Final Presentation

advertisement

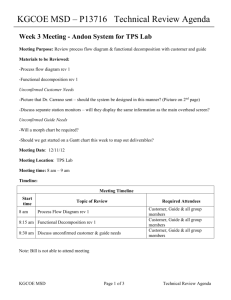

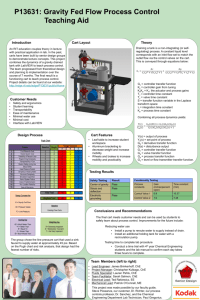

P13630 Process Control: Metered Flow Team Members: Andre Berwin – ChemE, Nathan Fulcher -ChemE, Andrew Watson – ChemE, Travis Bardsley – ChemE, Peter Dunning – ME, Anthony Parker – IE, James Mazza - EE Meeting Purpose: A detailed final review of the Metered Flow Loop (P13630) Materials Reviewed: Customer Needs, Engineering Specs, Budget Results and Conclusions P&ID and Completed Cart Process Dynamics Circuit and Wiring Diagrams LabVIEW GUI Attendees Steve Possanza – Process Engineer, Kodak Christiaan Richter, Ph.D. – Assistant Professor, RIT Department of Chemical Engineering Paul Gregorious – Senior Laboratory Technician, RIT Department of Chemical Engineering Meeting Time and Location: Thursday, December 5th 2013 ChemE Recitation Room – Institute Hall Meeting Timeline Start Time Topic of Review 9:00 Project Background Recap 9:05 Review Updated Customer Needs, Engineering Specs 9:15 Review Existing Pugh Diagrams 9:20 Review Updated P&ID 9:30 Review BOM 9:40 Review Updated Risk Analysis 9:45 Electrical Design Review 10:00 Test Plan Review 10:10 Feasibility Analysis 10:15 Cart Review 10:20 MSD II 3 Week Plan 10:25 Conclusion and Questions Required Attendees Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Steve Possanza and Christiaan Richter, Full Team Table of Contents Table of Contents High-Level Project Summary ......................................................................................................................... 4 Project Description ......................................................................................................................................... 4 Project Background: ................................................................................................................................... 4 Objectives/Scope: ....................................................................................................................................... 4 Deliverables: ............................................................................................................................................... 4 Expected Project Benefits:.......................................................................................................................... 4 Core Team Members: ................................................................................................................................. 4 Issues & Risks: ........................................................................................................................................... 4 P13630 – Customer Needs ............................................................................................................................. 5 Engineering Specifications ............................................................................................................................. 6 Test Results .................................................................................................................................................... 7 P&ID .............................................................................................................................................................. 8 BOM ............................................................................................................................................................... 9 Budget ...........................................................................................................................................................10 Electrical Design ...........................................................................................................................................11 Pressure Sensor ..........................................................................................................................................11 Powerflex 40..............................................................................................................................................12 Microcontroller ..........................................................................................................................................13 Complete Loop ..........................................................................................................................................14 Electrical Box ............................................................................................................................................15 Power .........................................................................................................................................................16 Test Plan ........................................................................................................................................................17 Process ...........................................................................................................................................................18 Control Loop .............................................................................................................................................18 Control Valve ............................................................................................................................................19 Pump ..........................................................................................................................................................19 Motor & Drive ...........................................................................................................................................19 Pump Characterization ..................................................................................................................................20 Cart ................................................................................................................................................................21 LabVIEW GUI ..............................................................................................................................................22 Questions? ........................................................................................... Ошибка! Закладка не определена. High-Level Project Summary Project # Project Name Project Track Project Family P13630 Metered Flow Loop Process Innovation Process Control Start Term Team Guide Project Sponsor Doc. Revision 2012 Q3 Steve Possanza Kodak A-2 Project Description Project Description Project Background: The Metered Flow Loop project specifically aims to create an educational experience for future Chemical Engineering students in the area of Process Control. The culmination of the project will be a small (3ft x 2ft) process control cart to demonstrate the concepts of controlling a metered flow loop. The cart will be used in conjunction with a detailed laboratory curriculum to more effectively teach process control to students. Objectives/Scope: 1. Design Cart to be portable and easily maintained 2. Design LabVIEW interface for easy use of cart 3. Design Lab to be used with cart to teach various concepts of process control. Deliverables: • • • • Fully functional cart to be used in Chemical Engineering Laboratories. LabVIEW GUI that can control the flow and control parameters Laboratory plan to be used by students Maintenance for cart and all components as well as a detailed user’s manual. Expected Project Benefits: • Effectively teach Process Control to future Chemical Engineering students. Core Team Members: Andre Berwin (Team Lead) Nathan Fulcher Andrew Watson Travis Bardsley Anthony Parker Peter Dunning James Mazza Issues & Risks: • • • • • • Insufficient time to finish lab experiments. Change in customer needs. Lead time on parts. DAQ issues. Edge issues. Structural Failure. MSD II Final Design Review P13630 – Customer Needs Customer Need # Importance CN1 9 Assembled Cart Designed – Will Be Built in MSDII CN2 9 Metered Flow Control Via Microcontroller/LabVIEW Interface CN3 9 Interface with LabVIEW for Automatic Control MSD II CN4 9 Cart Is Safe CN5 6 Recommended Lab Protocol CN6 6 Process and Control Interaction Analysis CN7 6 Known System Capability Evaluation CN8 6 Modeled After Current Lab Carts CN9 6 Manual Control of Cart CN10 6 Robust and Durable Via Physical Needle Valve, Ball Valve, Lab View Interface Through Normal Use CN11 6 Operated by 3 Students Will Test Group Size in MSDII CN12 6 Takes Place in Allotted Lab Time CN13 6 Automated Data Collection CN14 3 Modular and Adaptable CN15 3 Easily Moved and Portable CN16 3 Minimal Maintenance and Cleaning KGCOE MSD I Review Description Page 5 of 23 Comments/Status No Chance of Pressure Buildup Major Electrical Components in a Dry Box Rough Draft Already Completed Thorough testing with user feedback Initial Tests Completed, More Once Cart Is Assembled Initial Characteristic Curves Completed Visually Similar Rough Lab Protocol Completed Will Test Lab Duration in MSDII Via LabVIEW Interface into .csv file with Microcontroller All Swagelok Fittings are Modular Can Support Control Valve in Series and Parallel Cart is on Wheels May Interface with any Computer with LabVIEW Easy to Fix for Common Problems & Normal Wear Will Supply Basic Maintenance Kit Detailed Design MSD II Final Design Review Engineering Specifications Engr. Spec Description ES1 Maximum Process Flow Rate ES2 Minimum Process Flow Rate ES3 ES4 ES5 ES6 Process Fluid Operating Temp Process Fluid Viscosity Max Pressure in System Minimum Space Requirements Instrument and Controller Power Supply Motor and Drive Operating Power Supply ES7 ES8 ES9 Sampling Rate of Controller ES10 Response Time of Pump Automated Operation of Instruments Simple Wire connectivity Mobility adaptability in Lab setting Manual Operation of Instruments Safe and Ergonomic Design Automated Data Collection Time it takes to complete lab Cost Accuracy of Flow Measurements Lifetime of Cart ES11 ES12 ES13 ES14 ES15 ES16 ES17 ES18 ES19 ES20 KGCOE MSD I Measure of Performance Volume per unit time Volume per unit time Temperature Range Viscosity Pressure Volume Engr. Units Marginal Value Ideal Value Validation Method (TOAD) g/min 6785 1500 Run Pump Characterization tests g/min 158 500 Run Pump Characterization tests °F cP psi ft3 70-140 1 5-80 30 70-130 1 20 24 Demonstrate operating temps for equipment N/A Implement Pressure Sensors in Flow Loop Physical measurements Voltage V 110 120 Voltage Measurements using Multimeter Voltage Samples per unit time Time V 230 460 Voltage Measurements using Multimeter S/s 200,000 < 10 Test Microcontroller code s 1 0.01 Monitor pump speed for a changing flow Operationally Operationally mA Binary 4, 20 N/A 4 to 20 N/A Simulate 4-20mA signal to controller/device using fluke Successful operation by non-technical students Operationally Operationally Operationally Operationally Time Dollars Percent error Time Binary Binary Binary Binary Hours Dollars % Years N/A N/A N/A N/A 9 2000 <1 5 N/A N/A N/A N/A 7.5 1500 0.2 10 Successful operation by non-technical students Successful operation by non-technical students Successful operation by non-technical students Successful operation by non-technical students Successful operation by non-technical students Add up costs at the end of project Compare it Against Known Instrument/ Timing Method N/A Page 6 of 23 Detailed Design Review MSD II Final Design Review Test Results Parameter Target Test Plan results Reference Min Flow Rate 158 g/min Check flow rate at lowest pump settings Yes Max Flow Rate 1500 g/min Check flow rate at highest pump settings Yes, highest is 1504 g/min System Pressure 5 to 80 psi Check Pressure during operation Yes, pressure can span 0.5-30psi with supply Pump testing, 11/8/2013 Pump testing, 11/8/2013 Pump testing, 11/8/2013 Pump Response Time < 1 second Check time to new steady state after change is made Yes, pump response time can be set via the PowerFlex drive Operating manual pg. 3-12 Flow Accuracy < 1% error Compare flow meter value against another flow meter or total volume per time Yes, dependant on flow rate, ranged between 0.1-1% innacuracy Pump testing, 11/8/2013 Control Valve Response Time < 5 seconds Check time to new steady state after change is made < 1 second Leakage No Leaks Check for leaks under normal operating procedures Yes Operator 2 Minimum, 3 Maximum Functioning PID control with ability to alter constants Attempt to operate the system with 2 people Implement new set-points and observe system response Yes Can adjust flow manually Labview records data that can be graphed or exported to excel Adjust flow Yes Ensure it exists and check for accuracy Yes Automatic Control Manual Control Automatic Data Collection Yes Manual Data Collection Modularity Real time data is displayed Can alter system to put different comonents in series or parallel Ensure it exists and check for accuracy Reconfigure system to put different components in alternate order Yes Portability Easy to move, connect to and disconnect from utilities Connent and disconnect system from utilities. Push cart around. Yes but wheels need to be replaced Noise 2 Sources Test if our sources effect the data Yes KGCOE MSD I Review Page 7 of 23 Yes Detailed Design MSD II Final Design Review P&ID KGCOE MSD I Review Page 8 of 23 Detailed Design MSD II Final Design Review BOM Equipment List / BOM Component Category Component Type Cart Reservoir Pump Drive Motor Control Valve Major Components Flow meter DAQ-Controller* DAQ-MicroProcessor Shut-off Valve Pressure Relief Valve Needle Valve Tubing Fittings Fasteners Stud Nuts Connecting Plate Connecting Plate Framing Drive Box Power Strip AWG20 AWG14 T-junction Minor Components Tubing Size Converters Tubing Size Converters I/P Converters Power Supply Pressure Regulator Analog Pressure Sensor Digital Pressure Sensor Op Amp 9-Wire Cable Voltage Regulator LCD Screen Teflon Tape DAQ-MicroProcessor Spare Parts Pump Repair Kit KGCOE MSD I Review Part Number NI9208 MSP-EXP430G2 5181K25 3580T11 33125T34 33125T42 33085T43 G1561061 BE106001-08R-DP DW-65A 147-1472G AP358SG-13 31273 MSP-EXP430G2 - Size/ID 3ftx2ft 2L 16 Channel 3/8" & 1/2" 1/4" 90° 45° 304 SS 16"x20"x6" 6 outlets 65ft 250ft .5" 1/2" to 1/8" 1/2" to 3/8" 5V 8-SOIC 5ft 3.3V 4x16 520in - Page 9 of 23 Number 1 2 1 1 1 1 1 1 1 2 1 1 100 ft Assorted Assorted 40 10 8 20 ft 1 1 1 1 5 2 2 1 1 1 1 1 10 1 1 1 1 1 - Buy Location McMaster Carr Kodak Kodak Kodak Kodak Kodak Kodak National Instruments DigiKey Kodak Kodak Kodak McMaster Carr Kodak Home Depot McMaster Carr McMaster Carr McMaster Carr McMaster Carr Zorotools Home Depot Home Depot Home Depot Kodak Kodak Kodak Kodak Kodak Kodak Kodak Kodak DigiKey Kodak Digikey Digikey Home Depot DigiKey Info. from Kodak McMaster Carr National Instruments DigiKey Home Depot Zorotools Total High Total Low Price $150.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $585.00 $10.37 $0.00 $0.00 $0.00 $30.00 $0.00 $50.00 $188.00 $21.00 $16.40 $213.00 $200.00 $12.97 $4.97 $44.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $10.00 $0.00 $10.00 $12.00 $1.37 $10.37 $0.00 $618.40 $585.00 $52.74 $113.31 $200.00 $1,569.45 $984.45 Detailed Design MSD II Final Design Review Budget Team Spending 2500 2000 Amount ($) 2000 1760,62 1569,45 1500 1000 984,45 500 0 Predicted (Low) Predicted (High) Actual Budget Spending In the spring we have estimated our expenses to be $984.45 with the microprocessor. We estimated our expenses to be $1569.45 by replacing the microprocessor with the National Instruments controller. We decided to save money and use a microprocessor; however, we did not anticipate having to buy a drive which greatly changed out expenses. Ultimately we spent $1760.62 which was still in our allotted budget, but greatly exceeded our expectations. KGCOE MSD I Review Page 10 of 23 Detailed Design MSD II Final Design Review Electrical Design Pressure Sensor KGCOE MSD I Page 11 of 23 Detailed Design Review MSD II Final Design Review Powerflex 40 KGCOE MSD I Page 12 of 23 Detailed Design Review MSD II Final Design Review Microcontroller KGCOE MSD I Page 13 of 23 Detailed Design Review MSD II Final Design Review Complete Loop KGCOE MSD I Page 14 of 23 Detailed Design Review MSD II Final Design Review Electrical Box KGCOE MSD I Page 15 of 23 Detailed Design Review MSD II Final Design Review Power KGCOE MSD I Page 16 of 23 Detailed Design Review MSD II Final Design Review Lab Plan Disturbances: 1. Head pressure from switching tanks/ Pipe length with pressure drop 2. Control Valve/Needle Valve Control: 1. P (simulated noise) 2. PI (simulated noise) 3. PID (simulated noise) 4. Human vs. Computer 5. Level Controller on Tank 6. Different type of Pump Lab Design: First Lab (~3 hours) Scope: Introduce LabVIEW, PID control, and noise basics to students. Objective: Prove the necessity of control systems and their advantage over manual control. Deliverables: Manual Data vs. P, PI & PID Data o Introduction to system and LabVIEW controls o Human vs. Computer control (P, PI & PID) o Human vs. Computer control (P, PI & PID with noise) o Average data and compare Second Lab (~3 hours) Scope: Provide a deep understanding of PID control and each of its individual elements. Objective: The complete PID equation is understood, as well as the role each piece plays in a control system. The understanding of how to manipulate PID control and the effect of noise. Deliverables: Data of a control scenario with P, PI & PID control with an explanation of differences. Repeat except with noise. Data illustrating the limits of the system with noise. Data showing the improvement of a control scenario by manipulating PID constants. o In depth explanation of PID control o Differences in P, PI & PID control with actual flow o Differences in P, PI & PID control with actual flow and noise o Vary levels of noise and see impact on control o Vary Kp, Ki & Kd terms and see impact on control Third Lab (~3 hours) Scope: Provide knowledge of noise management. A final scenario to challenge and test students’ prowess of PID control. Objective: Provide insight in real-world methods of managing noise. Verify that the students have mastered a basic understanding of PID control. Deliverables: A new method for eliminating noise, or parameters used to properly control the scenario. o Methods of eliminating noise o Averaging data (filter noise) o Have students develop other methods to eliminate noise o Have students create a PID control for a given scenario (flow rate/noise/pressure drop) o Share with class what was done/learned on this cart KGCOE MSD I Review Page 17 of 23 Detailed Design MSD II Final Design Review Process Control Loop Diagram KGCOE MSD I Review Page 18 of 23 Detailed Design MSD II Final Design Review Control Valve The control valve regulates flow rate or pressure of a stream by changing the valve position by the following relation: 𝐹𝑉 = 𝐶𝑣 (𝑥)√∆𝑃 The Cv(x) parameter is a function of the valve position, which is regulated between 0100%. The valve position is controlled by sending a pressurized air signal to the valve, which moves a diaphragm connected to the valve stem. The air signal is regulated by a current to pressure (I/P) converter, which takes an analog current signal being sent by a processor (420mA) and converts it linearly to a (3-15psi) air signal. The converter is supplied with pressurized air via a regulator, which converts the pressure from 80 psi to 30 psi. An additional 30 psi air line is sent to the control valve to speed the valve dynamics. Pump: Micropump GJ.N-25 The positive displacement pump also regulates stream flow and pressure by driving a pump rotor via a motor, which is controlled via voltage supplied by a drive. The voltage sent by the drive is controlled via an analog current signal sent from the processor. The characteristic of the pump is the following: 𝐹𝑃 = (−𝛼 + 𝛽𝜔)∆𝑃 + 𝛾𝜔 ≈ 𝛾𝜔 Where 𝜔 is the speed (angular speed, RPM) of the motor and 𝛼, 𝛽, 𝛾 are fitting parameters characteristic to the pump. Motor and Drive The speed of the motor is regulated by the following equation which relates the frequency of the drive and the angular speed of the pump: 𝜔 = 𝑘𝑓 Where 𝑓 is the frequency of the drive, which ranges between 0-60 Hz and is directly controlled via a mA signal sent by the microprocessor. 𝑘 is the ratio between drive frequency and motor speed, which is set to 1800RPM/60Hz. KGCOE MSD I Review Page 19 of 23 Detailed Design MSD II Final Design Review Pump Characterization KGCOE MSD I Review Page 20 of 23 Detailed Design MSD II Final Design Review Cart A modular and adaptable cart was modeled after and consistent with existing flow carts. The cart was designed to house the process control system; prioritizing usability, safety and reliability for the students. The cart was designed to be portable, easily moved, and easily connected and disconnected to lab utilities. The cart was augmented with stainless steel framing to mount and support all of the system components. All of the system components may be removed and rearranged if needed. In order to avoid the previous balance issues, the frame was designed to be located in the center of the cart. In addition, the system components weights were evenly distributed across the whole cart, keeping the bottom of the cart weighted heavily. KGCOE MSD I Review Page 21 of 23 Detailed Design MSD II Final Design Review LabView GUI KGCOE MSD I Page 22 of 23 Detailed Design Review MSD II Final Design Review QUESTIONS? KGCOE MSD I Page 23 of 23 Detailed Design Review