about 500 units of progressive die & injection mold ,2

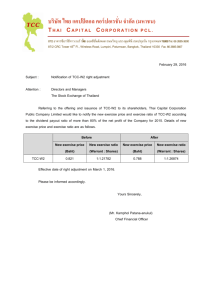

advertisement

Resume EDUCATION STATUS SCHOOL/UNIVERSITY PLACE CERTIFICATE 1. INSTITUTE OF TECHNOLOGY AND KHON KAEN VOCATIONAL VOCATIONAL EDUCATION (THAIAND DIPLOMA GERMAN) 2. KING MONGKUT’S INSTITUTE OF BANGKOK BACHELOR TECHNOLOGY NORTH BANGKOK DEGREE (THAI-GERMAN),(SPECIAL PROJECT: PRODUCTIVITY IMPROVEMENT IN YARN SPINNING FACTORY BY I.E. TECHNIC) 3. THE SANNO INSTITUTE OF BANGKOK DIPLOMA MANAGEMENT ORGANIZED BY TECHNOLOGY PROMOTION ASSOCIATION (THAILAND-JAPAN) 4.CHULALONGKORN UNIVERSITY BANGKOK MASTER (THESIS :SELECTION & DEGREE DEVELOPMENTS OF THE EXISTING PROGRESSIVE DIE FOR ELECTRICAL TERMINAL PRODUCTION BY VA/VE TECHNIC) WORKING EXPERIENCE COMPANY 1.PINEAPPLE CANNING INDUSTRY(THAI NATION),BY DIPLOMA DEGREE. 2.NATIONAL INSTITUTE LABOUR SKILL DEVELOPMENT , BY DIPLOMA DEGREE. 3.D.D.K. THAILAND LIMITED (第一 電子工業タイランド),(TEL.02- POSITION ASSISTANT ENGINEER FIELD G.P.A. FROM-TO AUTO MECHANICS 2.92/3.00 1982-1986 AND MECHANICAL TECHNOLOGY INDUSTRIAL 3.03 1988-1991 TECHNOLOGY (DURING IN PRODUCTION WORKING) TECHNOLOGY. MANUFACTURING MANAGEMENT.(4 COURSE OF THIS CURRICULUM) INDUSTRIAL ENGINEERING FROM-TO JAN.87-FEB.88 N.A. 3.31 OCT.1993MAY.1994( DURING WORKING) 19961999(DURI NG WORKING) DESCRIPTION MAINTENANCE, DRAWING & PART DESIGNING , ALL ASSISTANT TASKS. TECHNICAL MAR.90-JUNE.91 TEACH THEORY AND PRACTICAL TEACHER(GO (WHEN BACHELOR ABOUT MACHINING MECHANICAL VERNMENT DEGREE STUDYING) AND TECHNICS. OFFICER) PRESSING OR JULY.91-MAY.94 METAL PART MANUFACTURING AND STAMPING PROGRESSIVE DIE & PRESS MACHINE 5291428), START WORKING BY BACHELOR DEGREE. 4.TERMINAL LUGS CO.,LTD.(THAI NATION) (TEL. 02-4472333) 5.THAI MORITECH CO.,LTD.(タイモ リテック株式会社) (TEL. 035-350051-4 ) 6.THAI MORITECH CO.,LTD. THE PRESENT NAME IS PLASESS HITECH CO.,LTD(プラセスハイテック 株式会社) ENGINEER PREVENTIVE MANAGEMENT. PRODUCTION MAY.94 - APRIL 00 MANAGER (WHEN MASTER DEGREE STUDYING) PRESS OR APRIL 00 – APRIL03 STAMPING & ASSEMBLY ASSISTANT MANAGER. MOLD/PRESS APRIL 03 - MAY 04 ASSISTANT FACTORY MANAGER. ALL MANUFACTURING AND ENGINEERING MANAGEMENT OF METAL STAMPING FACTORY. ALL OF MANUFACTURING FUNCTIONS CONTROL (P.P.C, QA&QC, PRODUCTION AND MAINTENANCE).(BUSINESS UNIT MANAGER.) INJECTION MOLD DESIGN & MAKING AND PRESS OR STAMPING PARTS STAMPING DEPARTMENT.(BUSINESS UNIT MANAGER.) 7.MATSUSHITA ELECTRIC WORKS MOLD&DIE (THAILAND)LTD.(松下電工タイラン MAINTENANC ド) THE PRESENT NAME IS E MANAGER. PANASONIC ELECTRIC WORKS CO.,LTD.(TEL.02-5291671) 8.DAIPLA SYSTEC THAILAND CO.,LTD.( ダイプラシステックタイ ランド)(TEL.038-447066) 9.AAPICO HITECH PARTS CO.,LTD.(AHP FACTORY) (MALAYSIAN NATION) 10.THAI-NICHI INSTITUTE OF TECHNOLOGY(泰日工業大学) 11.SANSHIN HIGH TECHNOLOGY THAILAND LIMITED.(三進ハイテッ クタイランド株式会社) JAN 05 - APRIL 06 INJECTION MOLD & PRESS OR STAMPING DIE MAINTENANCE FOR PART OF ELECTRICAL RELAY MANUFACTURING. INJECTION JUNE 06 – JUNE 08. MOLD PRODUCTION MANAGER. PRODUCTION 4 JAN10 – 2 MAR10 MANAGER. ALL FUNCTION OF MOLD DIVISION WHICH COVER ALL MOLD DESIGN AND MANUFACTURING. SENIOR SPECIALIST ADVISE TO DIE MAINTENACE TECHNICIAN & ALL CONCERN PERSON IN STAMPING FACTORY. ALL FUNCTION OF AHP FACTORY MANAGEMENT.(FINE PART & AUTO PART STAMPING, ROBOT & SPOT WELDING AND DOOR CHECK MFG., PC&LOGISTIC). PRODUCTION 31 MAY10-20MAR11 INDUSTRIAL ENGINEERING ENGINEERING ,MOLD&DIE LECTURER TECHNOLOGY SUBJECT TEACHING INCLUDE COORDINATE BETWEEN THAI LECTURER AND JICA EXPERT. 1APR11 -31OCT11 JAPANESE LANGUAGE TRANSLATION. TRAINING BACKGROUND PLACE 1. POLICE OFFICE , KHON KAEN 2. NATIONAL INSTITUTE LABOUR SKILL DEVELOPMENT 3. D.D.K. JAPAN LIMITED.(日本の本社) 4. THE METAL WORKING AND MACHINERY INDUSTRIES DEVELOPMENT INSTITUTE 5. TECHNOLOGY PROMOTION ASSOCIATION (THAILAND-JAPAN) 6. TECHNOLOGY PROMOTION ASSOCIATION (THAILAND-JAPAN) 7. DUSITHANI HOTEL 8. THAI MORITECH CO.,LTD. 9. CENTRAL PARK HOTEL. 10. ISO/TS16949:2002 QUALITY SYSTEM REQUIREMENT. ITEM/SUBJECT NATIONAL DEFENCE TECHNICAL TEACHER PERIOD 3 DAYS 90 HRS. PROGRESSIVE DIE MAINTENANCE-DESIGN WASTE WATER TREATMENT AND MODERN ELECTRO PLATING 1 YEAR 3 DAYS SAFETY OFFICER MANAGEMENT LEVEL 12 HRS. COMPUTER AID PRODUCTION PLANNING AND CONTROL. SEMINAR ON ISO14000 FOR TOP MANAGEMENT LEADERSHIP AND EFFECTIVE TEAM BUILDING.(BY MR.TIERRASIT SINNSEANG) INDUSTRIAL COST REDUCTION.(BY JAPANESE OF COMMERCE) MATSUSHITA ELECTRIC WORKS,(THAILAND)LTD.(BY TOP MANAGEMENT CONSULTING THAILAND CO.,LTD.) 3 DAYS 2 DAYS 6-7MAY/2000 25SEP/2002 31MAR TO1APR/2005. OTHERS 1.STAMPING DIE MAINTENANCE AND RELATED ARTICLE WRITING THEN PUBLISHING AND ORGANIZING BY TECHNOLOGY PROMOTION ASSOCIATION(THAILAND-JAPAN)(TPA , 泰日経済技術振興協会・ソーソートー) AND THAI TOOL AND DIE INDUSTRY ASSOCIATION(TDIA , タイ金型工業会)MAGAZINE ALMOST EVERY ISSUE SINCE FROM 1993 UNTIL PRESENT. AND ALSO I HAD BEEN ANSWER ABOUT MOLD AND DIE TECHNICAL QUESTION IN WEBBOARD OF www.jeducation.com 2. DIES CORRECTIVE DESIGN, MAINTENANCE AND MACHINING BOOK WRITING THEN PUBLISHING AND ORGANIZING BY TPA(TECHNOLOGY PROMOTION ASSOCIATION ,THAILAND – JAPAN). 3. SHEET METAL STAMPING DIES BOOK CO-WRITING THEN PUBLISHING AND ORGANIZING BY TDIA(THAI TOOLS AND DIES INDUSTRY ASSOCIATION.) 4. “PRESS OR STAMPING DIE MAINTENANCE” COURSE LECTURER. 4.1 AT BUREAU OF SUPPORTING INDUSTRIES DEVELOPMENT ON 23 JANUARY 2003. 5. MOLD & DIE CLINIC CONSULTANT. 5.1 AT MUANGTONGTHANEE EXHIBITION HALL.ORGANIZING BY TDIA 2005. 5.2 AT BITEC EXHIBITION HALL IN INTERMOLD THAILAND SHOW JUNE 2006 ORGANIZING BY TDIA . 5.3 AT BITEC EXHIBITION HALL IN INTERMOLD THAILAND SHOW JUNE 2007 ORGANIZING BY TDIA. 5.4 AT BITEC EXHIBITION HALL IN INTERMOLD THAILAND SHOW JUNE 2008 ORGANIZING BY TDIA. 5.5 AT BITEC EXHIBITION HALL IN INTERMOLD THAILAND SHOW JUNE 2009 ORGANIZING BY TDIA. AND CONTINUE THIS ACTIVITY BOTH IN INTERMACH AND INTERMOLD THAILAND UNTIL PRESENT. 6. “METAL DIE MAINTENANCE” COURSE LECTURER. 6.1 AT BITEC EXHIBITION HALL IN THAI METALLEX SHOW WHICH ORGANIZING BY TDIA ON 19 NOVEMBER 2005. 6.2 AT COLLEGE OF INNOVATION THAMMASART UNIVERSITY, PATTAYA CAMPUS IN INTERMOLD THAILAND 2006 EASTERN SEABOARD ROADSHOW WHICH ORGANIZING BY REEDTRADEX ON 4 MAY 2006. 6.3 AT BITEC EXHIBITION HALL IN INTERMOLD THAILAND 2006 SHOW WHICH ORGANIZING BY TDIA ON 2 JUNE 2006. 6.4AT BUREAU OF SUPPORTING INDUSTRIES DEVELOPMENT ON 11 NOVEMBER 2006. 7. FOREIGN LANGUAGE EXAMINATION AND MY ABILITY ARE FOLLOWING. 7.1 I HAVE HAD ENGLISH LANGUAGE(TU – GET )EXAMINATION ON 1996 YEAR AND GOT 460 SCORE . 7.2 I JUST HAVE HAD JAPANESE LANGUAGE PROFICIENCY EXAMINATION AT FIRST TIME ON DECEMBER 7, 2008 AND GOT LEVEL 3 CERTIFICATION BY 258 FROM 400 SCORE. 8. OCCUPATION MEMBERSHIP ARE FOLLOWING. 8.1 THAILAND COUNCIL OF ENGINEER BY EXTRAORDINARY MEMBER NO. 51428 . 8.2 THE ENGINEERING INSTITUTE OF THAILAND UNDER H.M. THE KING ‘S PATRONAGE BY SENIOR MEMBER NO. 1/021028 . 8.3 THAI TOOL AND DIE INDUSTRY ASSOCIATION BY ORDINARY MEMBER NO. 561-2 . 8.4 TECHNOLOGY PROMOTION ASSOCIATION (THAILAND-JAPAN) BY PERMANENT ORDINARY MEMBER NO. 1930027 . 8.5 OLD JAPAN STUDENT’S ASSOCIATION , THAILAND.(OJSAT) (UNDER THE PATRONAGE OF HIS MAJESTY THE KING) 9. DONATION OF MINE FOR THAILAND RED-CROSS AND RELATED HOSPITAL ARE FOLLOWING . 9.1 MY ANATOMY(FOR MAHIDOL UNIVERSITY , ON OCTOBER 19, 1988) AND AN EYE (FOR THAI RED-CROSS ON JUNE 12, 1989 DOCUMENT NO. 128/1989). 9.2 “ B Rh positive “ BLOOD GROUP DONATION UNTIL JUNE 14, 2013 IS ACCUMUALTED AS THE 76 TIMES.(DONOR CARD NO. 110.25.00011.48) 10. MY FAMILY RELATIONS MOBILE PHONE NUMBER ARE FOLLOWING. 10.1 MY SISTER OR MY ELDER BROTHER IN LAW(MS.SUWIMOL , MR.LERPONG) TEL. NO. 081-6985116 , 074-356973 TO 4. 10.2 MY BROTHER OR MY ELDER SISTER IN LAW(MR.MONGKOL , MS.SOMMAI) TEL. NO. 081-5447680 , 081-6619708. DETAIL OF MY EXPERIENCE 1.AT D.D.K. THAILAND LTD. (第一電子工業タイランド)(FINE PITCH CONNECTOR MANUFACTURER) -ONE YEAR ON THE JOB TRAINNING AT D.D.K. JAPAN ABOUT PROGRESSIVE DIE DESIGN AND MAINTENANCE.AFTER THAT CAME TO THAILAND AND RESPONSIBILITY AS FOLLOWING. -ALL FUNCTION OF METAL PART STAMPING SECTION (ACTING AS SUPERVISOR & MY PRESSING ENGINEER POSITION) SUCH AS 30 UNITS OF PROGRESSIVE DIE CORRECTIVE AND PREVENTIVE MAINTENANCE,DAILY PRODUCTION PLANNING & CONTROL ,INITIAL QUALITY CONTROL BY INTERNAL SECTION,STAMPING OR PRODUCE PART BY 7 UNITS OF HIGH SPEED STAMPING PRESSING MACHINE. (500 SPM TO 1200 SPM BY KYORI AND YAMADA DOBBY M/C).DEPOSITRON MACHINE ,SURFACE GRINDING AND TURNING MACHINE EACH ONE. -COMPANY CUSTOMER ARE HEWLETT-PACKARD , HITACHI , NEC , TOSHIBA , EPSON , MATSUSHITA , IBM , FUJITSU , SONY , CANON , MITSUBISHI AND FUJIKURA. 2.AT TERMINAL LUGS CO., LTD.(ELECTRICAL CONNECTOR MANUFACTURER AND ALL PRODUCT SALE VIA SIRIRUNGROJ ENGINEERING COMPANY THAT IS A GROUP OF COMPANY ) -AT THIS COMPANY MY TITLE JOB IS PRODUCTION MANAGER THEN DAY WORKING AND MASTER DEGREE ON TWILIGHT ROUND LEARNING AT CHULALONGKORN UNIVERSITY. -ALL FUNCTION OF PRODUCTION DEPARTMENT SUCH AS PRODUCTION PLANNING & CONTROL,METAL PART STAMPING BY SINGLE ACTING DIE AND PROGRESSIVE DIE ,AUTOMATIC ASSEMBLY LINE,WELDING AND BRAZING ,PLATING,PACKING ,MACHINES & DIES PREVENTIVE MAINTENANCE,FACILITY MAINTENANCE,DIE DESIGN AND MAKING,AND WASTE WATER TREATMENT. -MANAGEMENT RESULT ARE MEET TO COMPANY PRODUCTION GOAL. -ABOUT 120 UNITS OF STAMPING DIE ,15 STAMPING MACHINE , SURFACE GRINDING , TURNING MACHINE EACH ONE , EACH 3 AUTOMATIC WELDING AND ASS’Y MACHINE , 1 UNIT OF PLATING MACHINE ,1 HEAT TREATMENT OVEN ,1 WASTE WATER TREATMENT UNIT AND 1 VACUUM SEALING MACHINE. 3.AT THAI MORITECH CO.,LTD. (タイモリテック株式会社) (METAL & PLASTIC PART MANUFACTURER) MY EXPERIENCE SEPARATE AS 2 STEPS. -AT FIRST TIME MY JOB TITLE IS PRESSING DEPT. & ASSEMBLY DEPT. ASSISTANT MANAGER THAT RESPONSIBILITY TO CONTROL BOTH DEPARTMENT BUT INTENSIVE TO PRESSING DEPT. BECAUSE OF SOME ASSEMBLY LINE HAD TRANSFERED TO CHINA PLANT. AT THIS COMPANY ALL DEPT. RESPONNSIBILITY IS PACKAGE MANAGEMENT STYLE.SO, MY RESPONSIBILITY ARE ORDER RECEIVE,PRODUCTION PLANNING & CONTROL,MACHINES AND ALL FACILITIES REPAIR AND MAINTENANCE(COMPANY HAS NO FACILITY MAINTENANCE DEPT.),SINGLE ACTING & PROGRESSIVE DIES REPAIR MAINTENANCE,PACKING,DELIVERY AND MATERIAL ORDER FROM DOMESTIC AND OVERSEA. -MANAGEMENT RESULT ARE ESTABLISHED ALL DOCUMENT AND PROCEDURE OF ALL SUB-SECTION THAT NEVER HAS ON THE DAY BEFORE, OVERCOME MINUS PROFIT BECAME AS PLUS PROFIT RESULT AND MOTIVATE SUBORDINATE TO DO KAIZEN ACTIVITY UNTIL RECEIVED COMPANY AWARD. -ON SECOND STEP BY LEVEL PROMOTION BECOME AS SECOND FACTORY ASSISTANT MANAGER POSITION.MY RESPONSIBILITY TO CONTROL PRESSING DEPT. & INJECTION MOLD DESIGN AND MAKING DEPT.FOR PRESSING DEPT. TASK STILL EXACTLY THE SAME AS PREVIOUS TIME .FOR NEW DEPT. TO BE CONTROL SINCE FROM CUSTOMER ORDER ,MOLD DESIGN,STANDARD MOLD COMPONENT ORDER,SPECIFIC PART MANUFACTURING,MOLD ASSEMBLY,INJECTION TRIAL,PLASTIC PART DIMENSION INSPECTION THEN SUBMIT TO CUSTOMER FOR APPROVAL BEFORE SALE THAT MOLD.AND ALSO MACHINES & FACILITY MAINTENANCE. (COMPANY HAS NO FACILITY MAINTENANCE DEPT.) -MANAGEMENT RESULT ARE ESTABLISHED ALL DOCUMENT AND PROCEDURE OF ALL SUB-SECTION THAT NEVER HAS ON THE DAY BEFORE ,INVESTIGATE CHEAT EMPLOYEE THEN GET RID OF THAT PERSON AND MOTIVATE SUBORDINATE TO DO KAIZEN ACTIVITY UNTIL RECEIVED COMPANY AWARD. -COMPANY CUSTOMER ARE CANON HI-TECH, OKI DATA MANUFACTURING ,NEC INFRONTIA ,TAKAHASHI KORAT ,TOKAI RIKA THAILAND,BANDO MANUFACTURING,THAI-NISCA , NSW THAILAND ,THAI SEAT BELT etc. -ABOUT 100 UNITS OF STAMPING DIE, 1 TIG WELDING MACHINE, 1 ULTRASONIC CLEANING M/C , 3 THREAD TAPPING M/C , 2 PROJECTION WELDING M/C AND 1 SURFACE GRINDING MACHINE FOR PRESSING DEPT. AND FOR MOLD DEPT. ARE CAD/CAM FOR MOLD DESIGN & MANUFACTURING ,1 HYDRAULIC PRESSING MACHINE, 2 SURFACE GRINDING MACHINE , HACK SAWING , RADIAL DRILLING ,MILLING , NC TURNING , MANUAL TURNING AND TRIAL INJECTION EACH 1 M/C, WIRE-EDM , EDM AND CNC MACHINING CENTER M/C EACH 3 M/C , 4.AT MATSUSHITA ELECTRIC WORKS LTD. (松下電工タイランド)/SINCE FROM FEBRUARY 2006 COMPANY NAME CHANGE BECOME AS PANASONIC ELECTRIC WORKS(THAILAND) CO.,LTD.(RELAY MANUFACTURING FACTORY) -AT THIS COMPANY MY JOB TITLE IS AUTOMATION CONTROL PART ENGINEERING MANAGER OF RELAY FACTORY THAT MEAN INTENSIVE PRECISION IN PLASTIC INJECTION MOLD AND METAL STAMPING DIE MAINTENANCE.(500 SETS UP) -MANAGEMENT RESULT ARE ESTABLISHED ALL DOCUMENT AND PROCEDURE OF THAT NEVER HAS ON THE DAY BEFORE ,INVESTIGATE CHEAT EMPLOYEE THEN GET RID OF THAT PERSON , MOLD AND DIE SPARE PART ORDER MONTHLY BUDGET CONTROL.(ASSIGNMENT IS 1 MILLION BAHT REDUCE FROM 4,500,000 BAHT TO 3,500,000 BAHT SINCE MARCH 2005 / HOWEVER, REALLY AVERAGE AMOUNT THAT PAID PER MONTH BEFORE I COME IS 5,632,928 BAHT) THEN ACTUAL RESULT IS AVERAGE FROM APRIL TO SEPTEMBER 2005 IS 4,044,541 BAHT , REDUCE TOTAL AMOUNT OF PARTS INVENTORY OR STOCK.(ASSIGNMENT IS 10%,TARGET TO REDUCE FROM 27.28 MILLION TO 24.80 MILLION) THEN UNTIL SEPTEMBER 2005 ACTUAL RESULT IS ABOUT 16 MILLION BECAUSE WE HAD MODIFY DEAD STOCK PART BE ABLE TO USE WITH PRESENT MOLD & DIE ,MODIFY DESIGN BOTH MOLD OR DIE AND SPARE PART , ELIMINATE LOW QUALITY SPARE PART MANUFACTURING SUPPLIER,UNIT PRICE COMPARISON AND PRICE NEGOTIATION FROM THE LOWEST QUOTED PRICE BY SAME LEAD TIME AND QUALITY) AND DRIVE TO MANUFACTURING DEPARTMENT TO ARRANGE OR SEIRI – SEITON N.G. PART THAT OCCURRED AND ACCUMULATED FOR LONG TIME MORE THAN 1 YEAR.(THIS BAD MANAGEMENT METHOD I NEVER FOUND WHEN WORKING WITH OTHERS COMPANY.) - ABOUT 500 UNITS OF PROGRESSIVE DIE & INJECTION MOLD ,2 SURFACE GRINDING M/C , 1 DEPOSITRON WELDING M/C, 1 ULTRASONIC CLEANING M/C 5.AT DAIPLA SYSTEC THAILAND CO.,LTD. ( ダイプラシステックタイランド) -AT THIS COMPANY MY TITLE JOB IS MOLD PRODUCTION MANAGER OF MOLD DIVISION THAT CONCERN WITH ALL TASK SINCE FROM PART OR PRODUCT DRAWING RECEIVE , MOLD DESIGN & MANUFACTURING ‘s QUOTATION ISSUING, MOLD AND MOLD PARTS DESIGN AND MANUFACTURING ,ASSEMBLING, TRIAL, THEN OUTPUT PLASTIC TRIAL SAMPLE PART DIMENSION MEASURING AND TUNING UNTIL OUR CUSTOMER ACCEPTANCE THAT MOLD. - MANAGEMENT RESULT ARE ESTABLISHED ALL DOCUMENT AND PROCEDURE THEN DRIVING MOLD DIVISION ISO9000:2001 QUALITY SYSTEM SINCE FROM START WORKING ON 28 JUNE 06 THEN ACHIEVED AND GOT THE CERTIFICATE OF DESIGN AND MANUFACTURING OF MOULD ON 11 NOVEMBER 06 , AND ALSO DRIVING ,CONTROLLING AND MANAGING UNTIL SALES AMOUNT MEET TO COMPANY TARGET( 2006 YEAR TARGET :27.5 MILLION BAHT / ACTUAL : 28.2 MILLION BAHT AND 2007 YEAR TARGET :50 MILLION BAHT / ACTUAL :52.6 MILLION BAHT) AND INCREASE SALES VOLUME OR SALES AMOUNT AS AROUND 2 TIMES ON 2007 YEAR(52.6 MILLION BAHT) WHEN COMPARE WITH AMOUNT OF 2006 YEAR(28.2 MILLION BAHT). ALTHOUGH ALL OF MANUFACTURING FACTORS NEARLY THE SAME ( ESPECIALLY MACHINE QUANTITY ARE SAME AS 2006 YEAR). -COMPANY CUSTOMER ARE NILES THAILAND , CALSONIC KANSEI , MITSUI SIAM COMPONENT , TOKAI RIKA, TOACS , TOSTEM, DAIWA KASEI ,ALPHA THAILAND ,THAI STARLITE , etc. -HARDWARE AND SOFTWARE ARE CAD/CAM FOR MOLD DESIGN & MANUFACTURING , 2 SURFACE GRINDING MACHINE , HACK SAWING , RADIAL DRILLING ,MILLING , MANUAL TURNING AND TRIAL INJECTION EACH 1 M/C, WIRE-EDM , EDM EACH 2 M/C AND 3 CNC MACHINING CENTER M/C. 6. AT AAPICO HITECH PARTS COMPANY -ALL FUNCTIONS OF AUTOMOBILE PART FACTORY THAT CONSIST OF PRECISION STAMPING PART DEPT. FOR HARD DISK DRIVE INSUSTRY , METAL STAMPING PART DEPT. , MANUAL AND ROBOTIC WELDING DEPT. , SPOT WELDING DEPT. AND DOOR CHECK PART FOR AUTOMOBILE INDUSTRY. -PRODUCTION PLANNING AND LOGISTIC CONTROLLING -CONSIST OF AUTOMOTIVE PARTS 5 STAMPING LINE(3 TRANSFER PRESS LINE, 1 TANDEM PRESS LINE AND 1 SINGLE ACTING & PROGRESSIVE PRESS LINE), HARD DISK DRIVE PARTS ONE STAMPING LINE, 3 UNITS OF ROBOTIC WELDING MACHINE AND ETC. 7.AT SANSHIN HIGH TECHNOLOGY(THAILAND) LTD. (三進ハイテックタイランド株式会社) - ALL FUNCTIONS OF JAPANESE INTERPRETER , ALL AROUND 500 SETS OF METAL STAMPING DIES PM. MANAGEMENT , COORDINATOR WITH ALL INTERNAL SECTIONS , ADVICE AND CONSULT FOR IMPROVE ALL ABILITY OF FACTORY.