Glenn Webber - Canadian Technical Asphalt Association

advertisement

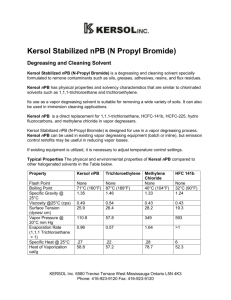

Alternatives to Chlorinated Solvents in Asphalt Testing With special focus on Tech Kleen ®* N Propyl Bromide solvents for extractions and recoveries. Glenn R Webber glennwebber@kersolinc.com 416-923-9120 The technical assistance of Andrew Pahalan of Lafarge and John Emery of the JEGEL Group is much appreciated. Alternatives to Trichloroethylene in Asphalt Testing Ignition Ovens – wider use of ignition ovens are anticipated with the continuing technical activities of asphalt producer user groups. Alternatives to Trichloroethylene in Asphalt Testing Extraction Solvents D Limonene Based Extraction Solvents D Limonene based products require a number of water rinses and drying. Also a wastewater issue identified by Lafarge. N Propyl Bromide Extraction Solvents (NPB) N Propyl Bromide works similar to trichloroethylene. Essentially a drop in replacement. So why Change from Trichloroethylene? Workplace Environmental Health and Safety. ODS and Global Warming issues Environment Canada is moving to reduce Trichloroethylene usage in the workplace Changes in Canada Effecting Degreasing Chemistry In 1993, Trichloroethylene (TCE) and Tetrachloroethylene (PERC) were assessed as toxic under CEPA 1988. In 1994, an Issue Table was convened under the Strategic Options Process to make recommendations on options for reducing the release of these toxic substances. The Issue Table was comprised of representatives of the provincial and federal governments, environmental non-governmental organizations, and industry. The Strategic Options Report of stakeholders’ consultations was released in 1996. Reference : www.ec.gc.ca/nopp/degrease/en/index.cfm CEPA- Canadian Environmental Protection Act Changes in Canada Effecting Degreasing Chemistry In February 1997, the federal Minister of the Environment announced that regulations would be developed under CEPA, as recommended in the Report, to reduce total Canadian consumption of TCE and PERC used in solvent degreasing operations. On July 5, 2001, Environment Canada conducted a one-day information session on the proposed regulations. In exploring the issues of content, design and implementation, the views and concerns from stakeholders were noted and reported. Reference : www.ec.gc.ca/nopp/degrease/en/index.cfm Changes in Canada Effecting Degreasing Chemistry The solvent degreasing regulations will implement a freeze in consumption of TCE and PERC for three years, followed by a 65% reduction in consumption for the following years. The regulations will apply to persons involved in degreasing operations (vapor and cold degreasing) who use more than 1000 kilograms of these solvents during a calendar year. An allowance system will set limits on the quantities of TCE and PERC that could be used each year, based on historical uses of these substances by the users. Allowance holders will be able to retire their allowance or to transfer it to other users. Sellers and users of TCE and PERC will be required to submit annual reports to Environment Canada. The regulations were published in Part II of the Canada Gazette August 13, 2003. Reference : www.ec.gc.ca/nopp/degrease/en/index.cfm Changes in Canada Effecting Degreasing Chemistry For information purposes a compilation of references and links to solvent alternatives and degreasing technologies is available on this web site. For further information, please contact: Solvent Degreasing Coordinator Tel.: 1-866-944-9944 Fax: (819) 994-5030 e-mail: tce@ec.gc.ca Reference : www.ec.gc.ca/nopp/degrease/en/index.cfm What it means for Trichloroethylene users in Canada All Trichloroethylene sales are tracked and reported to Environment Canada. 2007 a 65% reduction was implemented for users of Trichloroethylene for vapor degreasing in excess of 1000 kilograms. Reference : www.ec.gc.ca/nopp/degrease/en/index.cfm Effect of Environment Canada’s Reg.’s on Asphalt Labs In 2007 I was told verbally that EC had an exemption for laboratories that used Trichloroethylene in centrifugal extractors. EC’s intent was to re-examine this exemption at a later date. Laboratories using Trichloroethylene for asphalt extractions should consider evaluating alternatives like Tech Kleen AZE Stabilized NPB prior to forced cut backs. CTAA and the various asphalt associations should play a role in getting NPB approved by the various ministries. Trichloroethylene Replacement Solvent Characteristics Improved Health and Safety Improved toxicity No Flash Point High solvency power excellent cleaner Low boiling point Leave zero residues Low global warming Not regulated by Montreal Protocol Drop in replacement for chlorinated solvents Recyclable No extra steps or water rinsing. Solvent Comparisons Vapor Boiling Point Density Flash Point Trichloroethylene 1.1.1. Trichloroethane 87°C 74°C 1.46 none 1.32 none Methylene Chloride 40°C 1.32 none Perchloroethylene 121°C 1.62 none NPB 70°C 1.32 none D Limonene 176°C 0.844 46-48°C KB VALUE or CLEANING POWER 126 140 130 136 124 120 90 100 68 80 56 60 40 94 29 20 0 White spirit HCFC 141b d-Limonene Perchloroethylene Xylene NPB Trichloroethane Trichloroethylene Methylene chloride KB Value The maximum possible KB (Kauri-Butanol) value, is a solvency power of 140 EVAPORATION RATE 0.18 PERCHLOROETHYLENE 0.57 TRICHLOROETHYLENE 1.1.1 TRICHLOROETHANE 1 0.96 NPB 1.64 METHYLENE CHLORIDE 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 The evaporation rate is taken as free standing in air and compared to butyl acetate = 1. 1.8 GWP GLOBAL WARMING POTENTIAL 630 HCFC 141b HCFC 225b HFE 7100 111 TCA HFE 7200 Methylene chloride Trichloroethylene Perchloroethylene NPB 530 480 110 90 9 0.67 0.53 0.1 0 100 200 300 400 500 600 Global warming potentials are based on 100 yr horizons 700 NOT A HAP (Hazardous Air Pollutant) No reporting under NESHAP or SARA TITLE V LBS USED PER MONTH US reporting requirements for Trichloroethylene have encouraged the switch to NPB for vapor degreasing. ATMOSPHERIC LIFETIME CFC`s - general 100 Years 1.1.1. Trichloroethane6.5 Years Methylene Chloride 6 Months Perchloroethylene 84 Days Trichloroethylene 42 Days NPB 11 Days N Propyl Bromide Summary SNAP (Significant New Alternatives Policy) Approved by US EPA under section 612 of clean air act for solvent cleaning applications. NPB is not a HAP and is reportable by NESHAP Contains no chlorine High solvency - excellent cleaner. No residue No Flash Point DROP-IN REPLACEMENT a. No capital equipment investment b. No change in process TCE consumption must be reduced in Canada Min DOT Approval of NPB 1852 QUANTITATIVE EXTRACTION OF BITUMINOUS MIXTURES (CENTRIFUGE) AASHTO T 164, METHOD A (MN/DOT Modified) 1852.1 SCOPE This method of analysis quantitatively determines the asphalt content of bituminous mixtures using a centrifuge extractor and trichloroethylene or other approved solvents. The use of alternatives like n-propyl bromide and d-limonene, are suitable replacements. These solvents are generally non carcinogenic and essentially non-toxic. Required alterations to this procedure for using n-propyl bromide and d-limonene are covered in the numbered "Notes" below. This method is Mn/DOT's preferred method. NOTE 1: This procedure differs from AASHTO T 164 as follows: Mn/Dot allows the use of n propyl bromide and dlimonene. When using d-limonene a number of water rinses are required and then the sample is dried at 176.7 ± 5 °C (350 ± 9 °F). MN/DOT also requires the use of Celite (diatomaceous earth) to be added to the mixture. (When using Celite determining the amount of fines in the extract is not required by MN/DOT.) MN/DOT allows a minimum solvent soak time of 1 hour but the extraction process must be completed within 24hrs. Connecticut DOT Approval “The sample of Tech Kleen STNPB that you submitted December 1, 2007 has been evaluated. This product has been approved for recommended use as a solvent for extractions with no dilution rate.” Georgia DOT Approval “The Non Chlorinated Asphalt Extraction sample you submitted for an Initial Product Evaluation for Qualified Products List 67 has met all necessary specifications and testing requirements and is approved for use on Georgia Department of Transportation (DOT) projects.” “Tech Kleen NPB” Other Approvals Pennsylvania DOT Lafarge Canada Regional Research Laboratory n-Propyly Bromide Vs Trichloroethylene R047-06 Sample A (12.5mm SP) Target AC/Gradation 19.0m m 100.0 12.5m m 93.2 9.5m m 74.7 4.75m m 54.6 2.36m m 35.4 1.18m m 25.0 600um 17.5 300um 9.4 150um 5.4 75um 3.6 % AC 5.00 Split Test 1 n-Bromide Trichloroethylene 100.0 100.0 93.2 91.4 75.4 74.1 56.3 54.8 37.0 35.1 25.2 24.9 17.8 17.2 9.7 9.6 5.5 5.4 3.7 3.6 4.99 5.01 Split Test 2 n-Bromide Trichloroethylene 100.0 100.0 92.2 93.2 74.8 75.2 54.9 55.1 34.8 35.9 24.4 24.6 17.2 17.9 9.1 9.5 5.2 5.4 3.5 3.6 5.08 5.02 Split Test 3 n-Bromide Trichloroethylene 100.0 100.0 94.2 95.2 76.0 74.1 54.5 53.2 36.4 34.9 26.0 24.0 17.3 17.8 9.2 9.7 5.6 5.4 3.6 3.6 4.95 4.96 Split Test 4 n-Bromide Trichloroethylene 100.0 100.0 93.4 92.4 75.0 73.3 52.2 53.4 34.8 34.2 25.5 25.1 17.2 17.5 9.0 9.1 5.3 5.6 3.4 3.5 5.02 5.03 Sample B (19mm SP) Target AC/Gradation 25mm 100.0 19.0m m 96.0 12.5m m 83.7 9.5m m 75.2 4.75m m 49.6 2.36m m 34.1 1.18m m 24.4 600um 16.5 300um 9.2 150um 5.4 75um 3.6 % AC 4.70 Split Test 1 n-Bromide Trichloroethylene 100.0 100.0 94.3 95.0 81.2 79.6 71.3 71.1 46.4 47.1 32.0 33.2 23.2 23.5 15.7 15.5 8.3 8.4 4.8 5.1 3.3 3.6 4.56 4.60 Split Test 2 n-Bromide Trichloroethylene 100.0 100.0 95.8 96.8 83.0 87.3 74.6 78.1 48.7 50.0 33.1 34.3 24.0 24.6 16.1 16.6 9.1 9.3 5.2 5.4 3.5 3.6 4.72 4.73 Split Test 3 n-Bromide Trichloroethylene 100.0 100.0 96.3 95.3 84.1 82.1 79.9 74.1 50.5 49.3 34.8 33.2 25.9 24.0 16.2 16.4 9.8 9.4 5.6 5.5 3.6 3.6 4.67 4.61 Split Test 4 n-Bromide Trichloroethylene 100.0 100.0 96.8 97.6 83.4 84.6 75.5 76.7 50.1 50.3 34.3 34.8 25.0 25.0 17.0 17.1 9.4 9.8 5.5 5.8 3.5 3.7 4.60 4.61 Supplier of Trichloroethylene for Asphalt testing in Ontario. Provide waste disposal and recycling systems for Ontario Asphalt testing labs. Focus on N Propyl Bromide replacements for Trichloroethylene for Asphalt Testing and vapor degreasing. Stock Tech Kleen ®* NPB for Asphalt applications Solvent minimization can be achieved by using on-site recycling of Tech Kleen ®* NPB Kersol can provide all of the necessary recycling equipment, test kits and stabilizer boosters to safely and effectively recycle solvents on site. For Information on Tech Kleen ®* NPB Replacement Chemistry for Trichloroethylene Contact: Glenn Webber Email: glennwebber@kersolinc.com Phone: 416-923-9120 Fax: 416-923-9120 Email General: kersol@rogers.com