ATLAS|LIFT

advertisement

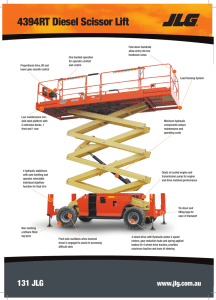

TEAM 8 ATLAS|LIFT grip it ‘n flip it MARK BECKMAN JON BROCK ERIK VAN KAMPEN TYLER WIERS Team Outline Project Overview Revised Scope Design Alternatives and Decisions Proposed Solution Future Challenges Questions E R I K The Team V A N K A M P E N J O N B R O C K T Y L E R W I E R S M A R K B E C K M A N Project Background Project Descriptions Vertellus Specialties Inc. Makers of Mouthwash and Gum Favor Improve Employee Safety Manual to Automatic Lifting of Barrels Less Strenuous More Efficient Design a Machine to Lift and Pour Fiber Drums Pour Powdered Chemicals into Reactors Revised Scope The Reactors • 36” - 46” High • 15” - 26” Deep • 2 Buildings Financial Stewardship • Increased focus on stewardship Power System Power Options Manual Electric/gearbox Pneumatic Air over Oil Hydraulics Manual Pros: simple, inexpensive Cons: slow, strenuous to worker Pros: lift and compact, precise Electric/Gears control Cons: explosion proof Pneumatic Hydraulic Pros: relatively inexpensive, high speed Cons: poor control, not enough power Pros: large lift capacity, explosion proof, fast Cons: relatively expensive, possibility of fluid leaks Uses the simple principle of Hydraulics leverage Hydraulic Components Power Options Electric Motor Air Motor Reciprocating Rotating Motion Options Rotary Actuator Linear Actuator Proposed Solution Simple Tilting Frame Manual Height Adjustment Linear Hydraulic Cylinder Rotary Air Motor Over Center Valve Manual Control Valves Future Challenges Hydraulic system analysis Chemical material properties Flow Optimize Frame strength and weight FEA Possible use of obsolete machinery Finalize PPFS Questions?