Sustainable Building & Site Management Practices

advertisement

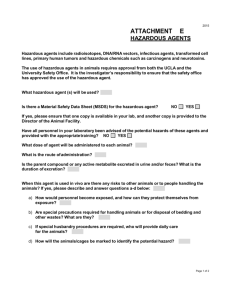

COMPREHENSIVE BUILDING & SITE MANAGEMENT DIRECTIVE Landscape Management Maintenance Equipment: With nearly 1,000 cultivated acres on the main campus, the equipment shop maintains and repairs all of the tools and machinery used to landscape the campus. We are responsible for tools as small as weedeaters to equipment as large as the Gradall. Our shop also fabricates handrails and other safety items that are used on campus. It is vitally important, with a department as large as ours, to keep all of our equipment running safely and efficiently. We are able to accomplish this with a staff of three full-time mechanics and a full parts inventory. The Heavy Equipment team has 12 full time employees, three of whom are on an on-call rotation. This means heavy equipment is always available to support other University departments, or handle after hour emergencies 24 hours a day, 7 days a week. The team has at their disposal all of the necessary equipment to accomplish the many tasks that they encounter. Currently, there are two backhoes, a front-end loader, a Gradall excavator, trencher, roller compactor, utility tractor, skid steer loader and five dump body trucks. Digging footers for brick wall projects, taking out broken concrete sidewalk for replacement, trenching to install piping, or digging for broken water lines are some of the many uses of the equipment. We also use rocks to enhance the landscape and build hills to provide elevation in design solutions. The Heavy Equipment team is also responsible for maintenance of roads and parking areas, as well as mowing main campus and outer areas. This includes street sweeping, which is scheduled weekly for 11pm to 7:30am Sunday thru Thursday. The sweeper runs on bio-diesel. We currently have 15 John Deere riding mowers comprising of 10 – F 1145 and 5 – 997 Z Tracks. The mowers run on bio diesel and an average of 310 gallons per month. One third (5) of our mowers have mulching blades, but all 15 actually mulch and leave the grass clippings on the lawn areas. We mow on an as needed basis with June through November being our busiest months. Mowing and trimming is done between 7:30am and 2:30pm. To ensure our operators are safe, we provide them with training, maintain factory installed safety shields, ROPS (roll over protection system) and mandate the wearing of eye and ear protection. To protect the general public, operators stop mowing when pedestrians are present and use safety shields. To minimize disturbance from noise, mowing around housing areas is done after 9am. Additionally, we limit our mowing around classrooms during testing times. Also we make sure that all mowers have good mufflers systems in place. Our newer mowers (Zero Track) are much more efficient and quieter than the older models. Plantings: The Urban Forester is responsible for the health and safety of all trees on more than two thousand acres campus. A diverse and healthy tree canopy is the goal of our Urban Forestry Program. Trees are a significant feature of the University of Florida campus, they define the exterior of our buildings, they reduce our energy consumption through cooling, they provide food and shelter for wildlife, the list goes on. Every tree on campus is important, regular maintenance by the Physical Plant Department Grounds Tree Crew, which includes pruning as well as removal of hazardous trees, is an integral part of the Urban Forestry Program here at The University of Florida. When a tree is removed because of new construction, injury, or disease, it is unfortunate, but we also see an opportunity. We replace them with a two for one policy, young trees are planted throughout the year to renew and refresh our dynamic tree canopy. The selection of replacement trees is impacted by our goal to use native species whenever possible. These new trees are evidence of our commitment to future generations. We have made a conscious decision to use native plants or xeri-scape plants in almost all of our landscaped beds. "Florida's Best Native Landscape Plants" by Gil Nelson is one of our best sources for native plants. Xeri-scape is a comprehensive approach that utilizes plants that are drought tolerant, non-invasive, pest resistant plants. This approach also emphasizes water conservation through landscaping techniques. The main principles of xeri-scape are soil analysis, appropriate planning and design, efficient irrigation, practical turf areas, plant selection, mulching and maintenance. Considerations for wildlife habitat and storm water runoff are also a very important component of xeri-scape. Our use of invasive exotics is almost non-existent. Some of the exotic plants on campus are Air Potato, Cats claw vine, Ardisia, Tradescathania (wandering jew) and Mexican petunia. We currently have some small contracts in place for removal of exotics in our natural areas. Where possible and appropriate, we limit the installation and size of lawns on campus. When grass is the right alternative, we try to use drought tolerant grasses which include Bahia, Centipede and Bermuda. It is our mission to maintain the urban forest within our campus. Safety is always our number one concern. Tree work is inherently dangerous and with, and countless trees to maintain, it is a daunting task. We are able to accomplish our goal with a three-man crew, which is supported by other crews as well. Landscape waste: With the addition of new buildings and the renovation of older and historic buildings, the Grounds Department strives to enhance these structures through landscaping with the use of native plants and non-native species when appropriate. As established landscapes become outgrown or damaged, the Grounds Department repairs and replaces plants as necessary. The Grounds Department also provides seasonal color with the use of annual flowers appropriate to the season in designated beds throughout the campus. The Grounds Department has three acres of Nursery located at the corner of Radio Road and Museum Road. Our operation consists of three greenhouses, a shade house, and numerous outdoor beds. We propagate annuals for campus beds, plugs for cut flowers and cuttings for woody ornamentals, trees, and groundcovers that are used in our campus beds. We also propagate and grow plants that are used in our interiorscapes. The nursery also schedules distribution of plant materials (cut flowers, interior plants, etc.) for special events on campus. All (100 %) of our organic waste goes to Wood Resource Recovery (WRR), a business that specializes in composting and utilizing organic materials for reuse. Since 1986, WRR has operated a wood yard in Gainesville, and led the industry in vegetative recycling, composting, and site management. The Gainesville WRR site was designated the statewide Compost Demonstration Project in cooperation with the University of Florida. Last year, the University of Florida sent on averaged 245.59 tons of organic waste per month Wood Resource Recovery instead of to the landfills. (http://www.woodresourcerecovery.com/index.php) Irrigation management: There are currently over 235 acres of active irrigation on the main campus. The University of Florida currently irrigates approximately 90% of the irrigated areas on campus using reclaimed water (a high quality non-potable water supply that is not meant for potable [drinking] purposes) from the Water reclamation Facility located on North/South Drive. The remaining 10% are supplied from wells on campus or from domestic (drinking) water. We are continually striving to increase the amount of reclaimed water used for irrigation by eliminating use of wells and domestic water where possible. Fertilizer use: We put out an average of 60 tons per year campus wide. Of the 60 tons, approximately 4 tons is 100 % organic for use on our fruit trees. The other 56 tons is a good, poly-coated fertilizer that is time released and does not leach out of the soil very rapidly. For additional information regarding landscape management, please contact: Martin L. Werts University of Florida Grounds Department (352) 392-1148 Ext 304 mwerts@ufl.edu Pest Management 1. General Household Pest Services (GHP): The Integrated Pest Management (IPM) approach is embraced by UF EH&S Pest Management. IPM, simply defined, is “common sense” techniques employed in a systematic fashion to prevent or minimize entry, introduction and survival of indoor and structural pests, which include insects, rodents and nuisance wildlife. Techniques employed to achieve this goal are provided on scheduled routine visits to all UF structures in Alachua County except those owned by the Division of Housing, which are serviced by Housing staff. GHP service is provided to Shands at UF, Shands at Vista Rehab and Shands Clinics, and IFAS facilities in and around Alachua County. GHP service includes monthly, bimonthly or quarterly (as required) inspecting, monitoring (sticky trap placement and checking,) applying baits, servicing and maintaining insect light traps, physical removal, (including specialized vacuuming as required,) applying residuals to exterior perimeter, around doors and windows, reporting entry points and structural deficiencies for repair orders and emphasizing sanitation. Rodent control measures utilize exclusion and mechanical trapping whenever possible to minimize the use of poisons. All “food areas” and other pest-prone areas serviced at least monthly. Records of services provided are kept electronically on EH&S Microsoft Access database and on paper reports are stored in Bldg 683. Service Requests (trouble calls:) Service requests are placed by calling 392-1904, giving pest type, location, name and phone number of caller. All non-hospital service requests are to be answered within 48 hours, whenever possible. Hospital trouble calls answered the same day or within 24 hours on UF work days. Technician is paged, a copy of the request is sent to pest@ehs.ufl.edu and monitored by the manager and technician adds comments to the note when completed. Completed calls are archived in a public folder on the EH&S file server. 2. Termite Prevention and Control: Soil pre-construction preventive termiticide applications containing Termidor (active ingredient, fipronyl) are provided on all new UF projects and renovations when slab is disrupted and re-poured. Corrective subterranean termite treatments are provided to UF structures when infestations are discovered or reported. Materials and methods vary according to nature of infestation, but include sub-slab termiticide foam injection, direct wood injection, surface application of liquid borates, and trench and treat application of liquids. Yearly inspections of each building are performed for subterranean termites and other Wood Destroying Organisms (WDO’s.) 3. Turf and Ornamental Pest Management: Comprehensive campus-wide fire ant broadcast baiting occurs each spring and fall. Mound treatments are provided during summer as required. Chinch bug control is provided for St. Augustine grass. Shrubbery and indoor tropical plants are treated for mealybug and scale insect control, greenhouse pest control is provided as requested. Sports Turf Pest Management to include weed insect and disease as required to maintain vigor. Sidewalk, fenceline and bare-ground weed control is applied around cooling towers and electrical substations with non-selective herbicides. 4. Nuisance Wildlife: Capture, relocation and exclusion for birds, squirrels, raccoons, opossums, snakes, bats as required. For nuisance alligators, contact UPD 392-1111. 5. Mosquito Control: Surveillance, larvacide application, source reduction, adulticide fogging coordination with Gainesville Mosquito Control and public relations services are provided. 6. Fumigation services: Administration and coordination of commercial structural fumigation contracts, in-house operation of fumigation chamber for museum artifacts and specimens, occasional commodity, warehouse and specialty general fumigation for structural and stored product pests are provided for UF clients. 7. Aquatic Weed Management: at Lake Alice, Lake Wauburg. 8. Rabies Prevention: (feral cat trapping,) Animal Control enforcement, interface with Alachua County Animal Control Services. 9. Oversight of UF Bat House Project- public interface, research project coordination, guano distribution. 10. Miscellaneous Services: Bee, wasp, hornet and yellow jacket nest treatment/removal in buildings and grounds. Dead animal removal inside and under UF buildings. Pigeon control project coordination. 11. Circumstances requiring emergency application of pesticides: Given alternative, nonchemical means, such as vacuum cleaners, sticky traps, damp cloths, duct tape as the primary strategy for emergency pest removal or exclusion indoors, virtually no circumstance can be envisioned requiring immediate application of liquid or aerosol pesticides without first notifying and evacuating building occupants prior to any treatment indoors. Applications of baits, sticky traps and use/maintenance of other monitoring devices are allowed in occupied rooms. 12: Advance notification procedures for pesticide application: Personal, verbal communication to building occupants potentially affected is the primary means of notification. UF maintains a chemically sensitive registry of staff and faculty that request a 24 hr. advance notification of pesticide application in or near their workplace. Communication with Deans, Directors, building managers or principal investigators is also achieved using email distribution lists, if required. Printed treatment notices are posted at all entrances to buildings or affected portions thereof. Prior to any aerosol or liquid pesticide treatment, all occupants are to be evacuated from treated areas until specified, posted time after treatment. Treated outdoor locations are posted with a notice of treatment sign advising people to remain and keep animals off treated areas until dry. For additional information regarding pest management, contact: Kenneth V. Glover, Coordinator EH&S Pest Management Services UF Bldg. 683 Box 112205 Gainesville, Fl. 32611-2205 (352) 392-3410 (fax) 392-0303 kglover@ufl.edu Stormwater Management, Erosion & Sedimentation Control Incorporate Low Impact Development In order to improve water quality and prevent additional erosion in the University’s streams, all projects which impact soil must incorporate the use of Low Impact Development (LID) stormwater techniques where physically, economically, and practically possible. Projects shall include in their presentation before the Lakes, Vegetation and Landscaping Committee or Landscaping Subcommittee a discussion of how LID techniques were/were not incorporated. These techniques include, but are not limited to: Mini-retention / detention, Bio-retention / rain gardens. Porous soil amendments, Lowered landscaping beds, Pervious pavement –hardscape storage, Curb openings (i.e. brick and other hardscape removal in edging and sweat wall footings) that allow water to enter vegetated areas, Use of lawn areas for incorporating slight depressions that retain rainfall, And elevating storm drains where water detention is acceptable so that they are not at the lowest elevation in the landscape. Overview of Existing Permit On December 8, 1987, the St. Johns River Water Management District (District) issued two stormwater permits to the University of Florida. The first was a conceptual permit that established the framework within which subsequent permits would be issued. The second was a general construction permit that authorized specific (within limits) construction activities. The conceptual permit remains in effect (through December 8, 2007). The general construction permit was modified and subsequently renewed on November 8, 2000. This modified general construction permit specifies design and review criteria to be used on the UF main campus area and authorizes construction, within limits, through November 8, 2010. Details of the abovereferenced permits are briefly summarized as follows: CONCEPTUAL PERMIT • District Permit No. 4-001-0040GC. • Issued December 8, 1987 for 20 years. • Provided conceptual approval of the Stormwater Management Master Plan for the main campus. • No construction was authorized under this permit. • Established certain other general conditions. CURRENT GENERAL (CONSTRUCTION) PERMIT: District Permit No. 4-001-15570-3 (initially issued as 4-001-0043 GM). • Issued December 8, 1987 for 10 years. Modified February 9, 1993, due to the reduction of effluent discharge from the University's WWTP to Lake Alice. Current permit modified and renewed November 8, 2000, for 10 years. • Provides construction approval within the Lake Alice Watershed and Depression Basins UF-1 through UF-3 and UF-5 through UF-9. (These areas are shown on the UF Study Area and Watershed Boundaries map and are further detailed on University of Florida Drainage Maps in the Stormwater Management Master Plan and Permit Application Report, dated July11, 2000. Copies are available on request from the Physical Plant Division A/E Department.) • Requires the University to obtain General or Individual Permits prior to construction of facilities located within Tumblin and Hogtown Creek basins; within Depression Basins UF-11, UF-12, or UF-14; and within the 100-year flood plain. (These areas are • • • • • • shown on the UF Study Area and Watershed Boundaries map and are further detailed on University of Florida Drainage Maps in the Stormwater Management Master Plan and Permit Application Report. Copies are available on request from the Physical Plant Division A/E Department). Requires additional District review prior to construction within a 50-foot buffer located upland of delineated wetland limits and prohibits wetland disturbance (except by subsequent General or Individual permit authorization of permit modification). Requires the University to obtain a permit modification for construction activities that are inconsistent with this permit. Requires an annual report to the District in January of each year documenting the details of new construction within the permitted area. Requires submittal of as built plans certified by a Florida Registered Professional Engineer. Requires the University to continue the groundwater and surface water monitoring programs as established by the WWTP Operation Permit. Establishes certain other general conditions. Permitting Framework Because many water management systems are designed and constructed in phases, a procedure was established by the District for review and approval of master development plans. The intent of this procedure was to assure that engineering concepts and design criteria, upon which current and future design decisions are based, are acceptable to the District. This “master plan” approach was chosen by the University during the initial stormwater planning and permitting process for the University of Florida Main Campus, and it resulted in the approval of the University's Conceptual Permit. The Drainage Maps, which are an attachment to and part of the University's Stormwater Permit, divides the campus into four main areas based on watershed divides. These four areas are comprised of; the Lake Alice watershed, several subbasins each within the Hogtown and Tumblin Creek watersheds, and a number of isolated depression basins. Basins and subbasins are identified on the Drainage Maps with lettered prefixes indicating which of the four areas the basin or subbasin are parts of. Subbasins in the Lake Alice watershed have an "LA-" prefix, Hogtown Creek subbasins have a "UF-H" prefix, Tumblin Creek subbasins have a "UF-T" prefix, and the depression basins have a "UF-" prefix. The University's General (Construction) Permit, described in Section I above, gives approval for construction projects located in most areas of the University of Florida Main Campus. Permit Condition 26 identifies these areas as being the Lake Alice watershed (all subbasins) and depression basins designated as UF-1 through UF-3 and UF-5 through UF-9. These areas are generally referred to as being the "included" areas. For construction planned to occur within these areas, separate permitting is usually not required. It is generally required only that construction planned for these areas comply with permit conditions, and that certain details about the completed construction be reported to the District each year. The exception to the above occurs when construction is proposed within areas of the 100-year flood plain as identified on the Drainage Maps and within wetland areas and an associated 50foot upland buffer adjacent to wetlands as identified on the Drainage Maps. For construction to occur within these areas, the following additional permit review/approvals must occur: • • • Construction within 100-year flood plain. Demonstrate no adverse flood conveyance or flood plain impact and subsequently apply for a separate General or Individual permit or for a permit modification. Construction within the 50-foot upland buffer located adjacent to wetlands. Submit plans for District review and approval prior to construction. District will determine if the proposed construction will adversely impact adjacent wetlands and will advise if a separate General or Individual permit or permit modification is needed. Construction within wetlands. Wetland disturbance is not authorized by this permit. A separate General or Individual permit will be needed for wetland disturbance. Separate permitting is required for campus projects located outside the areas included in the General (Construction) Permit. Permit Conditions 27, 28, and 29 requires this permitting to be either a general or individual permit. The District has previously issued general permits and may continue to issue such permits for future projects. District staff will determine which permit is required. Procedures for UF Stormwater Permitting Early on in the planning stage for any project making “significant” changes (plus or minus) to impervious surface area, the managing University agency (including Shands and the University Athletic Association) must notify PPD Architecture/Engineering of the project by requesting a determination of the stormwater permitting requirements. A site map depicting project location shall accompany this written request. New buildings or building additions, new parking lots or additions, paving of temporary parking lots, and similar types of construction are all considered "significant" in their effect on impervious surface areas. Upon receipt of the written request and accompanying site map, UF PPD Architecture/Engineering will determine whether the project is covered by the current general construction permit of if a separate permit is required. After these determinations are made, PPD A/E will inform the managing University agency, in writing, of the determination and then direct the managing University agency to either: Path A) Obtain the necessary separate permit from the District prior to construction of the project, or Path B) Proceed with construction based on authorization granted by the University’s general construction permit If the managing University agency is directed to follow Path A) above, the agency is required to perform the following: 1) Fill out the General Permit Application by naming the University of Florida as the Owner, the Director of the Physical Plant Division as the Applicant/Entity to receive the permit, and the University of Florida, Physical Plant Division as the proposed Operation/Maintenance entity. 2) After completely filling out the permit application and prior to submitting the application to the District the agency must submit the application to the Director of the Physical Plant Division for signature as the Applicant. 3) Provide original copy of the permit, and, copies of all pertinent information and correspondences, to PPD Architecture/Engineering. 4) Fill out and submit any required completion forms to the District, with a copy to PPD Architecture/Engineering. If the managing University agency is directed to follow Path B) above, the agency is required to perform the following: 1) Provide copies of all pertinent information and correspondences to PPD Architecture/Engineering. Submit Construction Commencement Notice Form No. 40C-4.900(3) to the District 48 hours prior to commencement of construction (Condition 6). When construction duration will exceed one year, submit Annual Status Report Form No. 40C-4.900(4) during June of each year (Condition 7). 2) Obtain copies of the conditions of the general construction permit and comply with the conditions of the permit during and following construction. 3) Upon completion of the project, provide PPD Architecture/Engineering with calculations indicating for each basin, or subbasin, the amount of any previously existing impervious surface that was removed, the amount of new impervious surface that was added, and the net change to the previously existing impervious surface area. A.100-Year Floodplain: If the project is located within a 100-year flood plain, the applicant will need to follow Path A. In such cases, PPD A/E will request additional information from the managing University agency to determine flood conveyance and flood plain impacts. PPD A/E will advise the agency if proposed flood conveyance and flood plain impacts are acceptable and will subsequently authorize separate general or individual permit application (managing University agency shall follow the steps outlined in Path A), above) for the proposed project (PPD A/E may require flood conveyance and flood plain impact mitigation before recommending approval). Upon separate permit application, the District may require further mitigation as a condition for permit approval. B. Wetland Buffer: If the project is located within the 50-foot upland buffer located adjacent to delineated wetlands, the applicant may follow either Path A or B depending on the District review. In such cases, PPD A/E will request additional information from the managing University agency to determine the extent of potential wetland impacts. Upon receipt of the requested additional information, UF PPD Architecture/Engineering will contact the District to determine whether the current general construction permit covers the project or if a separate permit is required. After these determinations are made, PPD A/E will inform the managing University agency, in writing, of the determination and then direct the managing University agency to proceed with either Path A) or Path B), as described above. C. Wetlands: Wetland disturbance is not authorized by the University’s permits. If the project is located within a delineated wetland or impacts a wetland, the managing University agency will be directed to follow Path A), above. Please note that the University’s buffer requirements are larger than the water management districts. The University requires an average vegetated buffer of 50 feet and a minimum of 35 feet. Inspection & Reporting PPD Architecture/Engineering will conduct monthly visual inspections of permitted surface water management basins called for in Condition 21 (sinkholes) and will document these inspections on District Condition Compliance Form No. EN-33. Two copies of the completed forms will be submitted annually to the District by May 31. PPD Architecture/Engineering will notify the District of any sinkhole development in the surface water management system within 48 hours of discovery and will complete sinkhole repair within 10 days of such discovery (Condition 22). PPD Architecture/Engineering will submit operation and maintenance reports called for in Condition 23 to the District two years after the operation phase permit becomes effective and every two years thereafter on District Form EN-46. Such forms will be signed and sealed by a Florida Registered Professional Engineer. PPD Architecture/Engineering will prepare and submit the annual report to the District as called for by Condition 26 of the modified General (Construction) Permit (4-001-15570-3). This report will be submitted to the District by January 31 of each year and will be for construction projects completed the preceding calendar year. Construction Site Stormwater Runoff Control Program The Florida Department of Environmental Protection issued a NPDES Phase II MS4 Generic Permit for stormwater discharge to the University of Florida on September 9, 2003. To comply with this permit, the University’s Construction Site Stormwater Runoff Control Program was established. This program is intended to ensure that the minimum control measures necessary to manage on-site erosion and sedimentation are identified and implemented for all construction activities on the University of Florida Campus. It is also intended that the program foster the elimination of all off-site impacts caused by stormwater runoff from University construction. Compliance with this program is required for all activities on the University of Florida campus. For construction projects, compliance requirements shall be included in project documents. Contractors/Construction Managers shall be responsible for maintaining compliance on-site. The University will maintain an inspection program, administered by the Physical Plant Division, Architecture/ Engineering Department (PPD A/E), to monitor and ensure permit and program compliance. Inspectors will be provided by the Physical Plant Division, Operations Engineering Department (PPD OE) and the Environment Health and Safety Division (EH&S). The PPD OEemployed inspectors will be responsible for inspecting all University projects, except projects administered by PPD OE, which will be the responsibility of an EH&S-employed inspector. Non-compliant conditions shall be remedied immediately or the offending activity will be subject to University-induced work stoppages as appropriate. (Construction is defined in this document as any construction, renovation, or repair to University of Florida facilities and infrastructure.) The construction site will fall into one of two categories: 1) One acre or larger of work zone. (one acre = 43,560 ft2) 2) Less than one acre of work zone. Category one projects shall apply for a NPDES Construction Generic Permit from the Florida Department of Environmental Protection. Category two projects shall operate under the existing UF NPDES Permit. Both categories shall develop a “Sedimentation and Erosion Control Plan” and submit the plan and/or permit for review and approval prior to construction. Submit these documents to PPD Operations Engineering. An approved plan will be required before any dig permits are issued. General Elements of a Sedimentation and Erosion Control Plan This plan is a complete description of actions the contractor will perform to manage and contain erosion and sedimentation. If the approved plan is not working, the plan shall be amended and those changes documented using the inspection form. Regular inspections and documentation thereof are an integral part of making the plan work. An example of a construction inspection form is included, and those items in the form are the minimum to be checked off during inspections. The elements of a complete plan are as follows: 1) Narrative- a brief description of the overall strategy for erosion and sedimentation control. 2) Map or Site Plan - site contours, critical areas such as wetlands, existing vegetation, limits of clearing and grading, locations and names of erosion and sedimentation control measures with dimensions. 3) Construction details, specifications, notes and contact information for personnel on-site. 4) Construction Inspection Form (A sample form is included at the end of this document). Construction Site Stormwater Runoff Control: The intent of control methods is to manage on-site erosion and eliminate any off-site erosion and sedimentation impacts. The project shall implement all measures necessary to manage on-site erosion and sedimentation and eliminate all off-site impacts. Control methods may include: Control waste such as discarded building materials, concrete truck washout, chemicals, litter, and sanitary waste at the construction site that may cause adverse impacts to water quality. Adequate layers of silt fence properly imbedded around areas to be disturbed. Gravel entrance to site, approximately 50’ long, width of the entrance, and 6”thick over filter fabric. Cover, seed or sod disturbed areas exposed to stormwater. Check dam to control water velocity. Curb and gutter sediment barrier for inlet protection of storm drain structures. Temporary structures such as dikes and drains before permanent ones are built. Dust control. Temporary sedimentation basins to treat stormwater and dewatering pump outflow. All methods used shall be properly maintained and inspected on a regular basis. For additional information regarding erosion and sedimentation control, please contact: Clark Collins PPD Operations Engineering (352) 392-5050 ccollins@ufl.edu Building Exterior & Hardscape Maintenance Cleaning Building Exterior: Building Exteriors are cleaned using a pressure washer and water. No chemicals are used in this process. Cleaning of building exteriors is only done on an as needed basis, which helps to conserve water. When the buildings are vandalized with graffiti, a chemical cleaning agent is used. Several different environmentally friendly graffiti removers have been tested by the University of Florida for use around campus, but none have been able to perform as effectively as what is currently used. UF will continue to test potential environmentally friendly graffiti removal products. Parking Lots and Roads: Parking lots and roads are maintained by the street sweeper. The schedule for the street sweeper is 11pm to 7:30am Sunday thru Thursday. The street sweeper runs on bio-diesel, conserving fossil fuels and reducing greenhouse gas emissions. Painting Painting of both the interior and exterior of the building must follow the requirements of the University of Florida Design and Construction Standards. The General Design Guidelines of the Design and Construction Standards state: 1.18 LEED CERTIFICATION I. Specify low VOC emitting materials including adhesives, sealants, paints, carpet and composite wood to meet or exceed the LEED requirements for Indoor Environmental Quality Credits 4.1-4.4. Chemical Usage and Disposal Both the State and Federal Environmental Agencies have regulations concerning the management of maintenance - related waste materials. The regulations are enforced by the Environmental Protection Agency (EPA) and by the Florida Department of Environmental Protection (DEP). The intent of these regulations is to establish a comprehensive program for the proper management and disposal of maintenance - related wastes. This document is based on those regulations and should serve as a guideline for all maintenance and repair shops located at the University of Florida. Every shop on campus is subject to unannounced inspections by both the Federal Environmental Protection Agency (EPA) and the Florida Department of Environmental Protection (DEP). Lack of compliance can result in citations and fines. No hazardous chemical or waste may be deliberately discharged to the sanitary sewer, to the ground or to the university storm water system. Towels, rags, absorbents or other debris contaminated by a hazardous chemical (either by process or due to a spill) should be considered to be a potential hazardous waste. Contact EH&S for assistance in making a hazardous waste determination. NOTE: NON-FLAMMABLE DOES NOT EQUAL NON-HAZARDOUS. Read product labels carefully or consult product MSDS sheet (section 2) for hazard information. Accumulation Requirements Satellite Accumulation Area (SAA): An accumulation point for waste near the point of generation and under the immediate control of the generator. All UF shops must accumulate hazardous waste in satellite areas and under those guidelines as described below. Each shop must post the SAA guidelines on the wall in the immediate area. The SAA should be in an appropriate/safe location in the shop and protected from the elements if outdoors. Hazardous Waste Hazardous Waste must be accumulated safely at or near the point of generation (designated location in the work shop) under the control of the generator (shop supervisor) Do not accumulate more than 55 gallons of waste at any one time. Keep all containers closed and labeled. Provide secondary containment for containers. Keep containment area clean and protected from the weather. Do not allow any accumulation of water or liquid on the top of the container. All waste containers must have a label identifying the contents. No un-approved waste in sink or trash. Do not overfill containers; leave at least 1 inch of headspace. Keep liquid and solid waste streams separate. Do not allow different/incompatible waste streams to be collected in the same container (i.e solvent rags should not wind up in the aerosol drum). Waste accumulated on vehicles must be held in labeled container and should be transferred to shop accumulation point upon return. Keep a spill kit within easy access for all shop personnel. Post the EHS Satellite Accumulation Area Form. (See Appendix B) Request waste P/U often to limit waste management concerns. Universal Waste Accumulation of universal waste – all universal waste must be labeled, dated and may be accumulated for no more than one year from the time it becomes at waste. Labeling & Chemical Waste Pick-Up Requests Labeling All containers must have a label identifying the contents. Waste containers must have the appropriate label identifying the type of waste and the contents (i.e. Hazardous Waste should have a Yellow Hazardous Waste label, batteries should have a “Universal Waste – Batteries” label, etc.) EH&S provides “Hazardous Waste” labels, “Used Oil” labels, as well as “Universal Waste” labels for batteries, fluorescent lamps and mercury containing devices. Universal Waste labels must include the date that accumulation began. Labels should include all constituents in the waste mixture as well as an approximate percentage of the total for that item. Labels should also include the Bldg and room number of the shop generating the waste and the name of the shop supervisor. Labels are available free of charge by calling the EH&S at 392-8400 and providing a P.O. Box number or specific delivery location. Pick-Up Requests Pick-up request should be made in advance of reaching the satellite area limit of 55 gal. If you anticipate reaching or going over the limit, contact EH&S at 392-8400. You can submit your pickup request online at : http://www.ehs.ufl.edu/hmm/pickups/chempick.asp Common Hazardous Maintenance Related Materials The following is a list of the more common wastes and processes generated by maintenance operations: Universal Wastes are noted by the letters “UW”. 1. Used Oil The term “Used Oil” is a broad category and includes motor oil, vacuum pump oil, synthetic oils, transmission and brake fluids, lubricating greases, etc. Used oil does not include products derived from vegetable or animal fat. Used oil is prohibited from going to a landfill or being discharged to the environment. EH&S must perform a hazardous waste determination on each oil waste stream to find out if it should be classified as hazardous. If the used oil stream is determined to be hazardous, then the oil must be handled as a hazardous waste and EH&S must dispose of it. The main reason for an oil stream to be classified as hazardous is through its contact with solvents (such as brake cleaners and paints) or heavy metals. Transformer oil (for PCBs) and refrigerant oil (for CFCs) must be tested by EH&S for contamination. Keep these oil waste streams separate-do not add to a larger used oil container or tank. If the used oil is determined not to be hazardous, it may be sent to a recycling center or to EH&S for disposal Shipments of Used Oil Generators must ensure that their used oil is transported only by transporters who have a current Used Oil Transporter Certificate of Approval issued by the Department of Environmental Protection. In order for a transporter to receive the Certificate of Approval, they must have a DEP/EPA identification number and a used oil training program, and will have demonstrated minimal insurance coverage. Contact EH&S at 392-8400 for the names of approved transporters Records must be kept for all used oil disposal “Oily wastes” are also covered under these regulations. Oily wastes are defined as “those materials, which are mixed with used oil and have become separated from that used oil.” This includes oil that has been mixed with “kitty litter,” absorbent clay and organic absorbent material. These materials (with the exception of rags and paper towels) may be land filled provided that: The amount generated is a small amount. It is the result of minor leaks or spills from a normal process operation. All free-flowing oil has been removed to the practical extent possible. Large quantities of oily wastes, generated as a result of a major spill or in lieu of proper maintenance of the processing equipment, must have a hazardous waste determination performed prior to disposal. Contact EH&S at 392-8400 to have a hazardous waste determination performed. EH&S strongly recommends that this type of waste be minimized through good housekeeping practices. Oily rags must be picked up by EH&S or sent to a rag cleaning service (See Shop Towels). 2. Used Oil-Filters Commercially generated used oil-filters are banned from landfill disposal. oil-filter processor must process the filters. A registered used The storage containers must be protected from weather, have a lid and stored on an oil impermeable surface. Records must be kept for all used oil filter disposal Used oil-filters must be stored in above ground containers, which are in good condition and are clearly labeled “Used Oil-Filters”. 3. Shop Towels Clean-up towels commonly referred to as “Shop Towels” are a re-usable product provided by a company which delivers, collects, launders and returns them. By virtue of this arrangement, the towels are never disposed of by the University of Florida and therefore not “waste”. No hazardous waste determination is required. Shop Towels should be collected in a fire-safe steel safety can. Shop Towels should not be soaked with liquid and there should be no standing liquid in the bottom of the Shop Towel container. Absolutely nothing other than used shop towels should be collected in a Shop Towel container! Contaminated paper towels and other disposable towels, when contaminated with Hazardous Materials are considered Hazardous Waste. Shop Towel collection container should be labeled “Shop Towels” If a Shop Towels service towel is disposed of it becomes a waste and is subject to hazardous waste determination. 4. Anti-freeze New or Unused anti-freeze is not considered a hazardous waste when disposed. Used antifreeze may contain regulated heavy metals such as lead, chromium and cadmium from normal use. It may also contain contamination from brake cleaners and other solvents through incidental contact. A hazardous waste determination must be made to insure proper disposal. Contact EHS for assistance in making the determination. Used anti-freeze should be stored in an area with appropriate secondary containment and with protection from the weather. Secondary containment must be kept free of spills and debris. Antifreeze containers must stay closed. Label containers with the words “Used Anti-freeze.” Proper recycling of used anti-freeze is encouraged. There are waste antifreeze service companies that will service and recycle your antifreeze. Copies of all notices, certifications, waste analysis data and other documentation must be retained for five years from the date that the waste was sent to a recycling facility or to EH&S’s Waste Management Facility. Contact EH&S at 3928400 to get a list of vendors approved for recycling antifreeze. 5. Batteries (UW) Many batteries contain regulated heavy metals and a strong acid or alkaline solution, which would qualify them as hazardous waste when they are disposed. Used batteries and a select few other materials that can be recycled instead of becoming hazardous waste are known as Universal Wastes. Universal Waste batteries may not be disposed of in the regular trash. 6. Only Alkaline batteries can be disposed of in the trash. Large Storage Batteries (Auto, Marine, etc.) must be taken to Hazardous Waste Management Facility (Bldg 831) in the Surge Area. Deliveries can be made every Monday, Wednesday and Friday between 8 and 9 AM. All other batteries such as Ni-Cds, Lithium ions etcetera which contain hazardous metals such as mercury, lead, silver, lithium and cadmium must be handled by EH&S . Containers of used batteries to be recycled must be labeled “Universal Waste- Batteries”, “Waste Batteries” or “Used Batteries”. Containers must be marked with the date accumulation began. Mercury Containing Devices (UW) Mechanisms or devices which contain elemental mercury (liquid) as an integral part of the device such as: thermostats, thermometers, pressure switches, etc. are considered Universal Waste if recycled. Mercury containing devices must not be disposed of in the regular trash. 7. Mercury Containing Devices must be accumulated in a closed, labeled container. Containers of mercury containing devices or mercury thermostats must be labeled ”Universal Waste-Mercury Containing Devices” or “Universal Waste- Mercury Containing Thermostats”. Containers must be marked with the date accumulation began. Light Bulbs (UW) Fluorescent, Mercury Vapor, High Pressure Sodium and High Intensity Discharge (HID) bulbs contain mercury and would qualify as a hazardous waste unless they are recycled. When sent for recycling they are considered Universal Waste. Universal Waste lamps may not be disposed of in the regular trash. 8. Used Lamps must be accumulated in a closed labeled container Broken lamps should be collected in a bag lined box or other sealed container Used lamps must be delivered to EH&S’s Waste Management Facility, Building 831 on Monday, Wednesday and Friday between 8 and 9 AM. Incandescent lamps may be disposed of in the regular trash. If you have a question, contact EH&S before disposing of any used lamp. Spent Lamps should be labeled (“Universal Waste – Lamps”) Containers must be marked with the date accumulation began Lamp Ballasts All lamp ballasts including PCB and “Non-PCB” are collected for recycling or processing. Lamp ballasts removed from lighting fixtures may include an insulating material which contains PCBs (Poly Chlorinated Biphenyls) or DEHP (Di (2-ethylhexyl) phthalate). Ballasts contaminated with these chemicals are prohibited from landfills and must be collected for recycling. Emergency lighting ballasts contain a circuit board and Ni-Cd rechargeable batteries (which must be recycled). All ballasts can be delivered to Bldg. 831 every Monday, Wednesday and Friday between 8 and 9 AM. 9. Smoke Detectors Some smoke detectors contain radioactive material. A label on the back or side of the detector will alert you to the presence of a radiation source. It is necessary to dispose of these detectors at a licensed radioactive waste disposal facility through EH&S. The detectors must be intact for disposal. Some smoke detectors containing radioactive materials may be exempt from these disposal requirements. Contact EH&S at 392-8400 to determine if your smoke detectors are exempt or regulated prior to disposing them. It is recommended that detectors, which do not contain radioactive materials be used, if they are appropriate for your application, to avoid disposal costs, which may exceed the purchase price of the detector. 10. Paints, Paint thinners and Solvents Latex Based Paints are not hazardous waste. However liquid latex paint may not be disposed of in solid waste containers or in storm drains. Old latex based paints may be consolidated into larger containers for disposal cost savings. Small quantities remaining in cans may be air dried before disposal. If the paint in the can is completely dry, it may be disposed of in the trash. Dried rags and paintbrushes that are contaminated with latex-based paints only may be placed in the trash. The rinsate water from the cleaning of rags and brushes contaminated with latex paints must be disposed of in a drain that goes directly to the wastewater treatment plant. No rinsate may go to the storm drains. Solvent Based (“oil based”) Paints, enamels, varnishes, sealants, etc. meet the definition of hazardous waste and unused portions must be disposed of by EH&S. Paint cans that once contained non-latex paints must meet the definition of empty before they can be placed in the trash. This is achieved by scraping the container to ensure that all pourable materials have been removed. The pourable material must be collected for disposal by EH&S. Waste mixtures of solvent based paint and paint thinners/solvent must be collected in a closed, labeled container. Each container of solvent based paint/paint thinner waste must be closed after additions and the funnels should be cleaned out regularly. No air drying of solvent based paint or paint waste is allowed. Waste containers must be stored with secondary containment and protected from the weather. Secondary containment must be kept clear of spills and debris. Containers and drums can be obtained by calling EH&S at 392-8400. Solvent Based Paints should be labeled as a Hazardous Waste. Solvent waste (including thinners, cleaners, degreasers, fuel additives, adhesive removers, etc.) qualifies as Hazardous Waste and cannot be disposed of in the trash or sink. Once these solvents are no longer usable, the liquid must be placed in a suitable closed container (preferably the original container) and be labeled as a Hazardous Waste. Brushes and rags that have been contaminated with hazardous waste (non-latex paints, cleaners, thinners, strippers, etc.) and/or waste solvents cannot be placed in the trash. Paper towels, wipes, rags or absorbents that have been contaminated with paint/paint thinner waste or solvent waste must be collected as hazardous waste in a steel safety container. Call EH&S at 392-8400 for information on special containers. Excess liquid that pools from contaminated rags must be separated and collected with liquid solvent waste. Each container of hazardous waste must be labeled and must stay closed. 11. Aerosol Cans Many of the products used in maintenance work including cleaners degreasers, adhesive and adhesive removers, paints, sealants and lubricants come in the form of an aerosol spray can. Nearly all of these aerosol products contain a flammable or poison solvent as the product base or the propellant. Waste poisonous or flammable solvent is hazardous waste. Any aerosol can with poisonous or flammable material left inside is hazardous waste. Only empty aerosol cans are to be placed in the trash. Aerosol cans that are not empty must be accumulated in a container or drum and picked up by EH&S. Remove spray tip to avoid discharge in the drum The aerosol waste container or drum must be labeled as Hazardous Waste. 12. Acid/Alkaline Wastes A method for cleaning AC coils involves spraying the coil with a strong acid or base. This should be followed with spraying the coil with a neutralizing solution prior to rinsing the coil. The neutralized solution must be directed into a drain which runs to the sanitary sewer. Discharges to the storm drain are not permitted. Contact EHS for variations to this protocol. Strong acid are also used for surface preparation during soldering. If a lead-base solder is used the acid solution may become contaminated with the metal and it will in turn contaminate the towel or rag used to apply it. Common acids include; muriatic acid (Hydrochloric acid), sulfuric acid, phosphoric acid and nitric acid Do not accumulate acids, bases and solvents together. They should each have their own separate containers and should be stored so that they cannot mix in the case of a leak Spent acid waste should be collected as Hazardous waste in a tight sealing plastic container. If used with metals, they should be included on label. Towels or rags used to apply acids or bases should be collected separately from the spent acid Spent Acid wastes should be labeled as Hazardous Waste 13. Building Services Waste The housekeeping, janitorial and floor maintenance work done by building services requires a wide variety of chemical products. Use of products that are known to be hazardous (Label, MSDS) will likely generate a hazardous waste. Attempt to find/use non-hazardous products whenever possible Hazardous Waste determination must be made to insure proper management Check Product Label, MSDS for information or contact EH&S for guidance on Hazardous Waste Determination If the waste is found to be hazardous, accumulate as Hazardous Waste for EH&S pick-up. No building service wastes should ever be discharged to the environment (parking lot, grass, storm drain, etc.) Use all products as directed on label, unusable products should be disposed of by EH&S Non-hazardous cleaning product waste liquids may be sent to the sanitary sewer Building service waste determined to be hazardous must be labeled as Hazardous Waste. 14. Parts Washing Waste Recycling parts washers – Recycling parts washers use a variety of solvents to clean small parts. The fluid is typically recycled internally and re-used until it is no longer viable. Due to contamination with regulated metals and solvents, all waste from parts washers should be considered hazardous unless testing confirms otherwise. The waste from these can be broken into three categories depending on the design: the fluid, sludge, and the filter (if equipped). Parts washer fluid and sludge should be collected separately from filters. Parts washer wastes should be collected in an appropriate container and stored in an area with appropriate secondary containment protected from the weather. Parts washer wastes should be labeled with a Hazardous Waste label DO NOT MIX PARTS WASHING WASTES WITH USED OIL 15. Vehicle and Equipment Washing Vehicle Washing must be conducted at a wash-down station equipped with a functioning and maintained oil water separator. Accumulated sludge from oil water separators may contain heavy metals or solvent contamination. A hazardous waste determination must be completed prior to sludge disposal. Effluent from the separator must be directed to the Wastewater Treatment Plant. Vehicle washing wastewater must not be sent to soil or to the storm water system. To limit contamination, solvent based cleaners are not permitted. Only soap and hot water or steam washing is permitted. Small Equipment and Parts Degreasing may require the use of a solvent or degreasing agent in order to prevent damage or corrosion to the equipment due to using water based cleaners. Degreasing of small equipment using solvents or degreasing solutions should be done in such a way that all waste and solvent used are contained or captured. Waste generated during degreasing of small equipment must be collected for characterization and proper disposal (This includes towels/rags contaminated with parts washing fluid. Shop Towels that are sent to a Shop Towel service may be use No discharge to the storm water system is permitted. Small equipment degreasing wastes should be collected in an appropriate container with a Hazardous Waste label. 16. Transfers of fuel or oil To prevent spills into the environment, transfers of fuel or oil between vehicles, tanks, transformers, etc must be done with equipment or a structure in place to provide spill containment. Spill containment may be temporary but must be fabricated in a manner that prevents any spillage from reaching the environment. During the transfer process an attendant who can terminate the transfer in event of spills must be present. Spill control equipment, clean up materials must be present. In the event of a spill that reaches soil or water contact EH&S Waste Management immediately at 392-8400 during normal operating hours or after hours contact University Police Department at 392-1111. Spill waste (including liquid and solid absorbent waste) must be collected. A hazardous waste determination based on the make-up of the spilled material should be made. If hazardous, spill waste should be labeled with a hazardous waste label and collected by EH&S. 17. Processes not listed in this guide For processes or waste not listed or described in this guide contact EH&S for assistance in making a Hazardous Waste determination and/or for proper waste management. Safety Precautions Do not mix incompatibles (ex. Acids/bases, flammables/oxidizers, reactives) Do not bring cleaning materials from home. Wear personal protective equipment. Spill Response Minor Spill: If the spill is isolated and the material can safely be handled by shop personnel, absorb and collect the spill waste. Place the spill waste in an appropriate container for EH&S waste pick up. Major Spill: In the event of a spill of a dangerous or hazardous chemical within the shop, contact EH&S @ 392-8400. If the spill represents a threat to personnel safety, evacuate the area immediately and prevent re-entry until the danger has been eliminated. Be prepared to provide information such as: name of material spilled; approximate quantity; specific location of spilled material; contact information (i.e. name and telephone number where you can be reached) Spill to the Environment: In the event of a spill that reaches soil or water contact EH&S Waste Management immediately at 392-8400 during normal operating hours or after hours contact University Police Department at 392-1111. Waste Minimization Waste minimization is any action that reduces the amount and/or toxicity of wastes that must be shipped off-site for disposal. There are three methods of waste minimization. Source Reduction: The most desirable method of waste minimization is source reduction. This is any activity that reduces or eliminates the generation of waste at the source. This can be accomplished by good materials management, substitution of less hazardous materials and good shop operating procedures. The following are some examples: Implement a waste minimization policy and train all employees. Make a commitment to reducing waste in all areas of the shop. Evaluate the wastes being generated and identify areas where changes can be made. Encourage employee participation through education, training and incentives. Evaluate procedures to see if a less hazardous or non-hazardous materials could be substituted. Centralize purchasing of material through one person in the department. Minimize inventory and use a first-in, first-out system. Keep MSDS’s for chemicals on file. Inventory materials and identify their location at least once a year. Update inventory when materials are purchased or used up. Purchase chemicals in the smallest quantities needed. Label all containers to prevent the generation of unknowns. Avoid the use of materials containing arsenic, barium, cadmium, chromium, lead, mercury, selenium, and silver. Substitute red liquid (spirit-filled), digital, or thermocouple thermometers for mercury thermometers when it is feasible. Consider using detergent and hot water for cleaning parts instead of solvents. Use latex-based paints because typically they are non-hazardous. Find a vendor that will recycle used antifreeze. Some vendors will recycle the antifreeze on site so the antifreeze never leaves the site. Use multi-purpose solvents to reduce the types of hazardous waste that needs to be managed Avoid offers of free materials and samples unless it is certain that they will be used and a clear savings will be achieved. Disposal of unwanted chemical material can easily become more costly than perceived savings Recycling: After source reduction, the next method to consider is recycling. When a waste material is used for another purpose, treated and reused in the same process, or reclaimed for another process, this is called recycling. The following are examples: When solvent is used for cleaning purposes, re-use contaminated solvent for initial cleaning and fresh solvent for final cleaning. Purchase compressed gas cylinders (including lecture bottles) only from manufacturers who will accept empty cylinders for return. Return excess pesticides to the distributor. Do not contaminate used oil with solvents because this prevents the oil from being recycled. Recycle solvents. Treatment: Materials which cannot be reduced, recycled or eliminated outright, may possibly be treated in lieu of hazardous waste disposal. Treatment must be conducted in accordance with federal and state regulations at an EPA permitted facility. Only simple neutralization is permitted at Satellite Accumulation Areas.