zemc2_38-58a_ds

advertisement

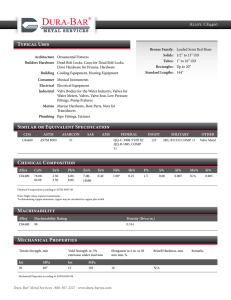

ZeMC², LLC We DO What Can’t Be Done 425 Lash Dr. Salisbury, NC 28147 704 - 633 2622 Fax 704 633 2635 www.ZeMC².com Product Data Sheet Rev. 2, 5/25/15 ZeMC² 38-58A Carbon Fiber and Ceramic Filled Bulk Molding Compound Product Description ZeMC² 38-58A is a Carbon Fiber and Ceramic filled BMC lubricated with Graphite. It has exceptional wear and thermal properties designed primarily for use in wear bushings and bearings. Phenomenal wear resistance is coupled with Thermal Conductivity to move heat through the wear component away from the heat generating area is part of the solution. Wear resistance, dimensional stability, high temperature resistance and thermal conductivity allow applications in areas previously untouchable. Excursion temperatures of 300° are achievable. Typical Cured Properties Specific Gravity ASTM D792 Mold Shrinkage mm/mm, Inch/inch Water Absorption Internal Flexural Strength ASTM D790 Compressive Strength Internal Izod Un-notched ASTM D256 Electrical Resistance Fluke Meter Ὠ @ 3.8 mm, 0.150” Glass Transition Temperature Typical Thermal Properties Un Post Baked DMA tan Δ Post Baked DMA tan Δ Excursion Temperature Coefficient of Linear Thermal Expansion mm/mm, in/in 10^-5 Metric 1.70 <0.001 0.40% 90.1 MPa 290 MPa 11.59 J 4.4 Ὠ English 1.70 <0.001 0.40% 13,065 PSI 42,000 PSI 8.55 Ft. LB. 4.4 Ὠ 220.9°C 237.7°C >300°C 429.6°F 459.9°F >572°F 2.25°C 1.25°C Disclaimer: The data provided is based on testing that does not reflect the conditions that exist in production. No warranty or legal responsibility is accepted or implied. The user should verify by testing the intended product in the intended process.