Challenger Accident updated Jun 09

advertisement

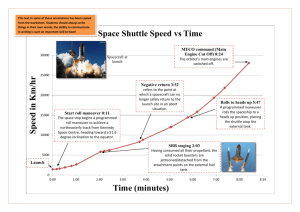

“engineers and managers together developed a definition of the situation that allowed them to carry on as if nothing was wrong when they continually faced evidence that something was wrong.” Challenger Accident or what you think you know can still hurt you -Much of what you think you know about Challenger is wrong since it is strongly influenced by hindsight --The big challenge in accident investigations is overcoming “How could they have been so careless/stupid” type thinking, which seriously degrades our ability to learn useful information CAPT RT Soule Supervisor of Shipbuilding Newport News Outline • • • • • • • • • NASA Shuttle Organization What We Think We Know Why Most Accident Investigations Get “it” Wrong Flight Readiness Reviews Brief History of Solid Rocket Boosters (SRBs) One Explanation: Normalization of Deviance SRB Specific Case Eve of the Launch Premise of the book is that individual behavior Conclusions cannot be understood without considering its organizational and environmental context. References • Report of the Presidential Commission on the Space Shuttle Challenger Accident • The Challenger Launch Decision: Risky Technology, Culture, and Deviance at NASA, Diane Vaughan • http://www.fas.org/spp/51L.html • http://ethics.tamu.edu/ethics/shuttle/shuttle1.htm • Just Culture, Sidney Dekker • Tenerife Air Disaster, Karl Weick NASA Shuttle Organization • Johnson Space Center, Houston TX – Orbiter management • Marshall Space Flight Center, Huntsville AL – Propulsion system (Main Eng, External Tnk, SRBs) • Kennedy Space Center, Cape Canaveral FL – Assembling components, launch • Morton Thiokol Wasatch, Brigham City UT – SRB Prime Contractor What We Think We Know • NASA compromised safety for cost and schedule • NASA pressured Morton Thiokol to launch • NASA ignored the O-ring risk • Accident cause was O-ring failure complicated by bad weather Getting it Wrong To understand failure • Don’t ask – Where did they mess up? – Why didn’t they notice what we find important now? • The real question is – Why did it make sense for them to do what they did? Otherwise, if they knew what you know after the fact, they would not have done what they did. Getting it Wrong (cont’d) • We want to find a cause “If there is no...cause, then the world is a more disordered and dangerous place Accident reports, and much of the history we write, struggle to hold that nightmare at bay” (Galison,2000,p.32) Flight Readiness Review Mission Management Team Level 1 Flight Readiness Review (FRR) Level 2 Pre-Flight Readiness Review Level 3 Marshall Space Flight Center FRR Level 4 Kennedy Space Center Launch Readiness Review Main Engine Contractor Solid Rocket Booster Cr External Tank Contractor Johnson Space Center Orbiter Contractor Shuttle Processing Contractor System Integration Contractor Risk Management • Risk cannot be eliminated, must be managed • NASA Acceptable Risk Process – Formal, technical, layered review • Flight Readiness Review – Show shuttle ready to fly and fly safely – Delta Review Concept History of the SRBs • Designed by MT, based on Titan III • Differed fm Titan III – Segment sealing method – Higher combustion pressure – Reusable Joint Rotation • Tendency to bend open • Joint deviated from industry std • More tests necessary to show risk acceptable History of the SRBs SRB Assembly Normalization of Deviance • Production of Culture • Culture of Production • Limited Knowledge Production of Culture • Work Group Culture • How Culture Is Produced – Language used – Types of meetings, formal rules – Tests and analyses – Schedule procedures – Complex problems Culture of Production • Production mentality -> get the job done • Need to maintain shuttle launch schedule • Pressure not to delay launch Limited Knowledge • Built-in impediments to knowledge flow – patterns of information – organizational structure, processes • Impact – mixed, weak, routine signals – unequal information SRB Specific Case of Normalization of Deviance • Re-defined deviation as acceptable – Danger signals – Official recognition of increased risk – Evidence review – Risk acceptance (not joint redesign) – Launch Eve of the Launch – 26 Jan • • • • Launch date slipped from 22 Jan to 26 Jan Launch postponed to 27 Jan – bad wx Launch postponed to 28 Jan – mech probs 1300 27 Jan – NASA asked MT to review effect of cold on SRM performance • 1530 EST MT O-ring task forces meets in UT Eve of the Launch – 27 Jan • 1745-1830, Telcon 1 – MT Engineers recommend delaying launch • 2045-2315, Telcon 2 – MT tried to prove launch risk not acceptable < 53 F – NASA challenged – MT management decision – MT recommends launch Eve of the Launch – 28 Jan • 0130 – Temp 29 F – Ice inspection – Rockwell asked about impact of ice on Orbiter • 0700, 0830 – Two more ice inspections • 0900 – Final NASA – Contractor mtg to assess readiness • 1030-1055 – Final ice inspection, Temp 36F Teleconference Participants Morton Thiokol Kennedy Space Center Marshall Space Flight Center Eve of the Launch • 1745-1830, Telcon 1 – – – – MT Engineers recommend delaying launch Thiokol too no official position Connection bad, not all people could hear 45 min, unstructured data discussion • There were no documents to lead or follow the discussion – Agreed to a follow up telcon using FRR format – Key Question: If primary O-ring did not seal, would sec O-ring seal before resiliency became more significant? Eve of the Launch • Between Conferences – Not everyone in the East was available – Thiokol engineers working on Rec’s/Concl’s did not have access to all charts • 2045-2315, Telcon 2 – MT tried to prove launch risk not acceptable < 53 F – NASA managers felt correlation of joint failure with temperature was not proven by Thiokol – MT management risk decision – MT recommends launch Eve of the Launch (just included to capture extra notes) • Between Conferences – Not everyone in the East was available – Thiokol engineers working on Rec’s/Concl’s did not have access to all charts • 2045-2315, Telcon 2 – MT tried to prove launch risk not acceptable < 53 F – NASA managers felt correlation of joint failure with temperature was not proven by Thiokol – MT management risk decision – MT recommends launch Post Accident Temperature Analysis 3 STS-51-C Number of Incidents 61A 2 41B 41D 41C 1 61C 0 50 55 60 STS-2 65 70 Calculated Joint Temperature, Degrees F 75 80 Post Accident Temperature Analysis 3 STS-51-C Number of Incidents 61A 2 41B 41D 41C 1 61C STS-2 Flts with no incidents 0 50 55 60 65 70 Calculated Joint Temperature, Degrees F 75 80 Eve of the Launch – 28 Jan Eve of the Launch – 28 Jan • 1125 – Terminal countdown • 1138 – STS 51 – L launched, Temp 36 F • T + 73 sec – Fireball erupted Summary • On Navy ships, shipyards, Rx Depts, there is always pressure to produce • Even processes designed to make us safer can lead us astray (if we don’t use them well) • Failure does not strike like bolt from the blue …(there are signs, but you must know where to look) • There are no simple fixes …(but there are things that can make us safer) Summary • Signs that failure may be near: – You are in a hurry (behind schedule or near the end of shift) – You want something very badly (or expect something) – You rushed through the brief (or did not do one) – You don’t know what to expect after you act – You are preoccupied – No one disagrees with you (or asks any questions at a brief) – You are doing something for the first time/infrequently – Something does not “feel” right Summary • Things that can make us safer: – Welcome disagreement – Speak up when you have a question or don’t understand, you may be the only one who sees “the problem” – Spend more time thinking about what could go wrong, how you would know, and what you could do about it – Learn to trust your sense that it’s not right For Further Study • http://rtsoule.squarespace.com/filestorage-area/carl-vinson/ • http://www.fas.org/spp/51L.html • http://ethics.tamu.edu/ethics/shuttle/shuttle 1.htm • http://onlineethics.org/CMS/profpractice/pp essays/thiokolshuttle/shuttle_post.aspx • http://onlineethics.org/CMS/profpractice/ex empindex/RB-intro/Erosion.aspx Further Reading • Challenger Launch Decision, Vaughan • Dekker: Ten Questions, Just Culture • Managing the Unexpected, Weick, Sutcliff Backup Slides Mission STS-2 Nov 81 Danger Signal STS-41B Feb 84 STS-41D Aug 84 STS-51C Jan 85 Erosion 1° of erosion, Primary 2 joints 1° Blow by Blow by 2° reached eroded, 2° 1° failed Recogniti on Only MT Started and Mrshll tracking Engrs officially Reviewed at all levels of FRR Major review Feb 85, all FRR Launch Constraint Imposed Review Calcs Low temps before launch 1° out of position, tests, calcs Acceptan ce Altered Erosion installation acceptable, process redund not impacted Performed as predicted Low temps rare, blow by within experience base Altered installation process to seal Orings better Launch STS-3 Nov 82 STS-41G STS-51E STS-51F Self-limiting Blow by small, self limiting STS-41C Apr 84 STS-51B Apr 85