Lecture Notes Part 1

advertisement

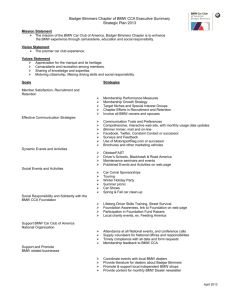

International Supply Case Study BMW Outline • BMW- The company • Build-to-Order & BMW • BMW Spartanburg Plant – Products – Sourcing – Capacity • Managing Supply BMW History • Founded in 1917 • Built engines for military aircraft • 1940’s WW2: repairs, manufactured spare parts, agricultural equipment and bicycles • 1950’s build motorcycles • Then the cars… • 1970’s: South Africa Plant • 1992: US Plant • 1994: Purchased Rover group (Rover, Land Rover, Mini, MG) • 1998: Rolls Royce (2003) • 2000: Sold Rover except Mini BMW Business Interests • Automobiles – BMW – Mini – Rolls Royce • Motorcycles • Financial services BMW • “The BMW Group is the only manufacturer of automobiles and motorcycles worldwide that concentrates entirely on premium standards and outstanding quality for all its brands and across all relevant segments.” • Premium sector of the international automobile market BMW Group. Brands and Models. 1 Series 3 Series 5 Series 7 Series X5 6 Series X3 Z4 Motorcycles Source: Goudiano CSCMP 2005 BMW Group Development and Production Network Berlin Oxford Leipzig Spartanburg Goodwood Regensburg Munich Graz Z8 Dingolfing (external production) Rosslyn Source: Goudiano CSCMP 2005 Shenyang Production Volume Total: 1119.1 Production Volume Ford’s Worldwide vehicle unit sales of cars and trucks in 2004 (in thousands): The Americas Ford Europe and PAG Ford Asia Pacific and Africa Total 3,915 2,476 407 6,798 Challenges • Excess capacity => Price pressures • Customer expectations – Personalization – Innovation – Service • Cost effective factories with flexible manufacturing abilities • New technologies and material • Regulations • …. Build to Order • Convert orders to products • No finished goods inventory • “Build-to-Order is the capability to quickly build standard or masscustomized products upon receipt of spontaneous orders without forecasts, inventory, or purchasing delays.” (D.M. Anderson) • Demand pulls production • WHY BTO? Why BTO? • LEAN!!! • 'Lean production is aimed at the elimination of waste in every area of production including customer relations, product design, supplier networks and factory management. Its goal is to incorporate less human effort, less inventory, less time to develop products, and less space to become highly responsive to customer demand while producing top quality products in the most efficient and economical manner possible.' Why BTO? • Other Alternatives – Build to Stock/Forecast • Assign to dealers • Sell from available stock Built-to-Order vs. Built-toForecast Built-to-Forecast Sale from stock Production Storage Customer Built-to-Order Customized vehicle Customer Production Customer – higher level of customer satisfaction due to personalization – better inventory management – less sales incentives Increasing Product Complexity • Product variety & Part complexity – 1032 possible combinations of products at BMW – 1017 possible combinations of BMW 7 series – ~70 million configurations of the Ford Escape – >240 configurations of Toyota Scion Ford Escape • • • • • • • • • • • • 5 models (XLS manual, XLS automatic, XLT automatic, XLT sport, Limited automatic) 2 drive options (Front-wheel drive or four-wheel drive) 2 engine sizes (2.3L or 3.0L) 9 exterior color options (Dark Shadow Grey, Titanium Green, Redfire, Blazing Copper, Sonic Blue, Dark Stone, Black, Silver, Oxford White) 3 interior colors (Black, Flint, Pebble) 2 transmission options (4-speed, 5-speed) 4 wheel options (15” aluminum, 15” styled, 16” aluminum, 16” Bright Machined aluminum 2 choices of tires (BSW or OWL) 4 options of electronics (AM/FM Single CD with clock, AM/FM 6-CD, AM/FM Single-CD Cassette, Audiophile 6-CD) 4 options of seats (Cloth, Premium cloth, leather trimmed, premium leather) 5 special package options (Cargo convenience, convenience, leather comfort, safety, towing) representing 32 different possibilities 4 different upgrades (Spare tire, moon roof, roof rack and side step) representing 16 further options. These options lead to 70 million ~ 5x2x2x9x3x2x4x2x4x4x32x16 BMW 7 Series 350 Model Versions 500 Extra Equipment Options 175 Interior Equipment Options 90 Standard Exterior Colors ... leading to e.g. 1017 theoretical combinations only for the BMW 7 Series Source: Goudiano CSCMP 2005 Product Complexity • A finite set of part numbers • “Infinitely” many end products BTO & Product Complexity • BTO makes it possible to – Address tremendous product variety – Face the challenges of managing the variability in component demand. Savings through BTO • In the U.S. • Potential savings through BTO~ $1500/car* • Average incentives per car sold ~$1900 in 2002* *Miemczyk and Holweg J. Bus. Logistics, 2004 Obstacles/ Requirements • Inability to supply customized vehicles within “acceptable” timeframes – Avg. Leadtime for customized vehicles: 610 weeks!!! • • • • Short OTD Process/Product/Volume flexibility Flexibility from suppliers Flexibility from logistics operators Current BTO Levels 1999: • • • • Avg. New Vehicle stock in days U.S.: ~ 5% 60-90 days U.K.: ~33% 64 days Europe: ~48% 55 days Japan (Toyota): ~60% 20 days Source: Miemczyk and Holweg (2004) % BTO BTO & BMW • • • • BMW BMW’s operations in SC Plant BMW’s challenges in BTO Available levers for control BMW USA BMW USA • Z4 • X5 BMW • “Every customer receives his/her personalized vehicle at a compulsory date – at best at his/her preferred date” – 100% delivery punctuality – Flexibility for order change Why offer flexibility? Flexibility Equipment changes in % (accumulated) 2,5 Navigation systems 2,0 Xenon lights Comfort seat adjustable electronically 1,5 1,0 % 0,5 Independent vehicle heater 0,0 -0,5 -1,0 30 20 10 days before order freeze Source: Goudiano CSCMP 2005 0 BMW USA • ~140,000 vehicles in 2004. • KOVP (Customer-oriented production and sales) • Over 6000 part numbers for X5 • 70% are option driven • Flexibility for order change • 40% of parts from Europe KOVP Ordering Optimize the whole process Production System Sales System Dealer Dealer orderPurchasingLogistics ProductionDistributionHand-over Sales Processes and Sales Processes and Online Ordering Online Ordering Productionand SupplyProcesses Distribution Process and Hand-over Process Monitoring and Target Control Delivery Sales System Planning Dealer KOVP The Push-Pull Interface Production System before KOVP Early Order Assignment Start Order Assignment Bodyshell work Sort Sort Paint shop Assembly Production System with KOVP Push Frozen Horizon Sort Late Pull Order Assignment Start order assignment OSM Bodyshell work Paint shop Assembly Reduction of Leadtime Flexibility for Order Change Ordering/Scheduling Before KOVP: Production/Distribution Process Feasibility Order freeze 13-17 WD 28-32 WD 15 WD Hand-over to Sales Breakthrough target KOVP : Supplier / Body shell work and Paint shop 1 4 WD Assem -bly Distribution 2 WD 3 WD Change flexibility till 6 WD 10 WD BMW USA • ~140,000 vehicles in 2004. • KOVP (Customer-oriented production and sales) • Over 6000 part numbers for X5 • 70% are option driven • Flexibility for order change • 40% of parts from Europe Sourcing • Why source from Europe – Relationship with suppliers – Tooling is already there – Social responsibility issues Why serve global markets? • Tooling • Volume • … BMW Sourcing Wackersdorf •Receive, Sort, Package •Handles >14,000 part numbers from other BMW plants and over 500 European suppliers. •Receives ~ 160 truckloads of parts per day •Ships ~ 75- 80 containers per day to the BMW assembly plants in Rosslyn, South Africa, Spartanburg, South Carolina and Shenyang, China. BMW: Capacity • Capacity is a major investment • Labor is highly skilled/ organized • Production set at “takt time” – “A vehicle every 50 seconds” • Capacity adjustments through adjustments to takt time, adding/reducing shifts, shutdowns… • Same number of cars/day Manage Capacity • From day to day – Mix of vehicles vary – Usage of parts vary Manage Capacity • Mix of vehicles Seasonality Source: Goudiano CSCMP 2005 Capacity oriented Production planning Manage Supply • • • • Over 6000 part numbers 70 % option driven Order changes 40% from Europe Usage Standard Deviation in Usage 18/day 90 Average Usage 32/day Daily Usage 60 30 106 101 96 91 86 81 76 71 66 61 56 51 46 41 36 31 26 21 16 11 6 1 0 Day SAME NUMBER OF CARS/DAY Managing Supply Forecast Decide Shipment Quantities Prepare Shipments Shipments Arrive Demand Demand Demand Demand Day 1 Day 10 Day 40 Challenge • Huge number of parts: Complexity • Order Flexibility: Variability • Long LeadTimes: Variability Levers for managing uncertainty • Capacity – Capacity on Supply – Production Capacity Infinite Constant • Inventory • Time – Order due date Given/Strict Manage Inventory • “Infinitely” many end products from finite number of parts • Stochastic demand • Variable long leadtimes • No shortages allowed: – Production in a predetermined sequence – Expedite Demand Modeling • Infinitely many end products • Not enough data points to estimate distribution of product demand • Instead: Components Challenge • • • • Huge number of parts: Complexity Order Flexibility: Variability Long LeadTimes: Variability No shortages allowed Some Tools & Mechanisms • • • • • Safety Stock Forecast Accuracy Frequency Global Supply process … Safety Stock • Protection against variability – – – – Variability in demand and Variability in lead time Typically described as days of supply Should be described as standard deviations in lead time demand Traditional basics Order-up-to level Stock on hand Reorder Point Reorder Point Actual Lead Time Demand Actual Lead Time Demand Actual Lead Time Demand Actual Lead Time Demand Order Quantity Lead Time Order placed Time T L Safety Stock Basics • Lead time demand N(m, s) • Safety stock levels – Choose z from N(0,1) to get correct probability that lead time demand exceeds z, – Safety stock is zs Safety Stock in Periodic Review • Probability of stock out is the probability demand in T+L exceed the order up to level, S • Set a time unit, e.g., days • T = Time between orders (fixed) • L = Lead time, mean E[L], std dev sL • Demand per time unit has mean D, std dev sD • Assume demands in different periods are independent • Let sD denote the standard deviation in demand per unit time • Let sL denote the standard deviation in the lead time. Only Variability in Demand • If Lead Times are reliable – Average Lead Time Demand (T+L) * D – Standard Deviation in lead time demand (T+L)sD Lead Time Variability If Lead Times are variable • D = Average (daily) demand • sD = Std. Dev. in (daily) demand • L = Average lead time (days) • sL = Std. Dev. in lead time (days) • Average lead time demand D(T+E[L]) • Std. Dev. in lead time demand (T+E[L])s2D + D2 s2L • Remember: Std. Dev. in lead time demand drives safety stock Levers to Pull • Std. dev in lead time demand s=(T+E[L])s2D + D2 s2L Reduce Time between orders Reduce Lead Time Reduce Variability in Demand Reduce Variability in Lead Time Safety Stock • Protection against variability – – – – • Variability in demand and Variability in lead time Typically described as days of supply Should be described as standard deviations in lead time demand Example: BMW safety stock – For axles only protects against lead time variability – For option parts protects against usage variability too