Otto, Diesel & Dual Combustion Cycles: Thermodynamics

advertisement

Thermodynamics 1

Otto Cycle, Diesel Cycle & Dual Combustion Cycle

Internal combustion engine is a

heat that derives its power from the

energy liberated by the explosion of a

mixture

gaseous

of

or

some

hydrocarbon,

vaporized

atmospheric air.

form,

in

with

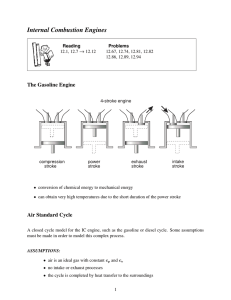

Spark – Ignition (SI) or Gasoline Engine

Four-Stroke Cycle Gasoline Engine

Intake stroke - piston moves down the

cylinder and draws in fuel-air mixture

Compression stroke - piston

compresses the mixture in the cylinder

and the spark plug ignites the mixture

Power stroke - burning gases push the

piston down

Exhaust stroke - piston pushes the

burned gases out

Four strokes of the piston and two

revolutions are required to complete a

cycle.

Air-Standard Otto Cycle

1-2: isentropic compression

2-3: constant volume addition of heat

3-4: isentropic expansion

4-1: constant volume rejection of heat

Air-standard cycle means that air alone is the working medium

QA = mcv (T3 – T2)

QR = mcv (T1 –T4) = -mcv (T4 – T1)

W = QA – QR = mcv (T3 – T2) – mcv (T4 – T1)

e=

W

QA

mcv T3 −T2 − mcv (T4 −T1 )

=

mcv (T3 −T2 )

T4 −T1

= 1{1}

T3 −T2

1

=1-

where rk =

x 100

rkk−1

𝑉1

,

𝑉2

the isentropic compression ratio

Derivation of the formula for e:

Process 3-4:

Process 1-2:

•

𝑇2

𝑇1

=

V1

V2

•

k−1

Process 3-4:

•

=

V4 k−1

V3

=

V4 k−1

V3

=

V1 k−1

V2

• T3 = T4rk k−1 {3}

• T2 = T1rk k−1 {2}

𝑇3

𝑇4

𝑇3

𝑇4

=

V1 k−1

V2

• T3 = T4rk k−1 {3}

Substituting equations {2}

and {3} in equation {1}

e = 1e=1-

T4 −T1

T4 rkk−1 −T1 rkk−1

1

rkk−1

Work from the pV plane:

p V −p V

p V −p V

W = ∑W = 2 2 1 1 + 4 4 3 3

1−k

1−k

Clearance volume, percent clearance

rk =

V1

V2

=

VD + V3

V3

=

VD + cVD

cVD

=

1+c

c

Where:

c = percent clearance

V3 = clearance volume

VD = displacement volume

Ideal standard of comparison

Cold-air standard, k = 1.4

Hot air standard, k < 1.4

The thermal efficiency of the theoretical Otto cycle is

• Increased by increase in rk

• Increased by increase in k

• Independent of the heat added

“The average family car has a compression ratio of

about 9:1. The economic life of the average car is 8

years or 80,000 miles of motoring.”

Sample Problem 1: Otto Cycle

1. An Otto cycle operates on 0.1 lb/s of air from 13psia and 130°F at the

beginning of compression. The temperature at the end of

combustion is 5000°R; compression ratio is 5.5; hot-air standard k = 1.3.

(a) Find V1, p2, t2, p3, V3, t4, and p4. (b) Compute QA, QR, W, e, and

the corresponding hp

Sample Problem 1: Otto Cycle

Point 3:

Solution

m = 0.1 lb/s

rk = 5.5

k = 1.3

p1 = 13psia

T1 = 130 + 460 = 590°R

T3 = 5000°R

V1 =

ṁ𝑹𝑻𝟏

𝒑𝟏

p 2 = p1

T2 = T1

=

(𝟎.𝟏)(𝟓𝟑.𝟑𝟒)(𝟓𝟗𝟎)

(𝟏𝟑)(𝟏𝟒𝟒)

= 1.681

𝑽𝟏

𝑽𝟐

𝒌

V2 =

𝑽𝟏

𝒓𝒌

𝒇𝒕𝟑

𝒔

= p1(rk)k = (13)(5.5)1.3

𝑽𝟏 𝒌−𝟏

𝑽𝟐

=

𝒑𝟐

𝑻𝟐

𝒇𝒕𝟑

𝒔

= (5000)

𝟏𝟏𝟗.𝟐

𝟗𝟖𝟑.𝟗

= 605.8psia

𝑽𝟑 𝒌−𝟏

𝟏 𝟏.𝟑−𝟏

T4 = T3

= (5000)

= 2998°R

𝑽𝟒

𝟓.𝟓

𝒑

𝟏𝟑

p4 = T4 𝟏 = (2998)

= 66.1psia

𝑻𝟏

𝟓𝟗𝟎

b) cv =

𝑹

𝒌−𝟏

=

𝟓𝟑.𝟑𝟒

(𝟕𝟕𝟖)(𝟏.𝟑−𝟏)

= 0.2285

𝑩𝒕𝒖

𝒍𝒃𝑹°

QA = mcv(T1 – T4) = (0.1)(0.2285)(5000 – 983.9)

𝟏.𝟔𝟖𝟏

𝟓.𝟓

= T1(rk)k-1 = (590)(5.5)1.3-1

= 0.3056

𝑩𝒕𝒖

= 91.77

𝒔

QR = mcv(T1 – T4) = (0.1)(0.2285)(590 – 2998)

= -55.03

= 983.9°R = 523.9°F

•

p3 = T3

•

= 119.2psia

•

•

•

Point 2:

•

V3 = V2 = 0.3056

Point 4:

a) Point 1:

•

•

Ẇ = QA –QR = 91.77 – 55.03 = 36.75

e=

𝒇𝒕𝟑

𝒔

𝑩𝒕𝒖

𝒔

W=

𝑾

𝑸𝑨

=

𝟑𝟔.𝟕𝟓

𝟗𝟏.𝟕𝟕

= 0.4005 or 40.05%

𝑩𝒕𝒖

𝒔

)(𝟔𝟎

)

𝒔

𝒎𝒊𝒏

𝑩𝒕𝒖

𝟒𝟐.𝟒

(𝒎𝒊𝒏)(𝒉𝒑)

(𝟑𝟔.𝟕𝟓

= 52hp

𝑩𝒕𝒖

𝒔

Sample Problem 2: Otto Engine

2. The conditions at the beginning of compression in an Otto engine

operating on hot-air standard with k = 1.34, are 101.3kPa, 0.038m3

and 32°C. The clearance is 10% and 12.6kJ are added per cycle.

Determine (a) V2, T2, p2, T3, p3, T4 and p4, (b) W, (c) e, and (d) pm.

Sample Problem 2: Otto Engine

Solution

p1 = 101.3kPa

V1 = 0.038m3

T1 = 32°C + 273 = 305K

cv =

𝑹

𝒌−𝟏

=

𝟎.𝟐𝟖𝟕𝟎𝟖

𝟏.𝟑𝟒−𝟏

m=

𝒑𝟏 𝑽𝟏

𝐑𝑻𝟏

=

(𝟏𝟎𝟏.𝟑)(𝟎.𝟎𝟑𝟖)

(𝟎.𝟐𝟖𝟕𝟎𝟖)(𝟑𝟎𝟓)

=

𝒌𝑱

0.8444

𝒌𝒈𝑲

= 0.04396 kg

rk =

𝟏+𝒄

𝒄

=

𝟏 + 𝟎.𝟏𝟎

𝟎.𝟏𝟎

•

=

𝟎.𝟎𝟑𝟖

𝟏𝟏

V2 =

•

•

T2 = T1rkk-1 =

p2 = p1rk k =

= 0.003455m3

(305)(11)1.34-1

= 689 K

(101.3)(11)1.34 = 2518 kPa

𝑻𝟑

𝑻𝟐

= (2518)

𝟏𝟎𝟐𝟖

𝟔𝟖𝟗

= 3757kPa

Point 4:

•

T4 = T3

𝑽𝟑 𝒌−𝟏

𝑽𝟒

= T3

𝟏 𝒌−𝟏

𝒓𝒌

= (1028)

𝟏 𝟏.𝟑𝟒−𝟏

𝟏𝟏

= 455 K

•

•

p3 = p2

= 11

a) Point 2:

𝑽𝟏

𝒓𝒌

Point 3:

QA = mcv (T3 – T2)

12.6 = (0.04396)(0.8444)(T3 – 689)

• T3 = 1028 K

p4 = p3

𝑽𝟑 𝒌

𝑽𝟒

= p3

𝟏 𝒌−𝟏

𝒓𝒌

= (3757)

𝟏 𝟏.𝟑𝟒

𝟏𝟏

= 151 kPa

b) QR = mcv (T1 – T4)

= (0.04396)(0.8444)(305 – 455) = -5.57kJ

W = QA – QR = 12.6 – 5.57 = 7.03 kJ

c) e =

𝑾

𝑸𝑨

d) pm =

=

𝑾

𝑽𝑫

𝟕.𝟎𝟑

𝟏𝟐.𝟔

=

= 0.558 or 55.8%

𝑾

𝑽𝟏 − 𝑽𝟐

=

𝟏𝟐.𝟔

𝟎.𝟎𝟑𝟖−𝟎.𝟎𝟎𝟑𝟒𝟓𝟓

= 364.7kPa

Compression Ignition or Diesel Engine

Four-Stroke Cycle Diesel Engine

Intake stroke - piston moves down

and draws air into the cylinder

Compression stroke - piston rises and

compresses the air to a temperature

of about 900°F (480°C)

Power stroke - oil is injected into the

cylinder, it mixes with the hot air and

burns explosively

Exhaust stroke - gases produced by

combustion push the piston up and

forces the burned gases out of the

cylinder

Air-Standard Diesel Cycle

1-2: isentropic compression

2-3: constant pressure addition of heat

3-4: isentropic expansion

4-1: constant volume rejection of heat

Air-standard cycle means that air alone is the working medium

QA = mcp (T3 – T2)

QR = mcv (T1 – T4) = -mcv (T4 – T1)

W = QA – QR = mcp (T3 – T2) – mcv (T4 –T1)

e=

W

QA

=

mcp (T 3− T2 )− mcv (T4 − T1 )

mcp (T3 − T2 )

=1-

T4 − T1

k(T3 − T2 )

=1-

rck −1

rkk−1 k(rc −1)

{4}

1

V1

V2

V3

V2

where rk = is the compression ratio and rc = is the cutoff ratio and Point 3 is called the cut-off point.

Derivation of the formula for e:

Process 1-2:

•

𝑇2

𝑇1

=

•

V1 k−1

V2

• T2 = T1 (rkk-1)

𝑇3

𝑇2

=

V3

V2

{5}

= rc

• T3 = T1 (rkk-1) (rc)

𝑇4

𝑇3

=

• T4 =

Process 2-3:

•

Process 3-4:

{6}

V3 k−1

V4

T1 (rkk-1)

=

V2 rc k−1

V1

(rc)

=

rck−1

rkk−1

rck−1

rkk−1

• T4 = T1 (rck) {7}

Substituting equations {5}, {6}

and {7} in equation {4}

e=1-

e=1-

T1 (rck )− T1

k T1 rkk−1 rc − T1 (rkk−1 )

rck −1

rkk−1 k(rc −1)

1

Relation among rk, rc and re (expansion ratio)

re =

rk =

𝑉4

𝑉3

𝑉1

𝑉2

=

=

𝑉1

𝑉3

𝑉3

𝑉2

𝑉1

𝑉3

rk = (rc)(re)

The efficiency of the Diesel cycle differs from that of the Otto cycle by

the bracketed factor

rck −1

.

k(rc −1)

This factor is always greater than 1, because rc is

always greater than 1. Thus, for a particular compression ratio rk, the Otto cycle

is more efficient. However, since the Diesel engine compresses air only, the

compression ratio is higher than in an Otto engine.

“An actual Diesel engine with a compression ratio of 15 is more

efficient than an actual Otto engine with a compression ratio of 9.”

Sample Problem 1: Diesel Cycle

1. A Diesel cycle operates with a compression ratio of 13.5 and with a

cut-off occurring at 6% of the stroke. State 1 is defined by 14 psia and

140°F. For the hot-air standard with k = 1.34 and for an initial 1 cu ft.,

Compute (a) t2, p2, V2, t3, V3, p4, and t4, (b) QR, (c) W, (d) e and pm

(e) For a rate of circulation of 1000cfm, compute the horsepower

Sample Problem 1: Diesel Cycle

Solution

a) Point 2:

rk = 13.5

•

T1 = 140+460 = 600°R

V1 = 1 cu ft.

=

𝟓𝟑.𝟑𝟒

(𝟕𝟕𝟖)(𝟏.𝟑𝟒−𝟏)

=

𝑩𝒕𝒖

0.2016

𝐥𝐛𝐑°

cp = kcv = (1.34)(0.2016)

=

m=

𝑩𝒕𝒖

0.2702

𝐥𝐛𝐑°

𝒑𝟏 𝑽𝟏

𝐑𝑻𝟏

=

𝟏

𝟏𝟑.𝟓

= 0.0741 ft3

T2 = T1 (rkk-1) = (600) (13.5)1.34 – 1

= 1454°R = 994°F

• p2 = p1 (rkk-1) = (14) (13.5)1.34 = 457.9psia

Point 3:

• V3 = V2 + 0.06VD = V2 + 0.06(V1 – V2)

• V3 = 0.0741 + (0.06) (1 – 0.0741) = 0.1297 ft3

p1 = 14psia

cv =

𝑽𝟏

𝒓𝒌

•

k = 1.34

𝑹

𝒌−𝟏

V2 =

=

(𝟏𝟒)(𝟏𝟒𝟒)(𝟏)

(𝟔𝟎𝟎)(𝟓𝟑.𝟑𝟒)

•

𝑽𝟑 𝒌−𝟏

𝑽𝟐

= (1454)

𝟎.𝟏𝟐𝟗𝟕

𝟎.𝟎𝟕𝟒𝟏

= 2545°R = 2085°F

Point 4:

•

•

= 0.630lb

T3 = T2

T4 =

p4 =

𝑽𝟑 𝒌−𝟏

T3

𝑽𝟒

𝑽𝟑 𝒌

p3

𝑽𝟒

= (2545)

= (457.9)

𝟎.𝟏𝟐𝟗𝟕 𝟏.𝟑𝟒−𝟏

𝟏

𝟎.𝟏𝟐𝟗𝟕 𝟏.𝟑𝟒

𝟏

= 1271°R = 811°F

= 29.7psia

Sample Problem 1: Diesel Cycle

b) QA = mcp (T3 – T2) = (0.063) (0.2702) (2545 – 1454) = 18.57 Btu

QR = mcv (T1 – T4) = (0.063) (0.2016) (600 – 1271) = 8.52Btu

c) W = QA – QR = 18.57 – 8.52 = 10.05Btu

d) e =

e) W =

𝑾

𝑸𝑨

=

𝟏𝟎.𝟎𝟓

𝟏𝟖.𝟓𝟕

= 0.5412 or 54.12% and pm =

𝒇𝒕𝟑

𝟏𝟎𝟎𝟎𝒎𝒊𝒏

𝑩𝒕𝒖

𝟒𝟐.𝟒𝒎𝒊𝒏 𝒉𝒑

𝑩𝒕𝒖

𝟏𝟎.𝟎𝟓 𝟑

𝒇𝒕

= 237hp

𝟏𝟎.𝟎𝟓 (𝟕𝟕𝟖)

𝟏−𝟎.𝟎𝟕𝟒𝟏 (𝟏𝟒𝟒)

= 58.64psi

Sample Problem 2: Diesel Engine

2. There are supplied 317 kJ/cycle to an ideal Diesel engine operating

on 227 g air: p1 = 97.91kPa, t1 = 48.9°C. At the end of compression,

p2 = 3930kPa. Determine (a) rk, (b) c, (c) rc, (d) W, (e) e, and (f) pm.

Sample Problem 2: Diesel Engine

Solution

m = 0.227kg

p1 = 97.91kPa

T1 = 48.9 + 273 = 321.9 K

p2 = 3930kPa

QA = 317kJ/cycle

•

Point 1:

•

V1 =

Point 2:

•

•

𝐦𝐑𝑻𝟏

𝒑𝟏

V2 = V1

T2 = T1

=

𝟏

𝒑𝟏 𝒌

𝒑𝟐

(𝟎.𝟐𝟐𝟕)(𝟎.𝟐𝟖𝟕𝟎𝟖)(𝟑𝟐𝟏.𝟗)

𝟗𝟕.𝟗𝟏

= (0.2143)

𝒌− 𝟏

𝒑𝟏 𝒌

𝒑𝟐

= (321.9)

𝟗𝟕.𝟗𝟏

𝟑𝟗𝟑𝟎

𝟑𝟗𝟑𝟎

𝟗𝟕.𝟗𝟏

𝟏

𝟏.𝟒

= 0.2143 m3

= 0.0153m3

𝟏.𝟒−𝟏

𝟏.𝟒

•

V3 =

= (0.0153)

𝟐𝟑𝟏𝟐

𝟗𝟐𝟒.𝟒

a) rk =

𝑽𝟏

𝑽𝟐

b) rk =

𝟏+𝒄

;

𝒄

=

= (2312)

𝟎.𝟐𝟏𝟒𝟑

𝟎.𝟎𝟏𝟓𝟑

𝟎.𝟎𝟐𝟖𝟑 𝟏.𝟒−𝟏

𝟎.𝟐𝟏𝟒𝟑

= 1161 K

= 14

𝟏+𝒄

𝒄

14 =

c = 0.0769 or 7.69%

𝑽𝟑

𝑽𝟐

=

𝟎.𝟎𝟑𝟖𝟑

𝟎.𝟎𝟏𝟓𝟑

= 2.50

d) QR = mcv (T1 – T4)

= (0.227) (0.7186) (321.9 – 1161)

= 924.4 K

= 0.0383m3

𝑽𝟑 𝒌−𝟏

𝑽𝟒

T4 = T3

c) rc =

Point 3:

QA = mcp (T3 – T2)

317 = (0.227) (1.0062) (T3 – 924.4)

• T3 = 2312 K

𝑻

V2 𝟑

𝑻𝟐

Point 4:

= -136.9kJ

W = QA – QR = 317 – 136.9 = 180.1 kJ

e) e =

𝑾

𝑸𝑨

f) pm =

𝑾

𝑽𝑫

=

𝟏𝟖𝟎.𝟏

𝟑𝟏𝟕

=

= 0.5681 or 56.81%

𝑾

𝑽𝟏 − 𝑽𝟐

=

𝟏𝟖𝟎.𝟏

𝟎.𝟐𝟏𝟒𝟑− 𝟎.𝟎𝟏𝟓𝟑

= 905kPa

Dual Combustion Engine

“In modern compression ignition engines the pressure

is not constant during the combustion process. The major

part of combustion can be considered to approach a

constant-volume process, and the late burning, a constantpressure process.”

Air-Standard Dual Cycle

1-2: isentropic compression

2-3: constant volume addition of heat

3-4: constant pressure addition of heat

4-5: isentropic expansion

5-1: constant volume rejection of heat

Air-standard cycle means that air alone is the working medium

QA = mcv(T3 – T2) + mcp (T4 – T3)

QR = mcv (T1 – T5) = -mcv (T5 – T1)

W = QA – QR = mcv (T3 – T2) = mcv (T4 – T3) – mcv (T5 – T1)

e=

W

QA

=1–

=1–

=

mcv T3 − T2 +mcp T4 − T3 −mcv (T5 − T1 )

mcv T3 − T2 +mcp (T4 − T3 )

T5 − T1

T3 − T2 + k (T4 − T3 )

1

{8}

rp rkk−1 −1)

rkk−1 rp −1+ rp k (rc − 1)

p

where rp = 3 is the pressure ratio during the constant volume portion of

p2

V

V

combustion, rk = 1 is the compression ratio and rc = 4 is the cut-off ratio

V2

V3

The thermal efficiency of this cycle lies between that of the ideal

Otto and the ideal Diesel.

Derivation of the formula for e: Process 4-5:

Process 1-2:

•

T2

T1

=

• T2 = T1rkk-1

Process 2-3:

•

T3

T2

=

p3

p2

T4

T3

=

V4

V3

{9}

• T5 =

= rp

• T3 = T1rkk-1 (rp)

Process 3-4:

•

•

V1 k−1

V2

{10}

= rc

• T4 = T1rkk-1 (rp)(rc)

V4 k−1

V4 k−1

=

=

V5

V1

V2 rc k−1

rck− 1

= k− 1

V1

rk

T5

T4

T1rkk-1(rp)(rc)

• T5= T1(rp)(rc)

=

V3 rc k−1

V1

=

rck− 1

rkk− 1

{12}

k

Substituting equations {9}, {10}, {11}

and {12} in equation {8}

e=

1-

{11}

e = 1-

𝑇1 𝑟𝑝 𝑟𝑐 𝑘 − 𝑇1

𝑇1 𝑟𝑘𝑘− 1 𝑟𝑝 − 𝑇1 𝑟𝑘𝑘−1 + 𝑘(𝑇1 𝑟𝑘𝑘−1 𝑟𝑝 𝑟𝑐 − 𝑇1 𝑟𝑘𝑘−1 𝑟𝑝 )

1

𝑟𝑝 𝑟𝑐 𝑘 −1

𝑟𝑘𝑘−1 𝑟𝑝 −1 + 𝑟𝑝 𝑘(𝑟𝑐 −1)

Sample Problem 1: Dual Cycle

1. At the beginning of compression in an ideal dual combustion cycle,

the working fluid is 1 lb of air at 14.1 psia and 80°F. The compression

ratio is 9, the pressure at the end of the constant volume addition of

heat is 470psia, and there are added 100Btu during the constant

pressure expansion. Find (a) rp, (b) rc, (c) the percentage clearance,

(d) e and (f) pm

Sample Problem 1: Dual Cycle

Solution

m = 1lb air

p1 = 14.1 psia

T1 = 80 + 460 = 540°R

p3 = 470 psia

rk = 9

Q3-4 = 100Btu

Point 1:

•

V1 =

𝐦𝐑𝑻𝟏

𝒑𝟏

=

𝟏 𝟓𝟑.𝟑𝟒 (𝟓𝟒𝟎)

𝟏𝟒.𝟏 (𝟏𝟒𝟒)

𝑽𝟏

𝒓𝒌

𝟏𝟒.𝟏𝟖𝟔

𝟗

= 14.186ft3

Point 2:

•

V2 =

=

•

T2 = T1

𝑽𝟏 𝒌−𝟏

𝑽𝟐

•

p 2 = p1

𝑽𝟏 𝒌

𝑽𝟐

= 1.576ft3

= (540) (9)1.4 – 1 = 1300°R

= (14.1) (9)1.4 – 1 = 305.6psia

Point 3:

•

T3 = T2

𝒑𝟑

𝒑𝟐

= (1300)

𝟒𝟕𝟎

𝟑𝟎𝟓.𝟔

= 𝟏𝟗𝟗𝟗°R

Point 4:

Q3-4 = (m) (cp) (T4 – T3)

100 = (1) (0.24) (T4 – 1999)

• T4 = 2416°R

•

V4 = V3

𝑻𝟒

𝑻𝟑

= (1.576)

𝟐𝟒𝟏𝟔

𝟏𝟗𝟗𝟗

= 1.905ft3

Point 5:

•

T5 =

𝑽𝟒 𝒌−𝟏

T4

𝑽𝟓

= (2416)

𝟏.𝟗𝟎𝟓 𝟏.𝟒−𝟏

𝟏𝟒.𝟏𝟖𝟔

= 1082°R

Sample Problem 1: Dual Cycle

a) rp =

𝒑𝟑

𝒑𝟐

=

𝟒𝟕𝟎

𝟑𝟎𝟓.𝟔

= 1.54

b) rc =

𝑽𝟒

𝑽𝟑

=

𝟏.𝟗𝟎𝟓

𝟏.𝟓𝟕𝟔

= 1.21

c) rk =

𝟏+𝒄

;

𝒄

9=

𝟏+𝒄

𝒄

c = 0.125 or 12.5%

d) QA = Q2-3 + Q3-4 = (m) (cv) (T3 – T2) + 100

= (1) (0.1714) (1999 – 1300) + 100 = 219.8Btu

QR = (m) (cv) (T1 – T5) = (1) (0.1714) (540 – 1082) = -92.9Btu

e=

𝑾

𝑸𝑨

pm =

𝟐𝟏𝟗−𝟗𝟐.𝟗

𝟐𝟏𝟗.𝟖

=

𝑾

𝑽𝟏 − 𝑽𝟐

=

= 0.5773 or 57.73%

𝟏𝟐𝟔.𝟗 (𝟕𝟕𝟖)

𝟏𝟒.𝟏𝟖𝟔−𝟏.𝟓𝟕𝟔 (𝟏𝟒𝟒)

= 54.37psi

Sample Problem 2: Dual Cycle

2. An ideal dual combustion cycle operates on 454g of air. At the

beginning of compression, the air is at 96.53kPa, 43.3°C. Let rp = 1.5,

rc = 1.60 and rk = 11. Determine (a) the percentage clearance, b) p,

V, and T at each corner of the cycle, (c) QA, (d) e, and (e) pm.

Sample Problem 2: Dual Cycle

Solution

m = 0.454 kg of air

p1 = 96.53 kPa

T1 = 43.3 + 273 = 316.3 K

rp = 1.5

rc = 1.60

rk = 11

a)

b)

𝟏+𝒄

𝟏+𝒄

rk =

; 11 =

;

𝒄

𝒄

𝒎𝑹𝑻𝟏

𝟎.𝟒𝟓𝟒

V1 =

=

𝒑𝟏

V2 =

𝑽𝟏

𝒓𝒌

T2 = T1

=

𝟎.𝟒𝟐𝟕𝟏

𝟏𝟏

𝑽𝟏 𝒌−𝟏

𝑽𝟐

=

c = 0.10 or 10%

𝟎.𝟐𝟖𝟕𝟎𝟖 (𝟑𝟏𝟔.𝟑)

𝟗𝟔.𝟓𝟑

= 0.4271m3

0.03883m3

= T1 (rk) k-1 = (316.3) (11) 1.4-1

= 825.4 K

p2 = p 1

𝑽𝟏 𝒌

𝑽𝟐

= p1 (rk) k = (96.53) (11)1.4

= 2770.8kPa

p3 = (p2) (rp) = (2770.8) (1.5) = 4156.2 kPa

𝟒𝟏𝟓𝟔.𝟐

𝟐𝟕𝟕𝟎.𝟖

𝒑𝟑

𝒑𝟐

= (825.4)

T4 = T3

𝑽𝟒

𝑽𝟑

= (1238.1) (1.6) = 1981 K

T5 = T4

𝑽𝟒 𝒌−𝟏

𝑽𝟓

T3 = T2

= 1238.1 K

V4 = (V3) (rc) = (0.03883) (1.60) = 0.06213m3

p5 = p1

𝑻𝟓

𝑻𝟏

= (1981)

= (96.53)

𝟎.𝟎𝟔𝟐𝟏𝟑 𝟏.𝟒−𝟏

𝟎.𝟒𝟐𝟕𝟏

𝟗𝟏𝟔.𝟐

𝟑𝟏𝟔.𝟑

= 916.2 K

= 279.6kPa

c) QA = (m) (cv) (T3 – T2) + (m) (cp) (T4 – T3)

= (0.454)(0.7186)(1238.1 – 825.4) +

(0.454) (1.0062) (1981 – 1238.1) = 474 kJ

d) QR = (m) (cv) (T1 – T5)

= (0.454)(0.7186)(316.3 – 916.2) = 195.7kJ

W = QA – QR = 474 – 195.7 = 278.3 kJ

e=

𝑾

𝑸𝑨

e) pm =

=

𝟐𝟕𝟖.𝟑

𝟒𝟕𝟒

𝑾

𝑽𝟏 − 𝑽𝟐

=

= 0.5871 or 58.71%

𝟐𝟕𝟖.𝟑

𝟎.𝟒𝟐𝟕𝟏 − 𝟎.𝟎𝟑𝟖𝟖𝟑

= 716.8kPa

Thermodynamics 1

Reference: Sta. Maria, H. B. (1990). Thermodynamics 1. Mandaluyong City, Philippines: National Book Store.

Presentation made by David Anthony C. Manalo & Gino Carlo O. Cadao