File

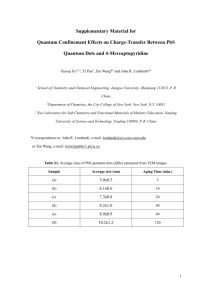

Photophysical Properties of CdSe/ZnS

Quantum Dots Embedded in Polymer

Films and Solubilized in Toluene

Final Presentation

Jamie Golden

CHEM 496

04/30/10

Introduction to Quantum Dots

• QDs are semiconductor particles; size = 1-99nm

• Photophysical properties (absorption & emission spectra) controlled by size and shape

• E x h

2

=

8 R

2

1 m e

1 m h

1 .

8 e

2

4

R

Atkin’s P. Chem Book p.(307)

• Use in applications such as LEDs, flat screen monitors, and solar cells.

– Must be suspended in solid (polymer) matrix for applications to be materialized

• Interaction between QDs and polymer matrix is of interest to investigate

Selection of polymers to be used

• PMMA polymer of choice

– Optically transparent

– Water resistant

– Chemically stable

• Amorphous thermoplastic

– Convenient rheological properties

– High strength-weight ratio

Previous Studies

• Previous studies involving CdSe/ZnS quantum dots involved the use of a thermal lens to measure the quantum yield of QDs in PMMA suspended in three different solvents

– toluene, tetrahydrofuran, and chloroform.

• Pilla et al found that the quantum yield of the QDs exhibiting fluorescence ranged from 0.60-0.85 at room temperature when suspended in organic solvents.

4

– were not able to explain the quenching mechanisms involved of the quantum yield in function of increasing concentration because it was not completely understood.

– Proposed behavior could be due to the formation of a cluster or due to particle agglomerations.

4

• In another study involving the same QDs and polymer film (PMMA) by Tamborra et al, optical and physical properties of nanocomposties were investigated.

– It was evident from fluorescence microscopy images that there is a presence of larger aggregates in CdSe/ZnS in PMMA than for CdS.

5

4 Pilla V, Alves LP, Munin E, Pacheco MTT. Radiative quantum efficiency of CdSe/ZnS quantum dots suspended in different solvents. Opt. Comm 2007;

5

280: 225-229.

Tamborra M, Striccoli M, Curri ML, Agostiano A. Hybrid Nanocomposites Based on Luminescent Colloidal Nanocrystals in Poly(methyl methracrylate):

Spectroscopical and Morphological Studies. J Nanoscience and Nanotechnology 2008; 8: 628-634.

Experimental

• QDs from Evident Technology; no further modification

• Temperature resolved laser photolysis setup using 3ns laser pulse

• Polymer film placed in quartz dewar to cool to

77 K using liquid nitrogen

• Fluoresceien used as a standard in order to calculate quantum yield of QDs in toluene

• Used simple formula: QY

1

/QY

2

= I

1

/I

2

50000

40000

30000

20000

10000

0

480

Emission Spectra

QD520 Toluene (RT)

QD520 Toluene (77K)

QD520/PMMA (RT)

QD520/PMMA (77K)

Emission spectra of QDs

Luminescence spectra

Ocean Optics Spec

337 nm laser excitation

12/1/07 solubilized in toluene and embedded in PMMA at RT and 77 K

No significant change in toluene

500 520 540 560

W A V E L E N G T H (nm)

580 600 and PMMA film

Indicates no change in QD size in film process

Slight change may be due to close proximity

Luminescence Quantum Yield of Quantum Dots Suspended in Toluene Solution

0.20

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

λ x

Fluorescein (Absorption)

QDs in Toluene (Absorption)

QDs in Toluene (Emission)

Fluorescein (Emission)

Fluorescein used as a standard

QY = 0.92

Absorption and Emission

Spectra of Fluorescein and QDs in toluene

excitation wavelength chosen to ensure identical spatial distribution of excited molecules in cell

Relative QY ratio = areas under emission spectra ratio

0.00

QY

1

/QY

2

= (Area)

1

/(Area)

2

450 500 550 600

W A V E L E N G T H (nm)

650

QY of QDs in toluene = 0.52

0.8

-20

0.6

0.4

0.2

Quantum Yield of QDs in PMMA Film

0 20 40 60 80

QD520 in Toluene (RT)

QD520 in PMMA (RT)

100

0.8

0.6

Laser photolysis used in order to avoid technical difficulties to determine QY of

QDs in PMMA film

Quantum Yield Measurement

Area

QD in Toluene

= 12.01752

Area

QD in PMMA

= 5.67362

0.4

Compared areas under emission decay curves of QDs in toluene and embedded in polymer film

QY

QD in Toluene

= .53

QY

QD in PMMA

= .25

0.2

QY

1

/QY

2

= (Area)

1

/(Area)

2

0.0

-20 0 20 40

T I M E (ns)

60 80 100

Fig. Emission decays of QDs in toluene and embedded in PMMA at RT

0.0

QY of QDs in PMMA = 0.25 which is only 46% of that measured in toluene

0.7

Emission Decays of QDs in PMMA Film at RT and 77 K

Insert: Laser Pulse Profile

0.6

0.5

0.7

0.6

0.5

0.4

Laser photolysis experiment

QD 520 in PS film

Room Temperature

2/1/2010

QD Luminescence

Laser pulse profile

ExpDec1 fit 2 t

1/2

= 1ns

ExpDec1 fit 1 t

1/2

= 7.5 ns

• Normalized RT quantum yield of QDs in PMMA film. From this value, can get QY at any temp.

0.3

0.4

0.3

0.2

0.1

0.2

0.1

0.0

0 5 10 15

T I M E (ns)

20

77K

296.1K

• Like to explore temp dependence on QY because electron transfer quenching is expected to slow on lowering the temp

0.0

0 20 40 60 80

T I M E (ns)

Fig showing 2 normalized emission decays at RT and 77 K of QDs in PPMA film. Insert : laser pulse profile and QD luminescence

Laser Pulse Profile and QDs Luminescence

• Insert is laser pulse profile and QDs luminescence

– Wanted to determine if laser pulse is short enough and detection system fast enough to accurately monitor QD’s luminescence decays

– Decay part of laser pulse profile was compared to actual decay of QD luminescence

– Found decay part of QD luminescence had a halflifetime ~ 7.5ns

– Found decay part of laser pulse profile had halflifetime ~ 1ns

– This proves that the laser photolysis apparatus is fast enough to accurately measure the decays

Quantum Yield of QDs in PMMA Film

0.40

0.38

0.36

0.34

0.32

0.30

0.28

50

QDs in PMMA film

100 150 200 250

T E M P E R A T U R E (K)

300

• QY at 77K is still less than that of toluene at RT

• Why is that?

PMMA and PP Structures

PP

PMMA

0.5

0.6

0.8

0.7

0.9

1.0

Temperature Dependence of QY

QD520 in PMMA (1st run)

QD520 in PMMA (2nd run)

QD520 in PP Area (2nd run)

QD520 in PP Area (1st run)

Temperature resolved laser photolysis technique

Relative QY of QDs in

PMMA film and relative

QY of QDs in PP film as a function of temperature

Found as temperature decreases, the QY increases continuously

50 100 150 200 250

T E M P E R A T U R E (K)

300

Summary of PMMA & PP Study

• Found that both PMMA and PP matrices reduce the QY of QDs to the same extent

• Conclusions about decrease in QY (from QDs in toluene

– Neither energy or electron transfer observed

– PP is an inert polymer matrix where energy or electron transfer cannot happen

• Decided to see QDs go through liquid to solid phase (Freeze toluene)

• Compare using another polymer to further investigate interaction; using polyestyrene (PS)

Introduction to PS

• Amorphous polystyrene

– Similar chemical composition as toluene

– Soluble in toluene

Polystyrene: Toluene:

• Interest to study

– Effects of a liquid to solid phase transition (QDs suspended in toluene)

Quantum Yield of QDs in PS Film

• Fluorescein used as a standard QY = 0.92

• Experimental parameters kept same

• Relative QY ratio = areas under emission spectra ratio

• QY of QDs in toluene = 0.52

• Laser photolysis used in order to avoid technical difficulties to determine QY of QDs in PS

• Ratio of Area under emission decay curves =

Ratio of QY (QDs in PS and QDs in toluene)

– QY of QDs in PS film equals 0.27

Emission Decays of QDs in Toluene and Embedded in PS at RT Insert: Excitation Wavelength

0.7

Fluorescein (2/15/10)

QDs in Toluene (2/15/10)

0.6

0.2

0.5

Excitation Wavelength = 472.7nm

0.4

0.3

0.2

0.1

0.0

0.0

300 350 400 450 500 550

W A V E L E N G T H (nm)

600

RT (toluene)

298.5 K; PS film

0 20 40 60

T I M E (ns)

80

Results/Discussion

• To further gain insight in this difference, QY’s of QDs in PS/Toluene solution measured as PS concentration increased

• Found:

– No change in emission decays for QDs in toluene upon adding 10% PS addition to solution

– Continuous decrease of QY as the weight by weight percent of PS increased

0.45

0.40

0.35

0.30

0.25

0

QY as a Function of PS Concentration

0.60

0.55

0.50

QD520 in Polystyrene/toluene solution

Laser photolysis data

Quantum yield was calculated by comparing the emission decays of the solution used in fluorimetry and PS liquid or solid solutions.

100 20 40 60

PS Concentration (w/w%)

80

•

Results/Discussion

emission decays of QDs in PS at 77 K and 298.1 K

• Comparing QY’s for QDs in Toluene and QDs in PS film as a function of temperature

• QY increases continuously as the temperature decreases for QDs in PS film

• DSC analysis did not show phase transition

• Different behavior observed for QDs in Toluene:

– QY constant, then decreases abruptly as temperature increases at approximately 250 K

– QY increases as temperature decreases at ~ 200 K

– Note melting point of toluene is -93

C (180 K)

Temperature Dependence of QY for QDs in

Toluene and QDs in PMMA

0.55

Melting Point:

180 K

0.50

0.45

0.40

0.35

0.30

0.25

50

QD's in toluene

QD's in PS

300 100 150 200

Temperature (K)

250

Conclusions

• Quantum yield of quantum dots in polymer films is lower than that of quantum dots in toluene (by about half)

• Faster emission decay for QDs in polymer film at RT than

77 K

• Study liquid to solid phase transitions QDs in polymer film from RT to 77 K

– QY of QDs in Polymer film increases as temperature decreases

– QY of QDs in Toluene decreases as temperature increases and around melting point, QY begins to increase as temperature decreases

• DSC analysis did not show phase transition