Job design - Binus Repository

advertisement

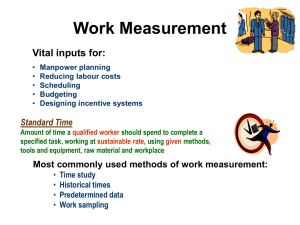

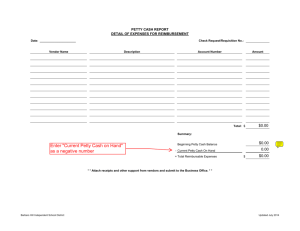

Mata kuliah : J0444 - Manajemen Operasional Tahun : 2010 System Design: Design of Work System Pertemuan 08 Learning Objectives • • • • • • Explain the importance of work design. Briefly describe the two basic approaches to job design. Discuss the advantages and disadvantages of specialization. Explain the purpose of methods analysis and describe how methods studies are performed. Describe four commonly used techniques for motion study. Discuss the impact of working conditions on job design. Learning Objectives • • • • • • • Define a standard time. Describe work sampling and perform calculations. Compare stopwatch time study and work sampling. Contrast time and output pay systems. List some of the main reasons organizations need to make location decisions. Explain why location decisions are important. Describe some of the major factors that affect location decisions. Job Design • Job design involves specifying the content and methods of job – – – – – What will be done Who will do the job How the job will bob will be done Where the job will be done Ergonomics: Incorporation of human factors in the design of the workplace Design of Work Systems • Specialization • Behavioral Approaches to Job Design • Teams • Methods Analysis • Motions Study • Working conditions Job Design Success Successful Job Design must be: • Carried out by experienced personnel with the necessary training and background • Consistent with the goals of the organization • In written form • Understood and agreed to by both management and employees Specialization in Business: Advantages For Management: For Labor: 1. Simplifies training 1. Low education and 2. High productivity 3. Low wage costs skill requirements 2. Minimum responsibilities 3. Little mental effort needed Disadvantages ForManagement: ForLabor: 1. Difficult to motivate quality 1. Monotonous work 2. Limited opportunities for advancement 2. Worker dissatisfaction, possibly resulting in 3. Little control over work absenteeism, high 4. Little opportunity for turnover, disruptive self-fulfillment tactics, poor attention to quality Behavioral Approaches to Job Design • Job Enlargement – Giving a worker a larger portion of the total task by horizontal loading • Job Rotation – Workers periodically exchange jobs • Job Enrichment – Increasing responsibility for planning and coordination tasks, by vertical loading Motivation and Trust • Motivation – Influences quality and productivity – Contributes to work environment • Trust – Influences productivity and employee-management relations Teams • Benefits of teams – Higher quality – Higher productivity – Greater worker satisfaction • Self-directed teams – Groups of empowered to make certain changes in their work process Methods Analysis • Methods analysis – Analyzing how a job gets done – Begins with overall analysis – Moves to specific details Methods Analysis The need for methods analysis can come from a number of different sources: • Changes in tools and equipment • Changes in product design or new products • Changes in materials or procedures • Other factors (e.g. accidents, quality problems) Selecting an Operation • Selecting a job to study consider: – – – – – – – High labor content Done frequently Unsafe Tiring Unpleasant Noisy Designated problem Analyzing the Job • Flow process chart – Chart used to examine the overall sequence of an operation by focusing on movements of the operator or flow of materials • Worker-machine chart – Chart used to determine portions of a work cycle during which an operator and equipment are busy or idle FLOW PROCESS CHART Job Requisition of petty cash ANALYST PAGE D. Kolb 1 of 2 Details of Method Requisition made by department head Put in “pick-up” basket To accounting department Account and signature verified Amount approved by treasurer Amount counted by cashier Amount recorded by bookkeeper Petty cash sealed in envelope Petty cash carried to department Petty cash checked against requisition Receipt signed Petty cash stored in safety box Motion Study Motion study is the systematic study of the human motions used to perform an operation. Motion Study Techniques • Motion study principles - guidelines for designing motion-efficient work procedures • Analysis of therbligs - basic elemental motions into which a job can be broken down • Micromotion study - use of motion pictures and slow motion to study motions that otherwise would be too rapid to analyze • Charts • Therbligs Developing Work Methods 1. 2. 3. 4. 5. Eliminate unnecessary motions Combine activities Reduce fatigue Improve the arrangement of the workplace Improve the design of tools and equipment Therbligs • Therbligs: Basic elemental motions that make up a job. – – – – – – Search Select Grasp Hold Transport load Release load Working Conditions Temperature & Humidity Illumination Ventilation Color Working Conditions Noise & Vibration Work Breaks Safety Causes of Accidents Work Measurement • Work measurement: Determining how long it should take to do a job. – Standard time – Stopwatch time study – Historical times – Predetermined data – Work Sampling Standard time Standard time: The amount of time it should take a qualified worker to complete a specific task, working at a sustainable rate, using given methods, tools and equipment, raw materials, and workplace arrangement. Stopwatch Time Study • • Stopwatch Time Study: Development of a time standard based on observations of one worker taken over a number of cycles. The basic steps in a time study: 1. 2. 3. 4. Define the task to be studied Determine the number of cycles to observe Time the job Compute the standard time Standard Elemental Times • • Standard elemental times: Time standards derived from a firm’s historical data. Steps for standard elemental times 1. 2. 3. 4. Analyze the job Check file for historical times Modify file times if necessary Sum elemental times to get normal time Predetermined Time Standards • • Predetermined time standards: Published data based on extensive research to determine standard elemental times. Advantages: 1. 2. 3. 4. Based on large number of workers under controlled conditions Analyst not requires to rate performance No disruption of the operation Standards can be established Work Sampling • Work sampling: technique for estimating the proportion of time that a worker or machine spends on various activities and idle time. • Work sampling involves making brief observations of a worker or machine at random intervals • Work sampling does not require – timing an activity – continuous observation of an activity Compensation • Time-based system – Compensation based on time an employee has worked during a pay period • Output-based (incentive) system – Compensation based on the amount of output an employee produces during a pay period Form of Incentive Plan • Accurate • Easy to apply • Consistent • Easy to understand • Fair Compensation • Individual Incentive Plans • Group Incentive Plans • Knowledge-Based Pay System • Management Compensation Need for Location Decisions • Marketing Strategy • Cost of Doing Business • Growth • Depletion of Resources Nature of Location Decisions • Strategic Importance of location decisions – – – Long term commitment/costs Impact on investments, revenues, and operations Supply chains • Objectives of location decisions – – – Profit potential No single location may be better than others Identify several locations from which to choose • Location Options – – – Expand existing facilities Add new facilities Move Making Location Decisions • • • • Decide on the criteria Identify the important factors Develop location alternatives Evaluate the alternatives – Identify general region – Identify a small number of community alternatives – Identify site alternatives • Evaluate and make selection Location Decision Factors Regional Factors Multiple Plant Strategies Community Considerations Site-related Factors Regional Factors • • • • Location of raw materials Location of markets Labor factors Climate and taxes Community Considerations • • • • • • • Quality of life Services Attitudes Taxes Environmental regulations Utilities Developer support Site Related Factors • • • • Land Transportation Environmental Legal Multiple Plant Strategies • Product plant strategy • Market area plant strategy • Process plant strategy Service and Retail Locations • Manufacturers – cost focused • Service and retail – revenue focused – Traffic volume and convenience most important – Demographics • Age • Income • Education – Location, location, location – Good transportation – Customer safety Comparison of Service and Manufacturing Considerations Manufacturing/Distribution Service/Retail Cost Focus Revenue focus Transportation modes/costs Demographics: age,income,etc Energy availability, costs Population/drawing area Labor cost/availability/skills Competition Building/leasing costs Traffic volume/patterns Customer access/parking Trends in Locations • Foreign producers locating in U.S. – – “Made in USA” Currency fluctuations • Just-in-time manufacturing techniques • Microfactories • Information Technology Global Locations • • • • • Reasons for globalization Benefits Disadvantages Risks Global operations issues Globalization • Facilitating Factors – Trade agreements – Technology • Benefits – – – – Markets Cost savings Legal and regulatory Financial Globalization • Disadvantages – – – – – Transportation costs Security Unskilled labor Import restrictions Criticisms • Risks – – – – Political Terrorism Legal Cultural Table 8.3 Foreign Government a. Policies on foreign ownership of production facilities Local Content Import restrictions Currency restrictions Environmental regulations Local product standards Liability laws b. Stability issues Cultural Differences Living circumstances for foreign workers / dependents Religious holidays/traditions Customer Preferences Labor Possible buy locally sentiment Resources Availability and quality of raw materials, energy, transportation infrastructure Level of training and education of workers Work ethic Possible regulations limiting number of foreign employees Language differences 8-46 Evaluating Locations • Cost-Profit-Volume Analysis – Determine fixed and variable costs – Plot total costs – Determine lowest total costs Location Cost-Volume Analysis • Assumptions – – – – Fixed costs are constant Variable costs are linear Output can be closely estimated Only one product involved Example 1: Cost-Volume Analysis Fixed and variable costs for four potential locations L o c a tio n A B C D F ix e d C ost $ 2 5 0 ,0 0 1 0 0 ,0 0 1 5 0 ,0 0 2 0 0 ,0 0 0 0 0 0 V a r ia b le C ost $11 30 20 35 Example 1: Solution Fixed Costs A B C D $250,000 100,000 150,000 200,000 Variable Costs $11(10,000) 30(10,000) 20(10,000) 35(10,000) Total Costs $360,000 400,000 350,000 550,000 Example 1: Solution $(000) 800 700 600 500 400 300 200 100 0 0 D B C A A Superior C Superior B Superior 2 4 6 8 10 Annual Output (000) 12 14 16 Evaluating Locations • Transportation Model – Decision based on movement costs of raw materials or finished goods • Factor Rating – Decision based on quantitative and qualitative inputs • Center of Gravity Method – Decision based on minimum distribution costs The End