Electronic Supplementary Material Selenium Catalyzed Fe(III)

advertisement

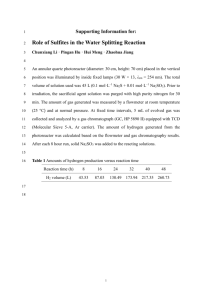

Electronic Supplementary Material Selenium Catalyzed Fe(III)-EDTA Reduction by Na2SO3: A Reaction-Controlled Phase Transfer Catalysis Kaisong Xiang a, Hui Liua,b,*, Bentao Yang a, Cong Zhang a, Shu Yang a, Zhilou Liu a, Cao Liu a, Xiaofeng Xie a, Liyuan Chai a,b, Xiaobo Mina,b,* (a School of Metallurgy and Environment, Central South University, Changsha, 410083, China b Chinese National Engineering Research Center for Control & Treatment of Heavy Metal Pollution, Changsha, 410083, China) Corresponding authors: Hui Liu*1: Tel.: +86 0731 88830875; Fax: +86 0731 88710171; Email address: huiliucsu@163.com; Xiaobo Min*2: Tel.: +86 0731 88830577; Fax: +86 0731 88710171; Email address: mxbcsu@163.com; 1/6 Fig. S1 Fe(III)-EDTA conversion after adding Na2SO3 solution then Na2SeSO3 solution. Fe(III)EDTA solution (50ml, 10mmol/L) was added with 50ml 1 mol/L Na2SO3 solution and then 10ml 0.2 mol/L Na2SeSO3 solution after 30min at 25 oC. The addition of Na2SeSO3 at the reaction time at 30 min greatly enhances the Fe(III)-EDTA conversion. Fe(III) conversion/% 80 a b c fitting curve for a fitting curve for b fitting curve for c 60 40 20 0 0 5 10 15 20 25 30 Time/min Fig. S2 Fe(III)-EDTA conversion after adding Na2SO3 solution (a), Na2SeSO3 solution (b) and Na2SO3 / Na2SeSO3 mixture (c). Fe(III)-EDTA solution (50 ml, 10 mmol/L) was added with 50 ml 1 mol/L Na2SO3 solution (a), 10 ml 0.2 mol/L Na 2SeSO3 solution diluted with 40 ml H2O (b), and 10 ml 0.2 mol/L Na2SeSO3 solution mixed with 40 ml 1 mol/L Na2SO3 solution separately. All the reduction experiments were performed at 25 oC. 2/6 Fig. S3 The ion chromatography of reference solution (a, 100 mg/L Na2SeO3, mixed with 80 mg/L SO42-) and diluted solution (100) from Na2SO3-Na2SeSO3-Fe(III)-EDTA reduction system (b) .The ion chromatography shows that peak I mismatches with the peak of SeO32- which means there is no SeO32- formed in the Na2SO3-Na2SeSO3-Fe(III)-EDTA reduction system. Peak II matches well with peak of SO42- which should be ascribed to the oxidation of SO32- or SeSO32- in the reduction system. Fig. S4 FT-IR spectra of Na2SeSO3 solution with varied concentration. (a) 0.04 mol/L, (b) 0.1 mol/L and (c) 0.2 mol/L. The above mentioned Na2SeSO3 solution was diluted by 1 mol/L Na2SO3 3/6 solution. The peaks at 930 cm-1 corresponding to the S-O bond from SO32- are little changed because the SO32- concentration of tested samples are the same. The peaks at 993cm-1 and 1117 cm-1 grow with the concentration of Na2SeSO3, which can be deduced that the characteristic peaks ascribed to Se-S bond and S-O bond from SeSO32- are located at 993cm-1 and 1117 cm-1. Fig. S5 EDS result of the red precipitate. 4/6 Table S1. The Fe(III)EDTA conversion rates at different temperature. Conversion rates Temperature Without catalyst With catalyst 25 oC 9.3% 47.6% 45 oC 15.6% 54.6% 60 oC 19.4% 69.4% Note: Fe(III)-EDTA solution (50 ml, 10 mmol/L) was added with 50 ml 1 mol/L Na2SO3 solution, and 10 ml 0.2 mol/L Na2SeSO3 solution mixed with 40 ml 1 mol/L Na2SO3 solution separately. Table S2. The calculation of peak area of S-O bonds from SO32- and S-O, Se-O bonds from SeSO32in HATR-FTIR spectra of Figure 3. Spectrum b Spectrum c (cm-1a.u.) (cm-1a.u.) 1117 cm-1 7.6876 13.8057 ≈1/2* 993 cm-1 3.0476 5.9807 ≈1/2 930 cm-1 25.9931 64.2088 <1/2 Locations *The Ratio of b/c ratio is actually 11% higher than 1/2. It should be ascribed to the over-lap of S-O bond from SO42- oxidized from SO32- by Fe(III)-EDTA. 5/6 Characterizations Ion Chromatograph (IC) The selenium speciation analysis is measured using a Metrohm 861 ion chromatograph (IC) with a conductivity detector. The eluent was 3.2 mmol/L Na2CO3 and 1.0 mmol/L NaHCO3 at a flow rate of 0.7 mL/min. Na2SeO3 (100 mg/L) mixed with SO42- was employed as reference solution for the determination of SeO32- and SO42-. Energy Dispersive Spectroscopy (EDS) Elemental analysis for the recovered catalyst was identified by EDS using an EDX-GENESIS spectrometer (EDAX, Ltd., USA). No treatment was done for the tested sample after vacuum drying at 40 oC. 6/6