Chapter 6 File

advertisement

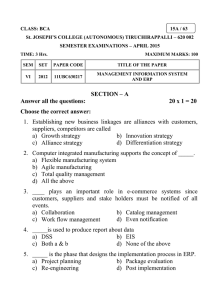

Chapter 6 The Production Process 1 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Learning Objectives Describe the master data associated with the production process. 2. Identify the key steps in the production process and the data, documents, and information associated with each step. 3. Effectively use SAP® ERP to execute the key steps in the production process. 4. Effectively use SAP ERP to extract meaningful information about the production process. 1. 2 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Types of Manufacturing Discrete vs. repetitive vs. process Discrete and repetitive Tangible products Manufactured in individual units Skateboards, bicycles Repetitive manufacturing Same or similar products are produced over a period of time A specified quantity is produced over a period of time Discrete Batches of different materials over time 3 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Types of manufacturing Process manufacturing Not manufactured in individual units Gallons, pints, liters Paint, soft drinks 4 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 A Basic Production Process 5 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Organizational Data Client Company code Plant Storage location 6 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Master Data Bill of materials (BOM) Work center Product routing Material master Production resource tools (PRT) 7 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Bill of Materials Identifies the components needed to make the material A component can have its own BOM to creates a multi-level BOM BOMs are used in Material planning Production Procurement Product costing 8 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Single-level and Multi-level BOMs 9 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Bill of Materials for Touring Bikes 10 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Bill of Materials for Off-road Bikes 11 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Bill of Materials - Header Applies to the entire BOM Status: active, inactive Base quantity: materials specified are needed to make the base quantity (typically 1 unit). Usage: production, engineering, costing, etc. Plant: each plant can have a different BOM Validity: date range 12 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Bill of Materials - Items Apply to the specific item in the BOM Item category: Stock item – must have a material master Nonstock item – no material master Variable-sized item – must specify size Document item – diagrams, additional instructions Material number Quantity 13 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 BOM Structure 14 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.1 BOM for Bike and Wheel Assembly Review some of the data included in a material master 15 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Work Center Basic data Name, description Person responsible for maintaining master data Task list usage (which routings can use this work center) Capacities Scheduling Cost center HR assignment 16 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Work Center Data 17 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 GBI Dallas Production Facility 18 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 GBI Work Centers 19 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.2 Review GBI Work Center Review the GBI work center 20 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Product Routing Steps necessary to produce a material Operations Sequence Standard Alternate Parallel Work center Times Setup, machine, labor 21 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Work Center Example 22 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Structure of a Routing 23 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Routing and Work Centers 24 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Routing for Deluxe Touring Wheel Assembly 25 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Routing for Deluxe Touring Bike 26 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.3 Review Routing for a Bike and Wheel Assembly Review the routing for a bike and wheel assembly 27 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Component Assignment Specifies the relationship between a BOM and a routing Assigns components (materials) in a BOM either to a routing or to a specific operation within routing If not assigned assumed to be assigned to the first operation 28 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Component Assignment 29 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Production Capability A measure of how many units of a material a plant can produce within a given timeframe A data source for production planning 30 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Sample GBI Production Plan 31 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Material Master Previously discussed views Basic data Purchasing related Sales related Accounting related Additional view needed for production Work scheduling – plant specific MRP – plant specific More relevant in material planning Will be discussed in that chapter 32 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Production Resource Tools Movable objects required for production Shared among different work centers Documents (instructions) Materials (calibration tool) Equipment (machine that is not in a fixed location) Miscellaneous 33 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 The Production Process 34 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Request Production Planned order What material How many When Generated by other processes Fulfillment Project management Material planning Can be created manually 35 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of the Request Production Step 36 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Data in a Planned Order 37 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.4 Create a Planned Order Review how to create a planned order 38 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Authorize Production With planned order: convert Convert to production order Without planned order: create production order Production order What material is to be produced? How many? When? Where will they be produced? What resources are to be used? How much is it expected to cost? 39 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of the Authorize Production Step 40 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Data in a Production Order 41 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Structure of a Production Order 42 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Authorize Production - Outcomes Scheduling Availability checks Reservations Preliminary costing Purchase requisitions 43 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Preliminary Cost Estimates for Men’s Off-road Bike 44 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Cost Estimates in a Production Order Planned cost: planned cost for planned quantity Based on material and labor cost estimates Target cost: planned cost for actual quantity Actual cost: actual cost for actual quantity 45 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.5 Create a Production Order Review how to create a production order 46 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Order Release On creation order status is created (CRTD) Order must be released (REL) to permit subsequent steps such as Goods movement not possible Confirmations not possible Documents cannot be printed Settlement 47 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of the Order Release Step 48 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Order Release Automatic or manual If no time is needed between creation and release for preparation, then release occurs automatically Release at different levels Header: All operations are released Operations: Release specific operations Operations status: REL Order status: PREL (partially released) 49 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Order Release - Outcomes Execution of subsequent steps is possible Shop floor papers can be printed Communication with PDC is possible 50 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Goods Issue Movement type 261 Impact Material, FI, CO documents G/L accounts updated Inventory updated Reservations updated (reduced) Costs updated (actual cost in order) 51 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of the Goods Issue Step 52 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Data in a Goods Issue Step 53 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Financial Impact of a Goods Issue 54 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.6 Goods Issue to Production Order Review the steps from goods issue to production order 55 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Confirmations Order level confirmation Operations level confirmation 56 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of the Confirmation Step 57 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Data in a Confirmation 58 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Financial Impact of a Confirmation 59 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.7 Confirm Production Review confirm production 60 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Goods Receipt Goods receipt into storage Movement type 101 Impact Material, FI, CO documents Material master update (quantity and value) Production order update (quantity, date, costing) 61 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Elements of a Goods Receipt 62 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Data in a Goods Receipt 63 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Financial Impact of a Goods Receipt 64 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.8 Goods Receipt from Production Review goods receipts from production 65 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Periodic Processing Overhead calculation Work in progress determination Settlement 66 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Overhead Calculation Indirect costs Supervisor, manager, other salaries Utilities Accumulated in cost centers Periodically allocated to production orders based on predetermined rules 67 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Work-in-Progress Determination Work-in-progress (WIP) inventory Inventory between GI and GR inventory Periodically the value of what is in the production process is calculated and posted to the general ledger Not essential For short production processes Value of materials is not high GBI Essential When value of materials is high Production takes weeks, months, or years Aircraft production, construction. 68 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Settlement Settle the difference between planned and actual costs (variance) Only panned costs are posted in the GR step Variance is settled in this step 69 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Financial Impact of a Settlement 70 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Reporting General SAP reporting options Online lists Work lists Analytics Production-specific reporting options Stock/requirement lists 71 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Production Information System Components 72 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Production Information Systems Operations 73 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Stock/Requirements List 74 Magal and Word | Integrated Business Processes with ERP Systems | © 2011 Demo 6.9 Stock/Requirement List Review/stock requirement list 75 Magal and Word | Integrated Business Processes with ERP Systems | © 2011