A High Quantum Efficiency Preserving Approach to Ligand

advertisement

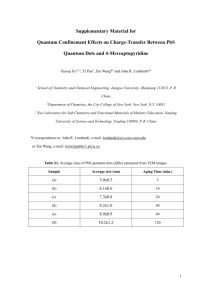

Micropatterning of Colloidal Quantum Dot Layers by Selective Wet Etching Chen Hu1,2,3,* , Tangi Aubert1, Yolanda Justo1, Stijn Flamee1, Alban Gassenq2,3, Gunther Roelkens2,3 , Zeger Hens1 1 Physics and Chemistry of Nanostructures, Ghent University, Krijgslaan 281-S3, 9000 Gent, Belgium 2 Photonics Research Group, INTEC Department, Ghent University-IMEC, Sint-Pietersnieuwstraat 41, 9000 Ghent, Belgium 3 Center for Nano- and Biophotonics (NB-Photonics), Ghent University, Belgium Abstract: Colloidal quantum dots (QDs) are new optoelectronic materials that raise interest in the photonics community. The hot injection chemical synthesis allows for a low-cost, precise and versatile production. By changing their size, the QD electrical and optical properties (absorption cut-off wavelength, luminescence wavelength) can be tuned due to quantum confinement. Furthermore, the fact that these QDs are available in solution allows for large-area heterogeneous integration on substrates, using dip coating or printing. This offers a considerable cost reduction compared to thermally evaporated or epitaxially grown layer stacks. However, the patterning of QDs remains a critical issue to achieve large scale device arrays. Here, we use PbS core and CdSe/CdS core/shell colloidal QDs to demonstrate a novel technique to form micro-patterns of QD layers. QD films are grown using a layer-by-layer approach where each cycle involves the deposition of a QD layer by dipcoating, the replacement of the native organic ligands by inorganic moieties, such as OH- and S2-, followed by a thorough cleaning of the resulting film. This results in a smooth, crack-free QD film on which a photoresist can be spun. The micro-patterns are defined by positive photoresist, followed by the removal of uncovered QDs by wet etching using an HCl/H3PO4 mixture. The resulting patterns can have feature dimensions down to 500 nm, limited by the resolution of the lithographic process and slight overetching. Key words: colloidal quantum dots, solid-state ligand exchange, micro-patterning * Corresponding author: chenhu@intec.ugent.be; gunther.roelkens@intec.ugent.be