Southern Company Presentation

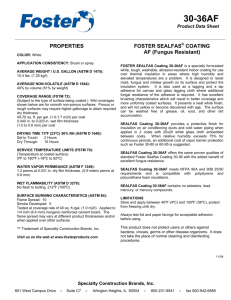

advertisement

THERMAL COATING TECHNOLOGIES FOR BOILER EROSION/CORROSION PREVENTION WHERTEC TECHNOLOGIES INC. By utilizing inspection services, specialized coatings and weld overlay, Whertec provides products and services that protect metal substrates against erosion and corrosion Our goal is to provide superior comprehensive services and resources to assure that our clients achieve maximum operational utilization of their equipment 2 WHERTEC PRODUCTS Thermal sprayed coatings Ceramics Weld overlay and weld repairs Inspection Services 3 Boiler Inspection Services (BIS) Visual Inspection Boiler Mapping U.T. readings / Trend Analysis Coating thickness readings / Trend Analysis Recommendations Reports and documentation 4 BOILER INSPECTION SERVICES Continuous Inspections during a Coating Project Tailored project QCP Technician accountability results in quality workmanship BENEFIT: Experienced boiler inspectors actively monitoring coating work to guarantee quality and customer satisfaction. 5 6 7 8 9 BOILER TUBE WASTAGE RATES CAN BE AFFECTED BY: Fuel type Bed material composition Particle size and shape Particle impact velocity Particle angle of attack Operating pressure and temperature Operating procedures 10 11 12 13 14 Typical areas of tube wastage 1- Refractory Interface 2- Corners 3- Cyclone inlet 4- Roof tubes 5- Wingwall tubes 6- Openings and ports 7- Water wall tubes/membrane WB 15 Thermal Spray Process 16 Thermal spray coating adhesion After impact the molten particles cool and shrink to mechanically lock onto the asperities (peaks and valleys) of the profiled substrate. 17 Thermal spray performance 30 mil of cored wire arc sprayed coating after 4 months in service 9 mils of W-915 HVOF coating after 2 years in service Gouging / erosion due to unpredictable eddy currents 18 Cored wires Thicker sacrificial arc sprayed coatings 19 ARC SPRAY 20 MATERIALS Pre alloyed wires and powders 21 THERMAL SPRAY SYSTEMS HVOF 22 HVOF MATERIALS Blended Agglomerated 23 HVOF Powder Pre Alloyed 24 W-915 COMPONENTS PRE-ALLOYED MATERILS NOMINAL CHEMISTRY -Chromium -Titanium -Nickel -Carbon 25 Application Procedures Lead Edge Erosion Taper Design 26 Tube Replacement Severe SH tube erosion Erosion resistant HVOF coating application 27 CASE HISTORY ADM Decatur #3 Inspection and W-915 thermal Spray reduced Repair Time from 14 days to 2 days 2001 – 9 Forced Outage 2002 – 4 Forced Outages 2003 – 1 Planned 2 Forced Outages 2004 – 1 Planned Outage 2005 – 2 Planned – 0 Forced Outages 2006 – 1 Planned – 0 Forced Outages 28 29 W-915 performance 30 AUTOMATION Automated Systems for vertical waterwall applications: • Quality & consistency • Repeatability • Cost savings • Improved production rates 31 Automation 32 THERMAL COATING (SPRAY & FUSE) • Metallurgical bond • High temperature erosion and corrosion resistance • No interconnected porosity, high density 33 Arc Spray 34 Cold Spray (W-750 CERAMIC COATING) • Visual ID of high wear areas - minimize your NDE time & expense • Quickly applied - 150 ft2/hour application rates • Low Cost • Coating thickness can be easily monitored & touched up 35 W-750 Ceramic New Application After Two years service 36 Whertec Mechanical, LLC Qualified and experienced personnel State of the art automation and equipment Proven industrial field performance R Stamp for repair of ASME vessels High quality materials Qualified technical support 37 Whertec Mechanical, LLC WELD OVERLAY PROTECTION On-Site Automated Welding Systems Surface Prep Equipment Operational and Safety Systems Over 400 combined years of Field Industrial Experience Proven Track Record for completing projects ON-TIME and within SPECS working in various types of boilers and pressure vessels 38 WHERTEC MECHANICAL Have completed projects with as many as <23> automation systems and <60> employees Use highly skilled employees with certifications in carbon steel, stainless steels and nickel alloy, overlay processes Shop and field capabilities State of the art automation Dedicated QA/QC Manager on every project 39 Proven Maintenance Solutions 40