38 Results from gas- and particle-phase analysis Preliminary quantitative result Pinonaldehyde Yield by mass References Gas-phase: 0.24 0.51±0.06 Hatakeyama et al. (1989) 0.19±0.04 Hakola et al. (1994) 0.06±0.19 Yu et al. (1999) 0.164±0.029 Baker et al. (2002) Particle-phase: 0.01 34/38 Further improvement Further characterisation of in-situ derivatisation on denuders has to be done to improve quantification: - Denuder properties (e.g. variation between duty cycle, variability between different denuders) - SPE method (recovery) - More standards need to be prepared (HCHO, acetone etc...) 35/38 Summary - An HPLC-ESI-TOFMS method was developed for some first generation monoterpene oxidation products (endolim, nopinon, pinonaldehyde) - - In-situ derivatistion on DNPH-coated denuders with campholenic aldehyde was performed and show a very good collection efficiency From the ozonolysis experiment of -pinene several carbonyl compounds were identified. The yield of pinonaldehyde in the gas- and particle-phase was determined 36/38 Acknowledgements - Organiser of the summer school - EUCAARI (European Commission grant number 036833) - IfT chamber team 37/38 End Thank You very much for your attention! 38/38 Derivatisation with 2.4-Dinitrophenylhydrazine - - Gives coloured hydrazones (UV detection possible!) Detection at the wavelength near the absorption maxima of the respective hydrazone (360 nm) 39/38 Oasis® HLB cartridges - - - Contain a reversed phase sorbent (Hydrophilic-Lipophilic-Balanced) Copolymer with aligned ratio of hydrophilic (N-Vinylpyrrolidone) and lipophilic compound (Divinylbenzene) Robust (pH) General procedure: - Coloumn solvation with methanol. water. acetonitrile Coloumn conditioning with the sample medium Sample loading Coloumn washing with water Target compound elution with acetonitrile 40/38 Conditions for HPLC-UV-ESI-TOFMS analysis Column Phenomenex® Gemini C6 Phenyl (3.5 µm. 150 x 2 mm) Eluents 0.2 % acetic acid in water (A) and 0.2 % acetic acid in acetonitrile (B) (programme: 70% A to 10% in 15 min) Flow rate 0.5 ml/min Sample injection 10 µl Mass calibration 0.2 % acetic acid/5 mM NaOH in 50/50 (v/v %) in water/i-propanol solution at the beginning of analysis 41/38