siloweigh - Enviromark

advertisement

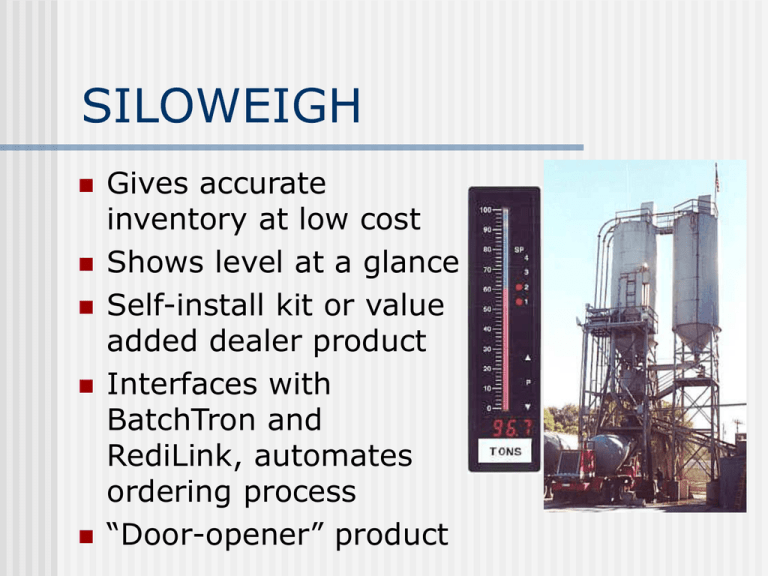

SILOWEIGH Gives accurate inventory at low cost Shows level at a glance Self-install kit or value added dealer product Interfaces with BatchTron and RediLink, automates ordering process “Door-opener” product PRINCIPLE OF OPERATION Weldable strain gauges on front and back of leg More accurate, less costly than bolt-on sensors (Kistler Morse etc.) Can use 2 or 4 legs OK for 6 or more legs H-beam, O-beam, L-beam or square section legs Must have at least 1500 psi stress in leg Minimize temperature changes for best accuracy HOW IT’S DONE Choose the location on leg Grind surface until smooth Drill cover mounting holes Weld gauges to leg Test gauges and connect All gauges daisy-chained from leg to leg and to bar graph indicator Seal gauges and fit cover Seal cover Test and calibrate All materials supplied in kit DEALER INSTALLATIONS Requires special installation tool (welder) which can be rented Better to purchase welder if intending to do many installations Keep spare bar graph indicators and train personnel Charge for installation – one man day per silo, gives extra income INDICATOR FEATURES Bar graph and digital display reads in tons and tenths Optional 4 setpoint relays for alarm indication Optional isolated 4-20mA or 0-10 volt analog output Up to 5 indicators in same SiloWeigh cabinet Simple programming/calibration Plug-in boards make replacement easy Does not need empty silo for calibration ALTERNATIVE INDICATORS Analog transmitter in place of bar-graph will interface with batching controllers, PLCs Digital transmitters also available Do not use weight indicators reading in lb or kg. This is too fine – normal drift appears much worse with small graduations IMPROVEMENTS Calibration “block” on input changes less than 1.3 mV removed in 2003, allowing 1-truck calibration on all silo sizes Interface to BatchTron/RediLink Updated manual available online New model SiloWeigh.Net displays silos on PC computers in local network Internet database stores silo data for whole company, allowing automatic reordering and truck fleet management OTHER APPLICATIONS Grain – corn, wheat, rice etc. Animal feed mills Breweries Bakeries and food Plastics, chemicals Liquid tanks Mines, refining Asphalt storage Instead of vertical legs, use cross beams in interconnected frames (consult us) Do not use for trade Do not use for batching, bag filling or truck loading – not enough accuracy OPPORTUNITIES Across the world, SiloWeigh has a unique niche in the market. It has the highest accuracy at a modest cost; lower than load cells. This plant in Korea is a typical example. All concrete plants in Korea use some type of silo indicator. Our dealer, Taeshin, makes concrete plants. These new silos are 500, 200 and 300 metric tons, fitted with SiloWeigh.