Design and Analysis of Multi-Factored Experiments

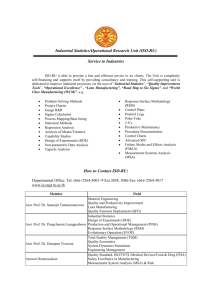

advertisement

Design and Analysis of

Multi-Factored Experiments

Response Surface Methodology

(RSM)

L . M. Lye

DOE Course

1

Introduction to Response Surface

Methodology (RSM)

• Best and most comprehensive reference:

– R. H. Myers and D. C. Montgomery (2002): Response

Surface Methodology: Process and Product

Optimization Using Designed Experiments, John Wiley

and Sons.

• Best software:

– Design-Expert Version 6 or 7- Statease Inc.

– Available at www.statease.com

– Minitab also has DOE and RSM capabilities

L . M. Lye

DOE Course

2

RSM: Introduction

• Primary focus of previous discussions is factor

screening

– Two-level factorials, fractional factorials are widely

used

• RSM dates from the 1950s (Box and Wilson,

1951)

• Early applications in the chemical industry

• Currently RSM is widely used in quality

improvement, product design, uncertainty

analysis, etc.

L . M. Lye

DOE Course

3

Objective of RSM

• RSM is a collection of mathematical and statistical

techniques that are useful for modeling and

analysis in applications where a response of

interest is influenced by several variables and the

objective is to optimize the response.

• Optimize maximize, minimize, or getting to a

target.

• Or, where a nonlinear model is warranted when

there is significant curvature in the response

surface.

L . M. Lye

DOE Course

4

Uses of RSM

• To determine the factor levels that will simultaneously

satisfy a set of desired specification (e.g. model

calibration)

• To determine the optimum combination of factors that

yield a desired response and describes the response

near the optimum

• To determine how a specific response is affected by

changes in the level of the factors over the specified

levels of interest

L . M. Lye

DOE Course

5

Uses of RSM (cont)

To achieve a quantitative understanding of the

system behavior over the region tested

To find conditions for process stability = insensitive

spot (robust condition)

To replace a more complex model with a much

simpler second-order regression model for use

within a limited range replacement models, meta

models, or surrogate models. E.g. Replacing a FEM

with a simple regression model.

L . M. Lye

DOE Course

6

Example

Suppose that an engineer wishes to find the levels

of temperature (x1) and feed concentration (x2) that

maximize the yield (y) of a process. The yield is a

function of the levels of x1 and x2, by an equation:

Y = f (x1, x2) + e

If we denote the expected response by

E(Y) = f (x1, x2) =

L . M. Lye

DOE Course

7

then the surface represented by:

= f (x1, x2)

is called a response surface.

The response surface maybe represented

graphically using a contour plot and/or a 3-D plot.

In the contour plot, lines of constant response (y)

are drawn in the x1, x2, plane.

L . M. Lye

DOE Course

8

L . M. Lye

DOE Course

9

These plots are of course possible only when we

have two factors.

With more than two factors, the optimal yield has

to be obtained using numerical optimization

methods.

In most RSM problems, the form of the

relationship between the response and the

independent variables is unknown. Thus, the first

step in RSM is to find a suitable approximation for

the true relationship between Y and the X’s.

L . M. Lye

DOE Course

10

If the response is well modeled by a linear function

of the independent variables, then the approximating

function is the first-order model (linear):

Y = b0 + b 1 x 1 + b2 x 2 + … + bk x k + e

This model can be obtained from a 2k or 2k-p design.

If there is curvature in the system, then a polynomial

of higher degree must be used, such as the secondorder model:

Y = b0 + Sbi xi + Sbii x2i + SSbij xi xj + e

This model has linear + interaction + quadratic terms.

L . M. Lye

DOE Course

11

• Many RSM problems utilize one or both of these

approximating polynomials. The response surface

analysis is then done in terms of the fitted surface.

The 2nd order model is nearly always adequate if

the surface is “smooth”.

• If the fitted surface is an adequate approximation

(high R2) of the true response function, then

analysis of the fitted surface will be approximately

equivalent to analysis of the actual system (within

bounds).

L . M. Lye

DOE Course

12

Types of functions

• Figures 1a through 1c on the

following pages illustrate possible

behaviors of responses as functions of

factor settings. In each case, assume

the value of the response increases

from the bottom of the figure to the top

and that the factor settings increase

from left to right.

L . M. Lye

DOE Course

13

Types of functions

Figure 1a

Figure 1b

Figure 1c

Linear function

Quadratic function

Cubic function

L . M. Lye

DOE Course

14

• If a response behaves as in Figure 1a, the

design matrix to quantify that behavior need

only contain factors with two levels -- low

and high.

• This model is a basic assumption of simple

two-level factorial and fractional factorial

designs.

• If a response behaves as in Figure 1b, the

minimum number of levels required for a

factor to quantify that behavior is three.

L . M. Lye

DOE Course

15

• One might logically assume that adding center points to

a two-level design would satisfy that requirement, but

the arrangement of the treatments in such a matrix

confounds all quadratic effects with each other.

• While a two-level design with center points cannot

estimate individual pure quadratic effects, it can detect

them effectively.

• A solution to creating a design matrix that permits the

estimation of simple curvature as shown in Figure 1b

would be to use a three-level factorial design. Table 1

explores that possibility.

• Finally, in more complex cases such as illustrated in

Figure 1c, the design matrix must contain at least four

levels of each factor to characterize the behavior of the

response adequately.

L . M. Lye

DOE Course

16

Table 1: 3 level factorial designs

• No. of factors

•

2

•

3

•

4

•

5

•

6

# of combinations(3k)

9

27

81

243

729

Number of coefficients

6

10

15

21

28

• The number of runs required for a 3k factorial

becomes unacceptable even more quickly than for

2k designs.

• The last column in Table 1 shows the number of

terms present in a quadratic model for each case.

L . M. Lye

DOE Course

17

Problems with 3 level factorial designs

• With only a modest number of factors, the number

of runs is very large, even an order of magnitude

greater than the number of parameters to be

estimated when k isn't small.

• For example, the absolute minimum number of

runs required to estimate all the terms present in a

four-factor quadratic model is 15: the intercept

term, 4 main effects, 6 two-factor interactions, and

4 quadratic terms.

• The corresponding 3k design for k = 4 requires 81

runs.

L . M. Lye

DOE Course

18

• Considering a fractional factorial at three levels is

a logical step, given the success of fractional

designs when applied to two-level designs.

• Unfortunately, the alias structure for the threelevel fractional factorial designs is considerably

more complex and harder to define than in the

two-level case.

• Additionally, the three-level factorial designs

suffer a major flaw in their lack of `rotatability’

• More on ‘rotatability’ later.

L . M. Lye

DOE Course

19

Sequential Nature of RSM

• Before going on to economical designs to fit secondorder models, let’s look at how RSM is carried out in

general.

• RSM is usually a sequential procedure. That is, it

done in small steps to locate the optimum point, if

that’s the objective. This is not always the only

objective.

• The analogy of climbing a hill is appropriate here

(especially if it is a very foggy day)!

L . M. Lye

DOE Course

20

Sequential Nature of RSM (continue)

• When we are far from the optimum (far from the

peak) there is little curvature in the system (slight

slope only), then first-order model will be

appropriate.

• The objective is to lead the experimenter rapidly

and efficiently to the general vicinity of the

optimum.

• Once the region of the optimum has been found, a

more elaborate model such a second-order model

may be employed, and an analysis performed to

locate the optimum.

L . M. Lye

DOE Course

21

L . M. Lye

DOE Course

22

• The eventual objective of RSM is to determine the

optimum operating conditions for the system or to

determine a region of the factor space in which

operating specifications are satisfied.

• The word “Optimum” in RSM is used in a special

sense. The “hill climbing” procedures of RSM

guarantee convergence to a local optimum only.

• In terms of experimental designs, when we are far

from optimum, a simple 2k factorial experiment

would allow us to fit a first-order model. As we

get nearer to the peak, we can check for curvature

by adding center-points to the 2k factorial.

L . M. Lye

DOE Course

23

• If curvature is significant, we may now be in the

vicinity of the peak and we use a more elaborate

design (e.g. a CCD) to fit a second-order model to

“capture” the optimum.

L . M. Lye

DOE Course

24

Method of Steepest Ascent

• The method of steepest ascent is a procedure for

moving sequentially along the path of steepest

ascent (PSA), that is, in the direction of the

maximum increase in the response. If

minimization is desired, then we are talking about

the method of steepest descent.

• For a first-order model, the contours of the

response surface is a series of parallel lines. The

direction of steepest ascent is the direction in

which the response y increases most rapidly. This

direction is normal (perpendicular) to the fitted

response surface contours.

L . M. Lye

DOE Course

25

First-order response and PSA

L . M. Lye

DOE Course

26

Path of Steepest Ascent (PSA)

• The PSA is usually the line through the center of

the region of interest and normal to the fitted

surface contours.

• The steps along the path are proportional to the

regression coefficients {bi}. The actual step size

would depend on the experimenter’s knowledge of

the process or other practical considerations.

L . M. Lye

DOE Course

27

For example, consider the first-order model:

y = 40.00 + 0.775 x1 + 0.325 x2

For steepest ascent, we move 0.775 unit in the x1

direction for every 0.325 unit in the x2 direction.

Thus the PSA passes through the center (0, 0) and

has a slope of 0.375/0.775.

L . M. Lye

DOE Course

28

If say 1 unit of x1 is actually equal to 5 minutes in

actual units, and 1 unit of x2 is actually equal to 5

F,

the PSA are Dx1 = 1.00 and

Dx2 = (0.375/0.775)

Dx2 = 0.42 = 2.1 F.

Therefore, you will move along the PSA by

increasing time by 5 minutes and temperature by 2

F. An actual observation on yield will be

determined at each point.

L . M. Lye

DOE Course

29

• Experiments are then conducted along the PSA

until no further increase in the response is

observed.

• Then a new first-order model may be fit, a new

direction of steepest ascent determined, and

further experiments conducted in that direction

until the experimenter feels that the process is near

the optimum (peak of hill is within grasp!).

L . M. Lye

DOE Course

30

Yield vs steps along the PSA

L . M. Lye

DOE Course

31

• The steepest ascent would terminate after about 10

steps with an observed response of about 80%.

Now we move on to the next step.

• Fit another first-order model with a new center

(where step 10 is) and check whether there is a

new PSA.

• Repeat until peak is near.

• See flowchart on the next slide.

L . M. Lye

DOE Course

32

Flowchart for RSM

L . M. Lye

DOE Course

33

Steps in RSM

• Fit linear model/planar models using two-level

factorials

• From results, determine PSA (Descent)

• Move along path until no improvement occurs

• Repeat steps 1 and 2 until near optimal (change of

direction is possible)

• Fit quadratic model near optimal in order to

determine curvature and find peak. This phase is

often called “method of local exploration”

• Run confirmatory tests

L . M. Lye

DOE Course

34

Steps in RSM

L . M. Lye

DOE Course

35

• With well-behaved functions with a single peak or

valley, the above procedure works very well. It

becomes more difficult to use RSM or any other

optimization routine when the surface has many

peaks, ridges, and valleys.

Response

surface with

many peaks

and valleys

L . M. Lye

DOE Course

36

Multiple Objectives

• With more than 2 factors, it is more difficult to

determine where the optimal is. There may be

several possible “optimal” points and not all are

desirable. Whatever the final choice of optimal

factor levels, common sense and process

knowledge must be your guide.

• It is also possible to have more than one response

variable with different objectives (sometimes

conflicting). For these cases, a weighting system

may be used to for the various objectives.

L . M. Lye

DOE Course

37

Methods of Local Exploration

• The method of steepest ascent, in addition to

fitting first-order model, must provide additional

information that will eventually identify when the

first-order model is no longer valid.

• This information can come only from additional

degrees of freedom which are used to measure

“lack of fit” in some way.

• This means additional levels and extra data points.

• It is rare to go more than 5 levels for even the

most complex response surfaces.

L . M. Lye

DOE Course

38

Consider the 2nd order model:

Y = b0 + b1 x 1 + b2 x 2 + … + bk x k

+ b11 x12 + b22 x22 + … + bkk xk2

+ b12 x1 x2 + … + b1k x1 xk + … + b23 x2 x3

+ … + bk-1,k xk-1 xk + e ------- EQN (1)

To be able to fit a 2nd order model like EQN (1),

there must be least three levels and enough data

points.

L . M. Lye

DOE Course

39

Designs for fitting 2nd order models

• Two very useful and popular experimental designs

that allow a 2nd order model to be fit are the:

Central Composite Design (CCD)

Box-Behnken Design (BBD)

Both designs are built up from simple factorial or

fractional factorial designs.

L . M. Lye

DOE Course

40

3-D views of CCD and BBD

L . M. Lye

DOE Course

41

Central Composite Design (CCD)

Each factor varies over five levels

Typically smaller than Box-Behnken designs

Built upon two-level factorials or fractional

factorials of Resolution V or greater

Can be done in stages factorial + centerpoints +

axial points

Rotatable

L . M. Lye

DOE Course

42

General Structure of CCD

• 2k Factorial + 2k Star or axial points + nc

Centerpoints

• The factorial part can be a fractional factorial as

long as it is of Resolution V or greater so that the

2 factor interaction terms are not aliased with

other 2 factor interaction terms.

• The “star” or “axial” points in conjunction with

the factorial and centerpoints allows the quadratic

terms (bii) to be estimated.

L . M. Lye

DOE Course

43

Generation of a CCD

Factorial

points +

centerpoints

L . M. Lye

Axial

points

DOE Course

44

Axial points are points on the coordinate axes at distances “a”

from the design center; that is, with coordinates: For 3

factors, we have 2k = 6 axial points like so:

(+a, 0, 0), (-a, 0, 0), (0, +a, 0), (0, -a, 0), (0, 0, +a),

(0, 0, -a)

The “a” value is usually chosen so that the CCD is rotatable.

At least one point must be at the design center (0, 0,

0). Usually more than one to get an estimate of “pure

error”. See earlier 3-D figure.

If the “a” value is 1.0, then we have a face-centered

CCD Not rotatable but easier to work with.

L . M. Lye

DOE Course

45

A 3-Factor CCD with 1 centerpoint

A 3 factor CCD with nc=1

L . M. Lye

Runs

x1

x2

x3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

-1

1

-1

1

-1

1

-1

1

-1.682

1.682

0

0

0

0

0

-1

-1

1

1

-1

-1

1

1

0

0

-1.682

1.682

0

0

0

-1

-1

-1

-1

1

1

1

1

0

0

0

0

-1.682

1.682

0

DOE Course

46

Values of a for CCD to be rotatable

k=2

3

4

5

6

1.414

1.682

2.000

2.378

2.828

7

3.364

The a value is calculated as the 4th root of 2k.

For a rotatable design the variance of the

predicted response is constant at all points that

are equidistant from the center of the design

L . M. Lye

DOE Course

47

Types of CCDs

The diagrams illustrate the three

types of central composite designs

for two factors. Note that the CCC

explores the largest process space

and the CCI explores the smallest

process space. Both the CCC and

CCI are rotatable designs, but the

CCF is not. In the CCC design, the

design points describe a circle

circumscribed about the factorial

square. For three factors, the CCC

design points describe a sphere

around the factorial cube.

L . M. Lye

DOE Course

48

Box-Behnken Designs (BBD)

• The Box-Behnken design is an independent

quadratic design in that it does not contain an

embedded factorial or fractional factorial design.

• In this design the treatment combinations are at

the midpoints of edges of the process space and at

the center.

• These designs are rotatable (or near rotatable) and

require 3 levels of each factor.

• The designs have limited capability for orthogonal

blocking compared to the central composite

designs.

L . M. Lye

DOE Course

49

BBD - summary

Each factor is varied over three levels (within low

and high value)

Alternative to central composite designs which

requires 5 levels

BBD not always rotatable

Combinations of 2-level factorial designs form the

BBD.

L . M. Lye

DOE Course

50

A 3-Factor BBD with 1 centerpoint

A 3-factor BBD with nc=31

L . M. Lye

1

Runs

x1

x2

x3

1

2

3

4

5

6

7

8

9

10

11

12

13

-1

-1

1

1

-1

-1

1

1

0

0

0

0

0

-1

1

-1

1

0

0

0

0

-1

-1

1

1

0

0

0

0

0

-1

1

-1

1

-1

1

-1

1

0

DOE Course

51

Brief Comparison of CCD and BBD

With one centerpoint, for

k = 3, CCD requires 15 runs; BBD requires 13 runs

k = 4, CCD requires 25 runs; BBD also requires 25 runs

k = 5, CCD requires 43 runs; BBD requires 41 runs

but, for CCD we can run a 25-1 FFD with Resolution V.

Hence we need only 27 runs.

In general CCD is preferred over BBD. See separate

handout comparing CCD and BBD in more detail.

L . M. Lye

DOE Course

52

Analysis of the fitted response surface

• The fitted response surface can take on many

shapes.

• For 2 or less dimensions, we can plot the response

against the factor(s) and graphically determine

where the optimal response is.

• We can also tell from the contour plots or 3-D

plots whether we have a maximum, minimum, or a

saddle point. These points are stationary points.

L . M. Lye

DOE Course

53

Types of stationary points

a) Maximum point; b) Minimum point; c) Saddle point

L . M. Lye

DOE Course

54

With more than 2 factors

• For more than 2 factors, we need to use numerical

methods to tell what kind of stationary point we

have.

• In some cases, even this fails.

• The levels of the k factors at which the response is

optimal can be determined for the unconstrained

case by simple calculus.

L . M. Lye

DOE Course

55

When k=1

Consider the 2nd order prediction model with k =1:

yˆ b0 b1x b2 x 2

Provided that b2 is not zero, the optimum response

is obtained by:

dy

b1 2b2 x 0

dx

Giving:

L . M. Lye

b1

x

2b2

DOE Course

56

For k > 1

In the case of k > 1, we can write the 2nd order equation

y = b0 + b1 x1 + b2 x2 + … + bk xk

+ b11 x12 + b22 x22 + … + bkk xk2

+ b12 x1 x2 + … + b1k x1 xk + … + b23 x2 x3

+ … + bk-1,k xk-1 xk

in a more convenient matrix form as:

y = b0 + x’ b + x’ B x

L . M. Lye

DOE Course

57

Where:

b1

b

b 2

bk

b11

1

b

12

2

B

1

2 b1k

L . M. Lye

x1

x

x 2

xk

1b

2 12

b22

1b

2 2k

DOE Course

1b

2 1k

1b

2 2k

bkk

58

Provided that matrix B is not singular, the 2nd order

model has a stationary point (i.e., a point at which

first partial derivatives with respect to x1, x2, …, xk

are all 0) given by:

1 1

xo B b

2

Depending on the nature of B, the stationary point

will be either a minimum, a maximum, or a saddle

point of the fitted surface. Moving away from a

saddle point in some directions produces an increase

in the response, while moving away in other

directions produces a decrease in the response.

L . M. Lye

DOE Course

59

Characterization of the stationary point

If B is positive definite all eigenvalues are positive

minimum pt.

If B is negative definite all eigenvalues are negative

maximum pt.

If B is indefinite eigenvalues are positive and

negative

saddle pt.

Eigenvalues of matrix B can be obtained using

MATLAB

L . M. Lye

DOE Course

60

Be aware that the xo obtained are random variables

and have associated uncertainty with them as are the

eigenvalues and matrix B.

There will be situations when an unconstrained

optimum will not be useful (when there is a saddle

point). We need to consider a constraint that forces us

to stay within the experimental region. The procedure

that has been developed for this is called ridge

analysis (see Myers and Montgomery). Need to use

Lagrange multipliers here for the optimization.

L . M. Lye

DOE Course

61

There are also other methods for solving

optimization problems constrained or unconstrained

that do not require the taking of partial derivatives

Direct Optimization procedures. E.g. NelderMead simplex search procedure, or by Monte Carlo

simulation.

RSM are now done mainly by software except for

simple cases.

L . M. Lye

DOE Course

62

Other Aspects of Response Surface Methodology

• Robust parameter design and process robustness

studies

– Find levels of controllable variables that optimize mean

response and minimize variability in the response

transmitted from “noise” variables

– Original approaches due to Taguchi (1980s)

– Modern approach based on RSM

• Experiments with mixtures

– Special type of RSM problem

– Design factors are components (ingredients) of a

mixture

– Response depends only on the proportions

– Many applications in product formulation

L . M. Lye

DOE Course

63

Designs for computer experiments

• Much developments of sophisticated engineering

designs, analysis, and products are now carried out

by high-powered computer simulations.

• Some of these sophisticated programs require

either expensive computing resources or computer

time.

• Hence simplifying the model by means of a meta

model or replacement model often makes more

sense. Done properly using DOE methods also

helps to understand the complex model a little

better.

L . M. Lye

DOE Course

64

• If the objective is to estimate a polynomial transfer

function, traditional RSMs such as CCD and BBD

have been used with some success.

• However, when analyzing data from computer

simulations, we must keep in mind that the true

model will only be approximated by RSM.

• The RSM metamodel will not only fall short in the

form of the model, but also in the number of

factors.

• Therefore, predictions will only be good within

the ranges of the factors specified and will exhibit

systematic error, or bias.

L . M. Lye

DOE Course

65

• The systematic error is what will be measured in

the residual – not the normal variations observed

from a random physical process.

• Despite these circumstances, much of the standard

statistical analyses remain relevant, including

model-fit such as the Prediction R2.

• However, the p-values will not be accurate

estimates of risks associated with the overall

model or any of its specific terms.

• The goal of fitting a RSM to deterministic

computer simulated data is for a perfect fit so that

there is no systematic error.

L . M. Lye

DOE Course

66

Check list for quality of fit of designs for RSM

•

•

•

•

•

•

Generate information throughout the region of interest.

Ensure the fitted value be as close as possible to the true value.

Give good detectability of lack of fit.

Allow designs of increasing order to be built up sequentially.

Require a minimum number of runs.

Choose unique design points in excess of the number of

coefficients in the model.

• Remain insensitive to influential values and bias from model.

• Allows one to fit a variety of models.

L . M. Lye

DOE Course

67

Newer DOE for Computer Experiments

• Computer models of actual or theoretical physical

systems can take many forms and different levels

of granularity of representation of the physical

system.

• Models are often very complicated and

constructed with different levels of fidelity such as

the detailed physics-based model as well as more

abstract and higher level models with less detailed

representation.

• A physics-based model may be represented by a

set of equations including linear, nonlinear,

ordinary, and partial differential equations.

L . M. Lye

DOE Course

68

• In view of the complex and nonlinear nature of modern

computer models, the classical RSM approaches usually do not

provide adequate coverage of the experimental area to provide

an accurate metamodel.

• To find a high quality metamodel, choosing a good set of

“training” data becomes an important issue for computer

simulation.

• Efficient “Space-Filling” designs are able to generate a set of

sample points that capture the maximum information between

the input-output relationships.

• E.g. Uniform Designs and Latin hypercube sampling are two

such designs.

• http://www.math.hkbu.edu.hk/UniformDesign/

L . M. Lye

DOE Course

69

L . M. Lye

A

B

C

3

1

1

1

2

3

1

1

3

2

2

4

4

1

2

3

2

2

4

3

4

2

4

1

1

2

1

3

1

4

4

3

1

3

3

3

2

1

2

1

4

2

2

4

4

2

3

1

3

4

3

1

3

4

4

4

2

4

2

3

Example of a 20 run, 3 factor, 4 level

Uniform Design Uqs (Centered L2)

Levels must be

equally spaced.

4 levels allow a cubic

equation to be fitted.

Correlations: A, B, C

B

C

DOE Course

A

-0.000

1.000

B

-0.040

0.867

0.000

1.000

70

Number of parameters for various models

# FACTORS

LINEAR

QUADRATIC

CUBIC

2

3

3

4

6

10

10

20

4

5

6

5

6

7

15

21

28

35

56

84

7

8

36

120

N = # of parameters + 4 additional points.

L . M. Lye

DOE Course

71

• How to find the best suited metamodel is another key

issue in computer experiments.

• Techniques include: kriging models, polynomial

regression models, local polynomial regression,

multivariate splines and wavelets, and neural networks

have been proposed.

• Therefore, design and modelling are two key issues in

computer experiments.

• Most of these techniques are outside of statistics

although knowledge of classical DOE and RSM

certainly helps in understanding these new techniques.

See papers by Kleijnen et al for more details.

L . M. Lye

DOE Course

72

5th Annual Golfing Challenge – 4 holes

• Conduct an experiment using the golfing toy and

obtain a prediction equation for the toy for use in a

4-hole golf championship to be played using the

toy in the Faculty Lounge on March 22nd.

• [Hint: Use a face-centered CCD RS design or

BBD RS design]

• Team with the least total number of strokes over 4

holes wins 5 extra marks and bragging rights!

• Each team must also summit a report of your

experimental design.

L . M. Lye

DOE Course

73