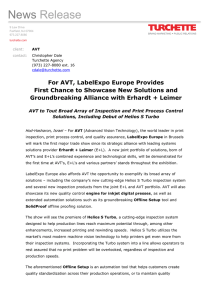

Comexi & AVT Collaborate on Next Generation Press Control

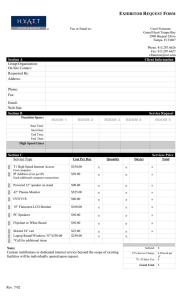

advertisement

News Release 9 Law Drive Fairfield, NJ 07004 973.227.8080 turchette.com client: AVT contact: Christopher Dale Turchette Agency (973) 227-8080 ext. 16 cdale@turchette.com Comexi & AVT Collaborate on Next Generation Press Control Automation to Significantly Reduce Waste & Boost Productivity Clondalkin Flexoplast in the Netherlands realizes 150-meter waste reduction and a 2 minute time savings in each makeready. Hod-Hasharon, Israel / Girona, Spain – Comexi Group, a leading company specializing in machinery solutions for the flexible packaging converting industry, has continued its collaboration with AVT (Advanced Vision Technology), the world leader in print inspection, print process control, and quality assurance, to introduce the next generation of Cingular Real. The solution aims to ensure the best-possible automatic print pressure and register during makeready. The upgraded Cingular Real 2 offers packaging manufacturers valuable enhancements to an already successful product in the form of significant waste reduction. It achieves this by optimizing the make-ready process and enhancing communication between the AVT Argus E Turbo system and the Comexi press. Cingular Real 2 was recently installed at Clondalkin’s Flexoplast facility in The Netherlands. Compared to the original version, the head of the Technical Department, Klaas Struiksma, experienced a 150-meter reduction in makeready waste and a time savings of two minutes each time the press made ready. For a typical day’s production of 10 to 15 makereadies this can equate to about half an hour in saved time and a significant amount of saved material. Cingular Real analyzes the printed image pressure without the use of marks and automatically drives each printing deck to ideal pressure during the makeready process. The solution also compares a PDF file of the printed job and drives the press to perfect registration during makeready. Cingular Real 2 is the result of Comexi’s and AVT’s lengthy experience improving the efficiency of converters within the flexible packaging industry. Both Cingular Real and the new upgraded version can operate on AVT’s Argus E Turbo solutions, which enables customers to enjoy speeds up to three times faster with significantly enhanced system resolution. The result is the highest-possible resolution at previously unattainable production speeds for best-in-class inspection with no quality compromise or lost data. Supported by a dedicated LED illumination technology, the solution’s camera provides an unprecedented combination of high-resolution and high-volume quality control. According to Comexi, “The Cingular Real has become an essential part in Comexi flexographic presses for those converters striving to achieve maximum efficiency. By now, the upgraded Cingular Real 2 further improves its original version, enabling customers to reduce time and material waste while maintaining the register adjustment according to 100% impression.” “Along with our partners at Comexi, AVT is committed to the continuous development of innovative solutions that save our customers time, materials and, ultimately, money,” said Amir Sheinman VP Marketing of AVT. “The Cingular Real 2 installation at Clondalkin Flexoplast exemplifies the sort of impact our print process control and inspection solutions can provide”. ### About Clondalkin Group Clondalkin Group is an international producer of high value added packaging products and services, with over 35 production locations in eight countries throughout Europe and North America and annual sales in excess of €700 million. About Comexi Comexi Group is a family company with worldwide presence and more than 450 employees. It has been committed to machinery manufacturing for the flexible packaging industry since 1954. Through sustainable innovation, we are committed to the research and the technological design aimed at creating products that are efficient, reliable, energy intelligent and environmentally sustainable. Comexi Group is made up of six trademarks, each one specialized in different converting processes. Comexi Flexo (flexo printing); Comexi Offset (offset printing); Comexi Acom (gravure printing); Comexi Nexus (lamination); Comexi Proslit (slitting and rewinding) and Comexi Enviroxi (logistics and environmental management solutions) About AVT AVT is the global leader in print process control, quality assurance, and press control for the packaging, labels, and commercial print industries. Backed by state-of-the-art technology and field-proven solutions, more than 7,000 AVT systems are installed at customer sites worldwide. AVT is headquartered in Hod-Hasharon, Israel with sales, marketing, and support offices in the United States, Europe and China. For more information, visit www.avt-inc.com.