Goal - Robotics - University of Michigan

advertisement

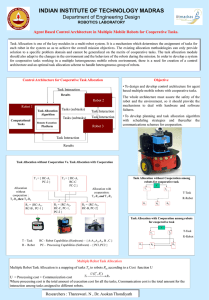

Robotics for Manufacturing A Michigan Robotics Focus Area: Manufacturing research has long been a strength at the University of Michigan, and robotics is already being widely used in automotive and other manufacturing plants. Continuing research is needed to expand the role of robotics in manufacturing applications by improving robot capabilities and safety and reducing cost and energy consumption. Contributing Faculty: Kira Barton Chinedum Okwudire Kazuhiro Saitou Dawn M. Tilbury A. Galip Ulsoy Introduction Industrial Robots • There are approximately 1.5 million industrial robots in operation today world-wide (e.g., approx. 300,000 in Japan, 200,000 in North America, 125,000 in S. Korea) • They perform tasks such as welding, spray paining and assembly in a variety of industries. • They are typically preprogrammed to repeat the same task, are among the most reliable machines available, and are operated in isolation from humans for safety. • Automated Guided Vehicles (AGVs) are also widely used in manufacturing plants for material handling. Automated Guided Vehicles (AGVs) Research Needs • Safety research is needed to enable operation with and around humans. • Cost reduction will enable use for smaller volume production and by small companies. • Energy consumption is high, and needs to be reduced. • Dexterity and precision must be improved for many assembly tasks. • Coordination among robots and with other automated machines. • Flexibility and Autonomy are important to move beyond mass production. Kiva Systems: Flexible Material Handling Rethink Robotics: Low-Cost Assembly Robot Baxter Precision Motion Control for High-Speed, HighResolution Manufacturing (Barton) • Goal: Design advanced sensing and controls algorithms for high precision motion control • Iterative Learning Control o o o Flexible learning strategies Robust learning for a range of applications Cooperative learning control strategies • Advanced Sensing Strategies o o o High-resolution sensing techniques Atomic force microscopy for topographical and charge density sensing Vision-based detection Fig. 1: Cooperative learning strategies. Develop cooperative learning control techniques to enable efficient and effective surveillance and monitoring operations. • Applications o o o o Emerging manufacturing processes High-resolution, high-speed manufacturing systems Rehabilitation robotics UAVs and other autonomous systems Fig. 2: ILC process. As the number of iterations increases, the feedforward time domain control signal is determined and the error signal is minimized. Design and Control of Cartesian Robots (Feed Drives) for Improved Performance and Energy Efficiency (Okwudire) Guideway • Goal: Improve performance and energy efficiency of feed drives • Dynamically adaptive feed drives o Design feed drives such that dynamic properties change based on manufacturing operation o Integrally design time-varying controllers to ensure stability and performance under various dynamic configurations o • Determine optimal dynamic configurations/controllers to ensure desired performance at minimal energy consumption Example: Hybrid feed drive o Feed drive is driven by linear and/or rotary motors depending on manuf. operation o Moving mass, drive point, sensing location, etc. change dynamically o Up to 25% improvement in energyefficiency anticipated Motor Table Screw (smooth shaft) Dynamically Adaptive Hybrid Feed Drive Linear Motor Engagement/disengageme nt mechanism (located under table) Disengagable Pneumatic pistons Roh’lix nut Toggle arms Improving Energy Efficiency by Multi-Robot Coordination and Task Scheduling (Saitou) • Goal: Reduce total energy consumption and peak energy demands in multirobot cells o Arm posture optimization to minimize idle time energy consumption o Multi-robot coordination to maximize the use of regenerative energy from one robot in other robots o Task scheduling to reduce the need of rapid acceleration o Task scheduling to spread energy peaks in multiple robots across cycle time Power profile of typical operation exhibiting multiple energy peaks during cycle time (Duflou, et al, 2012) Virtual Fusion for Robotic System Design, Evaluation and Monitoring (Tilbury) • Goal: Use high-fidelity simulation models running in parallel with physical system to evaluate new system designs • Validate performance by integration of simulated systems with physical systems • Quickly evaluate multiple scenarios for reconfigurability • Operator training with highfidelity models • Run high-fidelity simulation models in parallel with physical system for on-line monitoring Seamlessly swap a virtual robot for real : Identical controls and networking interface DeviceNet/ Ethernet Evaluate new robotic concepts (e.g. Motoman for material handling + assembly) Design for Improved Reliability and Efficiency (Ulsoy) • Goal: Design robots to be energy efficient, reliable and safe • Passive-Assist Design o • For each joint motor, design parallel and/or series spring for passive assist o Typical trajectory and load o Optimize spring design (b) (a) (c) Single-Link Manipulator o Experiments w/ and w/o spring o Properly designed torsional spring reduces max. torque by 50% and energy consumption by up to 25% Planned Extensions o Robust design for family of trajectories and loads o Multi-link robot arm o Co-design of robot and controller 0.2 Electrical Power [W] • Experimental setup: (a) Quanser DC motor and controller, (b) worm gear transmission, and (c) single link arm . Model - No Spring Model - With Spring Experiment - No Spring Experiment - With Spring 0.15 0.1 0.05 0 0 5 10 15 Time, t [s] 20 25 30