Conclusion to Proposal on Lift Truck Safety Manual

advertisement

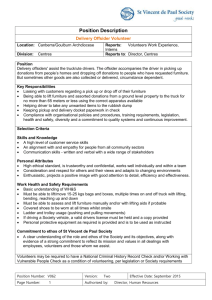

Proposal for Instruction Manual on Lift Truck Safety Prepared for The Home Depot Prepared by Edwin Ulloa 04/14/2013 Table of Contents Executive Summary………………………………………………....iii Introduction to Lift Truck Safety Manuaul………………………….1 Problems for The Home Depot……………………………………...1 Solution to Lift Truck Safety………………………………………..2 Qualifications for Lift Truck Safety Manual Making……………….3 Budget for Lift Truck Safety Manual………………………………..3 Conclusion to Proposal on Lift Truck Safety Manual……………….3 ii Executive Summary This letter is to propose a new Lift Truck Safety Manual for the company. I’m currently employed as a bilingual sales associate in Department 21. During my computer training, I was only told to complete the online training assessments, and the online training assessments for lift truck safety. Along with the online training, I completed the hands-on training to become certified to drive the lift trucks, but I was never given a hard-copy of the manual. I asked if we had a hard-copy and was told no. Therefore, I plan to create a manual because it makes it more efficient for associates to have a paper copy to read over, and then be tested on it once they’re ready for certification, along with the hands-on training. iii Introduction to Proposal on Lift Truck Safety Establishing this manual for the store will have some costs, but they will not be a lot. The only costs we will need to expect will be the print and binding of the manual, and to have a meeting with all of the associates seeking certification to present them with the manual. If you approve of this proposal, I can begin the manual April 15 and have it completed by April 29. Problems for The Home Depot The Home Depot has the following problems: Online Training Too Long No Hardcopy Simple Hands-On Training When The Home Depot associates are new hires we are required to take extensive online training. Sometimes the training has duration of multiple eight hour shifts. This is a problem because the associates become stressed due to the large amounts of hours they are required to take training. For example, the training for the lift trucks is broken down into a course overview, and then separate lessons for each lift truck. The overview itself lasts about three hours, and the separate lessons for each lift truck are each about an hour. Being in front of a computer for extraneous amounts of hours may lead to an employee Since The Home Depot requires their employees to take the majority of their training online, they aren’t provided with a hardcopy of a safety manual. Not having a tangible manual is a disadvantage to the associates because if they ever want to refresh their knowledge on some of the lift truck safety material, they need to be clocked in to access the training material on the computers. This means that the material cannot be reviewed in depth. For example, if an associate wanted to know what the “deadman pedal” does on a certain lift truck, the associate will need to either be scheduled to work, or request to come in to work to review the material. Having an employee review their knowledge while clocked in is a waste of payroll, and having to drive down to work to review their knowledge is an unnecessary waste of time and money for our employees. The hands-on training process to drive the lift trucks at The Home Depot is too simple. Once the employees pass all the online assessments the next step is to do hands-on training on the lift trucks. The hands-on training consists of simple tasks like identifying the parts on the lift truck, driving through a set of cones, and bringing down/putting up palletized/un-palletized merchandise. If the associate can perform those tasks, they are certified to drive the trucks that were trained on. This is a problem because the associate does not perform any of those tasks where customers are present. This means that the associates go out on the sales floor driving lift trucks without knowing how to properly maneuver the truck around customers. This can lead to lift truck accidents leading to potential injuries to the associate or a customer. 1 Solution to Lift Truck Safety My manual on Lift Truck Safety will help solve the following problems: Long Online Training No Hardcopy Simple Hands-On Training A hardcopy Lift Truck Safety Manual will be a benefit to The Home Depot because it will help the company save a lot of money and lives. No longer will the associates have to sit in front of a computer for long hours taking up company money. Instead they can read the hardcopy lift truck safety manual, and then test their knowledge with either a hand written or multiple choice tests. And the hands-on training will consists of more instore training so that The Home Depot can reduce the risks of receiving lawsuits over lift truck accidents. Having a hardcopy of the Lift Truck Safety Manual will allow for the company to prepare more safe lift truck drivers. Outline for Lift Truck Safety Manual Lift Truck Safety Course Overview o Lift Truck Training Overview o Lift Truck Safety Training Certification o Lift Truck License Visual Safety Inspection o Conducting a Visual Inspection o How to Handle and Change a Propane Tank o How to Properly Charge a Lift Truck Battery Know the Vehicle Controls o Operational Steps by Truck Sit-Down Forklift Reach Truck Order Picker Electric Pallet Jack Pacer Unit Assessment Preparation Hands-On Training o Proper Inspection of Vehicle o Drive to a Designated Area o Make a U-turn o Backing and Reversing o Loading/Unloading Techniques o Drive Safely Through Store o Proper Shut Down of Vehicle Certification 2 Work Plan for Lift Truck Safety Manual If you approve of this proposal, I will begin the Lift Truck Safety Manual on April 15, have the rough draft done by April 22, and have the final draft ready by April 29. The materials that will be used to make this manual will not be of great expense. The kind of paper that will be used is 100% Recycled Multipurpose Paper of 8.5x11in size. The manual will follow the layout of the outline provided above. Binding of will consists of Fellowes Plastic Comb Binding Spines, Black ¼” Diameter, with a 20 sheet capacity. Division of each section will be title pages, headings, and subheadings. Graphics for the manual will simply be software-made diagrams. Qualifications for Lift Truck Safety Manual Making I am currently a student at The University of North Texas and am enrolled in a technical communication class that has prepared me to write manuals like the one I am proposing. As an employee of The Home Depot, I have seen errors in the training of employees and know that they can be fixed through the making of a Lift Truck Safety Manual. I am also a certified safe lift truck driver at The Home Depot and am able to provide feedback on how to make training and certification of employees more efficient. Budget for Lift Truck Safety Manual Paper Binding Introduction Meeting Assessments Total 100% Recycled Multipurpose 8.5x11in Fellowes Plastic Comb Binding Spines ¼” Diameter 2hr Meeting to Introduce Manual 1hr Assessment before HandsOn Training $13.29/500 Pack $14.99/50 Pack Employee Hourly Income x2 Employee Hourly Income x1 ≈ $500.00 Conclusion to Proposal on Lift Truck Safety Manual Mr. Stacey, I think The Home Depot needs a tangible manual for employees seeking lift truck certification, and I hope you will agree. If you have any questions, feel free to email me at ulloa_edwin94@yahoo.com, or call me to my cell phone 832-456-8793. Thank you for taking the time to read this proposal. I look forward to further discussing this manual with you in depth. 3