PPT - Management of Technology – Step to Sustainable

advertisement

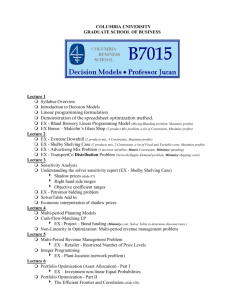

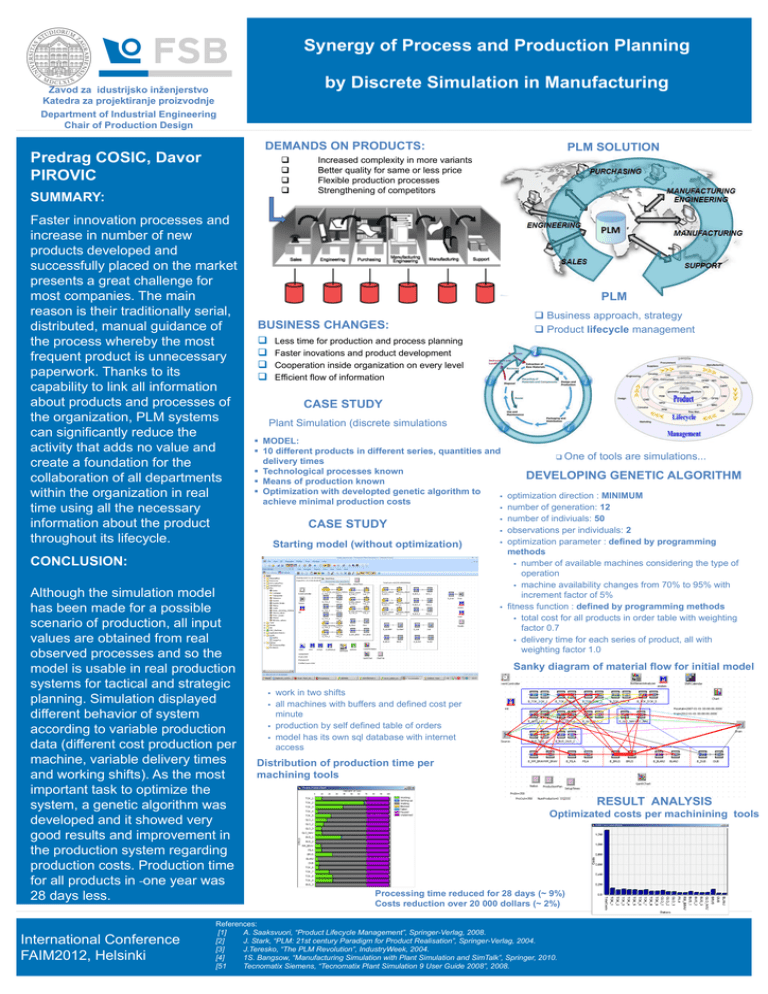

Synergy of Process and Production Planning by Discrete Simulation in Manufacturing Zavod za idustrijsko inženjerstvo Katedra za projektiranje proizvodnje Department of Industrial Engineering Chair of Production Design DEMANDS ON PRODUCTS: Predrag COSIC, Davor PIROVIC SUMMARY: Faster innovation processes and increase in number of new products developed and successfully placed on the market presents a great challenge for most companies. The main reason is their traditionally serial, distributed, manual guidance of the process whereby the most frequent product is unnecessary paperwork. Thanks to its capability to link all information about products and processes of the organization, PLM systems can significantly reduce the activity that adds no value and create a foundation for the collaboration of all departments within the organization in real time using all the necessary information about the product throughout its lifecycle. CONCLUSION: Although the simulation model has been made for a possible scenario of production, all input values are obtained from real observed processes and so the model is usable in real production systems for tactical and strategic planning. Simulation displayed different behavior of system according to variable production data (different cost production per machine, variable delivery times and working shifts). As the most important task to optimize the system, a genetic algorithm was developed and it showed very good results and improvement in the production system regarding production costs. Production time for all products in one year was 28 days less. International Conference FAIM2012, Helsinki PLM SOLUTION Increased complexity in more variants Better quality for same or less price Flexible production processes Strengthening of competitors PLM BUSINESS CHANGES: Business approach, strategy Product lifecycle management Less time for production and process planning Faster inovations and product development Cooperation inside organization on every level Efficient flow of information CASE STUDY Plant Simulation (discrete simulations MODEL: 10 different products in different series, quantities and One of tools are simulations... delivery times Technological processes known DEVELOPING GENETIC ALGORITHM Means of production known Optimization with developted genetic algorithm to optimization direction : MINIMUM achieve minimal production costs number of generation: 12 number of indiviuals: 50 CASE STUDY observations per individuals: 2 optimization parameter : defined by programming Starting model (without optimization) methods number of available machines considering the type of operation machine availability changes from 70% to 95% with increment factor of 5% fitness function : defined by programming methods total cost for all products in order table with weighting factor 0.7 delivery time for each series of product, all with weighting factor 1.0 Sanky diagram of material flow for initial model work in two shifts all machines with buffers and defined cost per minute production by self defined table of orders model has its own sql database with internet access Distribution of production time per machining tools RESULT ANALYSIS Optimizated costs per machinining tools Processing time reduced for 28 days (~ 9%) Costs reduction over 20 000 dollars (~ 2%) References: [1] A. Saaksvuori, “Product Lifecycle Management”, Springer-Verlag, 2008. [2] J. Stark, “PLM: 21st century Paradigm for Product Realisation”, Springer-Verlag, 2004. [3] J.Teresko, “The PLM Revolution”, IndustryWeek, 2004. [4] 1S. Bangsow, “Manufacturing Simulation with Plant Simulation and SimTalk”, Springer, 2010. [51 Tecnomatix Siemens, “Tecnomatix Plant Simulation 9 User Guide 2008”, 2008.