OTTO CYCLE (OR) CONSTANT VOLUME CYCLE The present day

advertisement

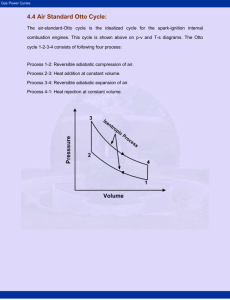

OTTO CYCLE (OR) CONSTANT VOLUME CYCLE The present day petrol engine operates on the otto cycle. This cycle was introduced in practical form by scientist Otto in 1876. An I.C. Engine does not undergo a cycle change but it is assumed here that the working medium is pure air which does not undergo chemical change. The air is simply heated and cooled to undergo a cycle. The working fluid is also assumed to be a perfect gas (having constant specific heats). Further it is assumed that the ideal indicator diagram is strictly followed. This cycle consists of two reversible adiabatic(isentropic) processes and two constant volume processes. The P-V and T-S diagrams are shown in fig (1.2) The otto cycle consists of Process 1-2: Isentropic compression Q 0 Air is compressed isentropically. Process 2-3: Constant volume heat addition Qs mCv T3 T2 Heat is added (spark ignites) while volume remains giant. Process 3-4: Isentropic Expansion Q 0 Expansion of air takes place isentropically Process 4-1: Constant volume heat rejection Qr mCv T4 T1 Heat rejected to the surroundings at constant volume. Net work done Wnet Qs Qr Heat supplied – Heat rejected air s tan dard thermal 1 Wnet Qs Qr Qs Qs mCv (T4 T1 ) Qr 1 Qs mCv (T3 T2 ) 1 r = compression ratio (T4 T1 ) (T3 T2 ) …(1) V1 V2 Volume at the beginning of compressio n V4 Volume at the end of compressio n V3 1-2 Isentropic process : T2 V1 T1 V2 1 r 1 3-4 Isentropic process : T3 V4 T4 V3 1 V 1 V2 1 r 1 T2 T3 T3 T4 , T1 T4 T2 T1 T3 T 1 4 1 T2 T1 T3 T2 T4 T1 T2 T1 T4 T1 T1 V2 T3 T2 T2 V1 T T V Substitute 4 1 2 T3 T2 V1 V 1 2 V1 1 1 1 r 1 1 1 in equation 1, we get V1 V4 and V2 V3 otto 1 V1 v1 Note : r V2 v2 1 r 1 This expression in which =1.4 is called air standard efficiency of the Otto cycle. So the efficiency is the function of compression ratio only. If the compression ratio is more, then efficiency will be more. However, we cannot increase the compression ratio beyond the limit since detonation (noisy and destructive combustion problem) occur in petrol engine at higher compression ratio. Work dome in otto cycle We know that the work done per kg in otto cycle is given by P V P4V4 P2V2 P1V1 W 3 3 1 1 Also P3 P2 r P4 P1 Also P3 P4 p (Pressure ratio) P4 P1 …(3) V V Alsowe know V1 rV2 and V4 rV3 1 4 r V2 V3 Substituting these in (2) we have W P3V3 PV 1 1 P1V1 2 2 1 P4V4 1 P4V4 P1V1 P3 P 1 1 P1V1 2 1 P4V4 1 P4 r P1 r V1 V4 r V2 V3 …(2) r V1 r P4 1 P1 1 1 r r P3 P2 r from (3) P2 P1 Work done W V1 P4 r 1 1 P1 r 1 1 1 V1 r 1 1P4 P1 1 P1V1 1 r 1rp 1 1 …(4) P4 rp P1 Mean effective pressure (M.E.P) Mean effective pressure is defined as constant pressure to which the cylinder is subjected to so that same work is developed. Expression For Mean Effective Pressure of Otto cycle Mean effective pressure is the ratio of net work done to the swept volume. Therefore Mean effective pressure (M.E.P) Pm Net work done W Swept volume V1 V2 From (2) we have P3V3 P4V4 P2V2 P1V1 1 1 Pm V1 V2 Now from (4) we have P1V1 1 r 1 rp 1 1 Pm V1 V2 Now V1 V2 V1 V1 r …(5) V1 r V2 r 1 V1 V2 V1 r …(6) Substituting (6) in (5) we get Pm P1V1 1 r 1 rp 1 1 1 r 1 V1 r Therefore we get Mean effective pressure Pm P r P1 r r 1 1 rp 1 1 r 1 1 p 1 r r r 1 1 DIESEL CYCLE OR CONSTANT PRESSURE CYCLE Dr.Rudholph Diesel introduced diesel cycle in 1897. In case of otto cycle heat is supplied to working fluid at constant volume while in case of Diesel cycle heat is supplied at constant pressure. Diesel cycle consists of the following four operations. Process 1-2 = Adiabatic compression Process 2-3 = Constant pressure heat Process 3-4 = Adiabatic expansion Process 4-1 = Heat rejection at constant The limitation on compression ratio in the S.I. engine can be overcome by compressing air alone, instead of the fuel-air mixture, and then injecting fuel into the cylinder in spray form when combustion is desired.' The temperature of air after compression must be high enough so that the fuel sprayed into the hot air burns spontaneously. The rate of burning can, to some extent, be controlled by the rate of injection of fuel. An engine operating in this way is called a compression ignition (C.I.) engine. The sequence of processes in the elementary operation of a C.I. engine is, shown in Fig. 1.4 Process 1-2, Intake. The air valve is open. The piston moves out admitting air into the cylinder at constant pressure. Process 2-3, Compression. The air is then compressed by the piston to the minimum volume with all valves closed. Process 3-4, Fuel injection and combustion. The fuel valve is open, fuel is sprayed into the hot air, and combustion take place at constant pressure. Process 4-5, Expansion. The combustion products expand, doing work on the piston which moves out to the maximum volume. Process 5-6, Blow-down. The exhaust valve opens, and the pressure drops to the initial pressure. Pressure 6-1, Exhaust. With the exhaust valve open, the piston moves towards the cylinder cover driving away the combustion products from the cylinder at constant pressure. The above processes constitute an engine cycle, which is completed in four strokes of the piston or two revolutions of the crank shaft. Figure 1.5 shows the air standard cycle, called the Diesel cycle, corresponding to the C.I. engine, as described above. The cycle is composed of: Two reversible adiabatic, one reversible isobar, and one reversible isochore. Air is compressed reversibly and adiabatically in process 1-2. Heat is then added to it from an external source reversibly at constant pressure in process 2-3. Air then expands reversibly and adiabatically in process 3-4. Heat is rejected reversibly at constant volume in process 4-1, and the cycle repeats itself. For m. kg of air in the cylinder, the efficiency analysis of the cycle can be made as given below. Heat supplied Q1 Q23 mc p T3 T2 Heat rejected Q2 Q41 mcv T4 T1 Efficiency 1 1 mcv T4 T1 Q2 1 Q1 mc p T3 T2 T4 T1 T3 T2 Let compression ratio, r (cut-off ratio) V3 v3 V2 v 2 Process 1-2 (Compression) …(1) V1 v1 V2 v2 T2 V1 T1 V2 1 r 1 or T2 T1 r 1 Process 2-3 (Constant pressure) T3 V3 T2 V2 1 or T3 .T2 .T1 r 1 Process 3-4 (Expansion) T3 V4 T4 V3 Now T4 1 r T3 r / 1 1 V4 V1 V1 V2 r V3 V3 V2 V3 T1 r 1 T1 . r 1 r / Substituting values of T2 , T3 , T4 in (1) we get T1 . T1 1 1 T1 .r .T1 .r diesel 1 Air Standard Efficiency diesel 1 1 1 1 1 1 1 1 r 1 r …(2) 1 1 is also greater than unity. As 1, 1 Therefore, the efficiency of the diesel engine is less than that of the Otto cycle for the same compression ratio. Work done in Diesel cycle The net work done in diesel cycle in terms of P, V is given as follow: The work done W P2 V3 V2 P3V3 P4V4 1 P2 V2 V2 P2V2 P1V1 1 P3 V2 P4 rV2 P2V2 P1 rV2 1 1 V3 V ;V3 V2 ; 1 r;V1 rV2 ;V1 V4 V4 rV2 V2 V2 W P2V2 1 V2 P2 1 1 P3 P4 r P2 P1r 1 W P3 V2 P4 rV2 P2V2 P1 rV2 1 1 P2V2 P4 P1 1 1 r 1 r P3 P2 1 P3 P2 P2V2 1r 1 r 1 1 r 1 1 P V 4 3 r r r P3 V4 P1V1r 1 1 1 r 1 1 r 1 W 1 P V V 2 1 orP2 P1 r and 1 r or V2 V1r 1 V2 P1 V2 Work Done W P1V1r 1 1 r 1 1 1 …(3) Expression for Mean Effective Pressure (Pm) for Diesel cycle We know that Mean Effective Pressure (Pm) is given by Net Work done W Swept volume V1 V2 …(4) 1 r 1 V1 V2 V1 1 V1 r r …(5) Pm Substituting (3), (5) in (4) we get Pm P1r 1 r 1 1 1r 1