Purchasing/procurement process

advertisement

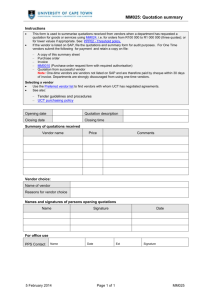

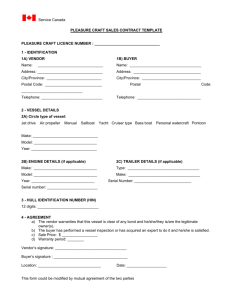

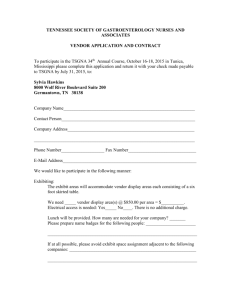

Purchasing/procurement process Step #1 Determination of Requirements • In this step, there is a requirement of material or service, which must be procured externally, from the user. • The requirement must be recorded as Purchase Requisition (PR)document in SAP MM. • Purchase Requisition (PR) is an internal purchasing document in SAP ERP that is used to give notification to responsible department about the requirement of material/service and to keep track of such requirement. • PR must contain clear information about the description and quantity of the material/service, the required date, and other information. • PR can be created directly in SAP MM module with ME51N t-code, or indirectly by another SAP component, such as: materials planning, maintenance order of PM module, production order of PP module, network activity of PS module, etc. • We have explained this in the previous article about MM integration with other modules. • We can set in SAP that the PR must be approved or released before it can be passed to the next step of purchasing processes. Step #2 Determination of the source of supply • After the PR has been created (and released if needed) in the previous step, the responsible department (usually purchasing/procurement department of the company) must process it. • The buyer of the procurement department must determine the possible sources of supply of the material/service specified in the PR. • With ME57 t-code, the buyer can check in the SAP whether the material/service needed can be obtained from the existing outline agreement (contract or scheduling agreement) documents or not. • If there is no existing outline agreement, the buyer can also check whether there is an existing info record documents (which contain information about the price and delivery conditions of the material/service agreed with vendor in the last Purchase Order/PO) that still can be used(valid) as a reference to create new PO to the same vendor. • If there is no valid info record at that time, the buyer can create Request For Quotation (RFQ) documents to one or some prospective vendors. • The buyer can access the procurement history of the material/service specified in the PR, so he can see which vendors that have provided it to the company before. • He can also create the RFQ to the new prospective vendor that might have never provided the material/service to the company before. • Request For Quotation (RFQ) is an external purchasing document that usually used as bidding process invitation. • RFQ is sent by a company to the prospective vendor to request the vendor to provide a quotation which contains information about the price and delivery conditions, terms of payment, etc that the vendor formally agree in case it is appointed to provide the material/service to the company. • In the RFQ, the buyer must include the information about the material/service needed from the vendors (can be copied from the PR), the latest submission date of the quotation, the preferred term of delivery, term of payment, currency, etc. Step #3 Vendor Selection • If in the previous step, there are some outline agreement or info record documents that can be used as references to create a PO, the buyer can select or choose which vendor that will be appointed to provide the material/service at this time. • If there is no outline agreement or info record documents that can be used as references to create PO, in the previous steps, the buyer will send the RFQ documents to one or some vendors. • The vendors will send their quotations which include the information about the price, delivery terms, terms of payment, etc that they offered to the company. • The buyer can input that information into SAP with ME47 t-code. • With ME49 t-code, the buyer can compare the offering of all vendors that have sent their quotation. • The comparison can be used to determine which vendor should be appointed to provide the material/service to the company. • SAP ERP can also create rejection letters to the vendors that are not selected as the supplier of the material/service. Step #4 PO Processing • In the previous step, the buyer has selected the vendor which will provide the material/service needed in PR. • In this step, the buyer creates a Purchase Order (PO) based on the PR and the reference document (that can be an outline agreement, an info record, or a quotation). • Purchase Order (PO) is a legally binding document that issued by a company to a vendor which contains information about description, quantity, delivery date, agreed prices, terms of delivery, and terms of payment for material or service the vendor will provide to the company. Step #5 PO Monitoring • After the PO has been sent to the vendor, the buyer has the responsibility to monitor whether the vendor delivers the material/service at the right time on the right place. • The buyer can monitor whether the material/service has been received by the person responsible (such as the warehouse man) online with PO history function in the PO document. • If the warehouse man or anyone else has received the material/service and posted the Goods Receipt/Service acceptance document, the PO history will be updated in a real-time basis. • SAP ERP can also has a functionality to give the reminder to the buyer if the PO item has not been GR in the specified period in respect of the delivery date agreed with vendors. Step #6 Goods Receipt • When the vendor delivers the material or perform the service, the responsible person of the company must perform the goods receipt (GR) or service acceptance (SA) transaction. • The GR/SA will update the PO history. • If the PO item is an inventory material, the GR will increase the stock level of the material. • When we perform the GR for the PO item for the first time, SAP will propose the quantity to be GR as the PO order quantity. • Depends on the delivery terms agreed with the vendor, the vendor might deliver the material partially. • We can post the GR partially too, so when the next material delivery is received, SAP will propose the quantity to be GR as the remaining quantity that has not been GR yet. Step #7 Invoice Verification • After the vendor delivered the material/service, it will send the invoice to the person responsible in the company. • Invoice is a formal document issued by a vendor to the company to request the payment for the material or service that the vendor has already provide to the company according to the terms of payment agreed in the PO. • An invoice is usually attached with the delivery note (goods receipt) document. • The person responsible, usually an accounting staff, will perform the three way matches. • He will check whether the invoice information (such as price, terms of payment, etc) is the same with the PO, and whether the PO item has been received (GR/SA). • If yes, then he will post the Invoice Receipt (IR) transaction in MM module. • The IR transaction will credit the account payable of the vendor which specified in the “pay to” partner function in the PO. Step #8 Payment Processing • After the IR transaction has been posted, the vendor’s account payable will increase and the company must process the payment to that vendor as stated in the terms of payment of the PO. • The payment transaction will be performed in FI module. • After the payment has been posted, the vendor’s account payable will be debited and the cash or bank account will be credited.