Document

How Artisan

Distillation

Works

Kris Arvid Berglund

University Distinguished Professor of Forestry and Chemical Engineering

Michigan State University

East Lansing, MI 48824 USA and

Professor of Biochemical &

Chemical Process Engineering

Luleå University of Technology

SE971 87 Luleå SWEDEN

MSU/ LTU ARTISAN DISTILLING PROGRAM

• Established to promote the establishment and expansion of artisan distillers

• Activities include: education, service, and research

• Designed as a dedicated program for distilled spirits

FACILITIES

• Michigan Brewing Company-houses program, alternating premises license

• A150l Christian Carl still equipped with a three tray side column and a packed column is for high rectification work. (120l to be added at LTU)

• A 450l Christian Carl still for stripping and botanicals

• An 800l, 38-tray Christian Carl still (on line in March

2009)

• A 10l Christian Carl still for experimental work

• Comprehensive analytical instrumentation: GC,

HPLC, Anton Paar DMA 5000 densitometer

EDUCATIONAL ACTIVITIES

• Workshops- two day

– MSU, Webberville, MI

– WSU, Mt. Vernon, WA

– Cornell University, Geneva, NY

• Coursework at MSU, CHE 491

• Book entitled, “Artisan Distilling” on CD-

ROM, internet download (free) at www.artisandistilling.org

RESEARCH ACTVITIES

• Develop quality indicators- congener monitoring and control

• Control of regulated compounds

• Yeast screening for congeners

• Activated carbon finishing

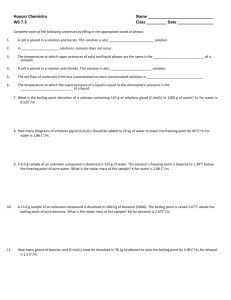

Some definitions

• The agency that licenses at the Federal level is Alcohol and Tobacco Tax and

Trade Bureau, the Department of Treasury

(TTB), not the Bureau of Alcohol, Tobacco and Firearms, the Department of

Homeland Security (BATF).

• All spirits are defined in the Code of

Federal Regulations-27 CFR Part 5.21

• Make sure anything you wish to make is defined!

•

•

•

•

•

•

•

•

•

•

•

•

Recognized classes of spirits

Class 1; neutral spirits or alcohol.

Class 2; whisky.

Class 3; gin.

Class 4; brandy.

Class 5; blended applejack.

Class 6; rum.

Class 7; tequila.

Class 8; cordials and liqueurs.

Class 9; flavored brandy, flavored gin, flavored rum, flavored vodka, and flavored whisky.

Class 10; imitations.

Class 11; geographical designations.

Class 12; products without geographical designations but distinctive of a particular place.

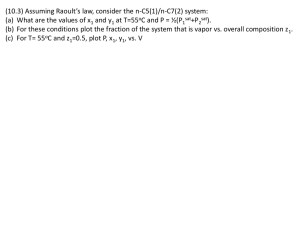

DISTILLATION- MOTIVATION

• Concentrate aromas, flavors, and alcohol

• Several operational parameters possible

• Remove the negative compounds

DISTILLATION

• A process involving an equilibrium between two phases - liquid and vapor.

• For a pure compound, a sharp boiling point usually exists.

• For a mixture, however, a phase equilibrium exists over a range of temperatures.

UNIQUE VLE OF ETHANOL-

WATER SOLUTIONS

• For ideal mixtures, the mvc is always at a higher concentration in the vapor phase than the lvc

• The boiling point of the mixture should be a continuously increasing value as the concentration of the lvc is increased

• This is not the case for ethanol-water

• The boiling point has a minimum value for a mixture

• This is called a minimum boiling azeotrope

Boiling Point Diagram

101

96

91

86 mixture vapor

DEW CURVE

81

BUBBLE CURVE liquid

76

0 0.2

0.4

0.6

Mole Fraction

0.8

1

Boiling Point Diagram Near Azeotrope

80

79.8

79.6

79.4

79.2

79

78.8

78.6

78.4

78.2

78

0.5

0.6

0.7

AZEOTROPE

0.8

Mole Fraction

0.9

1

Ethanol Water VLE

1

0.8

0.6

0.4

0.2

0

0

INCREASING TEMP.

0.2

0.4

0.6

Liquid Mole Fraction EtOH

0.8

1

COMPARISON

OF UNITS- MOLE,

WEIGHT, AND

VOLUME FRACTIONS

1

0.8

0.6

0.4

0.2

0

0

EtOH Water VLE

VOLUME

WEIGHT

MOLE

0.2

0.4

0.6

Liquid Phase

0.8

1

TYPES OF DISTILLATION

• Simple batch- no rectification

• Alambic- some rectification

• Column- active rectification

BATCH DISTILLATION

• Use “cuts”

• “Heads”- remove acetaldehyde, methanol

• “Hearts”- product rich in aromas and flavors

• “Tails”- fusel oils, dilute

RECTIFICATION- EQUILIBRIUM

CONTACT

• Rectification is the result of equilibrium contact between two phases

• The liquid and vapor leaving the contact are in equilibrium

• Rectification, also called enrichment, results in a higher concentration than would occur in a single equilibrium contact

L n-1

, x n-1

L n

, x n

V

V n

, y contact n+1 n

, y n+1 n

SIMPLE BATCH (RAYLEIGH)

DISTILLATION

Ethanol Water VLE

1

0.8

0.6

0.4

0.2

0

0

2

1

0.2

0.4

0.6

Liquid Mole Fraction EtOH

0.8

1

Boiling Point Diagram

101

96

91

86

81

76

0 mixture

0.2

2 vapor

1 liquid

0.4

0.6

Mole Fraction

0.8

1

DIRECT FIRED STILL (ALAMBIC)

Some vapor condenses to liquid and returns to the pot

Classic cognac distillation

INDIRECT STEAM HEATING

(ALAMBIC)

Some vapor condenses to liquid and returns to the pot

Steam

Figure courtesy of

Christian Carl Ing. GmbH

INDIRECT HEATING WITH

RECTIFICATION

INCREASING

TEMPERATURE

DOWN THE

COLUMN,

HIGHEST

TEMPERATURE

IS IN THE POT

Figure courtesy of

Christian Carl Ing. GmbH

•

RECTIFICATION COLUMNS

Figure courtesy of

Christian Carl Ing. GmbH

Top View

SIEVE TRAY

Condensed

Liquid

Vapor

Side View

Condensate Return

BUBBLE CAP TRAY

Condensed

Liquid

Vapor

Condensate Return

BATCH COLUMN STILL

Partial condensor

D, x

D

L

Reflux ratio

R

L

D

Boiler

Ethanol Water VLE

1

0.8

0.6

0.4

1

0.2

2

3

4

5

6

0

0

X

FEED 0.2

0.4

0.6

Liquid Mole Fraction EtOH

0.8

x

DIST 1

The number of trays needed for a specific separation is determined by stepping off……..

Boiling Point Diagram

101

96 vapor

91

86

81

76

0 mixture

0.2

1

2 liquid

0.4

0.6

Mole Fraction

3

4

5

0.8

1

Ethanol Water VLE

1

0.8

0.6

0.4

1

1

2

2

3

3

0.2

0

0 0.2

0.4

0.6

Liquid Mole Fraction EtOH

0.8

1

If the reflux ratio is constant, the product concentration will decrease during the batch

Ethanol Water VLE

1

0.8

0.6

0.4

1

1

2

2

3

3

0.2

0

0 0.2

0.4

0.6

Liquid Mole Fraction EtOH

0.8

1

Since the concentration in the pot decrease during a bath, in order to keep the product concentration high, the reflux must be increased

REFLUX IS INCREASED BY INCREASING COOLING

WATER FLOWRATE TO PARTIAL CONDENSER

TEMPERATURE

SENSOR

WATER TO

CONDENSER

T

Figure courtesy of

Christian Carl Ing. GmbH

FLAVOR COMPOUNDS (CONGENERS) IN

DISTILLED SPIRITS

2200

2000

1800

1600

1400

1200

1000

Methanol

Higher alcohols

Carbonyl compounds

Ethyl acetate

Other esters

800

600

400

200

0

Fr en ch

C og na c

W in e al co ho l

Po m ace Plu m

M ira be lle

C he rry

W ill ia m s

Po m e

C al va

G er m an do

ra s sp be rry

Fr en ch

ra

U

Ssp be rry bo n-

W hi sky hi ske y

Bo ur tch

B le nd ed

W

Sco

G in

Vo dka

TYPICAL COMPOUNDS BY GC

Chemical Name RetentionTime (min) Boiling point (deg. C)

Acetaldehyde 2.5

20.8

Acetone

Ethyl Formate

Ethyl Acetate

3.4

3.6

4.5

56.2

54.0

77.0

Methanol

Ethanol

1-propanol

Isopentanol

4.7

5.8

8.7

64.7

78.0

97.0

(isoamyl alcohol)

Benzaldehyde

16.3

33.0

132.0

179.0

1000 t s l o m v

500

0

0

TYPICAL GC RESULTS

50

Methanol

Ethanol

Ethanol t l s m v o 25

Acetone

Acetaldehyde

1-Propanol

0

0

Isoamyl Alcohol

Ethyl Acetate

5

Minutes

Benzaldehyde

1-Propanol

10

20

Minutes

30 40

10

ETHANOL RESULTS FROM PLUM

DISTILLATION

90

HEADS HEARTS TAILS

80

70

60

50

0 2000 4000

Distillate Volume (mL)

6000 8000

CONGENER CONCENTRATIONS IN

PLUM DISTILLATES

0.45

Congener Concentration vs Distillate Volume

HEADS

2 Trays with Catalytic Converter

HEARTS TAILS

0.60

0.20

0.15

0.10

0.05

0.00

-0.05

0

0.40

0.35

0.30

0.25

1000 2000 3000

Distillate Volume (mL)

4000 5000

0.35

0.30

0.25

0.20

0.15

0.10

0.55

0.50

0.45

0.40

Acetaldehyde

Ethyl Acetate

1-Propanol

Iso Amyl Alcohol

M ethanol

CONTACT

Prof. Kris Arvid Berglund

Email: berglund@msu.edu

Email: kris.berglund@ltu.se

www.artisandistilling.org

ACKNOWLEDGEMENTS

• Christian Carl Ing. GmbH

• Project GREEEN, State of

Michigan

• Michigan State University

• Luleå University of Technology