4 improve processes

advertisement

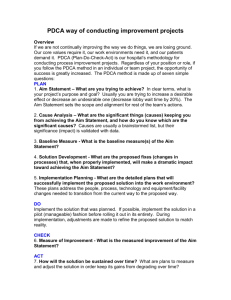

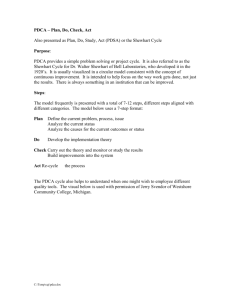

3. Improvement Methodology “Standards only exist to be superseded by better standards” “Making continual improvement of products, processes and systems an objective for every individual in the organization”. Process Improvement model F E E D B A C K 1. Operational Analysis of process 2.Application of Process improvement Principles 3. Benchmarking L O O P 4. PDCA 1. Operational Analysis of a Process • • • • This involves breaking the processes in 4 segments: Who? What? How? Where? 1. Operational Analysis of a Process Who is performing the task ? • Reveals hidden organizational problems • Shows division of responsibility and authority • Communication issues • Skill base and experience • Decision making power • Technical vitality 1. Operational Analysis of a Process What task is done ? • Helps in redistribution of task • Elimination of waste and unnecessary task • Proper utilization of skills • Consolidation of group activities • Elimination of wasted efforts • Correct skill deficiencies • Task dependencies • Time utilization 1. Operational Analysis of a Process How is the task done ? • Simplification of tasks • Prioritization of task elements • Elimination of excessive delays • Eliminating unnecessary transportation • Rearrangement of work stations • Use of faster methods and tools • Change in processing time • Work load balancing • Performance assessment 1. Operational Analysis of a Process Where is the task done? • Scrapping unwanted tools and equipment • Efficient location of work stations • Elimination of unwanted transportation • Improvement in employee morale • Changes in ergonomics • Changes in work design Process Improvement model 1. F E E D B A C K L O O P 2. Application of Process improvement Principles Operational Analysis of process 3. Benchmarking 4. PDCA 2. Application of process improvement principles 1. Waste Reduction Process Improvement Principles 2. Process Simplification 3. Cycle-time reduction 4. Process measures 5. Mistake - proofing 1. Waste reduction Techniques of waste reduction a )Value-added assessment b) Eliminating non-value adding activities c) Minimize checks and inspections d) Minimize administrative tasks e) Minimize storage and transportation activities Value added assessment Value to customer : First, the customer’s view point should be considered. The customers are only interested in receiving the product or service that satisfies their requirements. All activities that must be performed to cater to the customer’s requirements are value -added activities. Does the activity add value to the customer ? Would any customer care if the activity was not performed ? Would any customer object if the activity was not performed ? Do the customers appreciate the results of the activity? Eliminate non-value adding activities Value to business : There are many activities that may not add value from the customer’s point of view. Attending meetings, developing plans, compliance with regulatory guidelines, writing procedures etc are examples of activities that may not add value to the customers, but they do add value to the organization. Each of these activities must be carefully examined. Minimize checks & inspections • Checks and inspections may be necessary in a process, however they do not add value to the process. Each inspection point should be identified and challenged. • The next slide lists some questions to use in this challenge. What if the inspection was eliminated? • What if the inspection was eliminated? • Would the inspection be missed? • What is the potential impact in eliminating the inspection? • What potential consequences exist if the inspection is eliminated? • What is the likelihood that the inspection would have revealed a problem? Minimize administrative tasks Administrative tasks often result in delays in process time due to excessive paper work, levels of reviews and multiple signatures (mostly by people who, it seems, are never available when needed). Reviews, approvals, signatures, preparing written documentation, making and distributing copies etc needs to be thoroughly reviewed.. Minimize storage and transportation activities Sometimes storage and transportation are necessary evils but because they are both non-value adding they should be minimized. The purpose of justin-time inventory systems to minimize the amount of inventory stored. Minimize storage and transportation activities Transportation activities are also non-value adding. Often the relocation of single activity can significantly reduce the transportation requirements. 2. Process simplification Simplification means reducing the complexities of process. Simplification can lead to lessor activities and lessor things to go wrong. Process simplification can be done by combining similar activities and by analyzing decision points. 2. Process simplification Efforts should focus on reducing layers of management and structures that cause delays. Outdated systems and procedures need to be evaluated. 3. Cycle-time reduction Cycle-time is the time required to deliver a product or service to a customer. Long cycle-times not only prevent prompt delivery of product/ service to your customers, but also increase costs. One of the best ways to cut down on your cycle-time is to conduct activities in parallel and eliminate unnecessary waste times as demonstrated on the next slide. 1. Activities Performed in serial 2. Activities performed in parallel 4. Create and implement performance based measures • If the performance of any system or process is not measured, it can not be meaningfully improved. Quantitative and qualitative measures that address both objective and subjective elements should be implemented. • The measures recommended are Revenue per employee, percent defectives, cost of quality, profitability ratios, customer satisfaction index etc. Incorrect performance measures create barriers Profit Strategies Sales Customer satisfaction Build inventory Efficiency variance Many unfocused projects Many improved teams Select low price supplier Purchase price Performance measures Correct performance measures Profit Sales Customer satisfaction Strategies Cycle-time Performance measures Cost of poor quality Supplier quality 5. Mistake proofing Mistake proofing Mistake proofing Mistake proofing is a scientific technique for improvement of operating system including materials, machines and methods with an aim of preventing problems due to human error. The term “error” means a sporadic deviation from standard procedures resulting from loss of memory, perception or motion. Example : Bar codes and bar code readers prevents incorrect billing. Defect Vs errors It is important to understand that defects and errors are not the same thing. A defect is the result of an error, or an error is the cause of defects as explained below. Cause Result Error Defect Prevention of defects Cause Work Procedure Intermediate result Machine or human error Detect error Modify work procedure to prevent such errors Take corrective action Analyze for preventive action End result zero defect Process Improvement model 1. F E E D B A C K L O O P 2. Application of Process improvement Principles Operational Analysis of process 3. Benchmarking 4. PDCA 3. Benchmarking Benchmarking Benchmarking is quality by comparison for achieving better standards. In the global movement today, the competition is increasing at a faster rate, and the only way to improve your relative quality and move upwards is to find out and implement the best industry practices. Benchmarking processes :Stages of improvement World Class Recognized as the best. Benchmarked by others even in other sectors Best in Class Exceeds customer expectations,outperforms all competitors and has clear competitive edge Efficient Meets all internal requirements for cost margins, asset utilization, cycle-time and measures of excellence Effective Satisfies all customer requirements Incapable Is ineffective, inefficient and at the risk of failing. Needs major redesign Benchmarking methodology Benchmarking can be of various types - Competitive benchmarking, product benchmarking, process benchmarking and best practices benchmarking. Whatever be the category chosen by the organization, the benchmarking methodology remains the same in each case. Benchmarking methodology is explained through 5 simple steps in the following slides. a. Identify processes to benchmark • Select processes to benchmark. • Measure current process capability. • Understand detailed process which needs improvement. b. Select organization to benchmark • Select organizations which perform your process. • Compile a list of world class process parameters. c. Compile the required information • Develop a detailed questionnaire to obtain desired information. • Obtain the desired information. The information can be obtained from various sources viz: Internet, trade journals, professional associations, benchmarking centers, Industry publications, Industry experts, libraries etc. d. Analyze gaps Too much information is as bad as too little. Gather and analyze only the information you need to make a direct comparison of performance. Compare like with like - Compare apples with apples and pears with pears. Identify the performance gaps and develop an action plan to close the gaps. Also highlight and quantify the consequences of not closing the gap. e. Develop an action plan • Review observations of the gap analysis. • Set new performance standards. • Develop an action plan for meeting the new performance standards. Process Improvement model F E E D B A C K L O O P 1. Operational Analysis of process 2. Application of Process improvement Principles 3. Benchmarking 4. PDCA 4. PDCA PDCA ( Plan-Do-Check-Act ) Plan-Do-Check-Act ( PDCA Cycle ):- A four step process for quality improvement. • In the first step (PLAN), A plan to effect improvement is developed. • In the Second step (DO), the plan is carried out. • In the third step ( CHECK), the effects of the plan are observed. • In the last step (ACT) ,Action is taken to carry out the plan after making necessary corrections. This is repeated till the original plan is achieved. Continuous process The PDCA cycle has the advantage of being cyclical implying that improvement never ceases. Application of PDCA Cycle The ultimate aim of any management system is continual improvement of its performance. To achieve this, Deming’s PDCA cycle of improvement is interwoven in the structure of the new standard. PDCA Cycle applied to ISO 9001:2000 clause 4.1 ACT Implementation of improvement ( Clause 4.1f ) CHECK Monitoring, Measurement & Analysis ( Clause 4.1e) PLAN Identification of sequence, interaction criteria & methods ( Clause 4.1 a,b,c ) DO Implementation of the planning ( Clause 4.1.d) Deploying Quality Improvement Process Continual improvement process of Quality Management System can be deployed throughout the organization by undertaking PDCA activities at various levels as explained in the subsequent slides. Application of PDCA at top management level Plan • • • • • Establish Policy Define Objectives Plan and Provide Resources Define organization structure Plan development of customer focus Top Management DO • Lead by Example • Show commitment • Communicate Importance of customers throughout Organization • Deploy policy throughout Organization • Define measurable objectives • Delegate Top Management CHECK • • • • • • Undertake management review to assess: Is the system working for us? Are we meeting objectives? Is our policy being followed? Are our customers happy? How is our business doing? Are we planning anything that could affect the system? (New product line; reorganization etc) Top Management ACT • Incorporate review results into strategic planning • Provide for additional resources • Reorganize • Hire new staff • “Convert”, “Sideline” or Fire “nonbelievers/non-performers” Department/Section Heads PLAN • Establish procedures and instruction for departmental activities • Define responsibilities • Establish objectives • Plan resources including training of personnel • Establish communication channel for instructions and feed-back Department / Section Heads of Functional Units DO • • • • Allocate clear responsibilities Provide resources and support Coordinate and harmonize activities Resolve problems Department/Section Heads CHECK • • • • • • • How is my department doing? Are processes under control? What are my employees telling me? Are we meeting customer requirements? Am I meeting my objectives? What are the key problems in my area? How can we improve? Department / Section Heads ACT • Systematic problem-solving (based on importance, risks involved etc) • Develop action plans • Concentrate on improvement (incremental or “breakthrough” improvements) • Review existing procedures, and need for new procedures Management Representative PLAN • Co-ordinate definition of key processes, their sequences and interactions • Define needs for documented procedures • Co-ordinate preparation of Quality Manual • Co-ordinate elaboration of Inter-functional procedures (Document Control, Internal Audit etc) • Determine Legal and Regulatory Requirements • Coordinate Quality Planning Management Representative DO • Ensure processes are defined & maintained • Promote customer focus • Facilitate Internal Communication • Support line management functions • Coordinate Training Activities (with HR) • Collate measurement data (Product/ Process/System) Management Representative Check (Internal Audits) • • • • • Is everyone managing their processes? Are the customers happy? Is our system working? Are we communicating adequately? How can we improve? Management Representative ACT • Stimulate/co-ordinate inter-functional actions • Review Internal Audit frequency • Alert Top Management