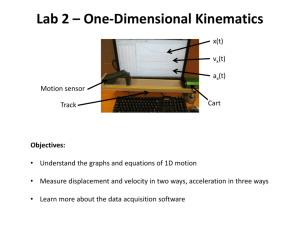

display

advertisement

Gravity Fed System Team Members: James Brinkerhoff, Christopher Kulbago, Patrick O’Connell, Lauren Pahls, Ted Rakiewicz, Sarah Salmon Group Number: P13631 1 Table of Contents 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. Team Roles Project Background Schedule MSD II High Level Customer Needs Budget and Costs Bill of Materials Engineering Specifications Concept Generation Feasibility Analysis Original System Architecture Original P&ID Original Cart Layout MSD I vs. MSD II Comparison Final P&ID Final Cart Layout Test Results Data Labview Layout Risk Assessment Successes and Failures Issues and Actions MSD I Issues and Actions MSD II Questions 2 Team Roles • Chris Kulbago- Project Manager • James Brinkerhoff- Lead Engineer • Lauren Pahls- Fluids Specialist • Sarah Salmon- Group Facilitator • Patrick O’Connell- Lead Mechanical • Ted Rakiewicz- Lead Electrical 3 Project Background • Task Demonstrate process control in a lab environment using a gravity fed loop with a control valve with an existing flow cart as reference. • Customer and Sponsor RIT’s Chemical Engineering Department • Other Support Kodak’s Steve Possanza was our guide through this process. Kodak also donated old parts to make our cart fully functional. • Product Stakeholders Students who will use the machine, the Department, Dr. Sanchez, Dr. Richter, and staff who will maintain the machine. • Collaboration Two other groups are designing similar process control machines whose aesthetic appearances must match ours. 4 Schedule MSD II 5 Customer Needs • Did we meet them? Customer need: Does project fulfill need? Safety Yes Ergonomics Yes Mobility Yes Teaching Manually Yes Teaching Auto-Controls Yes Ease of Assembly Yes Low Cost Yes Use of LabVIEW Yes Drained Tank Dynamics Yes 6 High Level Customer Needs • Machine Design Needs: • • • • • • • A way for students to manually manipulate flow. A way to manually measure flow. Easily operated by 3 students. A safely operating machine. Interface of machine with LabVIEW. A way to demonstrate main concepts of process control. A way to demonstrate noise and time lag in sensors. • Student Learning Needs: • A lab manual that guides students through lab in a way that engenders learning. • Discussion questions within lab manual that test understanding of process control. • Lab manual that focuses on PID control, noise, filtration, data modeling, disturbances, and/or hysteresis. 7 Budget & Costs Budget Tracking 1600 1500 1400 1200 1206.28 Money ($) 1000 1086.74 Actual Spent 800 Anticipated Spending Original Request 600 400 200 0 8 Bill of Materials Grouping of items: • Items were first divided into three main subsections: 1. Donated by Kodak 2. Donated by RIT 3. Bought ourselves • Items purchased were further divided: 1. Cart construction equipment 2. Electrical equipment 3. Miscellaneous Lowe’s items • Dimensions, part numbers, price, location, and arrival were all listed to better inform team of item status. • Budget was tracked by entering an estimated cost for items not yet purchased and confirming the cost when the items arrived. • Our bill of materials is very large and can be viewed on our Edge site. 9 Engineering Specifications • In order to complete the project, the group had to translate customer needs into technical specifications. • How well the group did in staying within the 19 specifications is summarized below: Specifications 1 Specifications met Specification assumed met Specification not met 18 10 Specifications Met: Part 1 11 Specifications Met: Part 2 12 Specifications Met: Part 3 13 Specification Assumed Met 14 Contingency Plan for Assumed Specification • Contact 4th year Chemical Engineering students to test cart. • Conduct time and operation trials on all contacted persons with cart and lab manual. 15 Concept Generation 16 Feasibility Analysis • Line pressure confirmation • With one faucet received around 50 psi • With all faucets on decreased to about 45 psi 17 Original System Architecture 18 Original P&ID 19 Original Cart Layout 20 MSD I vs. MSD II Comparison Item MSD I MSD II Overall goal Concept Generation Building and Integration Deliverables Theoretical; Organization As-built final documents and charts Time 10 weeks 16 weeks Individual Contributions About equal More work from EE and ME Grading Throughout; Several milestones Only a Functional Review and a Final Review 21 Final P&ID 22 Final Cart Layout 23 Test Results Data 24 Labview Layout 25 Risk Assessment 26 Successes & Failures • Successes • Cart is aesthetically constructed, and highly functional. • LabVIEW provides accurate data collection and adequately allows for student interaction for real-time process control of a dynamic system. • Group overcame an equipment failure, and adapted to prevent project hindrance. • Project is under budget. • All deliverables submitted on time. • Failures • Digital-to-Analog Converter operation is deviated from design intent (as of right now). • Cart water usage is not optimized. 27 Issues/Actions MSD I • Gravity fed to line feed • We initially were going to have a project that was “gravity fed to a line feed,” where we had a permanent height for a gravity feed stream. • Instead of this, we decided to use a second control loop and set of code in order to be able to be more versatile and mimic different heights with different water pressures from a water line. • Coordinating cart purchase • We discussed a cart design that fits the needs of all three groups. • After negotiating, we came up with a final cart to be used by all three groups. • Slow start to project • Edge was not readily available for students at the start of MSD I. • The lab learning portion was in progress 28 Issues/Actions MSD II • Misinterpreted Pressure Loss • Water pressure loss across flow tube was greater than calculated, and therefore the water flow rate out in preliminary testing was too low. • We rearranged the cart layout to use potential energy to make our cart drain at the required flow rate. • Delicate Level Transmitter • The original mounting design for the level transmitter damaged it. After mounting, it gave erroneous readings. • A new level transmitter was rush delivered and mounted with electrical tape. Special handling instructions were noted in manual. • Interface Issues • The equipment given to us by Kodak was very used and worn. At first, we did not know how to properly control the 2 I/P circuits, preventing control valve operation. • Through rigorous testing, this problem was solved and our I/P’s are now fully functional as anticipated. 29 Future Suggestions • Recycle Loop • Install a pump with a recycle stream and an additional tank or vessel in order to reduce water usage. • Time Study • Have 4th year Chemical Engineering students perform the lab procedure and measure time it takes for students to complete the lab. • Switch Microcontroller • Replace the msp430 Microcontroller with a more reliable National Instruments Data Acquisition for increased accuracy, ease of assembly and use. • Newer and More Robust Parts • The Level Transmitter we purchased was low in cost but carries a risk. A differential pressure cell would minimize this risk. • Parts donated by Kodak are used and worn, and if these are replaced the robustness of the cart can improve. 30 Questions? 31