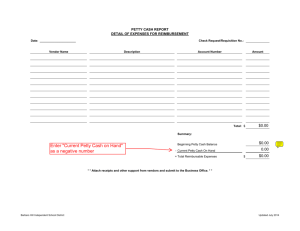

7-1 Design of Work Systems Operations Management William J. Stevenson 8th edition 7-2 Design of Work Systems CHAPTER 7 Design of Work Systems McGraw-Hill/Irwin Operations Management, Eighth Edition, by William J. Stevenson Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved. 7-3 Design of Work Systems Job Design Job design involves specifying the content and methods of job What will be done Who will do the job How the job will bob will be done Where the job will be done Ergonomics 7-4 Design of Work Systems Design of Work Systems Specialization Behavioral Approaches to Job Design Teams Methods Analysis Motions Study Working conditions 7-5 Design of Work Systems Job Design Success Successful Job Design must be: Carried out by experienced personnel with the necessary training and background Consistent with the goals of the organization In written form Understood and agreed to by both management and employees 7-6 Design of Work Systems Specialization in Business: Advantages Table 7.1 For Management: For Labor: 1. Simplifies training 1. Low education and 2. High productivity 3. Low wage costs skill requirements 2. Minimum responsibilities 3. Little mental effort needed 7-7 Design of Work Systems Disadvantages Table 7.1 ForManagement: ForLabor: 1. Difficult to motivate quality 1. Monotonous work 2. Limited opportunities for advancement 2. Worker dissatisfaction, possibly resulting in 3. Little control over work absenteeism, high 4. Little opportunity for turnover, disruptive self-fulfillment tactics, poor attention to quality 7-8 Design of Work Systems Behavioral Approaches to Job Design Job Enlargement Job Rotation Giving a worker a larger portion of the total task by horizontal loading Workers periodically exchange jobs Job Enrichment Increasing responsibility for planning and coordination tasks, by vertical loading 7-9 Design of Work Systems Motivation and Trust Motivation Influences quality and productivity Contributes to work environment Trust Influences productivity and employeemanagement relations 7-10 Design of Work Systems Teams Benefits of teams Higher quality Higher productivity Greater worker satisfaction Self-directed teams Groups of empowered to make certain changes in their work process 7-11 Design of Work Systems Methods Analysis Methods analysis Analyzing how a job gets done Begins with overall analysis Moves to specific details 7-12 Design of Work Systems Methods Analysis The need for methods analysis can come from a number of different sources: Changes in tools and equipment Changes in product design or new products Changes in materials or procedures Other factors (e.g. accidents, quality problems) 7-13 Design of Work Systems Methods Analysis Procedure 1. 2. 3. 4. 5. 6. 7. Identify the operation to be studied Get employee input Study and document current method Analyze the job Propose new methods Install new methods Follow-up to ensure improvements have been achieved 7-14 Design of Work Systems Analyzing the Job Flow process chart Chart used to examine the overall sequence of an operation by focusing on movements of the operator or flow of materials Worker-machine chart Chart used to determine portions of a work cycle during which an operator and equipment are busy or idle 7-15 Design of Work Systems Figure 7-2 FLOW PROCESS CHART ANALYST PAGE Job Requisition of petty cash D. Kolb 1 of 2 Details of Method Requisition made by department head Put in “pick-up” basket To accounting department Account and signature verified Amount approved by treasurer Amount counted by cashier Amount recorded by bookkeeper Petty cash sealed in envelope Petty cash carried to department Petty cash checked against requisition Receipt signed Petty cash stored in safety box 7-16 Design of Work Systems Motion Study Motion study is the systematic study of the human motions used to perform an operation. 7-17 Design of Work Systems Motion Study Techniques Motion study principles - guidelines for designing motion-efficient work procedures Analysis of therbligs - basic elemental motions into which a job can be broken down Micromotion study - use of motion pictures and slow motion to study motions that otherwise would be too rapid to analyze Charts 7-18 Design of Work Systems Developing Work Methods 1. 2. 3. 4. 5. Eliminate unnecessary motions Combine activities Reduce fatigue Improve the arrangement of the workplace Improve the design of tools and equipment 7-19 Design of Work Systems Working Conditions Temperature & Humidity Illumination Ventilation Color 7-20 Design of Work Systems Working Conditions (cont’d) Noise & Vibration Work Breaks Safety Causes of Accidents 7-21 Design of Work Systems Work Measurement Standard time Stopwatch time study Historical times Predetermined data Work Sampling 7-22 Design of Work Systems Time-based system Compensation Compensation based on time an employee has worked during a pay period Output-based (incentive) system Compensation based on the amount of output an employee produces during a pay period 7-23 Design of Work Systems Form of Incentive Plan Accurate Easy to apply Consistent Easy to understand Fair 7-24 Design of Work Systems Compensation Individual Incentive Plans Group Incentive Plans Knowledge-Based Pay System Management Compensation 7-25 Design of Work Systems Gortrac Manufacturing GTE5 Process improvement/examples/ teams 7-26 Design of Work Systems Gortrac Manufacturing GTE2 Teams/improvement