Nick2009

advertisement

Project Management

MBA

Winter 2009

Professor Nicholas G. Hall

Department of Management Sciences

Fisher College of Business

The Ohio State University

hall_33@fisher.osu.edu

Reasons for Studying Project Management

Product and service life cycles are shorter than

ever before, hence there is more rapid “change”

in industry, and managing this change requires

professional project management.

Emerging applications, especially IT

implementations, are often managed as projects.

More managers are using a project format to

motivate many different activities.

Project management skills are useful in both

manufacturing and service sectors.

2

Objectives of the Course

Understand the critical tradeoffs and decisions

in project management

Learn how to select and organize projects

Learn the uses and limitations of project

management software

Learn how to monitor and control single

projects

Learn how to manage uncertainty and risk in

projects

Learn how to prioritize and manage multiple

projects

Learn how to manage projects better than

typical business practice (70 – 30 mix)

3

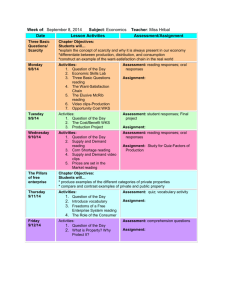

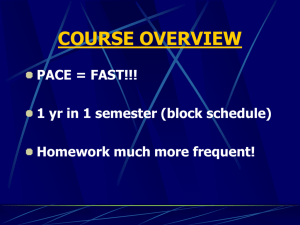

Course Overview (1 of 3)

History of the course

History of the subject

Textbook

Readings

4

Course Overview (2 of 3)

Software

Case studies

Case analysis presentations

Guest speakers

5

Course Overview (3 of 3)

Multitasking simulation game

Class participation

Final exam

Questions

6

Carmen Website Contents

Introduction: syllabus, frequently asked

questions

Lecture notes in Powerpoint

Background readings

Case report example

Software tutorials (5)

Multitasking simulation game: templates,

student note

Forms: guest speaker evaluation, course

midterm feedback, peer group evaluation

To be added: case analysis assignments, guest

speaker presentations, student requests, ... 7

Project Management Institute (PMI®)

“We’ve long been acknowledged as a pioneer

in the field and now our membership

represents a truly global community with over

100,000 professionals, representing 125

countries. PMI professionals come from

virtually every major industry…”

PMI offers a valuable certification program,

Project Management Professional (PMP). It

also publishes Project Management Journal, a

valuable source of practical research that is

available through OSU Library e-journals.

8

Useful Readings

Textbook

Klastorin, T. Project Management: Tools and

Tradeoffs, Wiley, Hoboken, NJ, 2004.

Other Useful Sources

Brooks, F. The Mythical Man-Month. Addison-Wesley,

Reading, MA, 1995.

Goldratt, E.M. Critical Chain. The North River Press,

Great Barrington, MA, 1997.

A Guide to the Project Management Body of

Knowledge (PMBOK Guide), PMI, Newton Square, PA,

2000.

Kerzner, H. Strategic Planning for Project Management

Using a Project Management Maturity Model, Wiley,

New York, NY, 2001.

Stevenson, N. Microsoft Project 2003 for Dummies,

Wiley, Indianapolis, IN, 2004.

9

Chapter

Introduction to Project

Management

History of Project Management

One of the first examples of project management was

the construction of the pyramids in Egypt

Henry L. Gantt (1861-1919) added an important

visualization tool around 1917 with the Gantt Chart

In the late 1950s, DuPont Company developed the

Critical Path Method (CPM)

Also in the late 1950s, Booz Allen Hamilton developed

the Program Evaluation and Review Technique (PERT),

which models uncertainty in project management

11

Importance of Project Management

Project management effectively controls

organizational change, allowing organizations

to introduce new products, new processes,

and new programs effectively.

Projects are becoming more complex,

making them more difficult to control without

a formal management structure.

Projects with substantially different

characteristics, especially in IT, are

emerging.

Project management helps cross-functional

teams to become more effective.

12

Comment on the Importance of

Project Management

“At last we are beginning to see

research which proves how important

project management is ... without

well-trained and capable project

managers the percentage of GDP

spent through projects is inflated due

to many exceeding their budget

through poor management.”

Richard Pharro, author and consultant (2003)

Still, many organizations underappreciate the

13

contributions made by their project managers.

What is a Project?

A project is a “temporary endeavor

undertaken to create a unique product or

service”. (PMBOK, 2000)

A project is a well-defined set of tasks or

activities that must all be completed in

order to meet the project’s goals. Two

prevalent characteristics:

Each task may be started or stopped

independently of other tasks;

Tasks are ordered such that they must be

performed in a technological sequence.

14

Examples of Projects

Construction of the pyramids

Apollo moon landing mission

Development of MS Windows

Making The Lord of the Rings

Organizing the Olympics Games

Development and marketing of a new drug

Implementing a new company wide IT system

Design of this course

Project management spans both the

manufacturing and service sectors.

15

Manufacturing Perspective

Flowshop: The same sequence of

operations is used to create each product

or service.

Job Shop: A product or service only flows

through centers which are required to

create it.

16

Characteristics of Flowshop, Job Shop

and Project

Flowshop Job Shop Project

Product

Mass

Custom

Labor

Low skill

High skill High skill

Capital

High

Medium

Low

Variable

Highly

variable

Performance Good

(time, cost,

quality)

Unique

17

Project Management versus Process

Management

“Ultimately, the parallels between process

and project management give way to a

fundamental difference: process

management seeks to eliminate variability

whereas project management must accept

variability because each project is unique.”

J. Elton, J. Roe. 1998. Bringing Discipline to

Project Management. Harvard Business Review.

See coursepack article: Oltra, Maroto and Segura

18

“Lean” Principles in Project Management

Focusing on customer needs

Balancing work to ensure an even

flow

Using “customer pull” rather than

“supplier push” to initiate work

Using principles of continuous

improvement

See coursepack article: Brown et al.

19

Measures of Project Success

Overall perception

Cost

Completion time

Technical goals, compared to initial

specifications

Technical goals, compared to other

projects in the organization

Technical goals, taking into account the

problems that arose in the project

R.J. Might and W.A. Fischer (1985)

Question: Was the movie Titanic successful?

See coursepack article: The Chaos Report

20

Nine Factors Critical to

the Success of Many Projects

Clearly defined goals

Competent project manager

Top management support

Competent project team members

Sufficient resource allocation

Adequate communication channels

Effective control mechanisms

Use of feedback for improvement

Responsiveness to clients

J. Pinto and D. Slevin (1987)

See coursepack article: Czuchry and Yasin

21

Famous Project Failures

In 1988, Westpac Banking Corporation initiated a 5-year,

$85m project to improve its information system. Three

years later, after spending $150m with nothing to show for

it, they cancelled the project and eliminated 500

development jobs.

The computerized baggage handling system at the Denver

International Airport delayed the opening of the airport

from March 1994 to February 1995 and added $85 million

to the original budget. The baggage system continued to

unload bags even though they were jammed on the

conveyor belt. The system also loaded bags into telecarts

that were already full. Hence, some bags fell onto the

tracks, causing the telecarts to jam. The timing between

the conveyor belts and the moving telecarts was not

properly synchronized, causing bags to fall between the

conveyor belt and the telecarts. Then the bags became

wedged under the telecarts, which were bumping into each

other near the load point.

22

Famous Project Failures (cont.)

Disney's shipbuilder was six months late in delivering its

new cruise ships in 1998. Thousands of Disney customers

who had purchased tickets had to be compensated for

making different plans.

In 1997-99, Universal Studios in Orlando, Florida, built a

new restaurant and entertainment complex, a two year

project. The opening was delayed by three months.

The “Big Dig” road construction project in Boston (19872007) was budgeted at $5.8b but cost over $15b. The

project resulted in criminal arrests, thousands of water

leaks, death of a motorist from a tunnel collapse, and

hundreds of millions of dollars in lawsuits.

In 2005, UK grocery chain J. Sainsbury wrote off its

$526m investment in an automated supply chain

management system. They hired 3000 additional workers

23

to stock their shelves manually.

Reasons why Projects Fail

Improper focus of the project management

system, e.g. on low level details

Fixation on first budget estimates

Too much reliance on inaccurate project

management software

Too many people on the project team

Poor communication within the project team

Incentives that reward the wrong actions

See coursepack article: Mulder

24

Common Excuses for Project Failures

Unexpectedly poor weather delayed

construction

Unforeseeable poor performance by

contractors

Senior management imposed an

unrealistic schedule

Instructions by senior management

were unclear

Many wasteful “synchronization”

meetings interrupted actual work

See coursepack article: Pinto and Kharbanda

25

Management of IT Projects

More than $250 billion is spent in

the US each year on approximately

175,000 information technology

projects.

IT project management is an $850

million industry and is expected to

grow by as much as 20 percent per

year.

Gene Bounds, “The Last Word on Project

Management”, IIE Solutions, 1998.

26

IT Projects are Different

“[in IT projects], if you ask people what’s

done and what remains to be done there

is nothing to see. In an IT project, you go

from zero to 100 percent in the last

second--unlike building a brick wall where

you can see when you’re halfway done.”

J. Vowler (2001)

Engineering projects are measured by tasks completed

Example: building construction

IT projects are measured by resources used

Example: software development

27

IT Project Outcomes

29%:

Cancellation

26%: On time

6%: Less than

20% late

6%: more than

200% late

8%: 21-50% late

16%: 101-200%

late

9%: 51-100%

late

Standish Group Survey, 1999.

(from a survey of 8000 business

systems projects)

28

Why do IT Projects Fail?

Ill-defined or changing requirements

Poor project planning/management

Uncontrolled quality problems, e.g.

software fails to complete computing task

in time

Unrealistic expectations/inaccurate

estimates

Adoption of new technology without fully

understanding it

Construx Software Builders, Inc., 2005.

Why are IT projects more difficult?

29

Wheelwright and Clark’s Classification

of Projects

30

Project Life Cycle

31

DESIGN

Design (Scope), Cost, Time Tradeoffs

Required

Performance

Target

COST

Budget

Constraint

Due Date

Optimal Time-Cost

Tradeoff

“You can have your job done cheap, quick, or

right; pick two.” [Sign in local copy center.]

32

Project Management Maturity Model

(PMMM)

PMMM is a formal tool that can be used

to measure an organization's project

management maturity.

Once the initial level of maturity and

areas for improvement are identified, the

PMMM outlines the steps to take toward

project management excellence

PMMM is based on extensive empirical

research that defines a “best practice”

database, as well as a plan for improving

the project management process

33

Project Management Maturity Model

1. Ad-Hoc: The project management

process is disorganized or even chaotic.

Systems and processes are not defined.

Chronic cost and schedule problems exist.

2. Abbreviated: Some project

management processes exist, but

underlying principles are not consistently

followed. Project success is largely

unpredictable. Cost and schedule

problems are common.

34

Project Management Maturity Model

3. Organized: Project management

processes and systems are

documented and and integrated.

Project success rates, and cost and

schedule performance, are improved.

4. Managed: Projects are effectively

controlled by management. Project

success is usually routine. Cost and

schedule performance usually

conform to plan.

35

Project Management Maturity Model

5. Adaptive: Continuous

improvement of the project

management process occurs through

feedback and testing of innovative

ideas and technologies. Project

success rates, and cost and schedule

performance, are continuously

improving.

Source: The Project Management Institute PM Network

1997. Micro Frame Technologies, Inc. and Project

Management Technologies, Inc.

36

Chapter

Project Initiation,

Selection, and Planning

Importance of Project Initiation &

Selection

“There are two ways for a

business to succeed at new

products: doing projects right,

and doing the right projects.”

R.G. Cooper, S. Edgett, E. Kleinschmidt. 2000.

Research and Technology Management.

Good project selection makes the later job of

running projects much easier.

Also, some poorly selected projects are

doomed from the start.

38

Project Selection - Overview

1. Strategic factors

Competitive necessity: keep a foothold in the

market, not get left behind

Market expansion opportunities: not yet

profitable, but need to establish a

presence

Consistency: in line with overall

organization’s mission statement

Image: potential impact of project on

corporate image

39

Project Selection - Overview

2. Project portfolio factors

Diversification: reduce market and other

risks by maintaining a mix of projects

Cash flow constraints: balance available cash

over time and across projects

Resource constraints: plan available

resources (facility, personnel) over time

40

Analyzing Project Portfolios:

Bubble Diagram

Prob of Commercial Success

High

Shapes

Shading

Zero

High

Expected NPV

Color

Size

Low

Bubble diagrams are useful for representing a set of

projects and visualizing a project portfolio.

41

Analyzing Project Portfolios:

Product vs Process

Shape represents

the production

resource used

Size represents the

resource requirement

Extent of Process Change

Source: S.C. Wheelwright and K.B. Clark, 1992,

Creating Project Plans to Focus, Harvard Business Review

42

Project Selection - Overview

3. Project risk factors

Probability of research being successful

Probability of development being successful

Probability of project success w.r.t. scope

Probability of commercial success

Overall risk of project

Competitors in market and their reactions

43

Project Selection - Overview

4. Quantitative factors

Payback period

Net present value / internal rate of return

Expected commercial value

Real options

Multifactor scoring

44

Payback Period Analysis

Number of years needed for the

project to repay its initial fixed

investment.

Example:

A project costs $100,000 and is

expected to save the company

$20,000 per year

Payback Period =

$100,000 / $20,000 = 5 years

45

Comments on Payback Period

Easy to calculate and explain, and

sometimes can be used to achieve a

common purpose throughout an

organization.

Ignores the time value of money,

including interest rates and inflation.

Ignores money earned after the

payback period.

46

Net Present Value (NPV)

Let Ft = net cash flow in period t

(t = 0, 1,..., T), where F0 = initial

cash investment at time t = 0 and

r = discount rate of return (hurdle

rate)

T

Ft

NPV

t

t 0 (1 r )

47

Internal Rate of Return (IRR)

Find a value of r such that NPV is

equal to 0 (but this value may not

be unique)

Example (with T = 2):

Find r such that

F1

F2

F0

0

2

1 r (1 r )

Note that, in a typical project, early cash flows are

negative.

48

NPV Example

Phase I Research and Product

Development: $18 million annual

research cost for 2 years.

Phase II Market Development: $10

million annual expenditure for 2 years

to develop marketing and distribution

channels.

Phase III Sales: All cash flows are

after-tax and occur at year's end.

49

NPV Example

The results of Phase II (available at the end of

year 4) identify the product's market potential

as indicated below:

50

NPV Example

Year

1

2

3

4

5-24

Expected Cash Flow ($m)

-18

-18

-10

-10

10

If the discount rate is 5 percent, the

discounted expected cash flow at the end of

the 4th year is $114.62m.

51

NPV Example

Expected cash flows (with sale of product at end of year 4)

Cash Outflow Cash Inflow

NPV

Year 1

18.00

-18.00/(1+r)

Year 2

18.00

-18.00/(1+r)2

Year 3

10.00

-10.00/(1+r)3

Year 4

10.00

124.62

+114.62/(1+r)4

This is the discounted value of sales at the end of year 4

The internal rate of return is 49.12%.

52

Criticisms of NPV Analysis

Assumes that cash flow forecasts are

accurate; ignores the “human bias” effect

Does not take into account the possibility that

decisions (and therefore cash flows) may

adapt to changing circumstances over time

Ignores project portfolio issues

Use of a single discount rate for the entire

project is problematic, since risk is typically

reduced as the project evolves

See coursepack article: Hodder and Riggs

53

Expected Commercial Value (ECV)

Probability = pc

Probability = pt

Develop

New

Product

Technical

Success

Probability = 1 - pt

Launch

New

Product

Commercial

Success (with net

benefit = NPV)

Commercial

Failure (with net

benefit = 0)

Probability = 1 - pc

Technical

Failure

Risk class 1

Risk class 2

ECV is the expected NPV of the project, calculated by using

the probabilities of the various alternatives.

54

ECV Example

The design of a new product is expected to

take 3 years, at a cost of $6m/year

There is a .8 probability that the product

will be technically feasible

If feasible, the product can be launched in

year 4 with an estimated cost of $5.5M

If launched, the product will be a

commercial success with probability 0.6,

earning gross revenues of $15M per year

for 5 years

If it is a commercial failure, then the

revenue is only $2M per year for 5 years

The discount rate is 10 percent

55

ECV Example

5 Years

Probability = 0.6

3 Years

Research &

Product

Development

Annual

Cost: $6M

Probability = 0.8

Development

Succeeds

One-time

cost of $5.5M

Launch

New

Product

Probability = 0.2

Development

Fails

Drop

Product

Commercial Success

Revenue $15M/yr

Commercial

Failure

Revenue $2M/yr

Probability = 0.4

No Cost

Discount rate

r1=10%

Discount rate

r2=10%

56

ECV Example

$M

Year

What’s

Happening

1

Commercial

Success

Commercial

Failure

10%

Expected

Annual

Cash

Flow

Discounted

Cash Flow

Technical

development

(6.00)

(5.45)

2

Technical dev.

(6.00)

(4.96)

3

Technical dev.

(6.00)

(4.51)

4

Product sales

$15

$2

3.44

2.35

5

Product sales

$15

$2

7.84

4.87

6

Product sales

$15

$2

7.84

4.43

7

Product sales

$15

$2

7.84

4.02

8

Product sales

$15

$2

7.84

3.66

Total = 4.40

Example calculation: .8[(.6)(15)+(.4)(2)-5.50]+.2(0)=3.44

57

Criticisms of ECV Analysis

The possibility of changing decisions

in the future changes the risk

characteristics of the project.

Consequently, the use of the same

discount rate may be inappropriate.

However, it’s not clear what other

discount rate should be used.

That’s where the idea of real options

analysis can (possibly) help.

58

Real Options Analysis

Based on the view that the evaluation of

financial options can be applied to other

investments.

Implicitly finds the correct discount rate by

expressing the cash flows in the project as

a combination of flows whose cost of capital

is supposedly known.

In principle, this should give more accurate

evaluation of projects than ECV.

However, the usefulness of real options

analysis for evaluating projects is unclear.

59

Real Options Analysis

A leader in the application of real options analysis is

Hewlett-Packard. But they mainly use it for

procurement and other low risk, contract-protected

decisions, not to evaluate projects.

Real options analysis is probably not useful in high risk

industries, such as pharmaceuticals.

Real options analysis may also not be useful if a

company lacks the discipline to end a project without

delay if the initial investment doesn’t work out.

Real options author N. Kulatilaka says, “Although you

can make any project look good if you build in enough

options, a real world approach must address two

questions: when exactly do you shut it down, and is

there a good mechanism in sight to do that?”

60

Multifactor Project Scoring Example

Attribute

Scale

Weight

Will the project

unlikely 1 2 3 4 5 likely

increase market share?

30%

Is new facility needed?

15%

Are there safety

concerns?

yes

(2)

likely

(1)

unsure

(3)

no

(4)

no

(5)

10%

Likelihood of

successful technical

development?

unlikely 1 2 3 4 5 likely

20%

Likelihood of

successful commercial

development?

unlikely 1 2 3 4 5 likely

25%

61

Multifactor Project Scoring Example

vi ( xi )

xi L

vi ( xi )

U L

To convert various

measurement

scales to a [0,1]

range.

LINEAR SCALE:

EXPONENTIAL

SCALE:

1 e( L xi )

vi ( xi )

1 e( L U )

1.00

0.90

0.80

Attribute Value

0.70

0.60

Linear Scale

Exponential Scale

0.50

0.40

0.30

0.20

Note that the

exponential scale

places a premium

on being

“acceptable”, but not

on “excellence”.

0.10

0.00

1

2

3

4

Response

5

6

7

xi

62

Multifactor Project Scoring Example

Weight

0.30

0.15

0.10

0.20

0.25

Attribute

#1

#2

#3

#4

#5

Project A

5

Yes (2)

Likely (1)

4

2

Project B

2

No (4)

Unsure (3)

3

4

Project

score (Vj)

Linear Scale

Project A

1.00

0.25

0

0.75

0.25

0.550

Project B

0.25

0.75

0.50

0.50

0.75

0.525

Exponential Scale

Project A

1.00

0.64

0.00

0.97

0.64

0.751

Project B

0.64

0.97

0.88

0.88

0.97

0.845

Note that the linear scale recommends Project A, whereas the

exponential scale recommends Project B.

63

Project Selection as a Portfolio

Problem

A project is a multi-period investment

problem

Top management typically allocates

resources to different product lines (e.g.,

compact cars, high-end sedans)

Product lines sell in separate (but not

necessarily independent) market segments

Product line allocations (which resources

should produce which products) may

change frequently

Conditions in each market segment are

uncertain from period to period due to

competition and changing customer

preferences

64

Project Selection Example

Project A

Revenue by Year

1

2

3

4

($40) $10

$20

$20

Project B

($65)

($25)

$50

$50

$90

$20

$40

$55

Budget Limit

Overall score of Project A: .581

Overall score of Project B: .845

We want to maximize the total overall

score, or value delivered, of the portfolio

65

0-1 Program for Project Selection

Maximize 0.581a + 0.845b

Subject to

40a + 65b ≤ 90 (Year 1)

-10a + 25b ≤ 20 (Year 2)

-20a – 50b ≤ 40 (Year 3)

-20a – 50b ≤ 55 (Year 4)

a, b = 0 or 1

where a = 1 if project A is selected

0 if not

and b similarly.

See coursepack article: Hall et al. (1992)

66

Project Planning Information

1. Project overview and organization

Summary statement, work breakdown

structure, organization plan, subcontracting

plan

2. Project scheduling

Time and schedule, budget, resource allocation

plan

3. Project monitoring and control

Cost control system, contingency plans

4. Project termination

Evaluation, benchmarking and archiving

67

Work Breakdown Structure (WBS)

Specifies the end-item “deliverables”

Divides the work, reducing the dollars and

complexity with each additional division

Stop dividing when the tasks are manageable “work

packages”, which will depend on:

Skill levels of group(s) involved

Managerial responsibility

Length of time

Value of task

Rules of thumb for tasks: small enough for

estimation, large enough for measurability

For example, the 1969 Apollo moon landing project

had about 500,000 tasks

68

Common Problem in WBS Design

“The usual mistake PMs make is to lay out too

many tasks; subdividing the major

achievements into smaller and smaller

subtasks until the work breakdown structure

(WBS) is a “to do” list of one-hour chores…

This springs from the screwy logic that a

project manager’s job is to walk around with

a checklist of 17,432 items and tick each item

off as people complete them….”

The Hampton Group (1996)

69

Two-Level WBS

WBS level 1

WBS level 2

1.1

Event

Planning

1. Charity Auction

1.2

Item

Procurement

1.3

Marketing

1.4 Corporate

Sponsorships

70

Three-Level WBS

1. Charity Auction

WBS level 1

WBS level 2

1.1 Event

Planning

1.2 Item

Procurement

1.1.1 Hire

Auctioneer

1.1.2. Rent space

WBS level 3

1.1.3 Arrange for

decorations

1.1.4 Print

catalog

1.3

Marketing

1.2.1 Silent

auction items

1.2.2 Live

auction items

1.2.3 Raffle

items

1.4 Corporate

Sponsorships

1.3.1 Individual

ticket sales

1.3.2

Advertising

71

Sandbagging

A common problem in estimation of task

durations is building in too much slack (also

known as “sandbagging”).

Sandbagging often results from poorly

aligned incentives. If project workers will

incur a penalty for missing a standard task

time, but no benefit from completing the

task earlier, then the natural tendency is to

inflate the standard task time.

A common problem in projects is that

sandbagging and other “slack” proliferate.

72

New Product Development

Projects

Sequential Approach

Design follows a sequential pattern where

information about the new product is slowly

accumulated in consecutive stages

Stage 0

Stage 1

Stage N

73

New Product Development

Projects

Overlapped Product Design Approach

Allows downstream design stages to start before

preceding upstream stages have finalized their

specifications….

Stage 0

Stage 1

Stage N

74

New Product Development

Projects

What are the tradeoffs when moving from a

traditional sequential product design

approach to an overlapped product design

approach?

Time to market is smaller in the

overlapped design

But the schedule is more vulnerable

(which requires additional monitoring)

Can add further resources to tasks to

reduce duration--but costs are increased

75

Chapter

Project Teams and

Organizational Relationships

Role of Project Manager and Team

Client

Top

Management

Project Manager

Subcontractors

Project Team

Regulating

Organizations

Functional

Managers

This structure is what makes being a project manager

both very interesting and very challenging!

77

Responsibilities of a Project

Manager

To the organization and top management

To the project team

Provide timely and accurate feedback

Keep focus on project goals

Manage personnel changes

To the client

Meet budget and resource constraints

Coordinate with functional managers

Communicate in a timely and accurate manner

Provide control over scope changes

Maintain quality standards

To the subcontractors

Provide information on overall project status

Comment: It’s a long list, and requires prioritization.

78

Project Team

What is a project team?

A group of people committed to achieving a

common set of goals for which they hold

themselves mutually accountable

Characteristics of a project team

Diverse backgrounds/skills

Need to work together effectively, often under

time and cost pressures

May not have worked together before

Have a sense of accountability as a unit (but

perhaps only temporarily)

79

Sources of Conflicts within

Projects

Scheduling and sequencing

Administrative procedures

Staffing issues

Budget and cost issues

Personality conflicts

Project priorities

Trade-off between technical performance

and business performance

Source: H.J. Thamhain and D.L. Wilemon, 1971

80

Artistic Viewpoint

“I design user interfaces to please an

audience of one. I write them for me. If

I’m happy, I know some cool people will like

it… As for schedules, I’m not interested in

schedules; did anyone care when War and

Peace came out?”

Developer, Microsoft Corporation

As reported by MacCormack and Herman,

HBR Case 9-600-097: Microsoft Office

2000

However, is this comment a reasonable one for most

project management environments?

81

Group Harmony and Project

Performance

What is the relationship between the design

of multidisciplinary project teams and

project success?

Two schools of thought:

“Humanistic” school -- groups that have

positive characteristics will perform well

“Task oriented” school -- positive group

harmony detracts from group performance

82

Group Harmony and Project

Performance

Experiment conducted with MBA students

at U. of Washington and Seattle U., using

computer based simulation of a nuclear

power plant.

14 project teams with a total of 44 team

members; compared high performance

(low cost) teams vs low performance

(high cost) teams

Measured:

Group harmony

Individual contributions to group

Speed of decision making

K. Brown, T.D. Klastorin, J. Valluzzi. 1990. “Project Management

Performance: A Comparison of Team Characteristics”, IEEE

Transactions on Engineering Management, 37, 2, 117-125.

83

Group Harmony:

High vs Low Performing Groups

High performing (low cost) groups

Low performing (high cost) groups

High performing groups began with lots of conflict!

84

Extent of Individual Contribution:

High vs Low Performing Groups

High performing (low cost) groups

Low performing (high cost) groups

High performing groups began with individual contributions low!

85

Decision Making Effectiveness:

High vs Low Performing Groups

High performing (low cost) groups

Low performing (high cost) groups

High performing groups began with slow decision making!

86

Organizational Issues

What administrative and control

relationships should be established

between the project and the existing

organization?

How much autonomy and authority

should be given to the project?

What management practices and

systems should be used to manage the

project, and how should they differ from

those used in the existing organization?

87

Fundamental Approaches

Project as a Distinct Entity: In order to

maximize the chances of success, it is better to

organize the project as an entity distinct from

the rest of the organization. This minimizes

interdependencies between the project and the

rest of the organization.

Project Integrated into Existing Structure:

When an organization undertakes a new

project, strong pressures favor the integration

of the project into the existing structure and

management systems and practices.

But, what is the overall company objective?

88

Autonomous Projects Tend to be

More Successful

Because their results are more visible and

attract more management attention

Motivation level tends to be higher

Because they suffer less from conflicts over

priorities than functionally managed projects,

which facilitates time and cost control

Because maintaining relationships between the

project and the organization creates complex

coordination problems

So, why aren’t all projects managed as autonomous

units?

89

Organizational Pressures for

Project Integration

Upper management may resist special status for

projects, because this creates additional risks and

setup costs as well as jealousy

Functional managers like to believe that the

project falls within their department’s jurisdiction

Department managers may feel threatened by

losing some of their best resources to the project

Personnel may resist transfer to the project,

especially for risky projects and when

reintegration after the project could be difficult

Personnel and accounting functions strive for

standardized methods and procedures across the

organization

Managers of autonomous projects choose

methods and materials to optimize locally, not

90

globally

Project Organization Types

1. Functional: The project is divided, and assigned

to appropriate functional departments. The

coordination of the project is carried out by functional

and high-level managers.

2. Functional matrix: A manager is designated to

oversee the project across different functional areas.

3. Balanced matrix: A manager is assigned to

oversee the project, and interacts on an equal basis

with functional managers.

4. Project matrix: A manager is assigned to

oversee the project as an independent entity, and is

responsible for the completion of the project. There

may be a project team, but part time.

5. Project team: A manager is put in charge of a

team drawn from several functional areas who are

assigned to the project full time.

91

Matrix Organization

Motivated by conflicting incentives in the

organization: functional managers typically

want to optimize scope and product

performance and design, project managers

focus more on the cost and schedule of the

project

Matrix organization became widely used in

the 1970’s and early 1980’s

More recently, has evolved into many

different forms (based on reporting

structure, level of standardization, sharing of

responsibility and authority)

92

A Business School as a

Matrix Organization

Dean

Associate Dean for

Undergraduate

Programs

Associate Dean for

MBA Programs

Director of

Doctoral Program

Management Science

Department Chair

Larry

Zelda

Diane

Marketing

Department Chair

Curly

Bob

Barby

Finance Department

Chair

Moe

Gloria

Leslie

Comments: bureaucratic, confusing, stressful

93

Organizational Structure & Project

Success

Studies by Larson and Gobeli (1988,

1989)

Sent questionnaires to 855 randomly

selected PMI members

Asked about organizational structure used

Perceptual measures of project success:

successful, marginal, unsuccessful with

respect to:

Meeting schedule

Controlling cost

Technical performance

Overall performance

94

Study Data

Classification of 547 respondents (64% response rate)

project managers or directors of PM programs

top management (president, vice president, etc.)

managers in functional areas (e.g., marketing)

specialists working on projects

Industries included in studies

30%

16%

26%

18%

14% pharmaceutical products

10% aerospace

10% computer and data processing products

others: telecommunications, medical instruments, glass products,

software development, petrochemical products, houseware goods

Organizational structures:

13% (71): Functional organizations

26% (142): Functional matrix

16.5% (90): Balanced matrix

28.5% (156): Project matrix

16% (87): Project team

95

ANOVA Results by

Organizational Structure

N

Controlling

Cost

Mean (SD)

A

Functional

Organization

71

1.76 (.83)

1.77 (.83)

2.30 (.77)

1.96 (.84)

B

Functional Matrix

142

1.91 (.77)

2.00 (.85)

2.37 (.73)

2.21 (.75)

C

Balanced Matrix

90

2.39 (.73)

2.15 (.82)

2.64 (.61)

2.52 (.61)

D

Project Matrix

156

2.64 (.76)

2.30 (.79)

2.67 (.57)

2.54 (.66)

E

Project Team

87

2.22 (.82)

2.32 (.80)

2.64 (.61)

2.52 (.70)

Total Sample

546

2.12 (.79)

2.14 (.83)

2.53 (.66)

2.38 (.70)

10.38*

6.94*

7.42*

11.45*

Organizational Structure

F-statistic

Scheffe Results

Meeting

Schedule

Mean (SD)

An exception

occurs here

Technical

Overall

Performance

Results

Mean (SD)

Mean (SD)

A,B < C,D,E

E<D

A,B < C < D,E A,B < C,D,E A,B < C,D,E

The results are statistically significant at the p<0.01 level

Higher values represent greater success

96

Principles for Determining Autonomy Level

in New Projects (Organizational Factors)

Ready availability of resources facilitates

the establishment of autonomous projects

The less the organization’s information

system and administrative policies and

procedures are able to serve a project, the

more the project needs specific and

dedicated systems

The more the firm’s culture differs from the

desired project management culture, the

more autonomous a project should be

97

Principles for Determining Autonomy Level

in New Projects (Project Factors)

The greater the strategic importance for an

organization and the larger the size of the project,

the more autonomous the project should be

The more a project is interdependent (“integrated”)

(e.g., there is a need for frequent project meetings),

the more autonomous it should be

The higher the complexity, and the more the

project’s success depends on its environment, the

more autonomous it should be

The greater the need to meet severe budget/time

constraints (especially time, from Larson and

Gobeli), the more autonomous the project should be

The more stable the resource loading, the more

economical it is to dedicate resources to the project

and run it as an autonomous unit

98

Decision Model for Determining the

Level of Autonomy in a New Project

A five step decision model (or, “scoring

model”) is now proposed for determining

the level of autonomy to be allowed in a

new project.

This model provides useful structure and

guidance to the process of determining an

appropriate level of autonomy.

But this model is definitely NOT AN

ALGORITHM! Thus, the same inputs can

lead to different outcomes, based on

judgment and interpretation.

This model is adapted from “Organizational Choices for

Project Management ”, B. Hobbs and P. Menard

99

Decision Model

Step 1. Evaluate the way in

which the organization reacts

to a new project.

Level or

Intensity

Low<-->High

Organizational Factors

_______

Availability of resources

Inflexibility of the organizational

_______

management system

_______

Unsupportiveness of culture

Find the mean

______

100

Decision Model

Step 2. Evaluate the project

itself.

Project factors

Level or

Intensity

Low<-->High

Strategic importance

Size

Novelty & need for innovation

Need for interdependence/integration

Environmental complexity

Need to meet tight constraints

Stability in resource loading

Find the mean

_______

_______

_______

_______

_______

_______

_______

______

101

Decision Model

Step 3. Using the information

from Steps 1 and 2, make a

subjective judgment about

the desired level of autonomy

in the new project. For

example, average the Step 1

and Step 2 numbers.

102

Decision Model

Step 4. Identify to what

extent the desired level of

autonomy from Step 3 is

compatible with the current

management culture (which is

identified on the following

page).

103

Current Management Culture

Ability to manage in an autonomous mode

Percentage of time assigned to projects

Quality of reporting process

Percentage of resources fully dedicated to

projects

Level of control over budget and

management of resources

Level of control over budget allocation and

expenditures

Ability to make independent decisions about

technical choices and tradeoffs

Project-specific systems and procedures

already in place

Project resources located together

Physical separation from parent organization

Find the mean

Level or

Intensity

Low<-->High

________

________

________

________

________

________

________

________

________

________

104

______

Decision Model

Step 5. Based on the information

from Steps 3 and 4, and the relative

importance of the project to the

organization, make a decision about

the appropriate level of autonomy

for the project. The numbers from

Steps 3 and 4 inform that decision,

but should not dominate it.

105

Scoring Model Application:

Control System Project

1.

2.

3.

4.

5.

A major utility is functionally structured

with culture unsupportive of project needs

Management systems cannot serve project

needs for planning, control, general

administration

Severe shortage of specialized human

resources, as they are badly needed for

ongoing operations

High strategic importance: technical failure

could result in a major public catastrophe

Medium to large project: cost is around

$200 million, and project duration is 6 years

106

Decision Model: Control System

Project (cont.)

6.

7.

8.

Strong need for innovation: control system of a large and

complex distribution network needs to be replaced.

Members of the project team participated in the design of

existing control system in the 1970’s, but the new system

is very complex and state of the art.

Strong need for integration: contributions from many

tech departments are needed and are highly

interdependent

Medium-high environmental complexity: many external

interfaces and high dependency on suppliers, because of

highly specialized consulting services and

software/hardware and because the number of potential

suppliers is extremely small. The project impacts many

users who have to be involved in design and

implementation. Industry in turmoil; inability to

terminate contracts, bankruptcies,…

107

Decision Model: Control System

Project (cont.)

9.

10.

11.

12.

13.

Project is very politically sensitive, because of the

visibility the press has given to the shortcomings of

the present system.

Medium budget/time constraints: There is no hard

deadline for the new system, but the risk of severe

problems in the existing system is too high after the

target date. Cost issues are not critical, but they

receive close attention from top management.

Medium stability of resource loading: the level of

internal resources assigned to the project varies

from phase to phase, but the most critical resources

will be with the project throughout.

Budget allocation and expenditures are tightly

controlled by the overall organization.

The accuracy of the financial reporting system is

low: poor control system, significant potential for

human error.

108

Summary of Project

Organization Structure

Project structure is significantly related to project

success

Projects that use a traditional functional organization

have the worst cost, time and scope performance

Projects using either a project matrix or a project team

were more successful in meeting their schedules than

those using the balanced matrix

Projects using the project matrix were better able to

control costs than those using the project team

Overall, the most successful projects used a balanced

matrix, project team, or--especially--project matrix. But,

were these the most successful organizations?

109

Subcontracting Issues

What parts of a project will be subcontracted?

What type of bidding process will be used?

What type of contract?

Should you use a separate request for bids for

each task or use one for all tasks?

What is the impact of subcontracting on the

expected duration of the project?

Should you offer incentives, such as a bonus for

finishing early? Or require penalties for

finishing late?

How does subcontracting impact risk?

110

Advice for Choosing a

Subcontractor

Talk to at least three potential subcontractors

Use referrals where possible

Face-to-face meetings are essential

Tradeoff between quality and price needs to be

considered

Present candidates with test scenarios

Communicate your needs and expectations in

detail

Establish benchmarks for performance

Establish guidelines for contract termination

111

Chapter

Precedence Networks and The

Critical Path Method (CPM)

Precedence Relationships

Several types of precedence requirements occur in practice.

Finish-to-start (FS = a): Task B cannot start until a

days after task A is finished

Start-to-start (SS = a): Task B cannot start until a

days after task A has started

Finish-to-finish (FF = a): Task B cannot finish until

a days after task A is finished

Start-to-finish (SF = a): Task B cannot finish until

a days after task A has started

The most common precedence network has FS = 0.

113

Precedence Networks

Networks represent immediate precedence

relationships among tasks and milestones

identified by the work breakdown structure

Milestones are tasks that take no time and have no

cost, but indicate significant events in the life of

the project (e.g., completion of a project phase)

Two types of networks: Activity-on-Node (AON)

Activity-on-Arc (AOA)

All networks must have only one starting and one

ending point. This can always be achieved

artificially, where necessary.

114

Precedence Networks:

Activity-on-Node (AON)

A

C

Start

End

B

D

115

Precedence Networks:

Activity-on-Arc (AOA)

2

Task C

Task A

Dummy

task

Star

t

Task B

1

End

Task D

Task A: (start, 2)

Task C: (2, end)

Task B: (start, 1)

Task D: (1, end)

Dummy task: (1, 2)

116

AON vs AOA

Arguments for AON

AON is easier to explain and understand

AON is used in most PM software (e.g., Microsoft

Project)

AON does not require the use of dummy tasks to

represent precedence relationships

Arguments for AOA

The PERT model (Chapter 6) is based on AOA

AOA can be drawn using arc lengths

corresponding to task durations, which adds

intuition to the network representation

117

Critical Path Method: AON with

Two Paths

The minimum time needed to complete a

project is equal to the length of the longest

path through the network; this path is known

as a Critical Path. Activities along the critical

path are called Critical Activities.

Task A

7 months

Task B

3 months

Start

End

Task C

11 months

118

CPM Example 1: AON

Calculations

ESB = 7

LFB = 11

ESA = 0

LFA = 8

ESStart = 0

LFStart = 0

Task A

7 months

Task B

3 months

Start

ESEnd = 11

LFEnd = 11

End

Task C

11 months ESC = 0

LFC = 11

Step 1.

Work ES

calculations

forward.

Step 2. Set

LFEND=ESEND.

Step 3.

Work LF

calculations

backward.

ESj = Earliest starting time for task (milestone) j

LFj = Latest finish time for task (milestone) j

119

Example 1: Network Paths and

Lengths

Path

1

Tasks

START-A-B-END

Duration (months)

10

2

START-C-END

11

• There may be more than one critical path,

but there must be at least one

• Critical paths can be found easily using CPM

(as in MS Project), linear programming or

other optimization methods

120

Critical Activities: Implications

Activity j is a critical activity if LFj – ESj = tj

Any activity on a critical path is a critical

activity

A delay to a critical activity causes a delay to

the completion of the entire project

Therefore, critical activities require particularly

efficient execution, so they often receive more

and better resources and closer monitoring

Critical chain project management (Goldratt,

1997) treats a critical path in a project similarly

to a “bottleneck” in a manufacturing process

121

CPM Example 2: AON Network

Task A

14 wks

Task F

9 wks

Task D

12 wks

START

END

Task B

9 wks

Task E

6 wks

Task C

20 wks

122

Example 2: Network Paths and

Lengths

Path

1

2

3

4

5

Tasks

START-A-D-F-END

START-A-D-E-END

START-B-D-F-END

START-B-D-E-END

START-C-E-END

Expected

Duration (wks)

35

32

30

27

26

Thus, START-A-D-F-END is a critical path.

123

Example 2: CPM Calculations

(EFi)

(LSi)

ESD=max{ESA+tA, ESB+tB}=max{0+14, 0+9}=14.

LFD=min{LFE-tE, LFF-tF}=min{35-6, 35-9}=26.

124

CPM Example 2: AON Network

ESA=0

LFA=26-12=14

Task A

14 wks

ESSTART=0

LFSTART=0

ESD= max{14,9} =14

LFD= min{35-9,35-6}=26

ESB=0

LFB=26-12=14

START

ESF=14+12=26

LFF=35-0=35

Task F

9 wks

Task D

12 wks

END

Task B

9 wks

ESC=0

LFC=35-6=29

Task C

20 wks

ESEND=35

LFEND=35

Task E

6 wks

ESE=max{0+20,14+12}=26

LFE=35-0=35

125

Types of Slack

Total Slack (TSi) assumes no delays at other tasks (i.e., all

the noncritical tasks before i use their ES times, and all the

noncritical tasks after i use their LS times)

Free Slack (FSi) assumes no delays at earlier tasks, but

allows delays at later tasks (i.e., all the noncritical tasks use

their ES times)

Safety Slack (SSi) assumes no delays at later tasks, but

allows delays at earlier tasks (i.e., all the noncritical tasks use

their LS times)

Independent Slack (ISi) allows delays at all other tasks (i.e.,

all the noncritical tasks before i use their LS times, and all the

noncritical tasks after i use their ES times)

126

Example 2:

Calculating Total Slack (TSi)

Task or

Milestone

START

A

B

C

D

E

F

END

Duration

( ti )

0

14

9

20

12

6

9

0

Earliest

Start Time

(ES i)

0

0

0

0

14

26

26

35

Lastest

Finish Time

(LFi)

0

14

14

29

26

35

35

35

Total Slack

(TSi)

Critical

Task?

0

0

5

9

0

3

0

0

Yes

Yes

No

No

Yes

No

Yes

Yes

Total Slack for task i = TSi = LFi - ESi - ti

127

Calculating All Slack Values

Total Slack (TSi)

= LFi - ESi - ti

Free Slack (FSi)

= ESi,min - ESi - ti

where ESi,min = minimum earliest start time of all tasks

that immediately follow task i

Safety Slack (SSi)

= LFi - LFi,max - ti

where LFi,max = maximum latest finish time of all tasks

that immediately precede task i

Independent Slack (ISi) = max (0, ESi,min - LFi,max - ti)

128

Slack Calculations: Example

Task A

14 wks

ESSTART=0

LFSTART=0

START

Task D

12 wks

Task B

9 wks

ESC=0

LFC=29

TSC=LFC-ESC-tC

=29-0-20=9

FSC=ESC,min-ESC-tC

=ESE-ESC-tC

=26-0-20=6

Task F

9 wks

Task C

20 wks

ESE=26

LFE=35

END

Task E

6 wks

SSC=LFC-LFC,max-tC

=LFC-LFSTART-tC

=29-0-20=9

ISC=max(0,ESC,min-LFC,max-tC)

=max(0,ESE-LFSTART-tC)

=max(0,26-0-20)=6

129

LP Model: Motivation

It is unnecessary to use an LP model just to

find the critical paths (because CPM is

simpler)

However, an LP model can easily be

extended to evaluate, for example, time /

cost tradeoffs, and task completion time

preferences for the noncritical activities

Also, LP output provides extensive

sensitivity and related information which

should be valuable to project managers

Whereas, most project management

software (such as MS Project) does not

130

LP Model for AON Network

Decision variables: STARTj = start time for task j

END = ending time of project (END milestone)

Minimize END

subject to

STARTj ≥ FINISHi for all tasks i that immediately precede task j

STARTj ≥ 0

for all tasks j in the project

where FINISHi = STARTi + ti

Note that the FINISHi variables will not explicitly appear in the

simplified version of the model

131

LP Model for Example 2

Minimize END

Subject to:

STARTD ≥ FINISHA = STARTA + 14

STARTD ≥ FINISHB = STARTB + 9

STARTE ≥ FINISHC = STARTC + 20

STARTE ≥ FINISHD = STARTD + 12

STARTF ≥ FINISHD = STARTD + 12

END ≥ FINISHE = STARTE + 6

END ≥ FINISHF = STARTF + 9

STARTA, STARTB, STARTC ≥ 0

132

Simplified LP Model for Example 2

Minimize END

Subject to:

STARTD STARTA 14

STARTD STARTB 9

STARTE STARTC 20

STARTE STARTD 12

STARTF STARTD 12

END STARTE 6

END STARTF 9

STARTA , STARTB , STARTC 0

133

Extension of LP Model:

Enforce Early Start Times

How to ensure that all tasks are started at

their earliest possible times.

134

Extension of LP Model:

Enforce Late Start Times

How to ensure that all tasks are started at

their latest possible times, subject to not

delaying the project.

Run any model (for example, CPM) that

minimizes the project duration.

Call the duration of the project

ENDTIME.

In the model on the previous page, add

constraints which ensure that all tasks

complete by ENDTIME

Change minimize to maximize

135

Microsoft® Project

MS Project is an excellent visual aid for

monitoring and controlling projects

For projects without time/cost tradeoffs,

uncertainty in task times, and resource

constraints, it delivers optimal solutions

Outside these simpler environments, the

performance of MS Project is less reliable

See Klastorin, p. 195, for a discussion of

the relative performance of several software

packages, including MS Project

See coursepack article: Fox and Spence (1998)

136

AOA: Precedence Networks

Task A

4 Weeks

2

Task C

7 Weeks

Dummy

task

Star

t

Task B

2 Weeks

End

Task D

10 Weeks

1

Task A: (start, 2)

Task C: (2, end)

Task B: (start, 1)

Task D: (1, end)

Dummy task: (1, 2)

137

AOA: Computing Earliest and

Latest Occurrence Times

TE2=4

TL2=5

Task A

4 Weeks

TESTART=0

TLSTART=0

2

Task C

7 Weeks

Dummy

task

Star

t

Task B

2 Weeks

Step 1. Work TE calculations forward

Step 2. Set TLEND=TEEND

1

TE1=2

TL1=2

TEEND=12

TLEND=12

End

Task D

10 Weeks

Step 3. Work TL

calculations backward

138

Slack Calculations for AOA

TSij = Total slack for Task (i,j)

T jL Ti E tij

FSij = Free slack for Task (i,j)

T jE Ti E tij

SSij = Safety slack for Task (i,j)

T jL Ti L tij

ISij = Independent slack for Task (i,j)

max( 0, T jE Ti L tij )

Interpretations are the same as in AON.

139

Slack Values for AOA: Example

Task

Duration

(tij)

Earliest

Start

Time

(TEj)

Latest

Finish

Time

(TLj)

Total Free Safety Indep.

Slack Slack Slack Slack

(TSij) (FSij) (SSij) (ISij)

A:

(START, 2)

4

2

0

7

10

0

0

2

4

2

5

2

5

12

12

1

0

3

1

0

B:

(START, 1)

Dummy

(1,2)

C:

(2, END)

D:

(1, END)

0

0

2

1

0

1

0

3

0

0

0

0

2

0

0

140

AOA: Calculating Slack

TSSTART2=1, FSSTART2=0

SSSTART2=1, ISSTART2=0

TE2=4

TL2=5

2

Task A

4 Weeks

TESTART=0

TLSTART=0

Star

t

TS12=3, FS12=2

SS12=3, IS12=2

TSSTART1=0, FSSTART1=0 Task B

SSSTART1=0, ISSTART1=0 2 Weeks

Step 1. Work TE calculations forward

Step 2. Set TLEND=TEEND

TS2END=1, FS2END=1

SS2END=0, IS2END=0

Task C

7 Weeks

TEEND=12

TLEND=12

Dummy

task

End

Task D

10 Weeks

1

TE1=2

TL1=2

TS1END=0, FS1END=0

SS1END=0, IS1END=0

Step 3. Work TL

calculations backward

141

LP Model for AOA Network

Decision variables: the occurrence time of each node

142

Chapter

Planning to Minimize Cost

Project Budget

The budget is an important communication

link between the functional units and the

project

Should be presented in terms of measurable

outputs, which correspond to work packages

in the WBS

Should clearly indicate project milestones

Establishes goals, schedules and

benchmarks, and assigns resources to tasks

Serves as a baseline for progress monitoring

and control

144

Types of Budgeting

Top-down Budgeting: Aggregate

measures (cost, time) provided by top

management, based on strategic goals

and constraints

Bottom-up Budgeting: Specific

measures aggregated up from WBS

tasks/costs and subcontractors

Hybrid: Top management typically

indicates a budget constraint, while

project managers use a bottom-up

approach to estimate individual costs

145

Types of Costs in Projects

Direct costs: resource costs, including expediting

costs. These vary with task duration.

Material costs: reflect the cost of acquiring

materials needed to complete work. These vary

with project scope.

Overhead costs: administrative costs allocated to

support the project, and usually not attributable

to any specific task. These vary with project

duration.

Performance costs / bonuses: vary with project

duration, or sometimes with performance relative

to milestones, depending on the contract.

146

Project Budget Example

ES A = 0

LF A = 14

Task A

14 wks

ES START = 0

LF START = 0

ES B = 0

LF B = 14

START

Task B

9 wks

ES C = 0

LF C = 29

ES F = 26

LF F = 35

ES D = 14

LF D = 26

Task F

9 wks

Task D

12 wks

ES END = 35

LF END = 35

END

ES E = 26

LF E = 35

Task E

6 wks

Task C

20 wks

147

Project Budget Example

Cost for Resource A worker = $400/week

Cost for Resource B worker = $600/week

148

Project Budget Example

Early Start Times

Tas k

1

A

1140

B

8925

C

9600

D

E

F

2

3

4

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

19665

19665

19200

38865

19200

58065

19200

77265

19200

96465

19200

115665

19200

134865

19200

154065

19200

173265

Wee kly Su btotals

Cumul ative

5

6

7

8

9

10

11

12

800

800

800

9600

9600

9600

10400

183665

10400

194065

10400

204465

Late Start Times

Tas k

A

B

C

D

E

F

Wee kly Su btotals

Cumul ative

1

2

3

4

5

6

7

8

1140

800

800

800

800

8925

800

8800

800

8800

800

8800

1140

1140

800

1940

800

2740

800

3540

9725

13265

9600

22865

9600

32465

9600

42065

9

10

11

12

800

8800

9600

800

8800

9600

800

8800

9600

800

8800

9600

19200

61265

19200

80465

19200

99665

19200

118865

The total duration is 35 weeks

149

Weekly Costs (Cash Flows)

Example 2 from Chapter 4

150

Cumulative Costs

1

3

5

7

9

11 13 15 17 19 21 23 25 27 29 31 33

151

Cash Flow Management

Need to manage both payments and receipts

It is usually better to pay as late and receive

as early as possible

Must consider budget constraints and

organizational requirements on projects

(e.g., payback period)

Noncritical activities may have flexibility in

their start times that affects cash flow and

NPV

Frequently, there is a tradeoff between cash

flow (prefer LS schedule) and completion

152

time reliability (prefer ES schedule)

Cash Flow Example

Make payment of

$5000

M1

Task A

2 mos

Task D

8 mos

Receive payment

of $3000

Task C

4 mos

START

END

Task B

8 mos

Task E

3 mos

M2

Receive payment

of $3000

153

Cash Flow Example: Solver Model

Objective: Maximize NPV

C

D

E

F

10

11

12

13

14

15

16

17

18

19

F19=F13+F15+F18

See cashflow analysis.xls on the CD

154

Material Management Example

LS A = 0

Task A

4 wks

LS B = 4

Task B

8 wks

LS C = 12

Task C

5 wks

2 units

Start

LS D = 6

LS E = 12

LS F = 14

Task D

6 wks

Task E

2 wks

Task F

3 wks

LSEND=17

End

30 units

A total of 32 units of resource must be acquired.

What is the best ordering policy?

155

Material Management Example

Main Issue: How much to order, and

when?

In the example:

Single material is needed for Task B (2 units) and

Task E (30 units)

Fixed cost (including delivery) to place order =

$300

Cost of holding raw materials is $2 times the

number of unit-weeks in stock

Cost of holding finished product is greater than

the cost of holding raw material, because of value

added

Project can be delayed (beyond 17 weeks) at cost

of $P per week, where $P > 30 x $2

156

Material Management Example

• To minimize holding costs, only place orders at Latest Start times

• Can never reduce total costs by delaying the project

Time

1

2

3

Demand:

4

5

6

7

8

9

10

11

2

12

30

Order option #1: 32

Order option #2:

2

30

Choose the option that minimizes inventory cost =

order cost + holding cost of raw materials

157

Material Management Example

Fixed cost to place order:

$300/order

Cost of holding raw material:

$2/unit/week

Cost of option #1:

$300*1+$2*30*8=$780

Cost of option #2: $300*2=$600

158

Time / Cost Tradeoffs

Crashing: investing in additional resources

(and usually incurring additional cost) in

order to reduce individual task durations and

therefore also overall project duration.

What are some methods for crashing?

Some practical models:

minimize total of overhead, indirect, direct

and penalty costs

minimize project duration subject to a budget

for direct cost.

159

Time / Cost Tradeoff Example

7 wks

15 wks

A

Critical path with

makespan 22

C

Start

End

B

D

6 wks

Task

Normal

Duration

A

B

C

D

7

6

15

10

10 wks

Marginal Cost

to Crash One

Normal Cost

Week

$60

$85

$55

$120

$8

$5

$10

$4

Assume constant

marginal crash cost,

i.e. linear cost of

crashing

Assume task C cannot be crashed below 13 weeks

160

Time / Cost Tradeoff Example

Project

Duration

(weeks)

As we

reduce

the

project

duration,

we need

to keep

track of

the

lengths of

all paths

Total Direct

Critical Path(s)

22

Start-A-C-End

21

Start-A-C-End

Task(s) Reduced

Cost

A

$320

C

$338

C

$348

A, B

$361

$328

Start-B-C-End

20

Start-A-C-End

Start-B-C-End

19

Start-A-C-End

Start-B-C-End

18

Start-A-C-End

Start-B-C-End

This “crashing” procedure is a heuristic ---- it does not

always find the cheapest sequence of reductions

161

Linear Time / Cost Tradeoff

Even where the duration of a task can be reduced by assigning

additional resources to it, in practice there is always a lower

limit on task duration.

Cost

Crash

point

Crash

cost = Ccj

Slope (bj) = increase in cost

from reducing task duration by

one time unit

Normal

point

Normal

cost = CN

j

c

Crash time = tj

Normal time

N

= tj

Time

162

Time / Cost Tradeoff Using LP

Assume marginal cost of crashing task j is bj = (CjC-CjN)/(tjN-tjC) > 0

Decision Variables:

Sj = starting time of task j

END = end time of project

tj = duration of task j

The following model allows us to minimize the total direct cost

required to complete the project by time Tmax

Minimize total direct cost =

b

j

tj

j

s.t. Sj ≥ Si + ti, for all tasks i that immediately precede job j

tjC ≤ tj ≤ tjN, for all tasks in the project

END ≥ Sj + tj, for all tasks in the project

END ≤ Tmax

tj , Sj ≥ 0, for all tasks in the project

163

Minimizing Total Cost

Cost

Total cost

Here we assume

that overhead

costs are

proportional to

project duration.

Overhead

costs

Direct

costs

Crash time

Minimum cost

solution

Normal time

Project

duration

164

Minimizing Total Cost

The following model allows us to minimize

the total of direct and indirect costs

Minimize total costs b j t j I ( END)

j

where

I = indirect (overhead) cost/time period

The constraints are the same as in the

previous model, except the upper limit

on END is deleted.

165

Chapter

Planning with Uncertainty

The Effects of Uncertainty

The most obvious effect is that uncertainty in a task

duration causes late completion of that task.

Depending on the criticality of that task, this may delay

overall project completion.

Effective planning can reduce uncertainty or mitigate its

effects.

The more uncertain a task when it is initiated, the more

monitoring and control are needed to ensure effective

performance.

There are three additional mechanisms by which

uncertainty interacts with project management practice

to create problems.

167

Uncertain Task Durations

It is widely assumed that, in many projects, task

durations follow the beta distribution shown below

Probability density

function

Completion time of task j

Time

Optimistic time, tjo

Most likely time, tjm

Expected time, m

Pessimistic time, tjp

168

Standard Approximations for

Task Durations

For each task, we need three estimates:

o

most optimistic time, t

most pessimistic time,

m

most likely time, t

tp

In practice,

how easy is it

to estimate

these?

t o t p 4t m

Expected duration m

6

p

o

t t

Standard deviation

6

These formulas are designed to approximate (simply, but

169

not very accurately) the beta distribution.

More Accurate Approximations

The approximations on the previous page are

most commonly used in practice, because

they are oldest and simplest. However, the

approximations of Perry and Grieg (1975)

shown below are more accurate.

t95 t5 .95t m

m

2.85

t95 t5

3.25

Note that these approximations require the

estimation of slightly different data, which

could be easier (or harder) to estimate.

170

Three Mechanisms by which

Uncertainty Creates Problems