Microsoft Dynamics AX 2012

®

The concept of routes, route

versions, and operations

Concept Paper

Microsoft Dynamics AX 2012 has an advanced concept of routes,

route versions, and operations for describing the production

process. This document explains how the main entities are

connected and provides recommendations about the route

setup.

August 2011

CCAX2012DI0051

Table of Contents

Overview..................................................................................................... 3

Conceptual data model................................................................................ 3

Operation ............................................................................................................................ 3

Route and route operation ..................................................................................................... 4

Simple network ................................................................................................................. 4

Complex network ............................................................................................................... 4

Operation relation ................................................................................................................. 5

Route version ....................................................................................................................... 5

Editing operation relations .......................................................................... 6

From an operation ................................................................................................................ 6

From a route ........................................................................................................................ 7

From a released product ........................................................................................................ 8

Avoiding duplicate routes ........................................................................... 9

No specific resource/group assignments .................................................................................. 9

Site-less routes .................................................................................................................... 9

Resource dependent process times ......................................................................................... 9

2

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Overview

Microsoft Dynamics AX 2012 has an advanced concept of routes, route versions and operations for

describing the production process. This document explains how the main entities are connected and

provides recommendations about the data setup.

Conceptual data model

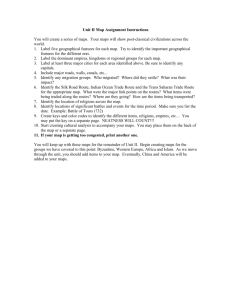

The conceptual data model for entities related to the routes can be seen in the diagram below. For

clarity only some of the primary attributes have been included.

Route version

3 Applicable for

Released product

Grouped by *

+Item number

1

*

0..1

*

+Fom date

+To date

+Dimension

+Approved

+Active

Applicable for4

1

1

0..1

Item group

+Group id

3 Item relation: Table

*

3 Item relation: Group

*

Operation relation

+Run time

+Formula

+Run time cost category

Route relation: Table4

*

0..1

1

Consists of

*

Applicable for

*

1

3 Described by

Operation

+Operation id

Route

+Route number

+Approved

1

Route operation

*

+Operation number

+Priority

0..1

Next operation

1

Operation

An operation is a discrete task or process connected with the production of a product. The operation

entity is base data and do not contain any other information than an Id and a simple description.

Typical operations from a machine shop could be:

Pipe cut

TIG Welding

Jig assembly

Inspection

3

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Route and route operation

The route is made up of a header and one or more operations. Each operation must be assigned a

number (10, 20, 30 etc.) and can be attached to other operations in a logical way to form a route

network that reflects the production process. We distinguish between two different kinds of networks.

Simple network

Operations are executed one after another and there is a single starting point for the route.

Complex network

There are multiple starting points for the route and some of the branches might be executed in

parallel.

Common for both of the above network types is that there can only be a single successor for a specific

operation and that there must be a single ending operation for the entire route.

For some operations there is a need for multiple resources at the same time. For example an

assembly operation might need a machine, a worker and a tool in order for the task to be performed.

This can be obtained using simultaneous operations, where one is the primary and all others are

secondary.

The primary operation is the one that represents a bottleneck and will limit the simultaneous

operations. The running time of these operations are always determined based on the primary

operation, and when scheduling with finite capacity only capacity for the primary operation is taken

into consideration.

4

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Operation relation

Operation relations streamline the task of creating and maintaining operation base data. Each relation

contains the information that is used by production orders when they are created or updated. This

includes the resource requirements, information about how to calculate consumption, cost categories,

measurement, times and overlap quantity that applies to the order.

An operation relation always applies to a specific operation. If the information that applies to the

operation is general and applies to all items and routes, only one relation for the operation needs to

be created. If individual relations are considered, several relations can be created for the same

operation regarding specific item number/item group, route number, configuration or site.

When the production order is created, the appropriate operation relations are identified based on the

product and the chosen route and information from the found relation is copied to the production

route.

Matching of the operation relations are always done from the most specific combination to the least

specific combination. With regards to the item this means that an operation relation which has the

specific item id set is preferred over the one which has the item group set which is again preferred

over the generic relation. The search is done in the following order:

1. Item code=Table and Item relation = <item Id>

2. Item code=Group and Item relation = <item group id>

3. Item code=All

4. Route code=Route and Route relation = <route id>

5. Route code=All

6. Configuration = <configuration id>

7. Configuration = blank

8. Site = <site id>

9. Site = blank

The way the matching is done effectively means that each operation Id like “Cutting” or “Drilling”

should only be used once for each route, otherwise the matched operation relation will always be the

same and can cause quite some confusion when editing the route.

Route version

The route version associates a specific released product with a specific route number. Route versions

are used to accommodate variations in the production of products or to provide greater control over

the production process. The production process for an item, and thereby the route, might vary

dependent on the following:

Product dimensions (Size, Color, Configuration)

Production quantity

Production site

Production date.

In order for the route version to be used in production it must first be approved. An approval indicates

that the route design has been completed and it is allowed to have multiple approved routes for the

same item and site. A route version can also be activated meaning it is the default route that will be

used when producing the item at a specific site. For an item/site/quantity/date combination there is

only allowed to be one active route.

5

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Editing operation relations

The operation relations is a very powerful concept, however there are certain pitfalls to be aware of

depending on the context in which the operation relation is being edited.

From an operation

Production control > Setup > Operations > Operation relations

Editing the Operation relation form from an operation is the easiest understandable way as this form

has no special automatic behavior but simply exposes the data directly from the table and lets the

user edit it.

In the example shown below a default operation relation has been created for the Drilling operation

that applies to all item and routes. Another relation has been created that applies to all items but only

for route 1003 and several relations that are specific to an item and route combination.

6

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

From a route

Production control > Common > Routes > All routes > Edit

When editing a specific route the route operations are shown in one grid and the operation relations

are shown in a separate grid. Only the operation relations that apply for the specific route context are

included in the view.

In the example below for route 7001, notice how the operation relation for the Drilling operation (see

previous example) that applies to only route 1003 is not included in the grid.

If a new record is inserted in the operation relation grid, the Route code field is automatically

defaulted to Route and the Route relation field is set to 7001, the value of the current route.

7

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

From a released product

Product information management > Common > Released products > Route

When opening the route from a released product the route versions that the product is used for are

shown in the top grid. The lower grid shows the route operations combined with the single best

matched operation relation per operation. This provides a very good overview of the runtime etc. that

will be applicable for the specific item and version without the need to navigate to a separate

operation relation form.

When editing e.g. the run time field on an existing line in the operation/relations grid, if the relation is

for the specific item and route then the record is simply saved. However if the operation relation was

for something less specific e.g. it was for All items and All routes, then upon save a copy will be made

of the original record and a new operations relations record specific for the item and route is inserted

behind the scenes. This ensures that the edit will only affect the current item and route.

One drawback of the form design with the combined operations and relations is that if the user adds a

new operation to a route that is used for more than the current item, then only the specific operation

relation will be created and the route is basically rendered unusable for other items.

8

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Avoiding duplicate routes

In order to avoid excessive data maintenance it is important to think about how the routes are created

in the system.

No specific resource/group assignments

In previous versions of Dynamics Ax and in many other systems it is required to specify in the route

which resource or resource group are going to perform an operation. In Dynamics Ax 2012 it is

instead possible to define a set of requirements that a resource must fulfill in order to be applicable for

the operation, and then defer the decision about the specific resource/group to use until the time of

scheduling. An example of such a requirement could be a resource of type “Machine” with a

“Stamping” capability of 20 tons. Simply stating these requirements instead of specifically binding the

operation to machine “Stamp42x” gives much more flexibility and eases the maintenance when

resources are moved or new resources are added.

Site-less routes

Larger production companies often have multiple sites that can produce the same products. In many

cases the process steps for making the product is the same and it is only the machines that will differ

by the location. If the previous advice of using more generic resource requirements is followed it will

be possible to reuse the same route across sites. If there are some small differences in run time or if

e.g. a setup time is needed just for a specific site, this can be handled by adding an additional

operation relation record with the Site field filled out and the specific values set.

If the same product is produced on two different sites but using different processes, the Site field on

the route version can be set to distinguish the two production methods.

To take full advantage of the site-less routes the Bills of Material (BOM) has an option called Resource

consumption. When using this option the warehouse and location that the raw materials are sourced

from do not have to be set upon design time but is instead determined based on which resource the

operation is scheduled on. This allows the BOM structure to also be site independent.

Resource dependent process times

When generic resource requirements are used it can often be a problem to specify the specific time it

takes to process an operation since the applicable resources might operate at different speeds. To

overcome this issue the Formula field on the operation relation offers multiple options for calculating

the process time:

Standard: (Default option) Uses only the fields from the operation relation and multiplies the

stated run time with the order quantity.

Capacity: Includes the Capacity field from the resource to make the time resource dependent.

The value stated on the resource is capacity per hour and will be multiplied by the Factor from the

operation relation and the order quantity.

Batch: Using fields from the operation relation a batch capacity is calculated and based on the

order quantity the number of batches and thereby the process time can be calculated.

Resource batch: Same as above, but the Batch capacity field from the resource is used to make

the time resource dependent.

9

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS

Microsoft Dynamics is a line of integrated, adaptable business management solutions that enables you and your

people to make business decisions with greater confidence. Microsoft Dynamics works like and with familiar

Microsoft software, automating and streamlining financial, customer relationship and supply chain processes in a

way that helps you drive business success.

U.S. and Canada Toll Free 1-888-477-7989

Worldwide +1-701-281-6500

www.microsoft.com/dynamics

This document is provided “as-is.” Information and views expressed in this document, including URL and other Internet Web site

references, may change without notice. You bear the risk of using it.

Some examples depicted herein are provided for illustration only and are fictitious. No real association or connection is intended or

should be inferred.

This document does not provide you with any legal rights to any intellectual property in any Microsoft product. You may copy and

use this document for your internal, reference purposes. You may modify this document for your internal, reference purposes.

© 2011 Microsoft Corporation. All rights reserved.

Microsoft, Microsoft Dynamics, and the Microsoft Dynamics logo are trademarks of the Microsoft group of companies.

All other trademarks are property of their respective owners.

10

THE CONCEPT OF ROUTES, ROUTE VERSIONS, AND OPERATIONS