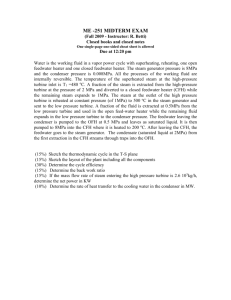

ME-602 Power Plant Engg1 - Gwalior Engineering College

advertisement

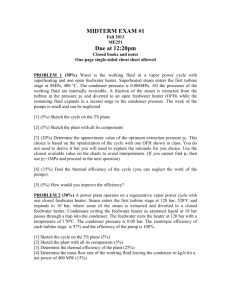

NOTES ON Power Plant Engineering ME-602 Unit I: Introduction to methods of converting various energy sources to electric power, direct conversion methods renewable energy sources, solar, wind, tidal, geothermal, bio-thermal, biogas and hybrid energy systems, fuel cells, thermoelectric modules, MHD-Converter. BY: Ravi Kant Rathore Asst. Prof. Mech. Deptt. GIIT GWALIOR INTRODUCTION Two important area of application of thermodynamics are power generation and refrigeration. Both power generation and refrigeration are usually accomplished by a system that operates on a thermodynamics cycle. Thermodynamics cycles can be divided into two generation categories : (a) Power Cycles (b) Refrigeration Cycles The devices or systems used to produce a net power output are often called engines and the thermodynamics cycles they operate on are called power cycle. The devices or systems use to produce refrigeration are called refrigerator, air conditioners or heat pumps and the cycles they operates on are called refrigeration cycles. Thermodynamic cycles can be categorized as : (a) Power cycles or Refrigeration cycles. (b) Gas Cycles or Vapor Cycles : In gas cycles, the working fluid remains in the gaseous phase throughout the entire cycle, where as in vapor cycles the working fluid exists in the vapor phase during one part of the cycle and in the liquid phase during another part. (c) Closed Cycles or Open Cycles : In closed cycles, the working fluid is returned to the initial state at the end of the cycle and is re-circulated. In open cycle, the working fluid is renewed at the end of each cycle instead of being re-circulated. BASIC CONSIDERATION IN THE ANALYSIS OF POWER CYCLES Actual Cycle The cycles encountered in actual devices are difficult to analyze because of the presence of complicating effects, such as friction and the absence of sufficient time for establishment of the equilibrium conditions during the cycle. Ideal Cycle When the actual cycle is stripped of all the internal irreversibilities and complexities, we end up with a cycle that resembles the actual cycle closely but is made up totally of internally reversible processes. Such a cycle is called an Ideal cycle. Heat Engines Heat engines are designed for the purpose of converting other form of energy to work and their performance is expressed as thermal efficiency. W th net Qin The Idealization and Simplification (a) The cycle does not involve any friction. (b) All expansion and compression process take place in a quasiequilibrium manner. (c) The pipe connecting the various component of a system are well insulated and heat transfer and pressure drop through them are negligible. Carnot Cycle The Carnot cycle is composed of 4 totally reversible processes : (a) Isothermal heat addition at high temperature (TH). (b) Isentropic expansion from high temperature to low temperature. (c) Isothermal heat rejection at low temperature (TL). (d) Isentropic compression from low temperature to high temperature. TL Thermal efficiency of Carnot cycle = 1 th, carnot TH The Carnot Vapor Cycle (a) A steady-flow Carnot cycle executed with the saturation dome of a pure substance is shown in Figures 2.1(a) and (b). The fluid is heated reversibly and isothermally in a boiler (process 1-2), expanded isentropically in a turbine (process 2-3), condensed reversibly and isothermally in a condenser (process 3-4) and compressed isentropically by a compressor to the initial state (process 4-1). (b) The Carnot cycle is not a suitable model for vapor power cycle because it cannot be approximated in practice. T 2 1 4 3 s (a) T 2 1 4 3 s (b) Carnot Cycle Rankine Cycle : The Ideal Cycle for Vapor Power Cycle (a) The impracticalities associated with Carnot cycle can be eliminated by superheating the steam in the boiler and condensing it completely in the condenser. This cycle that results is the Rankine cycle, which is the ideal cycle for vapor power plants. The construct of power plant and T-s diagram is shown in Figures 2.2(a) and (b). qin Boiler 3 2 Wturb,out Turbi wpump,in Pump 4 qout 1 Condenser (a) T 3 qin Wturb,out 2 4’ 1 qout wpunp,in s (b) Rankine Cycle vapor at state 3 enters the turbine, where it expands isentropically and produces work by rotating the shaft connected to an electric generator. The pressure and the temperature of the steam drops during this process to the values at state 4, where steam enters the condenser Process 4-1 At this state, the steam is usually a saturated liquid-vapor mixture with a high quality. Steam is condensed at constant pressure in the condenser which is basically a large heat exchanger, by rejecting heat to a cooling medium from a lake, or a river. Steam leaves the condenser as saturated liquid and enters the pump, completing the cycle. Energy Analysis of the Ideal Rankine Cycle All four components associated with the Rankine cycle (the pump, boiler, turbine and condenser) are steady-flow devices, and thus all four processes that make up the Rankine cycle can be analyzed as steady-flow process. The steady flow equation per unit mass of steam reduces to q (q in ) (w out h h (kJ/kg) w ) in out ei Pump (q = 0) : ( h h ) v(PP) w pump, in where h h 1 2 1 and v v f @ p1 1 2 1 v f @ p1 Boiler (w = 0) : qin h3 h2 Turbine (q = 0) : w turbine, out ( h h ) 3 4 Condenser (w = 0) h h q out 4 1 The thermal efficiency of the Rankine cycle is determine from w q th where q net net q in w q q in out 1 in ww out turbine, out pump, in Deviation of Actual Vapor Power Cycle from Idealized Ones The actual vapor power cycle differs from the ideal Rankine cycle, as a result of irreversibilites in various components. Fluid friction and heat loss to the surroundings are the two common sources of irreversibilites. Fluid friction causes pressure drop in the boiler, the condenser and the piping between various components. Also the pressure at the turbine inlet is somewhat lower than that at the boiler exit due to the pressure drop in the connecting pipes. To compensate for these pressure drops, the water must be pumped to a sufficiently higher pressure than the ideal cycle. This requires a large pump and larger work input to the pump T IDEAL CYCLE Pressure drop in the boiler Pressure drop in the pump 3 Irreversibility in the turbine 2 ACTUAL CYCLE 4 1 Pressure drop in the condenser s (a) T 3 2a 2s 1 4s 4a s (b) Vapour Power Cycle The other major source of irreversibility is the heat loss from the steam to the surrounding as the steam flows through various components. Pa rti cu la r importance is the irreversibilites occurring within the pump and the turbine. A pump requires a greater work input, and a turbine produces a smaller work output as a result of irreversibilties. Under the ideal condition the flow through these devices is isentropic. The deviation of actual pumps and turbine from the isentropic ones can be accurately accounted by isentropic efficiencies, define as : p h h ws 2s h2 a h1 wa h h w a 3 T 1 4a h h w s 3 4s How can We Increase the Efficiency of the Rankine cycle? Than Rankine cycle efficiency can be increased by increasing average temperature at which heat is transferred to the working fluid in the boiler or decreasing the average temperature at which heat is rejected from the working fluid in the condenser. That is, the average fluid temperature should be as high as possible during heat addition and as low as possible during heat rejection. The three ways by which efficiency of the Rankine cycle can be increased are : (a) Lowering the condenser pressure (Lowers Tlow, av). (b) Superheating the steam to high temperatures (Increases Thigh, av). (c) Increasing the boiler pressure (Increases Thigh, av). Lowering the Condenser Pressure (Lowers Tlow, av) Steam exists as a saturated mixture in the condenser at the saturation temperature corresponding to the pressure inside the condenser. Therefore, lowering the operating pressure of the condenser automatically lower the temperature of the steam, and thus the temperature at which heat is rejected. The effect of lowering the condenser pressure on the Rankine cycle efficiency is illustrated . T 3 2 2’ 4 1 1’ P’4< P4 4’ Increase in wnet s Rankine Cycle Drawback of lowering the condenser pressure is increase in the moisture content of the steam at the final stages of the turbine. The presence of large quantities of moisture is highly undesirable in turbines because it decreases the turbine efficiency and erodes the turbine blades. Superheating the Steam to High Temperatures (Increases Thigh, av) The average temperature at which heat is added to the steam can be increased without increasing the boiler pressure by superheating the steam to high temperatures. The effect of superheating on the performance of vapor power cycle is illustrated on a T-s diagram. Superheating the steam to higher temperatures has very desirable effect : It decreases the moisture content of the steam at the turbine exit as can be seen in T-s diagram The temperature to which steam can be superheated is limited by metallurgical consideration. T Increase in wnet 3’ 3 2 1 4 4’ Vapour Power Cycle T Increase in w net 3’ 3 Increase in wnet 2’ 2 1 4’ 4 s Vapour Power Cycle Increasing the Boiler Pressure (Increases Thigh, av) The average temperature during the heat addition process is to increase the operating pressure of the boiler, which automatically raises the temperature at which boiling take place. This, in turn, raises the average temperature at which heat is added to the steam and thus raises the thermal efficiency of the cycle. The Ideal Reheat Rankine Cycle The efficiency of the Rankine cycle can increase by expanding the steam in the turbine in two stages, and reheating it in between. Reheating is a practical solution to the excessive moisture problem in turbines, and it is commonly used in modern steam power plants. The schematic and T-s diagram of the ideal reheat Rankine cycle. The ideal reheat Rankine cycle differs from the simple ideal Rankine cycle in that the expansion process take place in two stages. In first stage (the high-pressure turbine), steam is expanded isentropically to an intermediate pressure and sent back to the boiler where it is reheated at constant pressure, usually to the inlet temperature of the first turbine stage. Steam then expands isentropically in the second stage (low-pressure turbine) to the condenser pressure. 3 High - p turbine Boiler Low p trine Reheater 4 P4 = P5 = 6 5 Condenser 2 Pump (a) Reheating T High-pressure turbine 3 4 2’ Low pressure 4 2 1 6 s (b) Ideal Reheat Rankine Cycle Thus the total heat input and the total work output for a reheat cycle become : q q q (h h ) inprimaryreheat w w turbine, out (hh) 32 5 w turbine, I 4 (h h ) turbine, II 3 4 (hh) 56 The Ideal Regenerative Rankine Cycle T-s diagram for the Rankine cycle shows that heat transferred to the working fluid during process 2-2at a relatively low temperature. This lowers the average heat-addition temperature and thus the cycle efficiency. To remedy this shortcoming, the temperature of the liquid leaving the pump (called feedwater) before it enters the boiler need to be increased. T Lowtemperature heat addition Steam exiting boiler 2’ Steam entering boiler 2 1 4 s Ideal Regenerative Rankine Cycle Another way of increasing the thermal efficiency of the Rankine cycle is by regeneration. During a regeneration process, liquid water (feedwater) leaving the pump is heated by steam bled off the turbine at some intermediate pressure in devices called feedwater heaters. There are two type of feedwater Heaters : (a) Open Feedwater Heater (b) Closed Feedwater Heater Open Feedwater Heater An open (or direct-contact) feedwater heater is basically a mixing chamber, where the steam extracted from the turbine mixes with the feedwater exiting the pump. Ideally, the mixture leaves the heater as a saturated liquid at the heater pressure. The schematic of a steam power plant with one open feedwater heater and the T-s diagram of the cycle . The heat and work interaction of a regenerative Rankine cycle with one feedwater heater can be expressed per unit mass of steam flowing through the boiler as follows : qin h5 h4 q (1 y) (hh) out 7 1 5 6 ( h h ) w turbine, out 67 (1 y) w w turbine, in y where (1 y )(hh ) w pump I, inpump II, in m 6 m5 v ( p w pump I, in 1 p ) 2 v ( p w pump II, in 3 1 p ) 4 3 5 Turbine Boiler y Open 6-y 1-y FWH 4 2 Condenser Pump II Pump 1 (a) T 5 4 6 3 3 1 7 s (b) Steam Power Plant The thermal efficiency of the Rankine cycle increases as a result of regeneration. This is because regeneration raises the average temperature at which heat is transferred to the steam in the boiler by raising the temperature of the water before it enters the boiler. Closed Feedwater Heaters Another type of feedwater heater used is steam power plants is the closed feedwater heater in which heat is transferred from the extracted steam to the feedwater without any mixing taking place. The two streams now can be at different pressure, since they do not mix. The schematic of a steam power plant with one closed feedwater heater and the T-s diagram of the cycle 6 Turbine Boiler Mixing chambe r 7 8 Closed FWH 9 5 4 2 3 Condenser Pump 1 Pump II (a) T 6 4 5 9 2 7 3 1 8 s (b) Steam Power Plant STEAM GENERATOR Steam is an important medium of producing mechanical energy. Steam has the advantage that, it can be raised from water which is available in abundance it does not react much with the materials of the equipment of power plant and is stable at the temperature required in the plant. Steam is used to drive steam engines, steam turbines etc. Steam power station is most suitable where coal is available in abundance. Thermal electrical power generation is one of the major methods. Out of total power developed in India about 60% is thermal. For a thermal power plant the range of pressure may vary from 10 kg/cm2 to super critical pressures and the range of temperature may be from 250°C to 650°C. Essentials of Steam Power Plant Equipment A steam power plant must have following equipment : (a) A furnace to burn the fuel. (b) Steam generator or boiler containing water. Heat generated in the furnace is utilized to convert water into steam. (c) Main power unit such as an engine or turbine to use the heat energy of steam and perform work. (d) Piping system to convey steam and water. In addition to the above equipment the plant requires various auxiliaries and accessories depending upon the availability of water, fuel and the service for which the plant is intended. The flow sheet of a thermal power plant consists of the following four main circuits : (a) Feed water and steam flow circuit. (b) Coal and ash circuit. (c) Air and gas circuit. (d) Cooling water circuit. A steam power plant using steam as working substance works basically on Rankine cycle. Steam is generated in a boiler, expanded in the prime mover and condensed in the condenser and fed into the boiler again. The different types of systems and components used in steam power plant are as follows : (a) High pressure boiler (b) Prime mover (c) Condensers and cooling towers (d) Coal handling system (e) Ash and dust handling system (f) Draught system (g) Feed water purification plant (h) Pumping system (i) Air preheater, economizer, super heater, feed heaters. shows a schematic arrangement of equipment of a steam power station. Coal received in coal storage yard of power station is transferred in the furnace by coal handling unit. Heat produced due to burning of coal is utilized in converting water contained in boiler drum into steam at suitable pressure and temperature. The steam generated is passed through the superheater. Superheated steam then flows through the turbine. After doing work in the turbine the pressure of steam is reduced. Steam leaving the turbine passes through the condenser which is maintained the low pressure of steam at the exhaust of turbine. Steam pressure in the condenser depends upon flow rate and temperature of cooling water and on effectiveness of air removal equipment. Water circulating through the condenser may be taken from the various sources such as river, lake or sea. If sufficient quantity of water is not available the hot water coming out of the condenser may be cooled in cooling towers and circulated again through the condenser. Bled steam taken from the turbine at suitable extraction points is sent to low pressure and high pressure water heaters.