patrick_ch12

advertisement

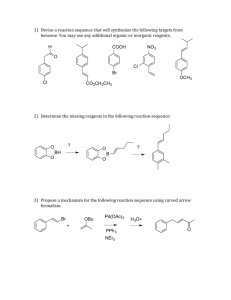

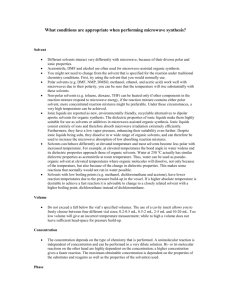

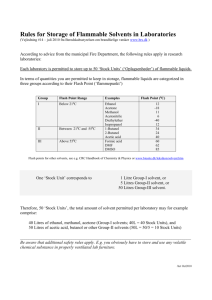

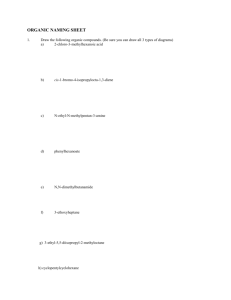

Patrick An Introduction to Medicinal Chemistry 3/e Chapter 12 DRUG DESIGN & DEVELOPMENT ©1 Contents 1. Preclinical trials 1.1. Chemical Development (2 Slides) 1.2. The Initial Synthesis (3 Slides) 1.3. Optimisation of Reactions 1.3.1. 1.3.2. 1.3.3. 1.3.4. 1.3.5. 1.3.6. 1.3.7. 1.3.8. 1.3.9. 1.3.10. continued… 1.5. Process Development 1.5.1. 1.5.2. 1.5.3. 1.5.4. Temperature Pressure (2 Slides) Reaction Time Solvent (3 Slides) Concentration Catalysts (2 Slides) Excess Reactant Removing a Product Methods of Addition (2 Slides) Reactivity of Reagents & Reactants 1.5.5. 1.5.6. 1.5.7. 1.5.8. 1.6. Specifications 1.6.1. 1.6.2. 1.6.3. 1.6.4. 1.6.5. 1.6.6. 1.6.7. 1.4. Scaling Up A Reaction 1.4.1. 1.4.2. 1.4.3. 1.4.4. 1.4.5. 1.4.6. 1.4.7. 1.4.8. Reagents (3 Slides) Reactants And Intermediates Solvents (4 Slides) Side Products Temperature Promoters Experimental Procedures (2 Slides) Physical Para Meters Number Of Reaction Steps Convergent Syntheses Number Of Operations Safety - Chemical Hazards 1.5.4.1. Main Hazards Safety - Reaction Hazards Purifications Environmental Issues Cost 1.6.8. 1.6.9. 2. 3. Properties And Purity Impurities Purifications Impure Reagents / Reactants (3 Slides) Reaction Conditions Order Of Addition Troublesome By-Products (2 Slides) Changing A Synthesis (2 Slides) Inorganic Impurities Patenting And Regulatory Affairs Clinical Trials (2 Slides) [67 slides] ©1 Drug design and development Stages: 1) Identify target disease 2) Identify drug target 3) Establish testing procedures 4) Find a lead compound 5) Structure Activity Relationships (SAR) 6) Identify a pharmacophore 7) Drug design- optimising target interactions 8) Drug design - optimising pharmacokinetic properties 9) Preclinical trials 10) Chemical development and process development 11) Patenting and regulatory affairs 12) Clinical trials Note: Stages 9-11 are usually carried out in parallel ©1 1. Preclinical trials Drug Metabolism Identification of drug metabolites in test animals Properties of drug metabolites Toxicology In vivo and in vitro tests for acute and chronic toxicity Pharmacology Selectivity of action at drug target Formulation Stability tests Methods of delivery ©1 1.1 Chemical Development Definition: Development of a synthesis suitable for large scale production up to 100kg. Priorities: • To optimise the final synthetic step and the purification procedures • To define the product specifications • To produce a product that consistently passes the purity specifications • To produce a high quality product in high yield using a synthesis that is cheap and efficient. • To produce a synthesis that is safe and environmentally friendly with a minimum number of steps ©1 1.1 Chemical Development Phases: • • • Synthesis of 1kg for initial preclinical testing (often a scale up of the original synthesis) Synthesis of 10kg for toxicological studies, formulation and initial clinical trials Synthesis of 100kg for clinical trials Notes: • • • • • Chemical development is more than just scaling up the original synthesis Different reaction conditions or synthetic routes often required Time period can be up to 5 years Need to balance long term aims of developing a large scale synthesis versus short term need for batches for preclinical trials The product produced by the fully developed route must meet the same specifications as defined at phase 1 ©1 1.2 The initial synthesis Origin • The initial synthesis was designed in the research lab Priorities of the original synthesis • To synthesise as many different compounds as quickly as possible in order to identify active compounds • Yield and cost are low priorities • usually done on small scale Likely problems related to the original synthesis • The use of hazardous starting materials and reagents • Experimental procedures which are impractical on large scale • the number of reaction steps involved • Yield and cost Scale up • Original synthesis may be scaled up for the first 1 kg of product but is then modified or altered completely for larger quantities ©1 1.2 The initial synthesis The initial synthesis of fexofenadine (anti-asthmatic) O C Cl R C O Cl C Me Me R C R2NH Me O R C C Me Me Friedel Crafts Acylation Cl Me R2N HO R C Me Me N Reduction HO Ph • • • Ph R= Me; Terfenadine R=CO 2H; Fexofenadine Fexofenadine synthesised by the same route used for terfenadine Unsatisfactory since the Friedel Crafts reaction gives the meta isomer as well Requires chromatography to remove the meta isomer ©1 1.2 The initial synthesis Revised synthesis of fexofenadine OH O OHC Me O Oxidation C Me CO2Et C Me Me MgBr CO2Et O O C Me HO CO2Et C O 1) CO2Et Me Me • • • 2) NaBH4 Me Me NH Amberlyst Me Me H O HO Ph Ph CO2Et N HO Ester hydrolysis Fexofenadine Ph Ph More practical and efficient synthesis using easily available starting materials No ‘awkward’ isomers are formed No chromatography required for purification ©1 1.3 Optimisation of reactions Aims: • To optimise the yield and purity of product from each reaction Notes: • Maximum yield does not necessarily mean maximum purity • May need to accept less than the maximum yield to achieve an acceptable purity • Need to consider cost and safety Factors: • Temperature, reaction time, stirring rate, pH, pressure, catalysts, order and rate of addition of reactants and reagents, purification procedure. ©1 1.3 Optimisation of reactions 1.3.1 Temperature • • • • Optimum temperature is the temperature at which the rate of reaction is maximised with a minimum of side reactions Increasing the temperature increases the reaction rate Increasing the temperature may increase side reactions and increase impurities Compromise is often required ©1 1.3 Optimisation of reactions 1.3.2 Pressure • • Increased pressure (> 5 kilobar) accelerates reactions where the transition state occupies a smaller volume than the starting materials. Useful if increased heating causes side reactions Examples of reactions accelerated by pressure • Esterifications; amine quaternisation; ester hydrolysis; Claisen and Cope rearrangements; nucleophilic substitutions; Diels Alder reactions Example: Esterification of acetic acid with ethanol • proceeds 5 times faster at 2 kbar than at 1 atm. • proceeds 26 times faster at 4 kbar ©1 1.3 Optimisation of reactions 1.3.2 Pressure Example 1: PPh3 O O O Br • • • benzene-toluene 20 oC / 15,000atm O PPh3 Good yield at 20oC and 15 kbar No reaction at 20oC and 1 atmosphere Decomposition at 80oC and 1 atmosphere Example 2: • • Hydrolysis of chiral esters using base with heating may cause racemisation Can be carried out at room temperature with pressure instead ©1 1.3 Optimisation of reactions 1.3.3 Reaction time • Optimum reaction time is the time required to get the best yield consistent with high purity. • Monitor reactions to find the optimum time using tlc, gas chromatography, IR, NMR, HPLC • If reaction goes to completion, optimum time is often the time required to reach completion • If reaction reaches equilibrium, optimum time is often the time required to reach equilibrium • However, optimum time may not be the same as the time to reach completion or equilibrium if side reactions take place • Excess reaction times increase the chances of side reactions and the formation of impurities. • Reaction times greater than 15 hr should be avoided (costly at production level) ©1 1.3 Optimisation of reactions 1.3.4 Solvent • • • Important to outcome, yield and purity Should normally be capable of dissolving reactants and reagents Insolubility of a product in solvent may improve yields by shifting an equilibrium reaction to its products (but this may be a problem with catalysts) Example: OH O H H N O C O O N H H OH O H3N H2 Pd/C O H O N H H O EtOH/H2O • • • Poor yield in ethanol - product precipitates and coats the catalyst Poor yield in water - reactant poorly soluble Quantitative yield in ethanol-water; 1:1 ©1 1.3 Optimisation of reactions 1.3.4 Solvent • • • • • • Should have a suitable boiling point if one wishes to heat the reaction at a constant temperature (heating to reflux) Should be compatible with the reaction being carried out Solvents are classed as polar (EtOH, H2O, acetone) or nonpolar (toluene, chloroform) Polar solvents are classed as protic (EtOH, H2O) or aprotic (DMF, DMSO) Protic solvents are capable of H-bonding The polarity and the H-bonding ability of the solvent may affect the reaction ©1 1.3 Optimisation of reactions 1.3.4 Solvent Example: • • Protic solvents give higher rates for SN1 reactions but not for SN2 reactions - they aid departure of anion in the rate determining step Dipolar aprotic solvents (DMSO) are better for SN2 reactions Cl R • • • • NaCN DMSO CN R SN2 reaction Solvent DMSO; reaction time 1-2 hours Solvent aq. ethanol; reaction time 1-4 days DMSO solvates cations but leaves anions relatively unsolvated Thus, the nucleophile is more reactive ©1 1.3 Optimisation of reactions 1.3.5 Concentration • High concentration (small volume of solvent) favours increased reaction rate but may increase chance of side reactions • Low concentrations (large volume of solvent) are useful for exothermic reactions (solvent acts as a ‘heat sink’) ©1 1.3 Optimisation of reactions 1.3.6 Catalysts • • • Increase rate at which reactions reach equilibrium Classed as heterogeneous or homogeneous Choice of catalyst can influence type of product obtained and yield Example: H H2 Pd/C R C C R R H C R C C R R C R Poisoned catalyst R H H H2 Pd/CaCO 3 C H C H ©1 1.3 Optimisation of reactions 1.3.6 Catalysts Example: O R Cl C R Lewis acid R R C O Vary Lewis acid catalysts (e.g. AlCl3 or ZnCl2) to optimise yield and purity ©1 1.3 Optimisation of reactions 1.3.7 Excess reactant • • • Shifts equilibrium to products if reaction is thermodynamically controlled Excess reactant must be cheap, readily available and easily separated from product May also affect outcome of reaction Example: O H2N Ph O O O Ph NH2 C O • H N + NH2 H N C C N H O Excess diamine is used to increase the proportion of mono-acylated product ©1 1.3 Optimisation of reactions 1.3.8 Removing a product • • Removing a product shifts the equilibrium to products if the reaction is in equilibrium Can remove a product by precipitation, distillation or crystallisation Example: O + R R OH HO Ptsa catalyst O O R R + H 2O Removing water by distillation shifts equilibrium to right ©1 1.3 Optimisation of reactions 1.3.9 Methods of addition • Adding one reactant or reagent slowly to another helps to control the temperature of fast exothermic reactions • Stirring rates may be crucial to prevent localised regions of high concentration + • Dilution of reactant or reagent in solvent before addition helps to prevent localised areas of high concentration • Order of addition may influence the outcome and yield ©1 1.3 Optimisation of reactions 1.3.9 Methods of addition Example: Ar Ar Ar 1) nBuLi 2) RCHO OMe N N P O + R N R OMe impurity • • Impurity is formed when butyl lithium is added to the phosphonate (the phosphonate anion reacts with unreacted phosphonate) No impurity is formed if the phosphonate is added to butyl lithium ©1 1.3 Optimisation of reactions 1.3.10 Reactivity of reagents and reactants Less reactive reagents may affect the outcome of the reaction Example: O Cl H2N O NH2 C O • • H N H N + NH2 C C N H O A 1:1 mixture of mono and diacylated products is obtained even when benzyl chloride is added to the diamine Using less reactive benzoic anhydride gives a ratio of mono to diacylated product of 1.86:0.14 ©1 1.4 Scaling up a reaction Priorities Cost, safety and practicality Factors to consider Reagents, reactants and intermediates, solvents, side products, temperature, promoters, procedures, physical parameters ©1 1.4 Scaling up a reaction 1.4.1 Reagents • • • • Reagents used in the initial synthesis are often unsuitable due to cost or hazards. Hazardous by products may be formed from certain reagents (e.g. mercuric acetate from mercury) Reagents may be unsuitable on environmental grounds (e.g. smell) Reagents may be unsuitable to handle on large scale (e.g. hygroscopic or lachrymatory compounds) Example: H H Zn/Cu Et2O CH2I2 H R R • • H R R Zn/Cu amalgam is too expensive for scale up Replace with zinc powder ©1 1.4 Scaling up a reaction 1.4.1 Reagents Examples: X X PdCl2 N N O CrO3Cl N OH R O H R C H • • • Reactions above should be avoided for scale up Palladium chloride and pyridinium chlorochromate are both carcinogenic Synthetic route would be rejected by regulatory authorities if carcinogenic reagents are used near the end of the synthetic route ©1 1.4 Scaling up a reaction 1.4.1 Reagents Choice may need to be made between cost and safety Example: O O O O C CH3 • OH Cl C O CH3 m-Chloroperbenzoic acid is preferred over cheaper peroxide reagents for the Baeyer-Villiger oxidation since mcpba has a higher decomposition temperature and is safer to use ©1 1.4 Scaling up a reaction 1.4.2 Reactants and intermediates • Starting materials should be cheap and readily available • Hazards of starting materials and intermediates must be considered (e.g. diazonium salts are explosive and best avoided) • May have to alter synthesis to avoid hazardous intermediates ©1 1.4 Scaling up a reaction 1.4.3 Solvents • Solvents must not be excessively flammable or toxic • Many solvents used in research labs are unsuitable for scale up due to flammability, cost, toxicity etc. (e.g. diethyl ether, chloroform, dioxane, benzene, hexamethylphosphoric triamide) • Concentrations used in the research lab are relatively dilute • The concentration of reaction is normally increased during scale up to avoid large volumes of solvent (solvent:solute ratio 5:1 or less) • Increased concentrations means less solvent, less hazards, greater economy and increased reaction rates • Changing solvent can affect outcome or yield • Not feasible to purify solvents on production scale • Need to consider solvent properties when choosing solvent ©1 1.4 Scaling up a reaction 1.4.3 Solvents 1.4.3.1 Properties of solvents • Ignition temperature - temperature at which solvent ignites • Flash point - temperature at which vapours of the solvent ignite in the presence of an ignition source (spark or flame) • Vapour pressure - measure of a solvent’s volatility • Vapour density - measure of whether vapours of the solvent rise or creep along the floor ©1 1.4 Scaling up a reaction 1.4.3 Solvents 1.4.3.2 Hazardous solvents • Solvents which are flammable at a low solvent/air mixture and over a wide range of solvent/air mixtures (e.g. diethyl ether has a flammable solvent/air range of 2-36%, is heavier than air and can creep along plant floors to ignite on hot pipes. • Solvents with a flash point less than -18oC (e.g. diethyl ether and carbon disulphide). ©1 1.4 Scaling up a reaction 1.4.3 Solvents 1.4.3.3 Alternative solvents for common research solvents • Dimethoxyethane for diethyl ether • (less flammable, higher b.pt. and higher heat capacity) • t-Butyl methyl ether for diethyl ether • (cheaper, safer and does not form peroxides) • Heptane for pentane and hexane (less flammable) • Ethyl acetate for chlorinated solvents (less toxic) • Toluene for benzene (less carcinogenic) • Xylene for benzene (less carcinogenic) • Tetrahydrofuran for dioxane (less carcinogenic) ©1 1.4 Scaling up a reaction 1.4.4 SIDE PRODUCTS •Reactions producing hazardous side products are unsuitable for scale up. •May need to consider different reagents Example P(OMe)3 R R OMe P Cl O NaH R Cl + CH3Cl OMe R OMe + NaCl P HPO(OMe)2 O OMe •Preparation of a phosphonate produces methyl chloride (gaseous, toxic and an alkylating agent. Trimethyl phosphite also stinks •Sodium dimethyl phosphonate is used instead since it results in the formation of non-toxic NaCl ©1 1.4 Scaling up a reaction 1.4.5 TEMPERATURE Must be practical for reaction vessels in the production plant ©1 1.4 Scaling up a reaction 1.4.6 PROMOTERS • • Certain chemicals can sometimes be added at a catalytic level to promote reactions on large scale May remove impurities in commercial solvents and reagents Example 1 • RedAl used as a promoter in cyclopropanation reaction with zinc • Removes zinc oxides from the surface of the zinc • Removes water from the solvent • Removes peroxides from the solvent Example 2 • Methyl magnesium iodide is used as a promoter for the Grignard reaction ©1 1.4 Scaling up a reaction 1.4.7 EXPERIMENTAL PROCEDURES Some experimental procedures carried out on small scale may be impractical on large scale Examples: Scraping solids out of flasks Concentrating solutions to dryness Rotary evaporators Vacuum ovens to dry oils Chromatography for purification Drying agents (e.g. sodium sulphate) Addition of reagents within short time spans Use of separating funnels for washing and extracting ©1 1.4 Scaling up a reaction 1.4.7 EXPERIMENTAL PROCEDURES Some alternative procedures suitable for large scale • Drying organic solutions - add a suitable solvent and azeotrope off the water - extract with brine • Concentrating solutions - carried out under normal distillation conditions • Purification - crystallisation preferred • Washing and extracting solutions - stirring solvent phases in large reaction vessels - countercurrent extraction ©1 1.4 Scaling up a reaction 1.4.8 PHYSICAL PARA METERS May play an important role in the outcome and yield Parameters involved - stirring efficiency - surface area to volume ratio of reactor vessel - rate of heat transfer - temperature gradient between the centre of the reactor and the walls ©1 1.5 PROCESS DEVELOPMENT DEFINITION Development of the overall synthetic route to make it suitable for the production site and can produce batches of product in ton quantities with consistent yield and purity PRIORITIES • Minimising the number of reaction steps • The use of convergent syntheses • Minimising the number of operations • Integration of the overall reaction scheme • Safety - chemical hazards • Safety - reaction hazards • Minimising the number of purification steps • Environmental issues • Cost ©1 1.5 PROCESS DEVELOPMENT 1.5.1 NUMBER OF REACTION STEPS Minimising the number of reaction steps may increase the overall yield Requires a good understanding of synthetic organic chemistry ©1 1.5 PROCESS DEVELOPMENT 1.5.2 CONVERGENT SYNTHESES • • • Product synthesised in two halves then linked Preferable to linear synthesis Higher yields LINEAR SYNTHESIS A B C D E F G H I J K Overall yield =10.7% assuming an 80% yield per reaction CONVERGENT SYNT HESIS L M N O P Q K R S T U V Overall yield = 26.2% from L assuming an 80% yield per reaction Overall yield from R = 32.8% © 1 1.5 PROCESS DEVELOPMENT 1.5.3 NUMBER OF OPERATIONS • • • • Minimise the number of operations to increase the overall yield Avoid isolation and purification of the intermediates Keep intermediates in solution for transfer from one reaction vessel to another Use a solvent which is common to a series of reactions in the process Example Alcohol SOCl2 Alkyl halide PPh3 Wittig reagent •The alkyl halide is not isolated, but is transferred in solution to the next reaction vessel for the Wittig reaction ©1 1.5 PROCESS DEVELOPMENT 1.5.4 SAFETY - CHEMICAL HAZARDS • Assess the potential hazards of all chemicals, solvents, intermediates and residues in the process. • Introduce proper monitoring and controls to minimise the risks ©1 1.5 PROCESS DEVELOPMENT 1.5.4.1 Main hazards Toxicity • Compounds must not have an LD50 less than 100mg/kg (teaspoon) Flammability • Avoid high risk solvents. • Medium risk solvents require precautions to avoid static electricity Explosiveness • Dust explosion test - determines whether a spark ignites a dust cloud of the compound • Hammer test - determines whether dropping a weight on the compound produces sound or light Thermal instability • Reaction process must not use temperatures higher than decomposition temperatures ©1 1.5 PROCESS DEVELOPMENT 1.5.5 SAFETY - REACTION HAZARDS • Assess the potential hazards of all reactions. • Carefully monitor any exothermic reactions. • Control exothermic reactions by cooling and/or the rate at which reactants are added • The rate of stirring can be crucial and must be monitored • Autocatalytic reactions are potentially dangerous ©1 1.5 PROCESS DEVELOPMENT 1.5.6 PURIFICATIONS • • • • • • • • Keep the number of purifications to a minimum to enhance the overall yield Chromatography is often impractical Ideally, purification should be carried out by crystallising only the final product of the process Crystallisation conditions must be controlled to ensure consistent purity, crystal form and size Crystallisation conditions must be monitored for cooling rate and stirring rate Crystals which are too large may trap solvent Crystals which are too fine may clog up filters Hot filtrations prior to crystallisation must be done at least 15oC above the crystallisation temperature ©1 1.5 PROCESS DEVELOPMENT 1.5.7 ENVIRONMENTAL ISSUES • • • • • • • • Chemicals should be disposed of safely or recycled on environmental and economic grounds Solvents should be recycled and re-used Avoid mixed solvents - difficult to recycle Avoid solvents with low b.pt.’s to avoid escape into the atmosphere Water is the preferred solvent Spent reagents should be made safe before disposal Use catalysts whenever relevant Use ‘clean’ technology whenever possible (e.g. electrochemistry, photochemistry, ultrasound, microwaves) ©1 1.5 PROCESS DEVELOPMENT 1.5.8 COST • Keep cost to a minimum • Maximise the overall yield • Minimise the cost of raw materials • Minimise the cost of labour and overheads by producing large batches on each run ©1 1.6 SPECIFICATIONS Definition Specifications define a product’s properties and purity All batches must pass the predetermined specification limits Troubleshooting Necessary if any batches fail the specifications Identify any impurities present and their source Identify methods of removing impurities or preventing their formation Sources of Impurities Impure reagents and reactants Reaction conditions Order of reagent addition Troublesome by products The synthetic route ©1 1.6 SPECIFICATIONS 1.6.1 PROPERTIES AND PURITY • Includes melting point, colour of solution, particle size, polymorphism, pH, chemical and stereochemcial purity. • Impurities present are defined and quantified • Residual solvents present are defined and quantified • Acceptable limits of impurities and solvents are defined • Acceptable limits are dependent on toxicity (e.g. ethanol 2%, methanol 0.05%) • Carcinogenic impurities must be absent (must not be present in final stage of synthesis) ©1 1.6 SPECIFICATIONS 1.6.2 IMPURITIES • Isolate, purify and identify all impurities (hplc, nmr, mass spectroscopy) • Identify the source of any impurity • Alter the purification at the final stage, the reaction concerned or the reaction conditions ©1 1.6 SPECIFICATIONS 1.6.3 PURIFICATIONS • Introduce a purification to remove any impurities at the end of the reaction sequence or after the offending reaction • Methods of purification - crystallisation, distillation, precipitation of impurity from solution, precipitation of product from solution ©1 1.6 SPECIFICATIONS 1.6.4 IMPURE REAGENTS / REACTANTS • Commercially available reagents or reactants contain impurities • Impurities introduced early on in the synthetic route may survive the synthetic route and contaminate the product • An impurity at an early stage of the synthetic route may undergo the same reactions as the starting material and contaminate the final product ©1 1.6 SPECIFICATIONS Example F Ar F F P hMe N AlCl3 Cl a) PhNHCH(CH3)2 b) ZnCl2 Cl N POCl3 CH3CN Cl H3C N H3C a) NaBH4 Et2BOCH 3 THF/MeOH b) H2O 2 Ar O NaOH EtOH H2O Ar OH O N N CH3 OH O tBu H3C CH3 CH3 O tBuOAcAc/THF nBuLi/hexane NaH CH3 O H3C H H O O O OH O tBu Ar OH O N H3C CH3 OH Fluvostatin Synthesis of fluvostatin ©1 O Na 1.6 SPECIFICATIONS Ar OH NH O N CH3 H3C OH O Na Fluvostatin Ar NHCH 2CH 3 OH Impurity O N N-Ethylaniline Impurity OH H3C O Na N-Ethyl analogue of fluvostatin ©1 1.6 SPECIFICATIONS 1.6.5 REACTION CONDITIONS • Vary the reaction conditions to minimise any impurities (e.g. solvent, catalyst, ratio of reactants and reagents) • Consider reaction kinetics and thermodynamics Heating favours the thermodynamic product Rapid addition of reactant favours the kinetic product • Consider sensitivity of a reagent to air and to oxidation N-Butyllithium oxidises in air to lithium butoxide Benzaldehyde oxidises to benzoic acid Consider using fresh reagents or a nitrogen atmosphere ©1 1.6 SPECIFICATIONS 1.6.6 ORDER OF ADDITION Order in which reagents added may result in impurities Example R OH PBr3 R R + Br R O Impurity Mechanism of impurity formation H R O R R Br R O + H Br Occurs when PBr3 is added to the alcohol but not when the alcohol is added to PBr3 ©1 1.6 SPECIFICATIONS 1.6.7 TROUBLESOME BY-PRODUCTS • By-products formed in some reactions may prove difficult to remove • Change the reaction or the reagent to get less troublesome byproducts Example - Wittig reaction R CH2Br PPh3 R CH2PPh 3 Br H O C R' O R' Wittig reaction C H R Ph P Ph + C H Ph T riphenylphosphine oxide By-product = triphenylphosphine oxide (requires chromatography to remove) ©1 1.6 SPECIFICATIONS 1.6.7 TROUBLESOME BY-PRODUCTS Horner-Emmons reaction - alternative reaction O H P OMe OMe R CH2Br MeO MeO P R O H nBuLi C R' O R' C Horner-Emmons reaction O C H R + MeO P OMe O Phosphonate ester H By-product = Phosphonate ester (soluble in water and removed by washing) ©1 1.6 SPECIFICATIONS 1.6.8 CHANGING A SYNTHESIS Example- Grignard synthesis CH3 CH3 CH3 + H3C MgBr H3C H3C C COCl C O C CH3 CH3 CH3 CH3 CH3 C CH3 O O Ester impurity • • • The ester impurity is formed by oxidation of the Grignard reagent to a phenol which then reacts with the acid chloride Avoidable by adding Grignard reagent to the acid chloride but... Not easy on large scale due to air sensitivity and poor solubility of the Grignard reagent ©1 1.6 SPECIFICATIONS 1.6.8 CHANGING A SYNTHESIS Different routes to same product Li CH 3 C CH3 O CH3 CH 3 C CH 3 Cl C CH3 CH 3 CH 3 CH 3 BrMg CH 3 C Lewis acid CH 3 O C CH 3 O Cl CH3 C C CH3 CH3 CH3 BrMg C CH3 CH 3 CH3 CH 3 CH 3 CN hydrolysis HN C C CH3 CH3 CH3 O C C CH3 CH3 CH3 ©1 1.6 SPECIFICATIONS 1.6.9 INORGANIC IMPURITIES • The final product must be checked for inorganic impurities (e.g. metal salts) • Deionised water may need to be used if the desired compounds are metal ion chelators or are isolated from water ©1 2. PATENTING AND REGULATORY AFFAIRS PATENTING • Carried out as soon as a potentially useful drug is identified • Carried out before preclinical and clinical trials • Several years of patent protection are lost due to trials • Cannot specify the exact structure that is likely to reach market • Patent a group of compounds rather than an individual structure ©1 2. PATENTING AND REGULATORY AFFAIRS REGULATORY AFFAIRS • • • Drug must be approved by regulatory bodies Food and Drugs Administration (FDA) European Agency for the Evaluation of Medicinal Products (EMEA) • Proper record keeping is essential • GLP - Good Laboratory Practice • GMP - Good Manufacturing Practice • GCP - Good Clinical Practice ©1 3. CLINICAL TRIALS Phase 1 • Carried out on healthy volunteers • Useful in establishing dose levels • Useful for studying pharmacokinetics, including drug metabolism Phase 2 • Carried out on patients • Carried out as double blind studies • Demonstrates whether a drug is therapeutically useful • Establishes a dosing regime • Identifies side effects ©1 3. CLINICAL TRIALS Phase 3 • Carried out on a larger number of patients • Establishes statistical proof for efficacy and safety Phase 4 • Continued after a drug reaches the market • Studies long term effects when used chronically • Identifies unusual side effects ©1