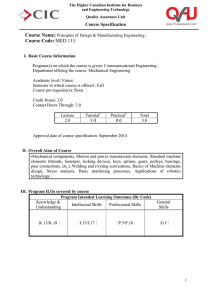

COURSE TITLE (COURSE CODE)

The Higher Canadian Institute for Business and Engineering Technology

Quality Assurance Unit

Course Specification

Course Name:

Computer Integrated Manufacturing (CIM)

Course Code :

MECH 355

I.

Basic Course Information

Core or Elective element of program Core course:

Department offering the course: Manufacturing Engineering

Academic level: 3rd level

Semester in which course is offered: Spring Semester

Course pre-requisite(s): MECH 252,

Credit Hours: 3 hrs

Contact Hours Through: 5 hrs

Lecture Tutorial

*

Practical

*

2.0 1.0

Approval date of course specification: Sep. 2014

II.

Overall Aims of Course

2.0

Total

5.0

Basics of robotics. Analysis and design of robot systems including arms and vehicles.

Kinematics and reverse kinematics. Robotics dynamics ( fixed and portable robots)- explanation procedures of command and planning. Robots control systems: position, speed and clipper speed control. Examples of practical applications of robots.

III.

Program ILOs covered by course

Knowledge &

Program Intended Learning Outcomes (By Code)

Intellectual Skills Practical Skills

Understanding

General

Skills

P3, P5,P6 Gc K3 , K4,K15, K19 I1,I2,I3,I11, I14

1

The Higher Canadian Institute for Business and Engineering Technology

Quality Assurance Unit

Course Specification

IV.

Intended Learning Outcomes of Course (ILOs) a. Knowledge and Understanding

On completing the course, students should be able to:

K3.

Characteristics of engineering materials related to the discipline.

K4 Principles of design including elements design, process and/or a system related to

specific disciplines.

K15 The specifications, programming and range of application of CAD and CAD/CAM

facilities

K19 Engineering design principles and techniques b. Intellectual/Cognitive Skills

On completing the course, students should be able to:

I1 Select appropriate mathematical and computer-based methods for modeling and

analyzing problems.

I2 Select appropriate solutions for engineering problems based on analytical thinking.

I3 Think in a creative and innovative way in problem solving and design.

I11 Analyze results of numerical models and assess their limitations.

I14 Analyze and interpret data, and design experiments to obtain primary data. c. Practical/Professional Skills

On completing the course, students should be able to:

P3 Create and/or re-design a process, component or system, and carry out

specialized engineering designs.

P5 Use computational facilities and techniques, measuring instruments,Workshop sand laboratory equipment to design experiments, collect, analyze and interpret results.

P6 Use a wide range of analytical tools, techniques, equipment, and software packages pertaining to the discipline and develop required computer programs. d. General and Transferable Skills

On completing the course, students should be able to

: Gc.

Communicate effectively.

V.

Course MatrixContents

1-

Main Topics / Chapters

Duration

(Weeks)

2

Course ILOs Covered by Topic

(By ILO Code)

K & U I.S. P.S. G.S.

K3 , K4 I1,I2 P3 Gc

2-

3-

4-

5-

6-

Basics of robotics

Analysis and design of robot systems

Kinematics and reverse kinematics

Robotics dynamics explanation procedures of command and planning

Robots control systems

2

2

2

2

3

K15, K19

K3 , K4

K15, K19 I1,I2

K3 , K4

K15, K19

I3,I11,

I14

I1,I2

I3,I11,

I14

I11

P5,P6

P3

P3

P5,P6

P5,P6

Gc

Gc

Gc

Gc

Gc

Net Teaching Weeks 13

2

The Higher Canadian Institute for Business and Engineering Technology

Quality Assurance Unit

Course Specification

VI.

Course Weekly Detailed Topics / hours / ILOs

Week

No.

Teaching/Learning

Method

Sub-Topics

K & U

Total

Hours

4

8

9

10

11

5

6

7

12

13

1

2

3

14

Basics of robotics

Analysis and design of robot systems including arms

Analysis and design of robot systems including vehicles

Kinematics

reverse kinematics

Robotics dynamics ( fixed )

5

5

5

5

5

5

Midterm Exam

Robotics dynamics (portable robots) 5 explanation procedures of command explanation procedures of planning

5

5 control systems: position control systems: speed control control systems: clipper speed control

Examples of practical applications of

5

5

5

5 robots.

15

Total Teaching Hours

VII.

Teaching and Learning Methods

Final Exam

65

Contact Hours

Theoretical

Hours

Practical

Hours *

2 3

2

2

2

2

2

2

2

2

2

2

2

2

26

3

3

3

3

3

3

3

3

3

3

3

3

39

Course ILOs Covered by Method (By ILO Code)

Lectures & Seminars

Tutorials

Computer lab Sessions

Practical lab Work

Reading Materials

Web-site Searches

Research & Reporting

Problem Solving /

Problem-based Learning

Projects

Independent Work

Group Work

Case Studies

Presentations

Simulation Analysis

Others (Specify):

All

All

Intellectual

Skills

All

All

Professional

Skills

All

All

General

Skills

3

The Higher Canadian Institute for Business and Engineering Technology

Quality Assurance Unit

Course Specification

VIII.

Assessment Methods, Schedule and Grade Distribution

Assessment

Method

Course ILOs Covered by Method

(By ILO Code)

K & U I.S. P.S. G.S.

Assessment

Weight /

Percentage

Week

No.

Midterm Exam

Final Exam

Quizzes

Course Work

Report Writing

Case Study

Analysis

Oral

Presentations

Practical

Group Project

Individual Project

All

All

All

All

All

All

All

All

All

20%

50%

10%

20%

Others (Specify):

IX.

List of References

Computer Integrated manufacturing , James A. Rehg

Essential Text Books Textbook ISBN #: 0131134132

Publisher : Prentice Hall

Course notes

CMS

Recommended books

Periodicals, Web sites,

etc …

X.

Facilities required for teaching and learning computers (Personal & Notebook).

data show

CNC Machine

7

15

6 and 13

All term

Course coordinator: Dr / Ashraf Kamal

Head of Department: Dr Hamdy hussein

Date: September 2014

4