GIT PLM-related Activities - Product & Systems Lifecycle Management

advertisement

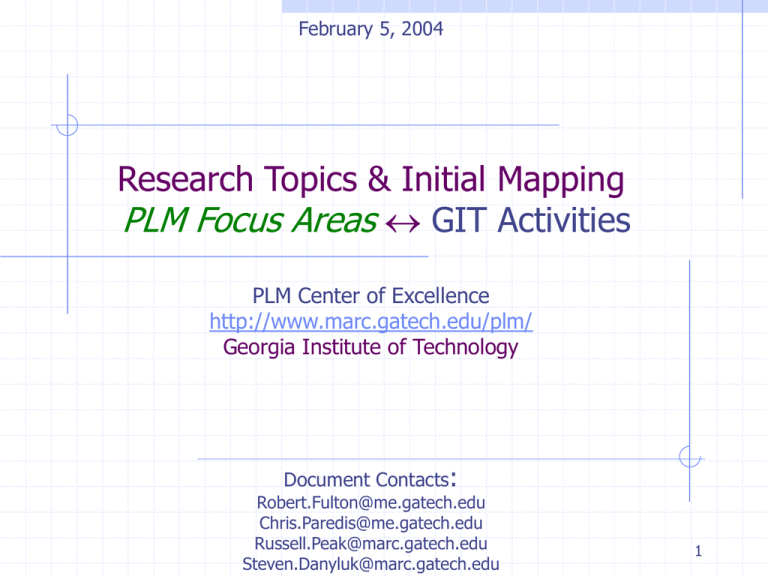

February 5, 2004 Research Topics & Initial Mapping PLM Focus Areas GIT Activities PLM Center of Excellence http://www.marc.gatech.edu/plm/ Georgia Institute of Technology Document Contacts: Robert.Fulton@me.gatech.edu Chris.Paredis@me.gatech.edu Russell.Peak@marc.gatech.edu Steven.Danyluk@marc.gatech.edu 1 Sample GIT PLM-Related Activities ME: Paredis Composable Simulations Design-Analysis Integration ME: Mistree Strategic Design MARC: Peak Standards for Systems Engineering Lean Principles IE: McGinnis Marketing Strategy Virtual Factories Mgt: Malhotra AE: Mavris Market Planning Portfolio Planning Concept Development Design Production & Testing Sales & Distribution Maintenance & Support PLM Robust Design Simulation Customer Requirements Design Collaboration Manufacturing Collaboration Aircraft Lifecycle Support Services Collaboration Customer Feedback PLM Collaborative Foundation Customers Product Family Design Customers Marketing/Sales Collaboration B2B integration CoC: Rossignac Collaborative Visualization Environments Design Definition Partners Component Management Other Enterprise Locations AE: Schrage Design Change Management Factory Information Systems MARC: Dugenske Change Mgt. in Product Model Databases Suppliers Source: IBM PLM definition slide at PDES Inc. Board Mtg. 2003-11 Engineering Knowledge Representation Arch: Eastman Collaborative Design Optimization Design-Supply Chain Process Integration Design Repositories ME: Fulton 2 PLM Focus Areas Addressing Top Industry Pain Points Source: IBM slides at PDES Inc. Board Mtg. 2003-11 3 Mapping PLM Focus Areas GIT Activities - p1 Product Innovation Management (and related faculty) Strategic design (Mistree) IPPD and PLM integration (Schrage, Hart) Marketing strategies over the product life-cycle (Malhotra) Component, Platform and Asset Commonality Product family design (Rosen, Mistree) Design repositories (Paredis, Eastman ) Domain-oriented product access and management (Eastman) Lean principles (Schrage) Adoption and continued use of products and technologies (Malhotra) Extended Enterprise Product Change Management Course: Interactive Computer Graphics and Computer-Aided Design (Fulton, Sitaraman, Dennis) Course: Intro to PLM (Schrage, Hart) Engineering knowledge representation & info. systems (Peak, Fulton) Change management in product model databases (Eastman) 4 Mapping PLM Focus Areas GIT Activities - p2 Virtual Product Introduction Course: Design and Engineering Database Management (Fulton, Eastman, Peak) Course: Modeling and Simulation in Design (Paredis, Peak) Design-analysis integration (Peak) Standards for systems engineering (Peak, Paredis) Decision-based design (Mistree, Allen) Designing open processes (Mistree) Composable simulations (Paredis) Virtual factories (McGinnis, Bodner) Factory information Systems (Dugenske) Robust design simulation (Mavris) Collaborative visualization environments (Mavris) Collaborative design optimization (Olds and Braun) Visualization and human computer interaction (Rossignac) 5 Mapping PLM Focus Areas GIT Activities - p3 Service after Sales Aircraft lifecycle support (Schrage) Manage Operations & Systems Course: Aerospace Systems Engineering (Schrage) Domain specific parametric tool specification and procurement (Eastman) Integrating design chain processes with supply chain processes (Mistree) Standards-based engineering frameworks (Peak) 6 Quad Charts for Sample Research Topics PLM Center of Excellence http://www.marc.gatech.edu/plm/ Georgia Institute of Technology 7 Next-Gen. PLM with Fine-Grained Interoperability Customer Needs / Acquisitions Abstraction Level … … Systems Engineering Legend Human Interaction Electronics Structures Requirements Development Process … … … … Model interfaces: Associativities among domain-specific models & system-level models Fine-grained models: Information objects Parametric relations … Domain Models of varied abstractions and domains After Bajaj, Peak, & Waterbury 2003-09 8 Hierarchic Market Space Definition and Exploration Student: Christopher Williams Faculty: Farrokh Mistree, Janet K. Allen Objectives Contributions & Benefits Scholarship • To develop formal, mathematically correct, and rigorous principles for Sequencing modes of managing product variety designing product architectures that facilitate the production of customized • How can a designer synthesize multiple modes of managing product variety in products. order to realize a customized product? • Determine an optimal arrangement of product variety techniques that link all • How does the designer select which mode to use first? What sequence will points in the market space in order to satisfy any customer demand so that provide the most affordable coverage of the market space at a high quality? cost is minimized. T T V Dealing with non-uniform demand V R • How does the arrangement of the hierarchy change as demand is non-uniform? 30 P 30 • Can this question be answered without using varying sized constructs? L • Will this affect the sequencing of the modes of managing product variety? P [MPa] P P [MPa] 20 Industry • Provision of manufacturing firms an efficient (through rigorous and systematic 10 methodology) foundation for realizing customized products, thus enhancing the 10 responsiveness of manufacturing organizations to changes in the market or 10 20 30 10 30 demands for customization. V [m3] V [m ] h s 3 1 1 2 3 Background Constructal Theory • The hierarchic structures (tree networks) that we observe in natural and artificial systems are the “fingerprint” of the minimization of flow resistance between a finite volume and one point. • An access problem can be solved through the optimization of the shape of the smallest, inner-most space elements and the hierarchic assembly of these elements into larger “constructs” until covering the entire geometric space. • The abstraction of a space of customization as a geometric space in need of access optimization, allows a designer to effectively develop a product architecture for customized products. S3 S4 S5 S6 S2 y The Smallest Area, S1 S1 D1 H1 V0 E V1 L1 . P(x,y) x Time, Complexity, Evolution Resources, Status, Publications, etc. Resources • SRL Knowledge Base • X-DPR, iSIGHT, Matlab, Concurrent Versioning System (CVS) Status • Nearing completion of MS Research • Adaptation to the development of a process family • Consideration of non-uniform demand, risk and uncertainty Publications Williams, C. B., Panchal, J., Rosen, D. W., 2003, “A General Decision-Making Method for the Rapid Manufacturing of Customized Parts,” accepted by the 23rd Conference on Computers and Information in Engineering, ASME, September 2-6, Chicago, Illinois. Carone, M. J., Williams, C.B., Allen, J. K., and Mistree, F., 2003, “An Application of Constructal Theory in the Multi-Objective Design of Product Platforms,” accepted by the 15th International Conference on Design Theory and Methodology, ASME, September 2-6, Chicago, Illinois. Hernandez, G., Williams, C. B., Allen, J.K., Mistree, F., “Design of Platforms for Customizable Products as a Problem of Access in a Geometric Space,” Journal of Mechanical Design, Submitted. Hernandez, G., Allen, J.K., and Mistree, F. 2002, “Design of Hierarchic Platforms for Customizable Products,” ASME Design Automation Conference, Montreal, Canada, DETC2002/DAC-34095. Hernandez, Gabriel, 2001, “Platform Design for Customizable Products as a Problem of Access in a Geometric Space,” Ph.D. Dissertation, George W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA. Strategic Design Student: Matthew Chamberlain Faculty: Farrokh Mistree Objectives Contributions & Benefits • To establish a method for allowing distributed designers to collaborate on the design of products while taking into account: •Changes in market trends •Changes in the capabilities of existing technologies •New or evolving technologies • To develop a number of new techniques that would be parts of a strategic design method, including: •N-dimensional market visualization techniques •Innovation modeling and early technology impact forecasting methods • To develop a plan for coordinating the many disparate methods that would make up strategic design as well as a logic for choosing between different modes of managing product variety Scholarship • Effective tools for creating representations of n-dimensional market spaces and design capabilities • Systematic approaches for designing families of products that can evolve and accommodate change and innovation and a systematic tool for choosing between multiple available approaches • Methods for forecasting and characterizing the impact of innovation on a feasible space in a manner meaningful to the design process Industry • Computing, information, and decision frameworks for coordinating distributed decision makers carrying out strategic design • Methods for linking market and design capability forecasts to design decisions and plans for product portfolios Background Tasks Strategic Design is a comprehensive approach for designing products and processes that efficiently and effectively accommodate… •changing markets and associated customer requirements •technological innovations • Strategic product planning techniques for forecasting dynamic requirements and technological capabilities and for assessing the potential impact of innovation on complex products and processes. • Product variety design techniques for leveraging and adapting existing products. • Decision support techniques that are formal, rigorous, and flexible, and account for uncertainty • Coordination mechanisms for multiple agents in product development activities • Flexible computing and information infrastructures for effective distributed design … In a collaborative, distributed environment Property B Expanded Technology Resources x • One student. Available Technology Property A Future Technology Publications • Seepersad, C. C., F. S. Cowan, M. K. Chamberlain and F. Mistree, 2002, "Strategic Design: Leveraging and Innovation for a Changing Marketplace," Engineering Design Conference, King's College, London, pp. 3-20. • Chamberlain, M. K., 2002, “A Step Towards Web-Based Strategic Design,” MS Thesis, G.W. Woodruff School of Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA. Design Process, Information, and Knowledge Management in Distributed, Collaborative Design Student: Jitesh H. Panchal Objectives Faculty: Farrokh Mistree, Janet K. Allen Contributions & Benefits Development of • A method for Integrated Design of Products and Design Processes • Computational model of design processes in the form of a design equation • Quantitative metrics for openness of products and processes • Method for synthesizing design processes • Application to design of materials Background • Means for improvement of design processes • Systematic method for configuring design chains • Design knowledge reuse in an organization • Tools for modeling and reconfiguring design processes • A new dimension to the design information management and reuse Collaboration Needed Design Equation: K = T (I) Decision Based Design Process Detail Decision Support Problem (DSP) Technique Scope Design process at various levels 2 PhD Students Student 1: Development of method for Integrated Design of Products and Design Processes Student 2: Application of the method to design of materials References [1] B. A. Bras, "Designing Design Processes for Decision-Based Concurrent Engineering," presented at CERC's First Workshop on Product Development, Process Modeling and Characterization, Morgantown, West-Virginia, 1992. [2] F. Mistree, W. F. Smith, B. Bras, J. K. Allen, and D. Muster, "DecisionBased Design: A Contemporary Paradigm for Ship Design," in Transactions, Society of Naval Architects and Marine Engineers, vol. 98. Jersey City, New Jersey, 1990, pp. 565-597. [3] D. Muster and F. Mistree, "The Decision Support Problem Technique in Engineering Design," International Journal of Applied Engineering Education, vol. 4, pp. 23-33, 1988. A Decision Support Framework (DSF) for Distributed Collaborative Design and Manufacture (DCDM) Student: Marco Gero Fernández Objectives Faculty : Farrokh Mistree and Janet K. Allen Contributions & Benefits • Develop and commercialize a Decision Support Framework (DSF) for Scholarship Distributed Collaborative Design and Manufacture (DCDM), where • Emphasis is placed on development of theory, creation of domain independent decision support refers to the cumulative means of modeling, structuring, constructs for characterizing and modeling decisions, and formalization of and negotiation solutions to decisions and any of their interactions. interactions among distributed design agents via digital interfaces • Provide a consistent mechanism for supporting designers in their • Development of logic for design process reconfiguration and investigation of capacity as decision-makers. The fundamental goals are to (1) manage strategic decision-making/resource allocation the design process, (2) facilitate the collaboration of stakeholders, and (3) Industry effectively share information. • Facilitation of strategic decision-making from a systems perspective and • Effectively structure design processes and properly reflect decision enhancement of design process reconfiguration with regard to flexibility, critical information and any dependencies. efficiency, and effectiveness. • Enablement of companies to trace errors to their origins within a given design Background chain and allow for remediation through dynamic design modification and/or • This research will expand upon a substantial knowledge base in process reconfiguration Decision Based Design, design theory, and decision theory that has The Role of Decisions throughout The Strategic Reduction of Design Freedom through Decisions… evolved in the Systems Realization Laboratory (SRL) since its the Design Process… establishment in 1992. STRUCTURAL ENGINEERING h ECONOMICS Ledger Ledger Resource Resource $$ Activity $ Activity $ Total Total $$ ELECTRICAL ENGINEERING R THERMAL ENGINEERING w + - i V T1 Q T2 L C k Resources, Status, Publications, etc. Designer #1 Designer #2 Designer #3 Designer #4 Fundamental Assertions • It is the nature and types of decisions, implemented that determine the progress of a design • Decisions in all stages of engineering design depend on scientific, factual information as well as empirical, experience-based knowledge, designer preferences, and uncertainty. • There is a need to propagate decision-critical, up-to-date information alongside design knowledge for both sequential and concurrent design tasks, particularly for dependent and interdependent decisions that cannot be made in isolation. Resources • SRL Knowledge Base • X-DPR, iSIGHT, Web Board, Concurrent Versioning System (CVS) Status • Completion of MS Research, Development of Decision Constructs and Information Model required for DSF • Active consideration/infusion of Risk and Uncertainty into decision-making Publications Fernández, M.G., D.W. Rosen, J.K. Allen, and F. Mistree (2002). “A Decision Support Framework for Distributed Collaborative Design and Manufacture”. 9th AIAA/ISSMO Symposium on Multidisciplinary Analysis and Optimization, Atlanta, GA, AIAA-4881. Others available upon request. Digital Clay for Shape Input and Display 15 Students Faculty: Wayne Book, Mark Allen, Imme Ebert-Uphoff, Ari Glezer, David Rosen, Jarek Rossignac Objectives Develop an interactive, 3-D haptic computer input/output device. Specifically, the device will enable: • Shape input through a “sculpting” interaction mode • Shape display of a computer model (e.g. CAD model) • Stiffness (“feel”) display of shapes with various material properties. Demonstrate the digital clay device on a variety of mechanical and architectural shape design applications, distributed collaboration, and dynamic simulations. Background Hydraulics will be used for actuation and sensing. A formable skin will comprises the bulk and shape of the “clay” device. The skin will have inflatable bladders to enable the skin to change shape and to sense user forces. Stereolithography used to fabricate skin and clay structure. MEMS technologies will be utilized to fabricate array of pressure sensors and valves in device backplane. Human-computer interface studies will determine appropriate methods of interaction with clay devices. Contributions & Benefits Define state-of-the-art in haptics (force-based) computer interaction. Greatly impact distributed collaboration when shape must be communicated. Potentially, impact the ability for visually impaired people to interact with computers. Significantly impact technology in hydraulics, controls, kinematics, manufacturing, and human-computer interface areas. Supported by 5 year NSF grant. Collaboration Needed 1 student to develop digital clay prototypes and test them in mechanical design applications. Materials and supplies to construct digital clay prototypes. References Bosscher, P. and Ebert-Uphoff, I., “Digital Clay: Architecture Designs for ShapeGenerating Mechanisms,” IEEE Robotics and Automation Conference, 2003. Rosen, D.W., Nguyen, A., and Wang, H., “On the Geometry of Low Degree-ofFreedom Digital Clay Human-Computer Interface Devices,” Proceedings ASME CIE Conference, paper DETC2003-48295, Chicago, Sept. 2-6, 2003. Zhu, H. and Book, W.J. “Control Concepts for Digital Clay,” 7th Annual International Symposium on Robot Control: SyRoCo 2003, Sept. 1-3, 2003, Wroclaw, Poland. Constrained Objects: A Knowledge Representation for Design, Analysis, and Systems Engineering Interoperability Students: Manas Bajaj, Injoong Kim, Greg Mocko Faculty: Russell Peak Chip Package Stress Analysis Template Objectives Contributions & Benefits Develop better methods of capturing engineering knowledge that : Are independent of vendor-specific CAD/CAE/SE tools Support both easy-to-use human-sensible views and robust computer-sensible formulations in a unified manner Handle a diversity of product domains, simulation disciplines, solution methods, and leverage disparate vendor tools Apply these capabilities in a variety of sponsor-relevant test scenarios: Proposed candidates are templates and custom capabilities for design, analysis, and systems engineering To Scholarship Develop richer understanding of modeling (including idealizations and multiple levels of abstraction) and representation methods To Industry Better designs via increased analysis intensity Increased automation and model consistency Increased modularity and reusability Increased corporate memory via better knowledge capture Constrained Object (COB) Formulations Approach & Status Collaboration Needed Approach Extend and apply the constrained object (COB) representation and related methodology based on positive results to date Expand within international efforts like the OMG UML for Systems Engineering work to broaden applicability and impact Status Current generation capabilities have been successfully demonstrated in diverse environments (circuit boards, electronic chip packages, airframes) with sponsors including NASA, Rockwell Collins, Shinko (a major supplier to Intel), and Boeing. Templates for chip package thermal analysis are in production usage at Shinko with over 75% reduction in modeling effort (deformation/stress templates are soon to follow) Constraint Schematic-S Additional Information: 1. http://eislab.gatech.edu/projects/ 2. Response to OMG UML for Systems Engineering RFI: http://eislab.gatech.edu/tmp/omg-se-33e/ 3. Characterizing Fine-Grained Associativity Gaps: A Preliminary Study of CAD-E Model Interoperability http://eislab.gatech.edu/pubs/conferences/2003-asme-detc-cie-peak/ Support for 1-3 students depending on project scope Sponsor involvement to provide domain knowledge and facilitate pilot usage Subsystem-S COB Structure Definition Language (COS) I/O Table-S Object Relationship Diagram-S Constraint Graph-S XML UML Express-G STEP Express COB-based Airframe Analysis Template CAD-CAE Associativity (idealization usage) lugs diagonal brace lug joint analysis context L [ j:1,n ] j = top hole lugj product structure (lug joint) Geometry 2 size,n deformation model diameters L [ k] k = norm Dk normal diameter, Dnorm oversize diameter, Dover mode (ultimate static strength) thickness, t 0.35 in edge margin, e 0.7500 in material Plug joint condition e W max allowable ultimate stress, FtuL Plu g jo in t Plug 67 Ksi Boundary Condition Objects Margin of Safety (> case) (links to other analyses) actual Requirements 0.7433 Paxu 14.686 K W 1) DtFtuax D Solution Tool Interaction estimated axial ultimate strength allowable MS Kaxu F tuax Paxu Kaxu ( 4.317 K n 8.633 K objective DM 6630 t Material Models 7050-T7452, MS 7-214 r1 D 0.7500 in effective width, W 1.6000 in Max. torque brake setting detent 30, 2=3.5º Lug Axial Ultimate Strength Model Model-based Documentation 2.40 Program L29 -300 Part Outboard TE Flap, Support No 2; Inboard Beam, 123L4567 Feature Diagonal Brace Lug Joint Template Lug Joint Axial Ultimate Strength Model Dataset j = top lug k = normal diameter (1 of 4) Composable Simulations: Model Archiving and Reuse for Systems Design Students: Rich Malak, Tarun Rathnam, Steve Rekuc Faculty: Chris Paredis Objectives Contributions & Benefits Develop integrated representations for multi-disciplinary products and their corresponding behavioral models To Scholarship Develop understanding of the relationship between configuration of components and configuration of simulation models Create ontology for ports (locations of intended interaction) and artifacts Develop understanding of validity and accuracy of models to enable reuse To Industry Faster and broader exploration of design space Capture history of design exploration and analyses Save resources by reusing validated simulation models Develop algorithms for reusing and composing simulation models of individual components into models for entire systems Characterize the validity and accuracy of simulation models at multiple levels of abstraction Support the seamless transition between models at multiple levels of abstraction while progressing through the design process Approach & Status Collaboration Needed Approach Semantically rich product representations in OWL (Web Ontology Language); combined with object-oriented simulation models in Modelica Define and populate a repository of components and models to demonstrate reuse and composition Investigate the compatibility, composability, and accuracy of models and model configurations. Status We have demonstrated the concept of composable simulations for satellite systems (with Lockheed-Martin) and for transportation systems (with Bombardier). We have implemented an initial software prototype, COINSIDE: Composition in Simulation and Design. Support for 1-2 students depending on scope of study Engineering support to provide application domain knowledge for example study. Additional Info C.J.J. Paredis, A. Diaz-Calderon, R. Sinha, and P.K. Khosla, "Composable Models for Simulation-Based Design", Engineering with Computers. Vol. 17, pp. 112128, 2001. (http://www.cs.cmu.edu/~paredis/pubs/EWC01.pdf) http://srl.marc.gatech.edu/people/paredis/ COINSIDE framework: Composition in Simulation and Design Composition of port-based objects allows for automatic composition of the corresponding simulation and CAD models Supply Chain Design and Analysis Testbed Students: Jin-Young Choi, Nan Li Faculty: Leon McGinnis Objectives Contributions & Benefits Develop distributed simulation testbed for analyzing global supply chains, including factories, warehouses, transportation To Scholarship Testbed for evaluating proposed supply chain planning/management methods To Industry Tools that permit collaboration between supply chain partners to analyze/design the supply chain without revealing proprietary data Use the distributed simulation testbed to investigate alternative designs, planning methods, and supply chain management methods Approach & Status Collaboration Needed Approach Use HLA to support distributed simulation, using legacy models where necessary Develop general purpose simulation models for warehouses and transportation Develop supply chain manager models Status First generation distributed simulation demonstrated, using factory models at SimTech, and warehouse and transportation models at Georgia Tech Ongoing development of generic warehouse, transportation and supply chain manager models Demonstration case study Development and evaluation of specific supply chain planning and/or management methods Integrating existing legacy models to permit supply chain analysis Additional Info This project has been conducted in collaboration with SimTech, the Singapore Institute for Manufacturing Technology School of Industrial and Sy stems Engineering Georgia Institute of Technology Atlanta, GA 30332-0205 http://factory .isy e.gatech.edu High Fidelity Factory Modeling Students: 5 PhD students Faculty: L. McGinnis, C. Zhou, S. Reveliotis Objectives Contributions Develop a new generation of factory modeling tools that: To Scholarship Comprehensive reference model for semiconductor fabrication operations Testbed for exploring alternative factory designs, alternative scheduling and control methods To Industry Testbed for evaluating proposed factory designs or factory planning and control strategies Support high fidelity description of factory resources and operations Are based on concepts that map one-to-one with factory entities Enable abstraction to support more aggregate models and analyses Demonstrate new tools in semiconductor wafer fabs Approach & Status Collaboration Needed Approach Object oriented Separation of process and control Explicit material handling Java, HLA Status Third generation toolkit Currently testing against Sematech 300mm model Demonstration case studies of specific fabs Evaluation of through-stocker versus point-to-point AMHS Linking factory operations models with “real” factory control software to create a “virtual” factory Additional Info http://factory.isye.gatech.edu/vfl/research/hifive.php For interim status report, presentations, and demonstrations School of Industrial and Sy stems Engineering Georgia Institute of Technology Atlanta, GA 30332-0205 http://factory .isy e.gatech.edu GIT Contacts & Departments Unit Dept. Admin - OIP First Name Last Name Titles Charles Liotta Vice Provost for Research and Dean of Graduate Studies MARC Dr. Steve Danyluk OIP OIP MARC Mr. MARC Dr. Andy Russell Dugenske Peak MARC Director, Prof. and Bryan Chair in ME Senior Researcher Senior Researcher CoA - Dr. Chuck Eastman Director, PhD Program and Professor CoC GVU Dr. Jarek Rossignac Professor CoE CoE CoE ECS ECS Dr. Mr. Ms. Narl Tord Sandra Davidson Dennis Pierotti Associate Dean Research Engineer I Manager, ECS CoE CoE CoE AE AE AE Mr. Dr. Dr. Pete Dimitri Dan Hart Mavris Schrage Research Engineer I Professor Professor CoE ISyE Dr. Leon McGinnis Professor CoE CoE CoE CoE CoE ME ME ME ME ME Dr. Dr. Dr. Dr. Dr. Bob Farrokh Chris Dave Suresh Fulton Mistree Paredis Rosen Sitaraman Professor Professor Assistant Professor Professor Associate Professor CoM - Dr. Naresh Malhotra Regents Professor Dr. Abbreviations AE School of Aerospace Engineering CoA College of Architecture CoC College of Computing CoM College of Management CoE College of Engineering CEE School of Civil and Environmental Engineering ECE School of Electrical and Computing Engineering ECS Engineering Computing Services (campus CAx services - under GIT CoE) ISyE School of Industrial and Systems Engineering MARC Manufacturing Research Center ME School of Mechanical Engineering (includes Nuclear and Health Physics) OIP Office of Interdisciplinary Programs PTFE School of Polymer, Textile & Fiber Engineering ASDL CBAR EIS Lab FIS Group MISL PLMCC PLM CoE RPMI SRL Aerospace Systems Design Lab Center for Board Assembly Research Engineering Information Systems Lab Factory Information Systems Group MARC Information Systems Lab Product Lifecycle Management Center of Competence Product Lifecycle Management Center of Excellence Rapid Prototyping & Manufacturing Institute Systems Realization Lab GIT Organization Charts http://www.provost.gatech.edu/flowchart.html Be aware that CoE has two meanings above: Center of Excellence and College of Engineering 18