Supply Chain Management Performance & Consulting

advertisement

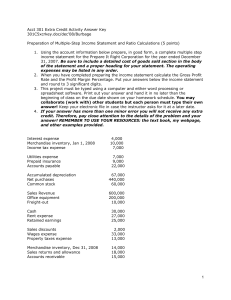

Mayo Clinic Supply Chain Management Performance Consulting Team Presented by: Carmel Porter, Senior Analyst Supply Chain Management Performance Consulting ©2012 MFMER | slide-1 Mayo Clinic: Group Practices in Rochester, Florida, and Arizona and the Mayo Clinic Health System ROCHESTER FLORIDA ARIZONA ©2012 MFMER | slide-2 Mayo Clinic Organizational and Cultural Factors • Mayo is a physician led organization. There is a clinical voice in decisions. • Physician/administrators/allied health are on salary (no bonuses on production or financial performance). • Financial targets are developed by physician and administrative leaders. • There is a strong alignment of mission and goals including financial performance and supply expense management. ©2012 MFMER | slide-3 Mayo Clinic Organizational and Cultural Factors Mayo’s Mission • To inspire hope and contribute to health and well-being by providing the best care to every patient through integrated clinical practice, education and research. Mayo’s Primary Value • The needs of the patient come first. ©2012 MFMER | slide-4 Mayo Clinic Supply Chain Management How is the supply chain organized? Customer Service Communication Opportunity Identification Issue Resolution Product Recall Product Standardization & Utilization Sourcing & Contracting Value Analysis Sourcing Dept. Resources Team Co-Lead Testing / Trials RFP / RFQ Best Practice Negotiations New Technologies Approvals Issue Resolution Contract Administration Procurement Filing Requisitioning Analysis Procurement Rebate Collection Transactions Ongoing Management Disbursements Accounts Payable Reimbursements Travel Management. Inventory Management Storage Inventory Picking Staging Logistics Shipping Receiving Stocking Replenishment SCM Performance Consulting • • • We provide consultative integration between all Supply Chain operations to offer a consolidated solution for our customers. We develop and maintain financial reporting tools and metrics to assess customer supply and service expense performance and confirm progress toward set goals. We initiate and facilitate operational process improvements to control supply and service expense and increase the value of services delivered to Mayo patients. Supply Chain Management Enterprise Responsibility Site Based Supply Chain Operations Responsibility ©2012 MFMER | slide-5 Mayo Clinic Supply Chain Management Performance Consulting Team History • Formed 10 years ago as Materials Management Financial Analysis • Address identified need for better supply & service management • Since formation, customer support as well as breadth of roles and responsibilities has expanded ©2012 MFMER | slide-6 Performance Consulting Team Guiding Principles Mission Mayo Supply Chain Performance Consulting develops and implements strategies to drive improvements in Supply Expense Management. The Performance Consulting Team will provide coordination and delivery of Mayo Supply Chain solutions in order to attain specific and measurable quality and cost outcomes for our customers. Vision Provide world class supply chain analysis and consultative support for all aspects of the supply chain process, by focusing on analytics, auditable controls, and optimization through the utilization of an integrated support team. Purpose Performance Consulting is the process by which we can work with Physicians, Administrative Leadership and others to identify and achieve performance excellence linked to the expense reduction goals of Mayo. ©2012 MFMER | slide-7 Performance Consulting Team Objectives • Commit to consistent and active participation to enable enterprise-wide collaboration, decision-making, implementation and compliance • Establish a framework to share best practices, process improvements, patient safety, compliance and risk reduction • Optimize the standardization of products/devices and develop the creation of a supply formulary for departments across the enterprise • Reduce the acquisition cost of products and devices and increase overall value • Assess, monitor and manage variation among clinicians on a cost/case or procedural basis ©2012 MFMER | slide-8 Performance Consulting Team Objectives • Provide Support of Mayo Clinic contracting philosophy and process - Monitor on/off contract spend and correct to ensure compliance - Analysis and support -make versus buy decisions • Manage assessment and availability of new products/devices • Manage and analyze non-labor spend versus plan or budget ©2012 MFMER | slide-9 Performance Consulting Role and Continuum of Services Inventory Supply Chain Technology Measurements Customer Service Analytical Support Performance Clinical Patient Consulting Practice Care Process Standardization Utilization Expense Management • • • • Supply Chain Consultation / Customer Integration Metrics Development Analytical Support Project Management ©2012 MFMER | slide-10 Performance Consulting Services: Supply Chain Consultation / Customer Integration • Act as liaison to high-spend specialty practice areas • Assist with contract communications and optimization • Perform analysis to support specific supply & service management initiatives • Develop dashboards and reports • Provide analytical and facilitation support to Supply & Technology Teams and Specialty Councils • Educate on Supply Chain Policies and Procedures ©2012 MFMER | slide-11 Integrated Team Coordination Supply Chain Management Integrated Department Support Office of Expense Management (Specialty Councils) Focus What are customer dept goals? What are the key performance metrics? How do we coordinate supply chain optimization plan? ( Projects, Technology, Contracting) Departmental Customer Service Needs Is SCM delivering intended results? Department New Technology Assessment Meetings Purpose: Coordinate support of SCM projects and Specialty Councils, including plan development, resources, timeline, and roles and responsibilities. Deliverables: Align SCM teams and support activities associated with the SCM Strategic Plan, Projects and Specialty Councils on an ongoing basis Tools: Standard Work Plan Standard Tracking Tools Standard Measurements of Success Project plans where appropriate Agenda with standing items Direct support of high-spend specialty practice departments and nonlabor services: Surgery Information Technology Radiology Capital Equipment Service and CV Maintenance GI Purchased Services Lab Team covers approximately 51% of Patient Care supply and service spend ©2012 MFMER | slide-12 Integrated Processes • Clinical Practice Committee • Specialty Councils • Standardized Analytics • Manage To Reimbursement Councils • Contract Management • Supply and Technology Teams • Inventory Management Integrated Structures ©2012 MFMER | slide-14 Committee Participation New Product / Technology Committees • • • • Financial analysis comparing products & equipment Contract review of current & new Case cost impact SCM consultation on best business opportunity Department / Finance Committees • Presentation of metrics • Strategies around supply expense • Coordination of finance and department activities Operational Supply Committees • Coordination of operational activities • Inventory management best practices • Hot topic forum ©2012 MFMER | slide-15 Supply and Technology Teams • • • • • • Physician Led Manages new technology and supplies Standardization of current supplies Supports product conversions Supports the Enterprise Value Analysis Process Membership includes: • Supply Chain Management • Procedural Areas • Sourcing & Contracting • Revenue Cycle • Finance Supply and Technology Team Guidelines • Must reduce net episode of care costs • Must replace an existing product • Must improve patient care by a measurable degree • Must fill a critical need for which there is no substitute • Validation of claims • Saves time • Reduces LOS • Data driven New Product / Technology Committees Process Flow Example - Surgery Request from Physician/Manager to add or evaluate product. Physician or Manager complete NPR (New Product Request) form with detailed information Surgery & SCM team confirms pricing detail and contractual relationships (negotiates as required) & completes financial impact analysis for committee review Coordination occurs with other areas which may be impacted by the request (e.g. clinical areas, IT interfaces, etc.) Committee review and decision is communicated to the Surgical practice and appropriate implementation as required ©2012 MFMER | slide-18 Specialty Councils Support • DLMP • Specialty Council Support: Laboratory Medicine Specialty Council • Subgroup: Enterprise Laboratory Medicine Supply Chain Leadership Team (LMSLT) • Surgery • Specialty Council Support: Enterprise Surgical and Procedural Committee • Subgroup: Surgical/Supply Chain Sub-Committee • Radiology • Specialty Council Support: Enterprise Radiology Specialty Council • Subgroup: Enterprise Radiology Equipment Supplies & Contracts Subcommittee (ESCS) • CV • Specialty Council Support: CV Specialty Council • Subgroup: Enterprise CV Supply and Equipment Subcommittee • GI • Specialty Council Support: GI Specialty Council • Subgroup: Enterprise GI Supply and Technology Team (GISTT) ©2012 MFMER | slide-19 Specialty Council Support Enterprise Supply Dashboard (Sample) Specialty Department A Comparison of Supply Indicators by Site Year-To-Date 2013 Dollars reported in millions March 2013 Minnesota YTD '12 YTD '13 Florida % Diff YTD '12 YTD '13 Arizona % Diff YTD '12 YTD '13 MCHS - NW WI % Diff YTD '12 YTD '13 % Diff NET OPERATING INCOME 47.35 49.92 5% 9.65 11.58 20% 14.05 13.76 -2% 13.25 11.14 -16% SUPPLY EXPENSE $ Medical Supplies (disposables) Non-Medical Supplies** Procurement Adjustments 4.66 0.55 (0.03) 4.98 0.47 0.02 7% -15% -150% 2.82 0.07 (0.00) 2.39 0.14 0.00 -15% 110% -106% 1.76 0.26 - 1.65 0.15 - -7% -43% 0% 1.40 0.06 - 1.56 0.19 - 12% 251% 0% 1.80 -11% 1.76 21% 0.11 -15% 0.02 0.17 960% 11% 19% Supply Expense $ **Minor Equip & Repairs (6113) (part of non-med supplies) 5.18 $ 0.39 EXPENSE (Efficiency) INDICATORS Med Supply Exp/GMSR Med Supply Exp/NMSR Med Suppy Exp/ Tech RVU Equip Support/Tech RVU 5.47 6% 0.31 -19% $ 2.88 $ 0.02 2.53 -12% 0.11 497% $ 2.03 $ 0.13 $ 1.46 $ 2.5% 3.9% $5.40 $2.65 2.6% 4.0% $5.92 $3.02 4% 2% 10% 14% 4.2% 9.1% $7.37 $2.94 3.5% 7.3% $6.36 $3.20 -17% -20% -14% 9% 2.9% 5.3% $6.11 $3.75 2.9% 5.0% $6.10 $4.38 0% -5% 0% 17% 2.7% 5.1% N/A N/A 3.0% 6.1% N/A N/A CONTRACTING INDICATORS Contract Utilization * 73.0% 76.2% 3.2% 77.5% 74.1% -3.4% 67.2% 77.6% 10.4% 77.4% 73.4% -4.0% EQUIPMENT SUPPORT Equipment Purch Maint Equipment Rental Expense Outsourcing Fees Equipment Repairs Other Purch Services $ 1.31 0.26 0.04 0.29 $ 1.47 0.15 0.07 0.53 12% 0% -40% 66% 80% $ 0.79 0.00 0.00 0.31 $ 0.91 0.02 0.01 0.15 14% 0% 1775% 163% -51% $ 0.74 0.03 0.10 0.09 $ 0.81 0.02 0.05 0.19 8% 0% -10% -47% 116% $ 0.46 0.37 0.16 0.92 $ 0.67 0.30 0.03 1.00 47% 0% -20% -82% 8% Purchased Services Expense $ 1.91 $ 2.23 17% $ 1.11 $ 1.09 -2% $ 0.96 $ 1.08 13% $ 1.92 $ 2.00 4% $ 0.39 2.29 $ 0.31 2.54 -19% 11% $ 0.02 1.13 $ 0.11 1.20 497% 7% $ 0.13 1.08 $ 0.11 1.18 -15% 9% $ 0.02 1.93 $ 0.17 2.17 960% 12% Minor Equipment Total Equipment Support N/A N/A EXECUTIVE SUMMARY Specialty Department A's supply expense through March was $11.5 million. This was an increase of $7k or 0% over last year. ©2012 MFMER | slide-20 Specialty Council Support – Work Plan • SCMPC coordinates regular updates of projects by Specialty. • Work Plan includes: • Initiative Name • Status • Impacted Sites • Primary Department • Initiative Type (contracting, utilization, etc.) • Key Contacts ©2012 MFMER | slide-21 Managing to Reimbursement Examples ©2012 MFMER | slide-22 MTR ©2012 MFMER | slide-23 Performance Consulting Services: Metrics Development • SCMPC provides customers with actionable financial metrics relating to supply expense and inventory management. ©2012 MFMER | slide-24 Collaborating on Strategy Performance Consulting Monitoring Stage Metrics Dashboards / Executive Leadership Updates All data contained in the following exhibits is for presentation purposes only and is not an indicator of actual financial or operational performance. Enterprise Supply Expense Monthly and YTD Supply Expense $12,000,000 $140,000,000 $120,000,000 $10,000,000 $100,000,000 $80,000,000 YTD Monthly $8,000,000 $6,000,000 $60,000,000 $4,000,000 $40,000,000 $2,000,000 $20,000,000 $- $0 Jan Feb March April May June July Aug Supply Expense 2010 Month Supply Expense 2009 YTD Supply Expense 2010 YTD Supply Expense 2009 • Compares monthly and year to date supply expense on a year to year basis Sept Oct Nov Dec 2010 Plan • Used to identify significant changes in supply expense requiring more detailed investigation Supply Expense Per Volume Supply Expense Comparison Chart Supply Expense per Volume % Supply Expense per Net Revenue Plan % Supply Expense per Net Revenue $6 25% $6 20% $5 $5 15% $5 $5 10% $5 $4 5% % Supply Expense per Net Revenue Supply Expense per Billable Volume $6 $4 $4 0% Dec-09 Jan-10 Feb-10 Mar-10 Apr-10 May-10 Jun-10 • Looks at supply expense per volume or as a percentage of revenue Jul-10 Aug-10 Sep-10 Oct-10 Nov-10 Dec-10 • Used to determine if supply expense is in proportion to volume and/or revenue Supplies as a % of Controllable Spending Supplies Expense as % of Direct Expense 30% 25% 20% 15% 10% 5% 0% Jan Feb Mar 2009 Month Apr May Jun 2010 Month • Looks at percentage of direct expense made up by supply expense Jul Aug 2009 YTD Sep Oct Nov Dec 2010 YTD • Used to identify significant changes in direct expense due to supplies Supplies and Services by Category SUPPLIES AND SERVICES EXPENSES (in millions) As of December 31, 2010 YTD Dec 2009 YTD Dec 2010 Change % Change (2010 - 2009) (2010 - 2009) $ $ $ $ $ 336.3 79.9 32.1 26.3 474.7 $ $ $ $ $ 322.8 90.8 35.5 29.2 478.3 $ $ $ $ $ (13) 11 3 3 3.5 -4% 14% 10% 11% 1% Contracted / Purchased Services Maintenance Contracts Contract Labor Insurance Sub Total $ $ $ $ $ 77.8 38.6 29.1 22.6 168.1 $ $ $ $ $ 77.8 40.9 33.0 29.1 180.8 $ $ $ $ $ (0) 2 4 7 12.7 0% 6% 13% 29% 8% Supplies and Services Total $ 642.8 $ 659.1 $ 16.3 2.5% Line SUPPLIES 1 2 3 4 Medical & Department Supplies Implants and Prostheses Organ Procurement Costs Minor Equipment Sub Total SERVICES 5 6 7 8 Performance Consulting Drill Down Metrics Departmental / Operating Unit Updates All data contained in the following exhibits is for presentation purposes only and is not an indicator of actual financial or operational performance. Supply Expense by Department Pharmacy 22% DOM 10% Other 27% Radiology 5% Surgery 18% Lab 18% SCMPC supports the Department of Medicine, Radiology, Surgery and Lab across the three sites, which comprises 51% of patient care supply expense Departmental Trending Supply Expense by Department Department YTD 2009 YTD 2010 $ Chg % Chg Lab $20.0 $22.0 $2.0 10.0% Surgery $16.0 $17.0 $1.0 6.3% Dept of Medicine $7.0 $8.0 $1.0 14.3% Radiology $5.0 $5.0 $0.0 0.0% $48.0 $52.0 $4.0 8.3% Total Patient Care Supplies Other Relevant Supply Ratios − Net Medical Service Revenue (NMSR) − Patient Care Supplies as a % of NMSR − Gross Medical Service Revenue (GMSR) − Patient Care Supplies as a % of GMSR − Total Operating Expense (TOE) − Patient Cares Supplies as a % of TOE Performance Consulting Operational Metrics Opportunity Analysis All data contained in the following exhibits is for presentation purposes only and is not an indicator of actual financial or operational performance. Item number Utilization and Contract Compliance Item Number Utilization and Contract Coverage 120% 100% 83% 80% 69% 84% 75% 92% 92% 94% 95% 94% 87% 86% 83% 82% 84% 100% 90% 92% 82% 60% 43% 30% Mar-10 40% 36% 27% 27% Jan-10 40% 20% % of $s with Mayo Item Nbrs Dec-10 Nov-10 Oct-10 Sep-10 Aug-10 Jul-10 Jun-10 May-10 Apr-10 Feb-10 0% % of $ on Contract • Used to identify contracting • Looks at percentage of supply opportunities dollars tied to a contract or using a Mayo item number Contract Compliance by Vendor Top Ten Vendor Spend Vendor Dec 2010 Mayo Contract Yes No Total VENDOR 1 $ 114,473 $ 11,067 $ 125,540 VENDOR 2 $ 55,943 $ 21,623 $ 77,565 VENDOR 3 $ 68,288 $ 4,614 $ 72,902 VENDOR 4 $ 41,655 $ - $ 41,655 VENDOR 5 $ 40,034 $ 280 $ 40,314 VENDOR 6 $ 26,139 $ 2,055 $ 28,194 $ 12,606 $ 12,606 $ 8,436 VENDOR 7 VENDOR 8 $ 8,436 VENDOR 9 $ 4,670 $ 4,670 VENDOR 10 $ 4,439 $ 140 $ 4,579 Grand Total $ 359,406 $ 57,055 $ 416,461 • Shows vendor spend on and off contract • Used to identify potential contract compliance issues Physician Variation/Standardization Case Cost Analysis • Identify standardization opportunities between physicians, procedures, and sites • Efficiencies in case costs and item utilization • Benchmark against other Mayo sites All data contained above is for presentation purposes only and is not an indicator of actual performance. Physician Variation/ Standardization Item Expense Analysis • Identify deviations between physicians • Support compliance with existing contracts • Actionable items for practice / physicians All data contained above is for presentation purposes only and is not an indicator of actual performance. Example of Customer Opportunity Analysis (Reprocessing) All data contained above is for presentation purposes only and is not an indicator of actual performance. Performance Consulting Services: Analytical Support Customized Solutions and Tools for: • Inventory Policies, Procedures, & Controls • Process Flows • Customer New Product and Technology Committees • Application of Economic Order Quantity (EOQ) • Lease vs. Buy Analysis • Opportunity Analysis for Supplies & Services (i.e. Reprocessing, Sequestering, Service Agreements Analysis) • Vendor Managed Inventory & Sequestering • Product Management (i.e. product utilization and standardization) Tool Development Principles • Reusable – build once, use multiple times • Automated – minimize manual effort • Targeted – built to serve a specific purpose • Simple – maximize clarity and ease of use • Actionable – provides direction, not just information • Standard – propagate enterprise wide ©2012 MFMER | slide-41 Performance Consulting Toolbox Expense Management Supply/Service Data Mining & Analysis • Expense Target Support Model • AP Database • Department Dashboard • Office Supplies Database • Lab Expense Reduction Resources • Supply Chain Analytics Tools Budgeting and Forecasting Standardization/Utilization of Supplies • Top Level Executive Reporting Package • “Best Value” Product Matrix • Where’s the Money? • Supply & Equipment Redistribution Website • Supplies and Services Budget Impact Forecast Model • Contract Optimization Summary • SCM Staffing Level Analysis Internal Controls • SCM Expense Forecast Model • Segregation of Duties Matrix • Value/Initiative Tracking • Inventory Reserve Inventory Optimization • Velocity Evaluation Tool (iVET) • Stocking Level Optimization Tool (iSLOT) ©2012 MFMER | slide-42 Operational Support – Inventory Management • SCMPC has developed and continues to develop a variety of tools to assist their customers with successful inventory management in order to reduce and avoid: • Excess inventory • Increased carrying costs • Insufficient inventory/stock outs • Obsolete inventory • Wasted inventory • Inaccurate supply on hand • Inventory adjustments Operational Support – Inventory Management • SCMPC tools for successful inventory management include, but are not limited to: • Use of available inventory systems – manual or automated • Development of inventory management policies and procedures • Inventory analysis including optimal inventory level setting via use of the Economic Re-order quantity (EOQ) technique • Metric to control and maintain optimal levels Inventory Metrics • Compares inventory value over time Inventory Value in Millions $4.5 $4.0 $3.9 $3.5 $3.5 $3.2 Inventory Value $3.0 $2.8 $3.0 $2.7 $2.5 • Increasing trends may indicate excess inventory or inventory with no usage • Decreasing trends may indicate improved inventory turns $2.0 $1.5 $1.0 $0.5 $Jul-10 Aug-10 Sep-10 Oct-10 Month Nov-10 Dec-10 Inventory Metrics Inv e ntory Value (In M illions of $) $5.0 $4.0 $3.0 $2.0 $1.0 $Jul-10 Aug-10 Sep-10 Owned Oct-10 Nov-10 Dec-10 Cons igned • Compares inventory value of owned and consigned products over time • Used to monitor proper mix of inventory types Inventory Metrics Inventory Turn Rate 9 8.8 8.6 Turns 8.5 8.3 8 • Higher inventory turns are usually preferred 7.8 7.5 • Inventory turnover rate compares amount of inventory on hand with amount used 7.6 7.5 • Decreasing trends should be investigated 7 6.5 Jul-10 Aug-10 Sep-10 Oct-10 Month Nov-10 Dec-10 Inventory Metrics Inventory Value with No Average Usage (In Thousands) • Shows stagnant inventory $900 $800 $780 $727 Inventory Value $700 $600 $500 $434 $384 $400 $306 $300 $228 $200 $100 $Jul-10 Aug-10 Sep-10 Oct-10 Month Nov-10 Dec-10 • Used to identify opportunities to remove unused inventory Performance Consulting Services: Project Management Customer Driven • • • • • • • • • • • Capital Budgeting / Coordination Specials Reduction & Conversions Reprocessing Savings & Standardization Opportunities Enterprise coordination Waste reduction opportunities Inventory management opportunities Equipment lease vs. buy analysis Service agreement analysis and consultation Sequestering reagents New Technology Installation Efforts Performance Consulting Services: Project Management Supply Chain Driven • • • • • • Product Categorization Par-Ex implementation / optimization Value stream mapping – Contract cradle to grave Customer focused contract compliance Product usage analysis Custom initiatives (i.e. freight, moving analysis, etc.) Project Management: The Supply Chain Analytics Project Goal: Organize and structure supply data to allow management access, understanding and action. Consolidate data from multiple sources to optimize data management and reporting. Provide timely and actionable information to those who can best manage supplies and services expenses. The Supply Chain Analytics Project • Phase I • Design architecture, build infrastructure, and integrate data into the Enterprise Data Trust (EDT) • Phase II • Deliver solutions based on that infrastructure Areas of Focus: 1. Performance Consulting/Departmental Reporting Financial statements drill-down; Analytic tools; Surgical procedural reporting 2. Category Management Contracting; formulary reporting; pharmacy reporting; Biomed engineering/Facilities; IT asset management 3. Supply Chain Operations Integration of inventory data Impact of Financial Statements Drill Reports • Increased access to supply data through multiple financial statement access points to expand analysis potential • Drill capability from summarized transactions in financial statements accesses integrated supply chain and accounting data without running separate reports • Detail reports are available for viewing on demand generating significant time savings compared to running separate reports • Reports provide detailed and actionable supplies and purchased services expense information to end users Performance Consulting Analytics Tool Supply and Purchased Services Overview: • • GPCR & NMSR Ratios Monthly Trending Links to Additional Detail: • • Variance Analysis Targeted Summary and Detail Reports (ex: Spend by Category) Supply Variance Analysis Summary Price, Volume, and Item/Technology Changes by account Spend without purchase orders Journal Entry transactions Ability to drill to additional detail