7

CHAPTER 7

Design of

Work Systems

McGraw-Hill/Irwin

Operations Management, Eighth Edition, by William J. Stevenson

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved.

Major Factors Affecting

Productivity

Technological Development and Raw

Materials

Employees’ Job Performance

Ability

Motivation

Motivational Theories (Theory X, Theory

Y, and Theory Z)

Technological Development

and Raw Materials

Technology

Materials

Plant Layout

Job Designs

Employees’ Job Performance

Ability

Skills

Training

Experience

Knowledge

Education

Employees’ Job Performance

Motivation

Economic Motivators

Individual’s Needs

Hierarchy of Needs

Formal Organization

Organization Structure

Leadership Climate

Personnel Policies

Motivation

Informal

Organization

Size

Goals

Cohesiveness

Leadership

Type of

Leadership

Autocratic

Close

Supervison

Democratic

General

Supervision

Motivation

Union

Cohesiveness

Goals

Leadership

Maslow’s Hierarchy of Needs

Achievement, Creativity,

SELF

Development &

FULFILLMENT Advancement

Self-respect,

EGO

Recognition,

Prestige, Status

SOCIAL

SECURITY

PHYSICAL

Friendship

Shelter &

Protection

Hunger,

Thirst,

Sex

Theory X

People lack motivation

People are basically lazy

People only work because they have to

Theory Y

People are interested in goal

accomplishments

People have the potential for creativity

People have many skills and potentials

Theory Z

William G. Ouchi’s

This theory explores the differences between

the Japanese and American management

systems.

Japanese system is designated as J type

American system is designated as A type

U.S. organizations that have some

characteristics of the Japanese organizations

as Z type

Examples: IBM, Eastman-Kodak, Hewlett-Packard

Theory Z

Characteristics of Z type organizations

Employment must be stabilized

This means employment security

Unions must be involved but not in an

adversary relationship

A system for slow evaluation and

promotion should be developed

Job Design

Job design involves specifying the

content and methods of job

What will be done

Who will do the job

How the job will bob will be done

Where the job will be done

Ergonomics

Design of Work Systems

Specialization

Behavioral Approaches to Job Design

Teams

Methods Analysis

Motions Study

Working conditions

Job Design Success

Successful Job Design must be:

Carried out by experienced personnel

with the necessary training and

background

Consistent with the goals of the

organization

In written form

Understood and agreed to by both

management and employees

Specialization in Business:

Advantages

For Management:

For Labor:

1. Simplifies training 1. Low education and

2. High productivity

3. Low wage costs

skill requirements

2. Minimum

responsibilities

3. Little mental effort

needed

Disadvantages

ForManagement:

ForLabor:

1. Difficult to motivate

quality

1. Monotonous work

2. Limited opportunities

for advancement

2. Worker dissatisfaction,

possibly resulting in

3. Little control over work

absenteeism, high

4. Little opportunity for

turnover, disruptive

self-fulfillment

tactics, poor attention

to quality

Behavioral Approaches to Job

Design

Job Enlargement

Job Rotation

Giving a worker a larger portion of the total

task by horizontal loading

Workers periodically exchange jobs

Job Enrichment

Increasing responsibility for planning and

coordination tasks, by vertical loading

Motivation and Trust

Motivation

Influences quality and productivity

Contributes to work environment

Trust

Influences productivity and employeemanagement relations

Teams

Benefits of teams

Higher quality

Higher productivity

Greater worker satisfaction

Self-directed teams

Groups of empowered to make certain

changes in their work process

Methods Analysis

Methods analysis

Analyzing how a job gets done

Begins with overall analysis

Moves to specific details

Methods Analysis

The need for methods analysis can come

from a number of different sources:

Changes in tools and equipment

Changes in product design

or new products

Changes in materials or procedures

Other factors (e.g. accidents, quality

problems)

Methods Analysis Procedure

Identify the operation to be studied

Get employee input

Study and document current method

Analyze the job

Propose new methods

Install new methods

Follow-up to ensure improvements

have been achieved

Analyzing the Job

Flow process chart

Chart used to examine the overall

sequence of an operation by focusing on

movements of the operator or flow of

materials

Worker-machine chart

Chart used to determine portions of a

work cycle during which an operator and

equipment are busy or idle

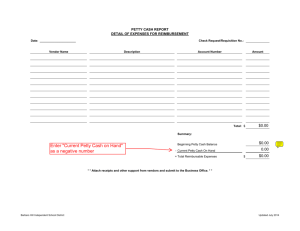

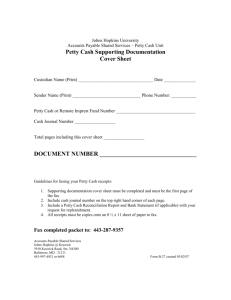

FLOW PROCESS CHART

ANALYST PAGE

Job Requisition of petty cash D. Kolb 1 of 2

Details of Method

Requisition made by department head

Put in “pick-up” basket

To accounting department

Account and signature verified

Amount approved by treasurer

Amount counted by cashier

Amount recorded by bookkeeper

Petty cash sealed in envelope

Petty cash carried to department

Petty cash checked against requisition

Receipt signed

Petty cash stored in safety box

Motion Study

Motion study is the systematic

study of the human motions used

to perform an operation.

Motion Study Techniques

Motion study principles - guidelines for

designing motion-efficient work procedures

Analysis of therbligs - basic elemental

motions into which a job can be broken

down

Micromotion study - use of motion pictures

and slow motion to study motions that

otherwise would be too rapid to analyze

Charts

Developing Work Methods

Eliminate unnecessary motions

Combine activities

Reduce fatigue

Improve the arrangement of the

workplace

Improve the design of tools and

equipment

Working Conditions

Temperature &

Humidity

Illumination

Ventilation

Color

Working Conditions (cont’d)

Noise & Vibration

Work Breaks

Safety

Causes of Accidents

Work Measurement

Standard time

Stopwatch time study

Historical times

Predetermined data

Work Sampling

Compensation

Time-based system

Compensation based on time an employee

has worked during a pay period

Output-based (incentive) system

Compensation based on the amount of

output an employee produces during a

pay period

Form of Incentive Plan

Accurate

Easy to apply

Consistent

Easy to understand

Fair

Compensation

Individual Incentive Plans

Group Incentive Plans

Knowledge-Based Pay

System

Management Compensation

Learning Curves

Learning curves: the time

required to perform a task

decreases with increasing

repetitions

Time per repetition

Learning Effect

Number of repetitions

Time per unit

Learning with Improvements

Average

Time

Improvements may create a

scallop effect in the curve.

Applications of Learning

Curves

Manpower planning and scheduling

Negotiated purchasing

Pricing new products

Budgeting, purchasing, and inventory

planning

Capacity Planning

Time/cycles

Worker Learning Curves

A (underqualified)

B (average)

Standard time

C (overqualified)

One week

Training time

Cautions and Criticisms

Learning rates may differ from

organization to organization

Projections based on learning curves

should be viewed as approximations

Estimates based the first unit should

be checked for valid times

Cautions and Criticisms

At some point the curve might level off

or even tip upward

Some improvements may be more

apparent than real

For the most part, the concept does not

apply to mass production