Setting Expansion

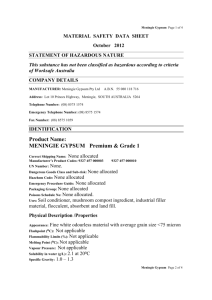

advertisement

• The dihydrate form of calcium sulfate, called • gypsum, usually appears white to milky yellowish • and is found in a compact mass in nature. DR .R.koohkan 2 • As the temperature is raised the remaining water is removed , and products are formed as indicated . 1100 –1300 [CaSO4]1/2 H2O CaSO4+2H2O GYPSUM 1300 –2000 CALCIUM SULFATE HEMIHYDRATE Dehydration by heat or other means Mineral gypsum 2000 –10000 CaSO4 HEXAGONAL ANHYDRATE CaSO4 ORTHOROMBIC ANHYDRATE formulation Plasters Model plaster Lab plaster Hydrocal Dental stone Densite DR .R.koohkan High-strength dental stone 3 IT IS OF THE FOLLOWING TYPES : Impression plaster TYPE Model plaster. TYPE Dental stone. TYPE Dental Stone , high strength . TYPE Dental stone, high strength & High expansion. TYPE DR .R.koohkan I II III IV V 4 • Most gypsum products are obtained from natural gypsum rock. The reaction is exothermic, CaSO4 · ½ H2O + 1 ½ H2O →CaSO4 · 2H2O + 3900 cal/g mol Plaster of Paris Water Gypsum Three types of base raw materials are derived from partial dehydration of gypsum rock, depending on the nature of the dehydration process.: Plasters: are fluffy, porous, and least dense, whereas hydrocal variety : has a higher density and is more crystalline. Densite : • is the densest of the raw materials DR .R.koohkan 5 ISO Classification of dental gypsum products Type 1 : Impression plaster. Type 2 : Dental plaster – model. Type 3 : Dental stone – die. Type 4 : Dental stone – die, high strength, low expansion. • Type 5 : Dental stone – die, high strength, high expansion. • Although these types have identical chemical formulas of calcium sulfate hemihydrate, CaSO4 · ½H2O,they possess different physical properties, Type 4 contains extra salts to reduce its setting expansion DR .R.koohkan 6 • the main difference being the manner of driving off part of the water of the calcium sulfate dihydrate. Plasters : • gypsum mineral is heated in an open kettle at a temperature of about 110° to 120° C β-calcium sulfate hemihydrate. • (irregular shape and porous) Hydrocal : • If gypsum is dehydrated under pressure and in the presence of water vapor at about 125° C α-calcium sulfate hemihydrate. more uniform in shape and denser than the particles of plaster low- to moderate-strength dental stones.. Densite: • Boiling gypsum rock in a 30% calcium chloride solution, is washed away with hot water(100° C) is ground fineness. • Types 4 and 5 high-strength dental stones are • A high-density DR .R.koohkan 7 • α – hemimhydrate β – hemihydrate 1. Type III , IV &V 2. Produced by wet calcination. 3. Requires less water for mixing. 4. Better packing ability. 5. Low surface free energy. 6. Crystal habit of hexagonal calcium sulfate . 7. High apparent density. 1. Type I & II 2. Produced by dry calcination. 3. Requires more water form mixing. 4. Less packing ability. 5. High surface free energy. 6. Crystal habit that of hemihydrate. 7. Low apparent density. DR .R.koohkan 8 Gypsum Mixing Water (mL/100 g of powder) Required Water (mL/100 g of powder) Excess Water ( mL/100 g of powder) Model plaster 37-50 18.6 18-31 Dental stone 28-32 18.6 9-13 High-strength dental stone 19-24 18.6 0-5 *Water-powder ratio varies with each product. When the set material is dried, porosity in the structure, weakening it. the excess water evaporates and leaves This difference in the physical shape and nature of the crystals makes it possible to obtain the same consistency with less excess water with dental stone than with model plaster. DR .R.koohkan 9 SETTING REACTION • PROPOSED THEORIES : 1- Colloidal theory – hemihydrate + water --> colloidal state through sol -gel mechanism. In sol state hemihydrate particles are converted to dihydrate and as the measured amount of water is consumed the mass converts to a solid gel. DR .R.koohkan 10 2- Hydration theory: suggests that rehydrated plaster particles join together through hydrogen bonding to the sulfate groups to form the set material. 3-Dissolution – precipitation theory: • (most widely accepted theory) the setting reaction of water with calcium sulfate hemihydrate to from calcium sulfate dihydrate is caused by the difference in solubility between these two components. based on dissolution of plaster and instant recrystallization of gypsum, followed by interlocking of the crystals to form the set solid. DR .R.koohkan 11 Hemihydrate is 4 times more soluble in water than is the dihydrate near room temp (20°C). Thus the setting reaction can be understood as follows:-hemihydrate + water Suspension is formed that is fluid and workable. Hemihydrate dissolves until it forms a saturated solution. This saturated solution supersaturated in dihydrate, precipitates out dihydrate. DR .R.koohkan 12 .. Thus solution is no longer saturated with hemihydrate, so it continues to dissolve. Dissolution of the hemihydrate and precipitation of dihydrate proceeds as new crystals form or further growth occurs on the present crystals. • In practice about 0.2% to 0.4% linear expansion is • obtained. DR .R.koohkan 13 The ratio of the water to the hemihydrate powder is usually expressed as the W/P ratio W/P ratio setting time . , strength , setting expansion example : if 100g is mixed with 60 ml of water, the W/P ration is 0.6. DR .R.koohkan 14 The fact that the contraction of gypsum is not visible does not invalidate its existence, and when the volumetric contraction is measured by a dilatometer, it is determined to be about 7%. DR .R.koohkan 15 The mixing process, called spatulation, has a definite effect on the setting time and setting expansion spatulation (either speed of spatulation or time or both) setting time Because an increased amount of spatulation causes more nuclei centers (dihydrate) to be formed, the conversion of calcium sulfate hemihydrate to dihydrate is accelerated. DR .R.koohkan 16 20° C 30° C The ratio of the solubilities of calcium sulfate dihydrate and calcium sulfate hemihydrate 4.5 3.4 the mobility of the calcium and sulfate ions increase increase the rate of the reaction increase Over 37° C 100° C 1 increase increase decreases no reaction I. The first effect of increasing temperature is achange in the relative solubilities of calcium sulfatehemihydrate and calcium sulfate dihydrate, which alters the rate of the reaction. II. In general, as the temperature increases, the mobility of the calcium and sulfate ions the rate of the reaction ,the setting time the temperature is raised over37° C, the rate of the reaction decreases, and the setting time is lengthened. DR .R.koohkan 17 The initial result is acceleration of setting. Produce dihydrate, providing more nuclei for crystallization . The final result is further contamination by moisture can reduce the amount of hemihydrate remaining to form gypsum retardation of setting will occur setting time DR .R.koohkan 18 Colloidal systems (agar , alginate) retard the setting of gypsum by being adsorbed on the hemihydrate and dihydrate nucleation sites retards the setting it is more effective on dihydrate nucleation potassium sulfate are added to improve the surface quality of the set CaSO4 · 2H2O against agar or alginate. DR .R.koohkan 19 Liquids with low pH, such as saliva, retard the setting reaction Liquids with high pH accelerate setting. DR .R.koohkan 20 The important properties of gypsum products include quality fluidity at pouring time Setting time linear setting expansion compressive strength hardness abrasion resistance Reproduction of detail DR .R.koohkan 21 The time required for the reaction to be completed is called the final setting time. The initial setting time is defined by: The loss of gloss from the surface Increase temperature of the mass INITIAL GILLMORE TEST FOR INITIAL SET The final setting time is defined as the time at which the material can be separated from the impression DR .R.koohkan 22 • The smaller needle is most frequently used for cements but it is sometimes used for gypsum products . The mixture is spread out, and the needle is lowered onto the surface. The time at which it no longer leaves an impression is called the initial set , noted as “Initial Gillmore”. It takes place at approx 13 mins. DR .R.koohkan 23 The Vicat apparatus: is commonly used to measure the initial setting time of gypsum products. It consists of a rod weighing 300g with a needle of 1-mm diameter. DR .R.koohkan 24 The setting time can control by: changing the temperature of the mix water a changing the degree of spatulation. Water-powder(W/P) ratio The easiest and most reliable way to change the setting time is to add different chemicals. The setting time is usually shortened for power mixing compared with hand mixing. DR .R.koohkan 25 ACCELERATORS: Sodium Sulphate - 3-4 % Potassium Sulphate - 2-3 % Sodium Chloride - 2% Gypsum - < 20% Potassium sulfate “ROCHELLE potassium sodium tartrate SALT” The acceleration caused by an additive depends on the amount and rate of solubility of the hemihydrate versus the same effect on the dihydrate. DR .R.koohkan 26 RETARDERS: Act by forming an adsorbed layer on the hemihydrate and on gypsum crystals to reduce its solubility.(organic materials) forms a layer of calcium salt that is less soluble than is the sulfate salt.(salts) ORGANIC MATERIALS: Glue, gelatin and some gums. SALTS: Borax 1-2% (sodium tetraborate decahydrate) sodium chloride ~ 20% DR .R.koohkan 27 Manipulative Variable Setting Time Consistency Setting Expansion Compressive Strength Increase water/powder ratio Increase Increase Decrease Decrease Increase rate of spatulation Decrease Decrease Increase No effect Increase temperature of mixing water from 23° to 30° C Decrease Increase No effect Decrease DR .R.koohkan 28 Gypsum products may be formulated with chemicals that modify their handling characteristics and properties. Setting time Expansion K2SO4 ↓↓↓ Borax ↑↑ ↓ K2SO4 + Borax ↓ ↓↓↓ Sodium chloride ? ↓↓↓ in small amounts Terra alba effective accelerators. (set calcium sulfate dihydrate) sodium citrate is a dependable retarder. 2% aqueous solution of borax prolong the setting time (a few hours) DR .R.koohkan 29 • More voids were observed in casts made from the stones with the higher viscosities. DR .R.koohkan 30 The compressive strength is inversely related to the W/P ratio of the mix. The more water , The excess water is uniformly distributed in the mix and contributes to the volume but not the strength of the material the most porous the lower compressive strength. the weakest stone Porous Model plaster>Dental stone > High-strength stone strength Model plaster<Dental stone <. High-strength stone DR .R.koohkan 31 Compressive strength (MPa) The dry compressive strength is usually about twice that of the wet strength. 60 50 40 30 Effect of loss of excess water on Compressive strength of dental stone. 20 0 DR .R.koohkan 2 4 6 8 Weight loss (%) 10 32 The surface hardness of un modified gypsum materials is related in a general way to their compressive strength. Increased surface hardness does not necessarily mean improved abrasion resistance because hardness is only one of many factors that can affect wear resistance impregnating the set gypsum by surface Hardness epoxy or methylmethacrylate monomer plaster compressive scratch strength resistance - - - - epoxy or methylmethacrylate monomer dental stone colloidal silica (about 30%) dental stone DR .R.koohkan 33 ANSI/ADA specification No. 25 requires that: types 1 and 2 reproduce a groove 75 mm in width types 3, 4, and 5 reproduce a groove 50 mm in width Gypsum dies do not reproduce surface detail as well as electroformed or epoxy dies gypsum does not wet some impression material (silicon) use of vibration during the pouring of a cast Use surfactants in silicone impression materials Rinsing the impression DR .R.koohkan 34 Gypsum product shows linear expansion during the setting due to outward thrust of crystals that is change from hemihydrate to dihydrate. Low – 0.06 % High – 0.5 % [CaSO4]₂ •H₂O + 3H₂O Molecular mass 290.284 54.048 Density(g/cm³) 2.75 0.997 Equivalent volume 105.556 54.211 Total volume 159.767 DR .R.koohkan 2 CaSO4 •2H₂O 344.322 2.32 148.405 148.405 35 SETTING EXPANSION CONTD . . Net change in volume is : (148.405 – 159.767) * 100 159.767 = -7.11% CRYSTALLIZATION MECHANISM: crystals grow outward thrust or stress develops expansion of the entire mass . • Practically the product is greater in external volume but less in crystalline volume. DR .R.koohkan 36 ) Hygroscopic expansion: In one technique the investment is immersed in water after setting has begun. A greatly increased setting expansion occurs. So less thermal expansion is required. Increased hygroscopic expansion is obtained in the following cases: 1) When a lower water/powder ratio is used 2) For an investment material of greater silica content. 3) If water of higher temperature is used. 4) For longer immersion in water DR .R.koohkan 37 DR .R.koohkan 38 If during the setting process, the gypsum materials are immersed in water, the setting expansion increases. Mechanical mixing decreases setting expansion. Properties of a High-Strength Dental Stone Mixed by Hand and by a Power-Driven Mixer with Vacuum DR .R.koohkan 39 Power-driven mechanical spatulator with a vacuum attachment. (Courtesy of Whip Mix Corporation,Louisville, KY.) Flexible rubber mixing bowl and metal spatula with a stiff blade. (Courtesy of Whip Mix Corporation,Louisville, KY.) A Vibrator is designed to promote the release of bubbles in the gypsum mix and to facilitate pouring of the impression. (Courtesy of Whip Mix DR .R.koohkan Corporation,Louisville, KY.) 40 Properties Required of an Investment : 1. 2. 3. 4. 5. 6. 7. 8. Easily manipulated: Sufficient strength at room temperature: Stability at higher temperatures: Sufficient expansion: Beneficial casting temperatures: Porosity: Smooth surface: Ease of divestment: 9. Inexpensive. DR .R.koohkan 41 Composition Investment is a mixture of three distinct types of materials: 1. Refractory material 2. Binder material 3. Other chemicals DR .R.koohkan 42 During the heating, the investment is expected to expand thermally to compensate partially or totally for the casting shrinkage of the gold alloy. Such as: Quartz Tridymite Cristobalite or a mixture of these. Microstructure of the surface of a set cristobalite investment. The large, irregular particles are ,silica, and the rodlike particles are cristobalite (~3000) Courtesy oR Earnshdw.) DR .R.koohkan 43 The common binder used for dental casting: α-calcium sulfate hemihydrate (gold alloy) Phosphate, (for high-temperature casting ) ethyl silicate, (for high-temperature casting) DR .R.koohkan 44 To produce the desirable properties required of an investment. such as : Sodium chloride Boric acid Potassium sulfate Graphite Copper powder Magnesium oxide small amounts of chlorides or boric acid enhance the thermal expansion of investments bonded by calcium sulfate. DR .R.koohkan 45 The final product’s properties are influenced by both the ingredients present in the investment and the manner in which the mass is manipulated and used in making the mold. The investment may contain 25% to 45% of the calcium sulfate hemihydrate. The remainder consists of silica allotropes and controlling chemicals. DR .R.koohkan 46 • Dimensional change of Three form of gypsum When heated • The calciumsulfate portion of the investment decomposes into sulfur dioxide at temperatures over 700° C sulfur trioxide embrittle the casting metal. Temperature ("C) DR .R.koohkan (Courtesy of K. Neiman,Whip-Mix (‘corporation, Louisville, I<Y.) 47 Effect of Temperature on Silicon Dioxide Refractories Effect of Temperature on Calcium Sulfate Binders DR .R.koohkan 48 The percentage of expansion varies from one type to another cristobalite and quartz each exist in two polymorphic forms β-Form .Stable at a higher temperature α-Form Stable at a Lower temperature. stable at room Tridymite has three stable polymorphic forms. DR .R.koohkan 49 cristobalite, the expansion is uniform up to about 200° C. Expansion increases 0.5% to 1.2% 573°c C , above 250° C it again becomes more uniform. Quartz: At 573° C also shows a break in the expansion curve, . Tridymite : Shows a similar break at a much lower temperature 105° and 160° C DR .R.koohkan 50 • Displacive transition temperatures. • A displacive change involves expansion or contraction in the volume of the mass without breaking any bonds. ( cristobalite 220° C quartz573° C , tridymite105° and 160° C ) • changing α-form to β-form at all three forms of silica expand. • The amount of expansion is highest for cristobalite and lowest for tridymite. DR .R.koohkan 51 • Reconstructive transition during which bonds are broken and a new crystal structure is formed. • The quartz can be converted to cristobalite and tridymite by being heated through a B-quartz 870° C B-tridymite 1475° C B-cristobalite 1700° C Fused silica 160° C 573° C Middle tridymite 220° C 105° C α-quartz α-tridymite α-cristobalite Displacive transition temperatures Fused silica DR .R.koohkan 52 Investment 105° C up to about 200° C Thermal expansion then Remains unchanged contracts slightly anhydrous calcium sulfate between 200° -700° C. Depending on the silica and composition of the investment Registers varying degrees of expansion, Dehydration of the dihydrate and a phase change of the calcium sulfate anhydrite cause a contraction. DR .R.koohkan 53 When the investment is allowed to cool, the refractory and binder contract according to a thermal contraction curve that is different from the thermal expansion curve of the investment Thermal expansion and contraction curves for calcium sulfate–bonded investment (thermal expansion type). Curve 1 is first heating, curve 2 is cooling curve 3 is reheating. DR .R.koohkan 54 ) Hygroscopic expansion: In one technique the investment is immersed in water after setting has begun. A greatly increased setting expansion occurs. So less thermal expansion is required. Increased hygroscopic expansion is obtained in the following cases: 1) When a lower water/powder ratio is used 2) For an investment material of greater silica content. 3) If water of higher temperature is used. 4) For longer immersion in water DR .R.koohkan 55 Thermal expansion curves for calcium sulfate–bonded investments. A, Hygroscopic type; B,thermal expansion type. For hygroscopic expansion,: the additional water provided must be presented to the investment during setting. The additional water be presented before the observed loss of gloss, which is when the setting reaction is not complete. This allows the additional water to join the remaining mix water and extend the water surface so that the action of surface tension is either delayed or inactive. DR .R.koohkan 56 melting temperatures Investment Phosphate- bonded investments Over 700° C Silica-bonded investments under700° C calcium sulfate–bonded investments cobaltchromium alloys Gold alloys Base metal alloys are usually cast into molds at 850° to 110° C. To with stand these high temperatures, the molds require different types of binders, such as silicate and phosphate compounds. ( less than 20% binder, remainder of investment is quartz or another form of silica.) DR .R.koohkan 57 Finer silica produces higher Setting and hygroscopic expansions. The particle size hygroscopic expansion calcium sulfate hemihydrate little effect silica significant effect Silica/Binder Ratio: Investments usually contain 65% to 75% silica, 25% to 35% calcium sulfate hemihydrate, 2% to 3% of some additive chemicals to control the different physical properties The strength of the investment decreases. The hygroscopic expansion of the investment increases, If the silica/stone ratio is increased, DR .R.koohkan 58 Manipulative Variable Setting Time Consistency Setting Expansion Compressive Strength Increase water/powder ratio Increase Increase Decrease Decrease Increase rate of spatulation Decrease Decrease Increase No effect Increase temperature of mixing water from 23° to 30° C Decrease Increase No effect Decrease DR .R.koohkan 59 The water bath has a measurable effect on the wax pattern. At higher water-bath temperatures 1-the wax pattern expands, requiring less expansion of the investment to compensate for the total casting shrinkage. 2- soften the wax provides less resistance to the expansion of the investment making the setting expansion more effective. DR .R.koohkan 60 Casting techniques involving gypsum bonded investments are often classified as 1- Thermal techniques the invested ring after setting placing into the burnout oven (649° C), 2- Hygroscopic techniques. the invested ring before setting (482° C). immersing in a water bath after setting directs the burnout oven Although all gypsum-bonded investments exhibit both thermal and hygroscopic setting expansion, DR .R.koohkan 61 Investments used in the thermal technique usually contain cristobalite has a high thermal expansion. Expansion (%) Investments used in the hygroscopic technique usually contain lower thermal expansions quartz or tridymite higher hygroscopic setting expansions. Thermal expansion of mixed hygroscopicthermal gold casting investment. DR .R.koohkan Temperature ( C) 62 Expansion (%) Setting and hygroscopic expansion of mixed hygroscopic-thermal gold casting investment. Temperature ( C DR .R.koohkan 63 This type of investment consists of three different components. 1. A water-soluble phosphate ion. 2. The second component reacts with phosphate ions at room temperature. 3. The third component is a refractory, such as silica. ANSI/ADA specification No. 126 (ISO 9694) for dental phosphate-bonded casting investments Specifies two types of investments for alloys having a solidus temperature above 1080° C: Type 1: For inlays, crowns, and other fixed restorations Type 2: For removable dental prostheses DR .R.koohkan 64 an acid-base reaction between acid monoammonium phosphate+ Mgo forming a binding medium with filler particles embedded in the matrix. Spatulation continues The water produced by this reaction at room temperature Phases formed at high temperatures DR .R.koohkan 65 • The special liquid is a form of silica sol in water • phosphate-bonded investments possess higher setting expansion when they are mixed with the silica sol than when mixed with water. (increases its strength) Thermal expansion type Effect of silica sol concentration on thermal expansion (solid lines) at 800° C and setting expansion (dotted lines) of two phosphate-bonded investments. A, Thermal expansion type; B, hygroscopic expansion type. DR .R.koohkan 66 • This type of investment may derive its silica bond from ethyl silicate, an aqueous dispersion of colloidal silica, or from sodium silicate. DR .R.koohkan 67 Setting reaction: a) Stage 1 : hydrolysis. Ethyl silicate can be hydrolysed to silica acid, with liberation of ethyl alcohol: Si(OC2H5)4 + 4H2O Si(OH)4 + 4C2H5OH ethyl silicate a colloidal solution of silicic acid and ethyl alcohol, In practical, a polymerised form of ethyl silicate is used, yielding a sol of polysilicate acid. DR .R.koohkan 68 b) Stage 2: gelation. The sol is mixes with cristobalite or quartz, then gel formation is made to occur under alkaline conditions by adding magnesium oxide. There is a slight shrinkage at this stage. c) Stage 3: drying. on heating, considerable shrinkage occurs and there is a loss of alcohol and water, leaving a mould made of silica particles tightly packed together. As alternative of the above, simultaneous hydrolysis and gel formation can occur, when an amine such as piperidine is incorporated. DR .R.koohkan 69 • ANSI/ADA specification No. 126 (ISO 11246) • The setting time must not differ by more than 30% from the time stated by the manufacturer. • The compressive strength at room temperature shall not be less than 1.5 MPa. • The linear thermal expansion must not differ by more than 15% from the time stated by the manufacturer. • Brazing Investment • When brazing (soldering) the parts of a DR .R.koohkan 70 ANSI/ADA specification No. 126 (ISO 11244) for dental brazing investments defines two types of investment: Type 1: Gypsum-bonded dental brazing investments Type 2: Phosphate-bonded dental brazing investments Soldering investments are designed to have lower setting and thermal expansions than casting investments , a feature that is desirable so the assembled DR .R.koohkan 71 INTRODUCTION Casting is the process by which a wax pattern of a restoration is converted to a replicate in dental alloy. It is used to make dental restorations such as inlays, onlays, crowns, bridges, and removable partial dentures DR .R.koohkan 72 1 . TOOTH PREPARATION . 2 . IMPRESSION . 3 . DIE PREPARATION . 4 .WAX PATTERN FABRICATION . - There are 4 methods for making wax patterns for a cast restoration . 5. SPRUING . DR .R.koohkan 73 Gingival retraction Retraction cord DR .R.koohkan 74 1 .Create a wax pattern of the missing tooth / rim 2 .Sprue the wax pattern 3 .Invest the wax pattern 4. Eliminate the wax pattern by burning it (inside the furnace or in hot water). This will create a mould. 5 . Force molten metal into the mould - casting. 6 .Clean the cast. 7 .Remove sprue from the cast 8 . Finish and polish the casting on the die DR .R.koohkan 75 DR .R.koohkan 76 The management of these dimensional changes is complex, but can be summarized by the equation: wax shrinkage + metal shrinkage = wax expansion + setting expansion + hygroscopic expansion + thermal expansion DR .R.koohkan 77 the wax will shrink significantly because of the high coefficient of thermal expansion of waxes. Metal shrinkage occurs when the molten metal solidifies, but this shrinkage is compensated by introducing more metal as the casting solidifies Cooling shrinkage may reach 2.5% for an alloy that cools from a high solidus temperature (1300" to 1400' C), depending on the coefficient of thermal expansion of the alloy. DR .R.koohkan 78 FUNCTIONS OF SPRUE 1 . Forms a mount for the wax pattern . 2 . Creates a channel for elimination of wax . 3 .Forms a channel for entry of molten metal 4 . Provides a reservoir of molten metal to compensate for the alloy shrinkage DR .R.koohkan 79 • 1 . DIAMETER : It should be approximately the same size of the thickest portion of the wax pattern .Too small sprue diameter suck back porosity results . • 2 . SPRUE FORMER ATTACHMENT : Sprue should be attached to the thickest portion of the wax pattern .It should be Flared for high density alloys & Restricted for low density alloys . DR .R.koohkan 80 3 . SPRUE FORMER POSITION Shape & form of the wax pattern . Patterns may be sprued directly or indirectly .. Indirect method is commonly used 4.Reservoir prevents localised shrinkage porosity . Reservoir And Its Location Reservoir portion of a Spruing system is a round ball or a bar located 1mm away from the wax pattern. . Round ball reservoir & a bar reservoir also called connector Significance of Reservoirs: DR .R.koohkan 81 Reservoir should be positioned in the heat centre of the ring . This permits the reservoir to remain molten for longer and enables it to furnish alloy to the pattern until they complete solidification process . 5. SPRUE FORMER DIRECTION Ideal angulation is 45 degrees 6 . SPRUE FORMER LENGTH Depends on the length of casting ring 7.TYPES OF SPRUES - Wax . II . Solid - Plastic . Hollow - Metal . DR .R.koohkan 82 VENTING Small auxilliary sprues or vents improve casting of thin patterns Acts as a HEAT SINK . DR .R.koohkan 83 To minimise the irregularities on the investment & the casting a wetting agent can be used . FUNCTIONS OF A WETTING AGENT 1 . Reduce contact angle between liquid & wax surface . 2 .Remove any oily film left on wax pattern DR .R.koohkan 84 It serves as a base for the casting ring during investing .Usually convex in shape.May be metal , plastic or rubber DR .R.koohkan 85 Most common way to provide investment expansion is by using a liner in the casting ring .Traditionally asbestose was used . Non asbestose ring liner used are : 1) Aluminosilicate ceramic liner . 2) Cellulose paper liner . a resilient liner is to allow different types of investment expansion facilitate venting during casting procedure. facilitate the removal of the investment block after casting . DR .R.koohkan 86 RINGLESS INVESTMENT TECHNIQUE Useful for high melting alloys used for phosphate bonded investments This method uses paper or plastic casting ring Solid rings do not permit the investment to expand laterally during the setting and hygroscopic expansions of the mold DR .R.koohkan 87 the correct water powder ratio of the investment mix, A required number of spatulation turns, A proper investing technique are essential to obtain acceptable casting results. hand investing and vacuum investing. requires 45 to60 minutes DR .R.koohkan 88 Two type of torch tips: • Multi-orifice is widely used for metal ceramic alloys. Main advantage is distribution of heat over wide area for uniform heating of the alloy. • Single-orifice tip concentrate more heat in one area. DR .R.koohkan 89 Three fuel sources are used for Casting Torch; 1-Acetylene 2-Natural Gas 3-Propane CASTING CRUCIBLES Four types are available ; 1) Clay . 2) Carbon . 3) Quartz . 4) Zirconia –Alumina . DR .R.koohkan 90 It is a device which uses heat source to melt the alloy casting force . Heat sources can be : 1) Reducing flame of a torch . ( conventional alloys & metal ceramic alloys ) 2) Electricity .(Base metal alloys ) DR .R.koohkan 91 Advantages of electric heating : -heating is evenly controlled . -minimal undesirable changes in the alloy composition - Appropriate for large labs . Disdvantages : Expensive . DR .R.koohkan 92 1) Air pressure . 2) Centrifugal force . 3) Evacuation technique Centrifugal casting machine, DR .R.koohkan 93 1) Alloy is melted in a separate crucible by a torch flame & is cast into the mold by centrifugal force .(centrifugal C M ) 2) Alloy is melted electrically by a resistance heating or by induction furnace & then cast centrifugally by motor or spring action (spring wound CM electrical resistance ) 3) Alloy is melted by induction heating cast into mold centrifugally by motor or spring action .(Induction CM ) 4) Alloy is vacuum melted by an argon atmosphere Torch melting / Centrifugal casting machine Electrical resistance /Heated casting machine DR .R.koohkan 94 Induction melting casting machine, water cooling induction coil. Induction melting casting machine, vertical crucible positional within the induction coil DR .R.koohkan Electrical resistance Spring-wound casting 95 DR .R.koohkan 96 DR .R.koohkan 97